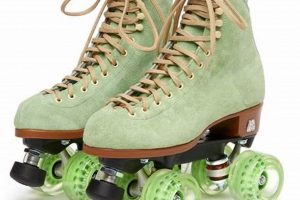

These specialized wheeled boots, typically employed on hard surfaces, represent a significant element within the skating community. Often favored for their durability and performance characteristics, they consist of a boot secured to a frame, which in turn holds the wheels. A classic example is a model known for its precision and responsiveness, sought after by serious skaters.

Their importance lies in the provision of a stable and maneuverable platform for various skating disciplines. Historically, these products have played a vital role in the evolution of roller skating, contributing to advancements in design and technology. The benefits include enhanced control, improved speed, and greater overall enjoyment for skaters across different skill levels.

This article will delve into specific aspects of these skating devices, examining their construction, different models available, maintenance procedures, and the role they play in competitive and recreational skating.

Maintenance and Optimal Usage Strategies

The following guidelines outline best practices for the upkeep and effective application of these specialized skating devices, ensuring longevity and peak performance.

Tip 1: Wheel Inspection and Rotation: Regularly inspect wheels for wear and damage. Rotate wheels to ensure even wear across all positions, extending their lifespan.

Tip 2: Bearing Maintenance: Clean and lubricate bearings periodically to maintain smooth rolling action. Debris accumulation can significantly reduce speed and increase friction.

Tip 3: Frame Alignment: Ensure proper frame alignment. Misalignment can cause uneven wear, instability, and reduced efficiency. A professional adjustment may be required.

Tip 4: Boot Care: Maintain the integrity of the boot by cleaning and conditioning the leather or synthetic materials. This prevents cracking, stiffness, and premature wear.

Tip 5: Hardware Tightening: Regularly check and tighten all nuts, bolts, and screws. Loose hardware can compromise stability and safety.

Tip 6: Storage Practices: Store equipment in a dry, cool environment to prevent corrosion and degradation of materials. Avoid prolonged exposure to direct sunlight.

These strategies collectively contribute to maximizing the performance and lifespan of the skating equipment, ensuring a safe and enjoyable skating experience.

The next section will provide a comprehensive analysis of the various models and their suitability for specific skating styles and skill levels.

1. Frame Precision

Frame precision, in the context of these roller skates, refers to the accuracy and consistency of the frame’s dimensions and alignment. This precision is fundamental because it directly influences the skater’s control and stability. Deviations from specified tolerances can introduce unwanted play or binding, leading to unpredictable handling characteristics. The cause-and-effect relationship is straightforward: higher frame precision results in more predictable and responsive skating performance. A real-world example of this is observed in competitive figure skating, where minute variations in frame alignment can significantly affect the skater’s ability to execute complex maneuvers accurately.

The importance of frame precision stems from its direct impact on power transfer and energy efficiency. A precisely aligned frame ensures that the skater’s effort is translated directly into forward motion, minimizing energy loss due to friction or misalignment. Furthermore, precise frame construction contributes to the overall durability of the skates. A well-engineered frame can withstand greater stress and strain without compromising its structural integrity. Practical applications of this understanding are seen in the manufacturing process, where stringent quality control measures are implemented to ensure frame precision meets established standards. This includes using advanced machining techniques and employing rigorous inspection procedures.

In conclusion, frame precision is a critical factor in the performance and longevity of these roller skates. Its influence extends from basic stability and control to advanced maneuvers and overall efficiency. Addressing challenges in maintaining frame precision requires ongoing advancements in manufacturing technologies and a commitment to rigorous quality control. Ultimately, understanding the significance of frame precision contributes to a more informed selection, maintenance, and utilization of this specialized skating equipment.

2. Wheel Hardness

Wheel hardness is a crucial property that significantly influences the performance characteristics of roller skates. It is measured using the durometer scale, with higher numbers indicating harder wheels. The selection of appropriate wheel hardness is paramount for optimizing the skating experience across various disciplines and surfaces.

- Grip and Roll Efficiency

Harder wheels exhibit lower rolling resistance, translating to increased speed and efficiency on smooth surfaces. Conversely, softer wheels provide enhanced grip, which is essential for maneuvers requiring traction, such as those performed on slick or uneven surfaces. In the context of these skates, skaters must balance the need for speed with the need for control, selecting wheel hardness appropriate to the intended use.

- Surface Compatibility

Wheel hardness must be matched to the skating surface. Harder wheels perform optimally on smooth, polished surfaces like those found in skating rinks, while softer wheels offer better performance on rougher outdoor surfaces, absorbing vibrations and maintaining contact with the ground. A mismatch can result in reduced efficiency, increased fatigue, and decreased control.

- Wear Rate and Durability

Softer wheels tend to wear down more quickly than harder wheels, especially on abrasive surfaces. The choice between longevity and performance becomes a key consideration. Skaters who prioritize durability may opt for harder wheels, even if it means sacrificing some grip. Conversely, those focused on performance may choose softer wheels, understanding that they will require more frequent replacement.

- Skating Style and Discipline

Different skating styles benefit from different wheel hardnesses. Speed skaters typically favor harder wheels to maximize velocity, while artistic skaters often prefer softer wheels for enhanced grip during spins and turns. Jam skaters may use a blend of different hardnesses to achieve a balance of speed and control. Selection should be a tailored choice.

In summary, wheel hardness is a critical factor in the performance of skates. Careful consideration of surface type, skating style, and desired balance between grip and roll efficiency is essential for selecting the appropriate wheel hardness. An understanding of these principles allows skaters to optimize their performance and enjoyment.

3. Bearing Smoothness

Bearing smoothness, as it relates to those roller skates, is a critical determinant of the overall skating experience. This characteristic refers to the reduction of friction within the bearings, which directly impacts the ease and efficiency with which the wheels rotate. Cause-and-effect is evident: smoother bearings require less energy input to maintain a given speed, resulting in increased glide and reduced skater fatigue. These skates, known for their robust construction and performance capabilities, rely heavily on high-quality bearings to deliver their intended functionality. Without adequately smooth bearings, the potential of these skates is substantially diminished. For example, in competitive speed skating, even slight improvements in bearing smoothness can translate into significant time advantages.

The importance of bearing smoothness extends beyond mere speed enhancement. Smooth bearings also contribute to improved control and responsiveness. Reduced friction allows for more subtle and precise movements, facilitating intricate maneuvers. Practical application of this understanding is evident in the routine maintenance procedures employed by serious skaters. Cleaning, lubricating, and, when necessary, replacing bearings are essential steps in preserving optimal performance. Furthermore, skaters often experiment with different types of bearings, seeking those that offer the best balance of smoothness, durability, and cost-effectiveness. Ceramic bearings, for instance, are often favored for their low friction properties, despite their higher price point.

In conclusion, bearing smoothness represents a key factor in maximizing the potential of skating equipment. This aspect influences speed, control, and overall skater experience. Addressing challenges related to bearing maintenance and selection requires a consistent commitment to proper care and informed decision-making. Ultimately, a comprehensive understanding of bearing smoothness contributes to a more rewarding and efficient skating pursuit, underscoring its importance within the broader context of skating technology.

4. Boot Material

Boot material significantly influences the performance and longevity of roller skates. The selection of appropriate materials directly impacts factors such as support, comfort, weight, and durability. The effects of material choice are evident in skating performance: stiffer materials provide greater ankle support, facilitating precise movements, while softer materials enhance comfort for extended use. Boot material is a critical component; examples may include leather, synthetic polymers, or composite materials, each imparting distinct characteristics. In skating, boot material selection often involves balancing the demands of support, comfort, and the specific requirements of the skating discipline.

Practical applications of understanding boot material properties are found in the design and maintenance of such skates. Leather boots, for example, require specific conditioning to maintain suppleness and prevent cracking, while synthetic materials may necessitate different cleaning protocols. The impact of boot material extends to the skater’s overall efficiency. A well-fitted boot constructed from appropriate materials can minimize energy loss and prevent discomfort, leading to improved performance and endurance. Furthermore, the choice of boot material can influence the skates’ resistance to environmental factors, such as moisture and abrasion, thus affecting their lifespan.

In summary, boot material is a key consideration in the design and application of these skates, impacting skater comfort, performance, and the skates’ durability. Boot material understanding is essential for skaters and manufacturers alike. Ongoing advancements in material science present opportunities to enhance boot design and performance characteristics, with a continued focus on balancing support, comfort, and longevity.

5. Toe Stop Adjustability

Toe stop adjustability is a significant feature in roller skates, directly impacting a skater’s stability, braking ability, and maneuverability. This adjustability, the capacity to alter the height and angle of the toe stop, allows skaters to customize their equipment to suit their specific skating style and skill level. The functionality is particularly important in high-demand disciplines such as roller derby, jam skating, and rhythm skating, where quick stops and rapid changes in direction are essential. Incorrect toe stop settings can compromise balance, increase the risk of falls, and reduce overall skating efficiency. A low toe stop setting may cause unwanted contact with the skating surface, while a high setting can make braking less effective.

The practical significance of understanding toe stop adjustability is evident in the maintenance and customization practices employed by skaters. Adjusting the toe stop often involves loosening a locking nut or screw, positioning the toe stop at the desired height, and then retightening the locking mechanism. This process may require experimentation to find the optimal setting for individual skaters. The use of different toe stop materials, such as natural rubber or harder compounds, further allows for customization based on surface conditions and skater preferences. For instance, softer toe stops provide greater grip but may wear down more quickly, while harder stops offer increased durability but can be less effective on slick surfaces.

In summary, toe stop adjustability represents a critical element in the overall performance and safety of roller skates. This feature enables skaters to fine-tune their equipment to match their specific needs and preferences. A proper understanding of toe stop adjustability, along with consistent maintenance and experimentation, contributes to a more enjoyable and efficient skating experience. Recognizing the connection is crucial for skaters seeking to optimize their performance and maximize their potential.

6. Plate Durability

Plate durability is a critical factor in the overall performance and lifespan of these specialized roller skates. The plate, the metal or composite chassis attaching the boot to the wheels, endures substantial stress during skating. Its resistance to deformation, cracking, and failure directly influences the skater’s control, safety, and the longevity of the equipment.

- Material Composition and Strength

The choice of material, typically aluminum alloys or reinforced polymers, significantly impacts plate durability. Higher-grade alloys offer greater tensile strength and resistance to fatigue, withstanding repeated stress cycles without deformation. Examples include aircraft-grade aluminum, known for its high strength-to-weight ratio. In the context of these skates, a robust plate ensures reliable performance under demanding conditions, preventing premature failure and maintaining structural integrity.

- Design and Stress Distribution

Plate design plays a crucial role in distributing stress effectively. A well-engineered plate incorporates features such as reinforcing ribs, optimized geometry, and strategically placed mounting points to minimize stress concentrations. Finite element analysis (FEA) is often used in the design process to identify and mitigate potential weak points. For these skates, an optimized design enhances durability by preventing localized stress failures and ensuring even load distribution.

- Manufacturing Processes and Quality Control

Manufacturing processes, such as casting, forging, or CNC machining, affect plate durability by influencing material properties and dimensional accuracy. Precision machining ensures tight tolerances and consistent quality, while proper heat treatment can enhance the strength and hardness of the material. Stringent quality control measures, including non-destructive testing (NDT), are essential for detecting flaws and ensuring compliance with specifications. With these skates, high-quality manufacturing processes translate to improved plate durability and long-term reliability.

- Impact of Skating Style and Environment

Skating style and environmental conditions contribute to plate wear and tear. Aggressive skating, involving jumps, slides, and hard impacts, places greater stress on the plate, accelerating fatigue and potential failure. Exposure to moisture, chemicals, and abrasive surfaces can also degrade the material and weaken its structural integrity. Skaters must consider these factors when selecting and maintaining their equipment to maximize plate durability and prevent premature damage.

These aspects collectively determine the plate’s ability to withstand the rigors of skating. Integrating robust materials, optimized designs, meticulous manufacturing, and appropriate usage practices significantly enhances plate durability and the overall value of these skate products. Continued advancements in materials science and engineering hold the potential for even further improvements in plate durability, ensuring a safer and more enjoyable skating experience.

7. Skating Style

Skating style dictates the necessary attributes of roller skates. The diverse range of skating disciplines necessitates tailored equipment to optimize performance and ensure safety. These roller skates, with their customizable components, can be adapted to various skating styles, though some models and configurations are better suited to specific disciplines than others.

- Artistic Skating

Artistic skating, encompassing figure skating and dance, demands precise control and maneuverability. Skates used in this discipline often feature a shorter wheelbase for enhanced agility and boots that provide substantial ankle support for executing complex spins and jumps. The responsiveness of the frame and the quality of the bearings are paramount, allowing skaters to translate subtle movements into controlled actions. These skates, when properly configured, can meet the demands of artistic skating due to their customizable nature.

- Speed Skating

Speed skating prioritizes velocity and efficiency. Skates used in this discipline typically feature a longer wheelbase for increased stability at high speeds and larger diameter wheels with harder durometers to minimize rolling resistance. Aerodynamic considerations also influence skate design. While these skates may not be the first choice for dedicated speed skaters, certain adjustments to wheel type and bearing quality can render them suitable for recreational speed skating.

- Roller Derby

Roller derby requires a combination of agility, speed, and durability. Skates used in this contact sport must withstand significant impact and provide the skater with the maneuverability needed to navigate tight spaces and execute strategic maneuvers. Strong ankle support and robust frame construction are essential. The adjustability of these skates allows them to be adapted for roller derby, provided that appropriate protective gear is also used.

- Jam Skating

Jam skating emphasizes rhythm, improvisation, and footwork. Skates used in this discipline typically feature a relatively short wheelbase and flexible boots that allow for a wide range of motion. The ability to execute quick turns and intricate footwork patterns is paramount. These skates, with their customizable plate and boot options, can be configured to meet the specific needs of jam skaters, providing a responsive and versatile platform for creative expression.

The selection of appropriate skates depends heavily on the intended skating style. While these roller skates possess the versatility to accommodate various disciplines, skaters must carefully consider their specific needs and preferences when selecting components and configuring their equipment. The interplay between skating style and equipment selection is crucial for optimizing performance, ensuring safety, and maximizing enjoyment.

Frequently Asked Questions

The following questions address common inquiries regarding these specialized skating devices, providing clear and concise answers based on factual information and industry standards.

Question 1: What distinguishes this type of roller skates from other models?

This specific brand is recognized for its robust construction, precision engineering, and customizable components. The primary differentiation lies in the quality of materials and the attention to detail in manufacturing, resulting in enhanced performance and durability.

Question 2: What are the primary factors to consider when selecting a size?

Proper sizing is crucial for comfort, control, and safety. It is recommended to consult a sizing chart specific to this brand, measuring foot length and width accurately. Allowance for sock thickness and individual foot shape should also be considered.

Question 3: How frequently should the bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage intensity and environmental conditions. Under normal circumstances, cleaning and lubrication are recommended every 20-40 hours of skating. However, more frequent maintenance may be necessary in dusty or wet environments.

Question 4: What types of wheels are compatible with these skates?

Compatibility depends on the axle diameter and the intended skating surface. Most standard-sized wheels are compatible, but it is essential to verify axle diameter and select wheels appropriate for the desired skating style and surface conditions. Wheel hardness (durometer) should also be considered.

Question 5: Is professional installation required for replacement parts?

While some replacement parts, such as wheels and bearings, can be installed by experienced skaters, others, such as the plate or boot, may require professional installation to ensure proper alignment and secure attachment, minimizing the risk of injury.

Question 6: What are the recommended storage practices to prolong lifespan?

Proper storage is essential for maintaining the integrity of the skates. It is advisable to store them in a cool, dry environment away from direct sunlight and extreme temperatures. Cleaning and drying the skates after each use can also prevent corrosion and material degradation.

In conclusion, proper selection, maintenance, and storage practices are critical for optimizing the performance and extending the lifespan. Adhering to these guidelines will ensure a safe and enjoyable skating experience.

The subsequent section will delve into case studies and user testimonials, providing real-world insights into the performance and reliability of these skates.

Conclusion

This exploration has detailed the multifaceted aspects of Snyder roller skates, ranging from their construction and maintenance to optimal usage strategies and the significance of individual components. Each element, including frame precision, wheel hardness, bearing smoothness, boot material, toe stop adjustability, and plate durability, contributes directly to the overall performance and longevity of these specialized skating devices.

The information presented aims to provide a comprehensive understanding of the factors influencing the selection, utilization, and care of these items. Continuous innovation and adherence to rigorous quality standards remain essential for advancing the capabilities of this type of equipment and ensuring a positive skating experience for all users. Further research and development efforts should focus on optimizing material properties, enhancing design features, and promoting sustainable manufacturing practices within the skating industry.