Footwear designed for gliding across ice surfaces, specifically crafted to accommodate individuals with larger feet, is a specialized product. These items provide the necessary support and stability for activities such as ice hockey, figure skating, and recreational skating. The numerical designation refers to the measured length of the foot, crucial for ensuring a secure and comfortable fit within the boot.

The availability of appropriately sized equipment is essential for promoting safety and performance in ice-related activities. Properly fitted boots contribute to enhanced control, reduced risk of injury, and improved overall skating experience. Historically, catering to individuals with larger shoe sizes has presented manufacturing and distribution challenges, leading to limited availability and higher costs. However, increased demand and advancements in production techniques are gradually addressing these issues.

The following sections will delve into the construction materials, common usage scenarios, key features to consider when selecting the correct fit, and maintenance practices for this specialized type of footwear.

Guidance on Acquiring Appropriately Sized Footwear for Ice Skating

The selection of ice skating boots necessitates careful consideration to ensure optimal performance and minimize potential risks. The following recommendations are intended to aid in the acquisition process for individuals requiring larger sizes.

Tip 1: Prioritize Accurate Measurement: Precise foot measurement is paramount. Professional fitting services utilize specialized devices to determine the exact length and width of the foot. This data should be the primary determinant of boot size.

Tip 2: Account for Sock Thickness: The thickness of the socks intended for use while skating should be considered during the fitting process. Thicker socks can significantly impact the internal volume of the boot, necessitating a larger size.

Tip 3: Seek Expert Consultation: Specialty retailers staffed by experienced professionals offer invaluable guidance. Their knowledge of various brands and models, combined with their fitting expertise, can significantly streamline the selection process.

Tip 4: Verify Ankle Support: Adequate ankle support is crucial for stability and injury prevention. Ensure the selected boots provide sufficient rigidity and reinforcement around the ankle joint. Evaluate the lacing system for secure and customizable closure.

Tip 5: Inspect Internal Padding and Liners: The interior of the boot should feature ample padding and a comfortable liner. These elements contribute to shock absorption, moisture management, and overall comfort. Removable liners facilitate cleaning and replacement.

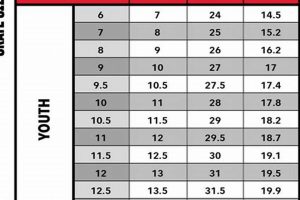

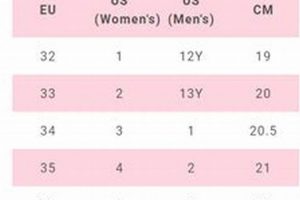

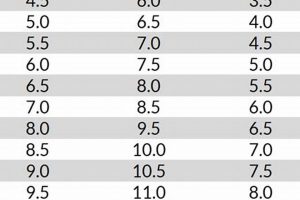

Tip 6: Research Brand Reputations and Sizing Charts: Different manufacturers may employ varying sizing conventions. Consult brand-specific sizing charts to ensure accurate translation of foot measurements to the appropriate boot size. Research brand reputations for quality and durability.

Tip 7: Consider Heat Molding Options: Certain high-end models offer heat-moldable features, allowing the boot to be custom-fitted to the unique contours of the foot. This process enhances comfort and performance by minimizing pressure points and maximizing energy transfer.

Selecting footwear designed for gliding across ice surfaces that properly fit is critical for comfort, safety, and optimizing performance. These tips can provide a better purchase experience.

The subsequent sections will cover the various types of equipment, including recreational, figure skating, and hockey-specific options, as well as guidance on proper maintenance.

1. Availability

The availability of footwear designed for gliding across ice surfaces in the specific size of 15 presents a significant constraint for prospective purchasers. This limited accessibility stems from several interconnected factors that impact production, distribution, and retail practices.

- Production Volume and Market Demand

Manufacturing facilities typically prioritize the production of standard sizes, reflecting the bulk of consumer demand. Larger sizes, such as 15, represent a smaller segment of the market. Consequently, manufacturers often produce these sizes in lower quantities, leading to increased scarcity and longer lead times for consumers.

- Retail Inventory Management

Retailers strategically manage their inventory based on anticipated sales volume and storage capacity. Given the relatively low turnover rate for larger sizes, many stores opt to carry a limited selection, or none at all, of footwear designed for gliding across ice surfaces in size 15. This practice necessitates that consumers rely on online retailers or special orders, further complicating the acquisition process.

- Specialized Manufacturing and Cost Considerations

The production of larger-sized ice skating boots may require specialized molds and manufacturing techniques, adding to the overall cost of production. These increased costs can be passed on to consumers, resulting in higher prices and potentially deterring purchases. The economic implications of producing and stocking larger sizes influence the availability of these products.

- Geographic Distribution and Accessibility

Even if footwear designed for gliding across ice surfaces are manufactured in size 15, its physical availability may be limited based on geographic distribution. Rural areas may lack any source, requiring significant travel or the use of online vendors with the added risk of improper fit. The need for specialty stores to serve a wider region due to low volume is necessary.

The interplay of production volume, retail inventory management, specialized manufacturing costs, and geographic distribution significantly impacts the availability of ice skating boots in size 15. Consumers requiring this specific size often face challenges in locating and acquiring appropriately fitted equipment, necessitating proactive research and potentially requiring special orders or online purchases.

2. Ankle Support

The provision of adequate ankle support in size 15 footwear designed for gliding across ice surfaces is a critical factor influencing both performance and injury prevention. The increased leverage exerted due to larger foot size necessitates a robust support structure to maintain stability and control during skating maneuvers. Inadequate ankle support can lead to excessive pronation or supination, increasing the risk of sprains, strains, and other lower extremity injuries. The design must accommodate the dimensions of larger feet while ensuring a snug and secure fit around the ankle joint.

The construction materials and design features contribute significantly to the level of ankle support provided. Stiffer boot materials, such as reinforced polymers or composite materials, offer greater rigidity and stability. A higher boot cuff that extends further up the leg can provide additional support and limit excessive ankle movement. The lacing system also plays a crucial role; a well-designed lacing system allows for customized tightening and adjustment, ensuring a secure and supportive fit. Examples of injuries from soft sided models are commonplace. Furthermore, the internal padding and liner should be contoured to provide cushioning and support around the ankle bone.

Properly designed equipment contributes to enhanced control, reduced risk of injury, and improved overall skating experience, and this is especially necessary for people with larger feet. Failure to adequately address the support needs of larger feet can compromise performance and increase the likelihood of injuries. The selection process should prioritize models specifically engineered to provide robust ankle support. The need for proper ankle support is a common thread across all types of skating.

3. Blade Quality

The quality of the blade affixed to footwear designed for gliding across ice surfaces significantly impacts performance, particularly for individuals requiring larger sizes. Given the increased force exerted on the blade due to greater body mass and leverage, blade quality becomes a critical factor in ensuring stability, control, and longevity of the equipment.

- Steel Composition and Hardness

The type of steel used in blade construction directly influences its hardness, edge retention, and resistance to corrosion. Higher-quality steel alloys, often containing chromium or other hardening elements, provide superior edge sharpness and durability. A harder blade requires less frequent sharpening and maintains its edge for longer periods, crucial for consistent performance in a larger size where forces are amplified.

- Blade Profile and Geometry

The curvature and shape of the blade, known as the profile and geometry, affect the skate’s maneuverability and gliding efficiency. A well-designed blade profile optimizes the distribution of pressure along the blade, allowing for smooth turns, controlled stops, and efficient energy transfer. For larger sizes, a properly designed blade profile is essential for maintaining balance and stability, particularly during complex skating maneuvers.

- Blade Mounting and Alignment

The method by which the blade is attached to the boot directly impacts the skate’s responsiveness and stability. Precise alignment of the blade with the boot is essential for ensuring proper balance and preventing uneven wear. A secure and rigid mounting system minimizes energy loss and maximizes control. For larger sizes, a robust mounting system is particularly important to withstand the increased stresses placed on the blade during skating.

- Blade Finish and Maintenance

The surface finish of the blade affects its gliding properties and resistance to corrosion. A smooth, polished finish reduces friction and improves glide. Proper maintenance, including regular sharpening and cleaning, is essential for preserving blade quality and performance. For larger sizes, where blade wear may be accelerated, diligent maintenance practices are particularly important for prolonging the lifespan of the equipment.

In conclusion, the quality of the blade is a determinant factor in the performance and durability of footwear designed for gliding across ice surfaces, especially size 15. Selecting equipment with high-quality blades, ensuring proper mounting and alignment, and adhering to diligent maintenance practices are essential for optimizing the skating experience and prolonging the life of the equipment.

4. Boot Comfort

Boot comfort constitutes a critical element in footwear designed for gliding across ice surfaces, particularly when considering the specific requirements of size 15. Ill-fitting or uncomfortable boots can lead to a range of adverse effects, including compromised performance, increased risk of injury, and diminished enjoyment of the activity. The extended contact between the foot and the boot necessitates a design that minimizes friction, pressure points, and moisture accumulation. Size 15 individuals, due to their larger foot volume, may be particularly susceptible to discomfort if the boot’s internal geometry and materials are not appropriately configured. For example, a boot that is too narrow can cause blisters and nerve compression, while a boot that is too shallow can lead to toe cramping and reduced circulation. A properly designed boot, on the other hand, provides a secure yet comfortable fit, enabling the wearer to focus on technique and performance without distraction.

The materials used in boot construction play a pivotal role in determining overall comfort. High-quality liners, often constructed from moisture-wicking fabrics and strategically placed padding, can help to regulate temperature and minimize friction. Shell materials that offer a degree of flexibility can conform to the foot’s contours, reducing pressure points and enhancing comfort. Customization options, such as heat-moldable liners, provide an opportunity to fine-tune the fit and address individual anatomical variations. In practical terms, a size 15 individual who invests in boots with superior comfort features is more likely to experience prolonged skating sessions without fatigue or discomfort, resulting in improved skill development and a reduced risk of overuse injuries. Conversely, neglecting the importance of boot comfort can lead to a cycle of pain, frustration, and ultimately, a premature abandonment of the activity.

In summary, boot comfort is inextricably linked to the performance, safety, and enjoyment of footwear designed for gliding across ice surfaces, particularly in size 15. The selection process should prioritize models that offer a combination of appropriate sizing, high-quality materials, and customizable features to ensure a comfortable and supportive fit. While challenges may exist in finding readily available options in this size, the investment in a well-fitting and comfortable boot is essential for maximizing the benefits and minimizing the risks associated with ice skating.

5. Lacing System

The lacing system on footwear designed for gliding across ice surfaces is a critical component, particularly in larger sizes such as 15. It directly impacts foot stability, ankle support, and overall skating performance. A well-designed system enables customized tightening, accommodating the unique contours of the foot and providing secure closure. In size 15, where leverage forces are amplified due to larger foot dimensions, an inadequate lacing system can result in slippage, instability, and an increased risk of ankle injuries. Conversely, a robust and adaptable system contributes to enhanced control and efficient energy transfer. For example, a skater with high arches may require asymmetrical lacing to alleviate pressure points, while one with narrow ankles may benefit from a system that allows for precise tightening in the lower portion of the boot. The effectiveness of the lacing system is therefore paramount in ensuring a comfortable and secure fit within the larger confines of a size 15 boot.

Different lacing system designs offer varying degrees of adjustability and support. Traditional lacing, utilizing eyelets or hooks, provides a familiar and reliable method of closure. However, it may lack the precision and adjustability required to accommodate specific foot shapes or skating styles. Speed lacing systems, incorporating strategically placed loops and locking mechanisms, enable faster and more consistent tightening. These systems are particularly advantageous for skaters who frequently adjust their laces during training or competition. Power lacing systems, often found in high-end models, utilize mechanical or electronic mechanisms to automate the tightening process and provide precise control over pressure distribution. Regardless of the specific design, the lacing system must be durable enough to withstand the stresses of repeated use and resistant to loosening during skating sessions. It must also be easy to manipulate, even with gloved hands, ensuring that skaters can make quick adjustments as needed.

In summary, the lacing system plays a vital role in the functionality and safety of footwear designed for gliding across ice surfaces, and even more so in larger sizes. A poorly designed system can compromise performance and increase the risk of injury, while a well-executed system enhances comfort, stability, and control. When selecting ice skating boots in size 15, careful consideration should be given to the type of lacing system, its adjustability, and its overall durability. The selection is a pivotal aspect that shouldn’t be overlooked.

6. Heat Molding

Heat molding represents a customization technique frequently employed in the fitting of footwear designed for gliding across ice surfaces. Its relevance to size 15 is particularly pronounced due to the challenges in achieving an optimal fit for larger feet. Standard manufacturing processes may not adequately address the unique anatomical variations present in individuals requiring size 15 footwear. Heat molding offers a means to mitigate these discrepancies and enhance overall comfort and performance.

- Conformity to Unique Foot Contours

Heat molding allows the boot’s internal structure to adapt to the specific shape of the foot. This process involves heating the boot’s liner and shell to a pliable state, followed by wearing the boot while it cools. The materials then conform to the foot’s contours, creating a personalized fit that minimizes pressure points and maximizes contact. Individuals with bunions, bony protrusions, or other anatomical irregularities can benefit significantly from this customization, as the heat molding process can create localized accommodations, reducing discomfort and the risk of blisters. For example, the process could be used to give a more precise fit along the arch of the foot.

- Enhanced Ankle Support and Stability

Proper ankle support is crucial for stability and control during skating. Heat molding can improve ankle support by creating a snug and secure fit around the ankle joint. By conforming the boot’s cuff to the ankle’s shape, the molding process minimizes unwanted movement and provides enhanced lateral stability. This is particularly beneficial for size 15 skaters, where the increased leverage can place greater stress on the ankle joint. Heat molding improves the efficacy of the lacing system.

- Improved Performance and Energy Transfer

A well-fitted boot enhances energy transfer between the skater’s foot and the blade. Heat molding improves the fit, and eliminates gaps and pressure points that can impede energy transfer. By maximizing contact between the foot and the boot, the process allows for more efficient and responsive skating. This is particularly advantageous for size 15 skaters, where every movement can be amplified by larger dimensions, and therefore proper fit leads to more efficient movement.

- Mitigation of Fit Discrepancies in Mass-Produced Footwear

Mass-produced footwear may not always accommodate the variations in foot shape and size present in individuals requiring size 15. Heat molding serves as a corrective measure, addressing these discrepancies and creating a more personalized fit. It allows skaters to achieve a level of customization that is not possible with off-the-shelf options, mitigating the compromises often associated with mass production. It’s a way to achieve a near custom fit, without the cost and time to create a custom boot.

The application of heat molding offers a viable solution for optimizing the fit and performance of footwear designed for gliding across ice surfaces, particularly in size 15. By addressing the unique anatomical challenges associated with larger feet, this customization technique enhances comfort, support, and energy transfer, ultimately improving the skater’s overall experience.

7. Intended Use

The connection between “intended use” and size 15 footwear designed for gliding across ice surfaces is paramount, dictating the specific features and construction required for optimal performance and safety. Different disciplines, such as recreational skating, figure skating, and ice hockey, place distinct demands on the equipment. Recreational use emphasizes comfort and stability, while figure skating necessitates precision and flexibility, and ice hockey demands robust protection and maneuverability. Selecting equipment inappropriate for the intended activity can lead to compromised performance and increased risk of injury. For example, employing recreational boots for competitive hockey would leave the wearer vulnerable to impacts and limit agility. Conversely, using rigid hockey boots for recreational skating would diminish comfort and restrict movement.

The construction and design of size 15 equipment varies considerably based on the intended use. Recreational models typically feature softer materials, generous padding, and a more forgiving fit, prioritizing comfort over performance. Figure skating boots incorporate a stiffer construction, higher ankle support, and a specialized blade designed for executing intricate maneuvers. Ice hockey boots prioritize impact resistance, featuring reinforced materials, protective padding, and a rigid outsole to withstand high-speed collisions and puck impacts. The selection of appropriate blade profiles and materials also depends on the intended activity; figure skating blades often have a pronounced rocker for enhanced maneuverability, while hockey blades are typically flatter for increased speed and stability. The differences are significant and ignoring them can have consequences.

In summary, the intended use is a critical determinant in the selection of size 15 footwear designed for gliding across ice surfaces. Each discipline requires specific features and construction to optimize performance, ensure safety, and enhance the overall skating experience. Understanding the demands of the intended activity and selecting equipment accordingly is essential for both novice and experienced skaters. Failure to consider the intended use can lead to compromised performance, increased risk of injury, and diminished enjoyment of the sport. It is also noted that the intended use can determine availability as well, as some specialty size 15 types may be difficult to find.

Frequently Asked Questions Regarding Size 15 Footwear Designed for Gliding Across Ice Surfaces

The following addresses common inquiries concerning the acquisition, fitting, and maintenance of larger-sized ice skating boots.

Question 1: Why is it difficult to find size 15 ice skates?

Manufacturing and retail practices contribute to limited availability. Production volumes are typically skewed towards standard sizes, resulting in reduced output of larger sizes. Retailers often stock limited quantities due to lower turnover rates, necessitating special orders or online purchases.

Question 2: What factors should be prioritized when selecting the correct size?

Accurate foot measurement, consideration of sock thickness, and professional fitting services are paramount. Consultation with experienced professionals, brand-specific sizing charts, and heat-molding options should be considered.

Question 3: How crucial is ankle support in larger-sized ice skates?

Adequate ankle support is essential for stability and injury prevention, particularly given the increased leverage exerted by larger feet. Stiffer boot materials and a well-designed lacing system are crucial for providing necessary support.

Question 4: Does blade quality impact performance in size 15 ice skates?

Blade quality significantly affects performance, stability, and control. The composition of steel, blade profile, mounting system, and maintenance practices are important considerations.

Question 5: How can boot comfort be optimized for larger feet?

High-quality liners, flexible shell materials, and customization options like heat molding contribute to enhanced boot comfort. Proper sizing to avoid constriction or movement is key to a comfortable and safe skating experience.

Question 6: How does intended use affect the selection of ice skates?

The specific demands of recreational skating, figure skating, and ice hockey necessitate distinct features and construction. Choosing equipment designed for the intended activity is crucial for safety and performance.

The acquisition of properly fitted footwear designed for gliding across ice surfaces is critical for comfort, safety, and optimizing performance. Addressing these common questions facilitates the process and promotes a more informed purchase decision.

The subsequent sections will cover maintenance and storage practices to extend the lifespan of such footwear.

Conclusion

This exploration of size 15 ice skates highlights the unique considerations necessary for individuals requiring this specialized footwear. Availability, ankle support, blade quality, boot comfort, lacing systems, heat molding options, and intended use are all critical factors in ensuring a safe, comfortable, and performant skating experience. The challenges in obtaining appropriately sized equipment necessitate proactive research and informed decision-making.

The future of this niche market hinges on increased manufacturer responsiveness to diverse sizing needs and advancements in customization technologies. Prioritizing proper fit and construction will promote greater participation and longevity in ice skating activities. The pursuit of well-engineered, properly fitted size 15 ice skates remains paramount for enabling individuals to fully engage in this activity.