Wheels of this diameter, frequently found in skateboarding and related disciplines, offer a balance between speed and acceleration. The specified dimension refers to the wheel’s diameter in millimeters. This size is often favored by skaters seeking versatility across various terrains and skating styles. For example, a longboard setup might incorporate these wheels for cruising and carving.

The selection of this particular wheel size can significantly impact a skater’s performance and overall experience. These wheels provide a smoother ride on rough surfaces compared to smaller options, while still allowing for responsive turning and maneuverability. Their use can be traced back to the evolution of skateboarding, where advancements in materials and design led to a wider range of wheel sizes to suit different skating preferences and requirements. They bridge the gap between smaller, trick-oriented wheels and larger, speed-focused options.

Further discussion will elaborate on the specific applications of this wheel size, including its suitability for different board types, bearing considerations, and optimal durometer ratings for various skating conditions. The analysis will also examine the relative advantages and disadvantages of this wheel size compared to other available options.

Tips for Utilizing 65mm Skate Wheels

The following suggestions offer guidance on maximizing performance and longevity when using wheels of this diameter in skateboarding and related applications.

Tip 1: Terrain Selection: This wheel size is well-suited for a variety of surfaces, but performs optimally on moderately smooth pavement. Avoid excessively rough or debris-laden areas to minimize wear and maintain speed.

Tip 2: Durometer Considerations: The wheel’s durometer, or hardness, should be chosen based on intended use. Softer durometers (78A-85A) offer greater grip and shock absorption for cruising, while harder durometers (86A and above) prioritize speed and slide capability.

Tip 3: Bearing Compatibility: Ensure compatibility with standard skateboard bearings (608 size). Regularly inspect and maintain bearings to prevent performance degradation and potential wheel damage.

Tip 4: Wheel Spacers: Utilize wheel spacers between the bearings to maintain proper alignment and prevent excessive bearing wear. Spacers contribute to a smoother and more stable ride.

Tip 5: Regular Rotation: Rotate the wheels periodically to promote even wear and extend their lifespan. This practice is particularly important for directional wheels.

Tip 6: Truck Adjustment: Adjust truck tightness to complement the wheel size and intended skating style. Looser trucks offer greater turning ability, while tighter trucks provide increased stability at higher speeds.

Tip 7: Weight Distribution: Practice proper weight distribution to optimize wheel contact with the riding surface. This technique enhances control and reduces the risk of wheel slippage.

By adhering to these recommendations, skaters can enhance the performance, durability, and overall riding experience associated with the wheels. Consistent maintenance and informed selection are paramount to achieving optimal results.

Further exploration will delve into advanced techniques and considerations for maximizing the utility of this wheel size in various skating disciplines.

1. Diameter

Diameter, in the context of wheels, refers to the measurement of the wheel across its widest point, directly influencing rolling speed, acceleration, and obstacle clearance. For wheels designated as “65mm,” this measurement is standardized, offering a specific set of performance characteristics.

- Rolling Efficiency

The wheel’s diameter directly impacts its rolling efficiency. Larger diameters, like 65mm, generally maintain momentum better than smaller wheels on smooth surfaces. However, the relationship is not linear; beyond a certain point, the increase in diameter yields diminishing returns in speed while increasing weight and inertia.

- Acceleration and Torque

Smaller wheels generally offer quicker acceleration due to lower rotational inertia. While 65mm wheels provide a balance, their acceleration will be comparatively slower than smaller-diameter wheels, but faster than larger alternatives. Torque requirements for starting and stopping are also influenced, impacting the rider’s effort and control.

- Obstacle Negotiation

Larger diameters facilitate the traversal of cracks, pebbles, and other minor obstacles more effectively. Wheels with a 65mm diameter offer improved obstacle negotiation compared to smaller wheels, contributing to a smoother ride, especially on less-than-perfect surfaces. This increased capability reduces the likelihood of abrupt stops and loss of control.

- Wheel Weight

The weight of a wheel generally increases with diameter, impacting the overall weight of the board and affecting maneuverability. Wheels specified to a 65mm diameter will be heavier than a 50mm wheel. Skaters must consider this factor when building a setup that favors either agility or stability.

The 65mm specification represents a compromise between the competing demands of rolling speed, acceleration, obstacle clearance, and weight. Its popularity stems from its versatility, rendering it suitable for a wide range of skateboarding styles and terrains.

2. Durometer

Durometer, a measurement of a wheel’s hardness, significantly impacts the performance characteristics of wheels. The durometer rating, typically expressed on the A scale (e.g., 78A, 99A), dictates grip, roll speed, and wear resistance. When considering wheels, durometer selection is critical, especially in conjunction with wheel diameter. Harder wheels roll faster and slide easier but offer less grip and shock absorption; softer wheels grip better, provide a smoother ride on rough surfaces, but may roll slower and wear more quickly.

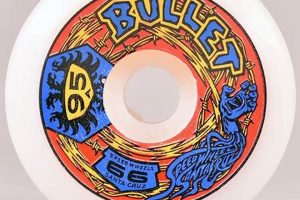

For wheels, a durometer range of 78A-85A is often favored for cruising and longboarding applications. This softness provides ample grip and cushioning on varied terrains. For example, a 78A wheel is commonly selected for longboards intended for cruising on rough asphalt, maximizing comfort. Conversely, for street skating or skate park use, a durometer of 95A or higher is more common. This increased hardness enhances roll speed on smooth surfaces and facilitates controlled slides for performing tricks. An improperly chosen durometer can negatively affect the riding experience. A wheel that’s too soft may feel sluggish, while a wheel that is too hard may make riding uncomfortable on rough surfaces.

The interplay between diameter and durometer is thus paramount. Users of wheels must carefully evaluate the intended use case, surface conditions, and desired riding style to select the optimal durometer. Ignoring this relationship can lead to suboptimal performance, reduced control, and accelerated wheel wear. The selection of this specific wheel size offers versatility, and the durometer rating is the primary factor in tailoring the wheel’s performance to a particular skateboarding discipline. Proper understanding of durometer ensures performance and satisfaction.

3. Contact Patch

The contact patch, the area where a wheel makes physical contact with the riding surface, is a critical determinant of grip, rolling resistance, and overall performance in skateboarding. In wheels, the size and shape of this contact area are influenced by wheel diameter, durometer, and profile.

- Grip and Traction

A larger contact patch generally provides increased grip and traction. In the context of wheels, a wider contact area allows for a more secure connection with the pavement, enhancing control during turns and acceleration. For instance, wheels with a larger, square-edged contact patch are often preferred for downhill skateboarding, where maximum grip is essential.

- Rolling Resistance

A larger contact patch also increases rolling resistance. This means more energy is required to maintain speed. However, wheels minimize the effects of this by using high rebound urethane formulas. Generally, smaller contact patches are prefered. However, this can be offset by harder durometer wheels. Softer wheels may have a larger contact patch.

- Wheel Wear

The distribution of wear across the wheel is directly related to the contact patch. A wider contact patch tends to distribute wear more evenly, potentially extending the lifespan of the wheel. Conversely, a smaller or uneven contact patch may lead to localized wear and premature degradation. For example, wheels with a rounded profile and smaller contact patch may exhibit increased wear on the edges.

- Surface Condition Adaptation

The contact patch’s characteristics dictate its ability to adapt to varying surface conditions. A wheel with a pliable, larger contact patch is better equipped to conform to uneven or rough surfaces, maintaining grip and stability. Conversely, wheels with smaller, harder contact patches may lose traction more easily on such surfaces. Wheels are best for smooth surfaces.

The relationship between the contact patch and wheels underscores the importance of considering the intended riding environment and desired performance characteristics. Balancing grip, rolling resistance, and wear is crucial for selecting wheels that optimize the skating experience.

4. Core Material

The core material within wheels fundamentally influences performance characteristics, durability, and overall riding experience. In the context of wheels, core material selection directly impacts the wheel’s ability to maintain shape under load, resist deformation, and transmit energy efficiently.

- Stiffness and Energy Transfer

The core’s stiffness determines the efficiency of energy transfer from the skater’s push to the wheel’s rotation. A stiffer core minimizes energy loss due to deformation, resulting in faster roll speeds. For wheels, a rigid core material, such as high-density nylon or glass-filled polymers, enhances energy transfer, optimizing speed and responsiveness. This is particularly beneficial in longboarding or cruising scenarios where sustained speed is paramount. In contrast, a softer core might absorb more energy, leading to a slightly dampened ride feel but potentially sacrificing speed.

- Durability and Structural Integrity

The core material’s inherent strength directly affects the wheel’s resistance to damage from impacts, abrasions, and prolonged use. High-quality core materials, like reinforced plastics or aluminum alloys, enhance structural integrity, preventing core cracking or deformation under stress. Durable cores contribute to extended wheel lifespan, ensuring consistent performance over time. A robust core is crucial when tackling rough terrains or performing aggressive maneuvers.

- Heat Resistance

Friction generated during skating can cause wheels to heat up, potentially affecting their performance and longevity. Core materials with high thermal resistance, such as certain polymers or heat-treated alloys, mitigate heat buildup, preventing the urethane from softening or delaminating from the core. This is especially important in downhill skating or prolonged sessions where wheels are subjected to considerable friction.

- Weight

The density of the core material contributes to the overall wheel weight, influencing the board’s maneuverability and responsiveness. Lighter core materials, such as some advanced polymers or composite blends, reduce rotational inertia, enabling quicker acceleration and easier trick execution. However, excessively lightweight cores may compromise structural integrity. Core density must balance weight reduction with durability and performance requirements.

The interplay between core material and the urethane compound significantly influences the wheel’s final properties. Carefully considering core material characteristics allows skaters to optimize performance, durability, and overall riding experience. Selections can be based on specific needs and preferences.

5. Bearing Seat

The bearing seat, the precisely machined recess within a wheel designed to accommodate skateboard bearings, is a critical structural element directly influencing the performance and reliability of wheels. In wheels, the bearing seat’s dimensional accuracy and surface finish dictate bearing alignment and rotational efficiency. Improper bearing seat tolerances can lead to bearing misalignment, causing increased friction, reduced roll speed, and premature bearing failure. A well-designed bearing seat ensures that the bearings sit flush and square within the wheel, distributing load evenly and maximizing energy transfer. For example, a poorly manufactured bearing seat in a wheel might cause the bearings to wobble, creating vibrations and slowing the skater down.

The material composition of the bearing seat also plays a crucial role. A durable, rigid material is necessary to withstand the forces exerted by the bearings during skating. Deformations in the bearing seat can compromise bearing alignment and lead to performance degradation. Furthermore, the bearing seat’s design must account for thermal expansion and contraction. Variations in temperature can affect the dimensions of both the wheel and the bearings, and the bearing seat must allow for slight movement without compromising bearing fit. A properly designed seat maintains correct fit during use.

In summary, the bearing seat is an indispensable component of wheels, directly impacting performance, durability, and safety. Precise manufacturing tolerances, robust material selection, and thoughtful design considerations are paramount to ensuring optimal bearing alignment and maximizing the wheel’s lifespan. Understanding the bearing seat’s role is essential for skaters and manufacturers alike, enabling informed decisions that improve the overall skating experience and minimize equipment failures.

6. Wheel Shape

The shape of wheels, particularly in the 65mm diameter range, significantly influences riding characteristics and intended use. Wheel profile affects grip, slide initiation, and overall maneuverability, making it a crucial consideration for skaters.

- Rounded Edge Wheels

Wheels with rounded edges are commonly employed for cruising and carving. The curved profile facilitates smooth transitions between turns and allows for easier slide initiation. This shape is favored for longboards and cruisers where maneuverability and predictable sliding are prioritized. A rounded edge is less prone to catching on surfaces, offering a forgiving ride experience.

- Square Edge Wheels

Square-edged wheels maximize grip and stability. The sharp edge provides a larger contact patch with the riding surface, enhancing traction during cornering and acceleration. This shape is typically used in downhill skateboarding or racing, where maintaining control at high speeds is paramount. However, square edges are more susceptible to catching on cracks and imperfections in the pavement, potentially leading to abrupt stops or falls.

- Beveled Edge Wheels

Beveled edge wheels represent a compromise between rounded and square profiles. The angled edge provides a balance of grip and slide capability, making them versatile for various skating styles. Beveled edges are often found on freeride wheels, allowing for controlled slides and smooth transitions. This shape is suitable for skaters seeking a predictable and adaptable riding experience.

- Conical Wheels

Conical wheels feature a distinct, angled profile that promotes controlled slides and reduces wheel bite. The tapered shape minimizes contact with the deck, preventing the wheel from rubbing against the board during sharp turns. Conical wheels are frequently used in street skating and technical downhill, where precise control and slide management are essential.

The selection of wheel shape directly impacts the performance and suitability of 65mm wheels for various skateboarding disciplines. Each profile offers unique advantages and disadvantages, catering to specific riding styles and preferences. Understanding the nuances of wheel shape enables skaters to optimize their setup for the desired riding experience.

7. Intended Use

The intended use of wheels dictates critical performance characteristics and directly influences the selection of specific wheel attributes, including diameter, durometer, and shape. Wheels designated as 65mm in diameter are suitable for a range of skateboarding applications, but their optimal performance is contingent upon aligning their characteristics with the desired riding style and terrain.

- Cruising and Commuting

For cruising and commuting, wheels offer a balance of speed and shock absorption. Softer durometers (78A-85A) enhance ride comfort on varied pavement conditions. This use case favors rounded edge profiles to facilitate smooth turning and minimize the risk of wheel bite on carving maneuvers. The wheel size enhances stability.

- Longboarding and Downhill

Longboarding and downhill applications demand high-speed stability and predictable slide characteristics. While wheels can be suitable, larger diameters are often preferred. If wheels are selected, harder durometers (83A+) and square-edged or beveled profiles optimize grip and control during high-speed turns. The size offers balance here.

- Freeride

Freeride skating requires a balance between grip and slide capabilities. Wheels in the 65mm range with beveled or rounded edges are commonly chosen. Durometer selection depends on the rider’s preference for grip versus slide, but typically falls within the mid-range (80A-86A). Controlled slides are essential for this riding style, and the wheel size offers a suitable balance of speed and maneuverability.

- Street Skating

Street skating generally favors smaller, harder wheels for trick execution. Wheels may be employed in specific situations, such as filming or navigating rougher urban terrain. In such cases, harder durometers (90A+) and square or conical profiles offer the necessary responsiveness and durability for performing tricks and handling street obstacles. The size offers practicality when smaller sizes aren’t a good fit.

The diverse range of skateboarding disciplines necessitates a careful consideration of intended use when selecting wheels. While the wheels offer a versatile platform, optimizing their performance requires aligning their attributes with the specific demands of the intended riding style and terrain. Factors such as durometer, edge profile, and core material play a crucial role in tailoring the wheels to the skater’s needs.

Frequently Asked Questions About 65mm Skate Wheels

This section addresses common inquiries regarding wheels, providing clarity on their characteristics, applications, and maintenance.

Question 1: What are the primary benefits of selecting 65mm wheels over other sizes?

Wheels of this diameter offer a balanced compromise between rolling speed, acceleration, and obstacle clearance. This size is often favored for its versatility across different skateboarding disciplines and terrains.

Question 2: What durometer rating is most suitable for 65mm wheels used for cruising?

For cruising applications, a durometer range of 78A to 85A is generally recommended. Softer wheels provide enhanced shock absorption and grip, improving comfort on uneven surfaces.

Question 3: How frequently should 65mm wheels be rotated to ensure even wear?

Wheels should be rotated regularly, ideally every few weeks or after approximately 20-30 hours of use. This practice promotes uniform wear and extends the wheels’ lifespan.

Question 4: Are 65mm wheels compatible with standard skateboard bearings?

Wheels are designed to be compatible with standard 608-sized skateboard bearings. Ensure that the bearings are properly seated and maintained for optimal performance.

Question 5: What types of skateboarding are generally not recommended for wheels?

While versatile, these wheels may not be ideal for highly technical street skating or vert ramp skating, where smaller, harder wheels offer greater responsiveness and control for specific tricks.

Question 6: How does the core material of 65mm wheels affect their performance?

The core material influences the wheel’s stiffness, energy transfer, and durability. Stiffer cores enhance speed and responsiveness, while more durable materials improve resistance to damage and deformation.

In summary, the selection and maintenance of these wheels require careful consideration of intended use, riding conditions, and individual preferences. Understanding these factors will maximize performance and longevity.

The following section will provide information on troubleshooting tips to maximize performance and to know when its time to replace your wheels.

Conclusion

This examination of 65mm skate wheels reveals their balanced attributes applicable across a spectrum of skateboarding styles. From cruising to freeriding, these wheels offer a compelling compromise between speed, maneuverability, and terrain adaptability. Precise specification of durometer, core material, and edge profile allows for customization that optimizes performance in specific disciplines. Rigorous attention to bearing seat integrity and consistent maintenance practices ensure extended lifespan and reliable operation.

The continued evolution of skateboarding technology will undoubtedly refine wheel design and material composition. Ongoing research into advanced polymers and manufacturing processes promises to further enhance the performance characteristics of wheels. Skaters and equipment specifiers should remain informed of these advancements to make data-driven decisions. Continued diligence in component selection and maintenance is necessary to ensuring optimal safety, and maximizing the enjoyment of the skating experience.