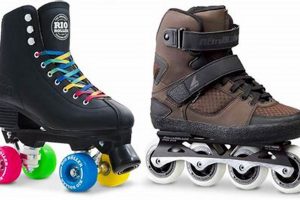

Footwear designed for gliding movement, featuring wheels attached to a boot or shoe, manufactured under the Salomon brand, enables individuals to propel themselves across surfaces. These products serve as a recreational and fitness tool, allowing for various maneuvers and speeds depending on user skill and terrain.

The significance of such wheeled footwear lies in its provision of a low-impact cardiovascular workout and a dynamic form of transportation. Historical development reveals a progression from rudimentary wheel attachments to sophisticated designs incorporating advanced materials and performance-enhancing features, reflecting a commitment to both user comfort and athletic capability.

A discussion of these skating products will delve into aspects of design innovation, the diverse range of models available, and the technologies employed to enhance performance and user experience. Factors such as wheel configuration, boot construction, and closure systems will be examined to provide a thorough understanding of this equipment.

Guidance for Optimizing Use

Effective utilization requires understanding equipment capabilities and safety protocols. The following points emphasize best practices for a beneficial experience.

Tip 1: Prioritize Protective Gear: Consistent use of helmets, wrist guards, elbow pads, and knee pads minimizes the risk of injury during falls or collisions. Inspect gear regularly for wear and tear.

Tip 2: Select Appropriate Skating Surfaces: Opt for smooth, paved areas free from obstacles, debris, and pedestrian traffic. Avoid surfaces with excessive slopes or uneven textures.

Tip 3: Maintain Equipment Regularly: Inspect wheels, bearings, and closure systems before each use. Clean bearings and wheels periodically to ensure optimal performance and longevity.

Tip 4: Develop Fundamental Skills: Master basic skills such as balance, gliding, braking, and turning before attempting advanced maneuvers. Consider professional instruction for structured learning.

Tip 5: Adhere to Traffic Regulations: Observe local traffic laws and regulations applicable to wheeled devices. Be aware of surroundings and yield to pedestrians and vehicular traffic.

Tip 6: Adjust Equipment for Comfort: Ensure proper fit and adjustment of boot closures to maximize comfort and control. Avoid overtightening, which can restrict circulation and movement.

Tip 7: Gradually Increase Skating Duration: Begin with shorter sessions and progressively increase the duration and intensity of skating activities. This allows the body to adapt and reduces the risk of overuse injuries.

Applying these guidelines promotes safer and more enjoyable use, maximizing the benefits derived from skating activities. The emphasis on safety and maintenance contributes to long-term satisfaction.

Following these tips enhances both user experience and equipment lifespan, leading to a greater appreciation for the activity.

1. Boot Construction

Boot construction is a critical determinant of the performance characteristics and overall user experience of wheeled footwear manufactured under the Salomon brand. The architecture of the boot directly influences support, responsiveness, and comfort, thereby affecting the skater’s ability to execute maneuvers and maintain control. Improper boot construction can lead to instability, reduced energy transfer, and increased risk of injury. For instance, a boot lacking sufficient ankle support may contribute to ankle sprains, while a boot with excessive stiffness could hinder maneuverability.

Salomon’s approach to boot construction often integrates advanced materials and ergonomic designs to optimize fit and performance. Examples include the utilization of thermo-moldable liners, which conform to the skater’s foot shape, providing a customized and secure fit. Furthermore, the strategic placement of reinforced materials in high-stress areas enhances durability and support. The integration of ventilation systems within the boot design can also mitigate moisture buildup, improving comfort during extended skating sessions. These features represent a direct response to the biomechanical demands placed on the foot and ankle during skating activities.

In summary, the boot construction is not merely an aesthetic consideration; it is a fundamental element that dictates the functionality and safety of the skating product. Understanding the principles and techniques employed in boot construction enables informed purchasing decisions and promotes the safe and effective utilization of Salomon wheeled footwear. The ongoing refinement of boot designs reflects a continuous effort to enhance the skater’s experience through improved support, comfort, and performance.

2. Wheel Durometer

Wheel durometer, a measurement of a wheel’s hardness, exerts a significant influence on the performance characteristics of Salomon wheeled footwear. This metric, typically expressed on the A scale, directly affects the wheel’s grip, roll speed, and durability, impacting the overall skating experience. A lower durometer value indicates a softer wheel, offering enhanced grip and shock absorption on rough surfaces. Conversely, a higher durometer value signifies a harder wheel, providing greater roll speed and increased resistance to wear on smoother terrains. The selection of an appropriate wheel durometer is thus crucial for optimizing performance across diverse skating environments.

The interplay between wheel durometer and skating surface manifests in several practical applications. For example, skaters utilizing Salomon products on outdoor surfaces characterized by uneven pavement and debris may benefit from softer wheels (e.g., 78A-82A). These wheels provide improved grip and a smoother ride, mitigating the effects of surface irregularities. In contrast, skaters operating within controlled environments such as indoor rinks or smooth skate parks may favor harder wheels (e.g., 84A-88A or higher). These wheels facilitate faster speeds and enhanced responsiveness, catering to the demands of competitive skating and trick execution. The correct durometer will also affect the lifespan of the wheel. Harder wheels on rough surfaces will wear down faster and softer wheels on smooth surfaces will be slow and cumbersome.

In summary, wheel durometer represents a critical parameter influencing the functionality and performance of Salomon wheeled products. The appropriate selection of wheel hardness, guided by the intended skating environment and desired performance characteristics, is essential for maximizing user satisfaction and safety. Understanding this relationship allows skaters to fine-tune their equipment configuration, thereby optimizing their skating experience and mitigating potential risks associated with inappropriate wheel selection. The choice of hardness will affect speed, comfort, and longevity, all key performance indicators.

3. Frame Material

Frame material is a foundational aspect of Salomon wheeled footwear, directly impacting the equipment’s weight, durability, stability, and responsiveness. The material composition of the frame significantly influences energy transfer during skating, affecting both performance and the overall user experience.

- Aluminum Alloys

Aluminum alloys are frequently employed in the construction of Salomon skate frames due to their favorable strength-to-weight ratio. These alloys provide a rigid platform for efficient power transfer, enhancing responsiveness and control. Different aluminum series (e.g., 6000 series, 7000 series) offer varying levels of strength and corrosion resistance, affecting the frame’s longevity. For example, frames intended for aggressive skating may utilize a higher-strength alloy to withstand the stresses of jumps and grinds. The higher the number, the more durable.

- Composite Materials

Composite materials, such as carbon fiber and reinforced polymers, are sometimes incorporated into Salomon frame designs to reduce weight and enhance vibration dampening. These materials can improve comfort and reduce fatigue during extended skating sessions. While offering weight advantages, composite frames may not possess the same level of impact resistance as aluminum alloys. Composite frames are likely to be less durable but more comfortable.

- Frame Length and Configuration

The choice of frame material is often intertwined with frame length and wheel configuration. Shorter frames, typically found on aggressive skates, prioritize maneuverability and control, while longer frames, common on fitness and speed skates, emphasize stability and speed. Frame material must be selected to withstand the stresses associated with the intended skating style and wheel arrangement. The length and number of wheels are key performance indicators.

- Manufacturing Processes

The manufacturing process used to create the frame, such as extrusion, casting, or machining, affects the frame’s structural integrity and precision. Extruded aluminum frames, for example, offer consistent strength and dimensional accuracy. Machined frames allow for more intricate designs and precise tolerances, enhancing performance characteristics. How a frame is made determines its strength.

The selection of frame material for Salomon roller skates represents a critical engineering decision that balances weight, strength, durability, and performance characteristics. The optimal material choice depends on the intended skating application, user skill level, and desired performance attributes. Understanding the properties and trade-offs associated with different frame materials enables informed purchasing decisions and promotes the effective utilization of Salomon wheeled products. The frame is the backbone of the product and dictates many aspects of how it will ride.

4. Bearing Precision

Bearing precision constitutes a critical factor in determining the rolling efficiency and overall performance of Salomon roller skates. The precision with which bearings are manufactured directly affects the smoothness and speed of wheel rotation, influencing the skater’s ability to maintain momentum and execute maneuvers effectively. Understanding the nuances of bearing precision is therefore essential for both selecting and maintaining Salomon skating equipment.

- ABEC Rating

The Annular Bearing Engineers’ Committee (ABEC) rating system provides a standardized measure of bearing tolerances. Bearings are classified according to numerical grades (ABEC-1, ABEC-3, ABEC-5, ABEC-7, ABEC-9), with higher numbers indicating tighter tolerances and greater precision. Higher ABEC ratings often correlate with smoother rolling and increased speed, but also with higher cost and potentially reduced durability in harsh environments. Bearings with higher ABEC ratings provide less friction.

- Material Composition

The materials used in bearing construction, including the inner and outer races, balls, and retainers, influence both precision and durability. Stainless steel bearings offer corrosion resistance, suitable for wet or humid conditions, while ceramic bearings provide reduced friction and increased hardness, potentially extending bearing life and enhancing rolling efficiency. Bearing materials should be chosen based on environmental conditions.

- Lubrication

Proper lubrication is essential for maintaining bearing precision and performance. Lubricants reduce friction, dissipate heat, and protect bearing components from wear. The selection of an appropriate lubricant, such as oil or grease, depends on the skating environment and desired performance characteristics. Regular cleaning and re-lubrication are necessary to remove contaminants and maintain optimal bearing function. Dirty or worn lubricants lead to less precision.

- Impact on Skating Style

Bearing precision requirements vary based on skating style. Aggressive skaters may prioritize durability over precision, opting for robust bearings that can withstand impacts and stresses associated with jumps and grinds. Speed skaters and fitness enthusiasts may favor high-precision bearings to maximize rolling efficiency and minimize energy expenditure. Different skating types will require different bearing considerations.

In summary, bearing precision is a multifaceted attribute that significantly affects the performance and longevity of Salomon roller skates. The selection of bearings with appropriate ABEC ratings, material composition, and lubrication, aligned with the intended skating environment and style, is crucial for optimizing rolling efficiency and ensuring a smooth, enjoyable skating experience. Regular maintenance and timely replacement of worn bearings further contribute to sustained performance and equipment reliability. Bearing choice can drastically alter the feel of the skates.

5. Closure System

The closure system on Salomon roller skates is a primary determinant of fit, support, and performance. It directly affects the skater’s ability to transfer power efficiently and maintain control. Inadequate closure leads to instability, reduced responsiveness, and an increased risk of injury. Conversely, a well-designed system provides a secure, comfortable fit that enhances performance and safety. The system’s functionality is thus inextricably linked to the overall effectiveness of the skating product.

Salomon typically employs a combination of closure mechanisms in its roller skate designs. These may include traditional laces, buckles, hook-and-loop straps, and ratcheting systems. The precise configuration and materials used vary depending on the intended use of the skate. For example, aggressive skates often feature robust buckles and reinforced straps to withstand the high impacts associated with jumps and grinds. Fitness skates may prioritize comfort and ease of use, employing quick-release buckles and breathable materials. The design and integration of the closure system reflect a deliberate effort to optimize performance for specific skating styles.

Understanding the nuances of Salomon’s closure systems enables skaters to make informed purchasing decisions and properly adjust their equipment. A secure and comfortable fit, achieved through a well-designed closure, translates to improved control, reduced fatigue, and enhanced overall skating experience. The closure system is not merely an accessory but an integral component directly influencing performance, safety, and enjoyment. Failure to maintain or properly adjust this system can negate the benefits of other high-performance features.

6. Braking Mechanism

The braking mechanism constitutes an indispensable safety feature integrated into Salomon roller skates, designed to provide controlled deceleration and prevent collisions. Its functionality directly influences the skater’s ability to manage speed and avoid hazardous situations. The effectiveness of the braking mechanism is paramount, given the inherent momentum generated during skating, and its reliability is a key factor in mitigating the risk of injury. For instance, a properly functioning brake enables a skater to halt swiftly when encountering unexpected obstacles or pedestrians, thus preventing potential accidents. Without a dependable braking system, the skater is at a significantly increased risk of losing control, particularly on declines or at higher velocities.

Salomon typically employs a heel brake design in many of its roller skate models, wherein a brake pad is affixed to the rear of one or both skates. Applying pressure to the brake pad by tilting the foot backward initiates the deceleration process. The efficacy of this system depends on several factors, including the composition of the brake pad material, the skater’s technique, and the condition of the skating surface. Worn brake pads diminish braking performance and necessitate timely replacement. Moreover, different brake pad materials offer varying degrees of grip and durability, affecting the stopping distance and the longevity of the component. Routine inspection and maintenance of the braking system are therefore essential for preserving its functionality. Some skates also have optional or aftermarket toe stop options for different braking styles.

In conclusion, the braking mechanism is not merely an accessory but a fundamental safety component of Salomon roller skates. Its reliable operation is critical for managing speed, preventing accidents, and ensuring the well-being of the skater. Regular inspection, maintenance, and timely replacement of worn brake pads are imperative for upholding the integrity of the braking system and maximizing its effectiveness. The ability to control one’s speed is the most important factor. Compromising on the braking system is not an option for a skater.

Frequently Asked Questions About Salomon Roller Skates

This section addresses common inquiries regarding Salomon roller skates, providing factual and objective responses to enhance understanding and informed decision-making.

Question 1: What factors determine the appropriate size of Salomon roller skates?

Skate size is determined by foot length and width, typically measured in millimeters. Consult the manufacturer’s sizing chart and consider foot shape and sock thickness for optimal fit. Improper sizing compromises comfort and performance.

Question 2: How frequently should Salomon roller skate wheels be rotated?

Wheel rotation frequency depends on skating surface and style. Regular rotation, typically after 5-10 hours of use, promotes even wear and extends wheel lifespan. Uneven wear reduces performance and stability.

Question 3: What maintenance procedures are essential for preserving Salomon roller skate bearings?

Bearing maintenance includes periodic cleaning and lubrication. Remove dirt and debris with a solvent, and apply a bearing-specific lubricant. Proper maintenance ensures smooth rolling and prolongs bearing life. Neglecting bearing maintenance leads to premature failure.

Question 4: How does wheel durometer impact Salomon roller skate performance?

Wheel durometer, measured on the A scale, affects grip, roll speed, and durability. Softer wheels (lower durometer) offer increased grip on rough surfaces, while harder wheels (higher durometer) provide faster roll on smooth surfaces. Wheel durometer should align with skating environment and desired performance characteristics.

Question 5: What safety equipment is recommended when using Salomon roller skates?

Essential safety equipment includes a helmet, wrist guards, elbow pads, and knee pads. Protective gear minimizes the risk of injury during falls or collisions. Consistent use of safety equipment is paramount.

Question 6: How can the braking mechanism on Salomon roller skates be adjusted for optimal performance?

Brake pad height and angle can be adjusted to optimize braking efficiency. Ensure the brake pad makes full contact with the skating surface. Regular inspection and adjustment are necessary for reliable braking performance. A properly adjusted brake enhances safety and control.

These FAQs offer insights into key aspects of Salomon roller skate selection, maintenance, and usage. Addressing these points enhances understanding and promotes informed decisions.

The next section will discuss troubleshooting techniques for common issues encountered with these skating products.

Conclusion

This exploration of Salomon roller skates has detailed critical elements, spanning from boot construction to braking mechanisms. Understanding these factorswheel durometer, frame material, bearing precision, closure systemis essential for optimal performance and safety. Regular maintenance and informed selection based on individual needs and skating environment are crucial.

The information presented underscores the importance of considering all aspects of Salomon roller skates to ensure a safe and enjoyable skating experience. Continued advancements in design and technology will undoubtedly shape the future of these products, emphasizing the need for ongoing awareness and informed decision-making within the skating community. Prioritizing knowledge and safety practices will contribute to the responsible and sustainable use of this equipment.