These are a specific line of ice skates produced by CCM, a manufacturer of hockey equipment. They are designed with a focus on providing players with a quick and efficient release when shooting the puck. The construction and features aim to maximize energy transfer from the skater’s stride to the puck.

The line’s significance lies in its ability to cater to players seeking an edge in performance through enhanced agility and responsiveness. Over the years, this family of skates has evolved with technological advancements in materials and design, consistently striving to improve upon key attributes such as fit, comfort, and power transmission. This continuous innovation has solidified its position within the hockey equipment market.

The subsequent sections will delve into the specific models available, the key technologies employed in their construction, and considerations for selecting the optimal pair based on individual player needs and skating style.

Selecting Ice Skates

Choosing ice skates requires careful evaluation to ensure optimal performance and comfort. The following points offer guidance for making an informed decision.

Tip 1: Assess Skating Frequency and Intensity: Determine the level of usage. Recreational skaters may prioritize comfort and affordability, while competitive players will require skates engineered for performance and durability.

Tip 2: Prioritize Proper Fit: The skates should fit snugly without causing discomfort or restricting movement. Professional fitting at a specialized retailer is recommended for accurate sizing and heat molding.

Tip 3: Consider Boot Stiffness: Stiffer boots provide greater support and power transfer, which is advantageous for advanced players. Beginners might benefit from more flexible boots that allow for greater ankle movement and control.

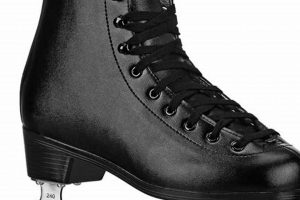

Tip 4: Examine Blade Quality: The blades steel composition and profile directly impact performance. Higher-quality steel retains its edge longer and provides superior glide. Replaceable blades offer long-term cost savings.

Tip 5: Understand Skate Radius: The radius of the blades curve influences maneuverability. Smaller radii enhance agility, while larger radii promote speed and stability.

Tip 6: Factor in Personal Skating Style: Aggressive skaters who prioritize speed and power should consider models designed for maximum energy transfer. More finesse-oriented players may prefer skates that emphasize agility and responsiveness.

Tip 7: Maintain Skates Regularly: Proper maintenance, including blade sharpening and drying the boot after each use, is essential for prolonging the life of the skates and maintaining optimal performance.

Adhering to these guidelines will assist in selecting ice skates that align with individual needs and skill level, ultimately contributing to an enhanced skating experience.

The following section will discuss specific technologies often found in modern ice skates and their respective benefits.

1. Quick Release Technology

Quick release technology constitutes a significant design focus within the CCM Ribcor ice skate line. It aims to facilitate rapid and efficient puck release during shooting, a critical attribute for competitive hockey players.

- Optimized Boot Construction

The boots construction is strategically engineered to maximize forward flexion. This allows the skater to lean more effectively into their shot, generating greater power and transferring it to the puck with minimal energy loss. Rigid materials in key areas provide support and stability during this process, ensuring that the generated force is directed appropriately.

- Enhanced Ankle Mobility

Some Ribcor models incorporate features to enhance ankle mobility. This allows for a greater range of motion, enabling players to achieve a lower stance and further optimize their shooting posture. Increased ankle flexibility also contributes to improved agility and maneuverability on the ice.

- Blade Holder Design

The design of the blade holder and its connection to the boot can also contribute to quick release capabilities. By optimizing the angle and stiffness of the holder, manufacturers aim to improve the transfer of energy from the boot to the blade, resulting in more powerful and accurate shots.

- Energy Transfer Materials

The use of specialized materials within the boot construction plays a critical role in maximizing energy transfer. These materials are chosen for their ability to efficiently transmit force from the skater’s leg muscles to the blade, minimizing energy dissipation and maximizing the power of the shot. These materials ensure minimal waste of energy while executing shot.

The integration of optimized boot construction, enhanced ankle mobility, innovative blade holder design, and advanced energy transfer materials collectively contributes to the enhanced quick release capabilities characteristic of CCM Ribcor ice skates. These skates are not merely about comfort, they emphasize maximizing the athlete’s ability to generate powerful and rapid shots. The specific implementation and effectiveness of these features will vary across different Ribcor models and generations.

2. Ankle mobility maximization

Ankle mobility maximization is a significant design consideration in CCM Ribcor ice skates, directly impacting a player’s agility, power, and overall performance. Restricted ankle movement limits the skater’s ability to achieve a deep knee bend, essential for generating power in strides and maintaining balance. A greater range of motion allows for more efficient energy transfer from the legs to the ice, resulting in increased speed and acceleration.

The design integrates features promoting unrestricted ankle movement. Specific boot construction techniques, such as strategic flex zones and softer materials in the ankle area, enable a more natural and complete range of motion. This design characteristic contrasts with stiffer skate models that prioritize support over mobility, potentially limiting the skater’s ability to execute dynamic movements. Improved ankle mobility allows a skater to transition from a low, powerful stance for acceleration into quicker turns. Examples would include a forward being able to receive a pass at speed and perform a quick turn in order to create space to shoot the puck, where a higher degree of ankle mobility would offer them more stability in a wide stance to evade a defender, and then better energy transfer into the shot.

Maximizing ankle mobility in ice skates presents a trade-off between support and freedom of movement. While increased mobility enhances agility and power generation, it may reduce the level of ankle support, potentially increasing the risk of injury. Manufacturers address this challenge by incorporating features that balance mobility with adequate support. The benefits of improved ankle movement include more efficient skating strides, quicker turns, and better balance. Understanding the impact of ankle mobility on overall performance is crucial when selecting ice skates. It links to the overall goal of enhancing athletic performance of the skates.

3. Energy transfer efficiency

Energy transfer efficiency is a critical performance metric in ice skate design, directly influencing a skater’s speed, acceleration, and overall power. In the context of CCM Ribcor ice skates, this efficiency dictates how effectively the energy generated by the skater’s stride is converted into forward momentum. Design choices within the Ribcor line are strategically implemented to minimize energy loss during this conversion process.

- Boot Stiffness and Responsiveness

The boot’s rigidity is a key determinant of energy transfer efficiency. A stiffer boot minimizes energy dissipation by preventing the foot from moving excessively within the skate. This rigidity ensures that the skater’s power is directly translated to the blade. However, excessive stiffness can limit ankle mobility, potentially hindering agility. CCM Ribcor designs often incorporate varying degrees of stiffness in different zones of the boot to balance support and flexibility. For example, the use of composite materials in strategic areas of the boot upper minimizes energy loss during stride push-off, directly contributing to enhanced acceleration. Similarly, a well-contoured heel lock prevents heel slippage, eliminating wasted motion and ensuring that every push is effectively translated into forward movement. Skates such as the CCM Ribcor 100K feature composite boots which maximizes the skaters stride, ensuring maximum energy transfer when skating.

- Blade Holder and Chassis Design

The blade holder and chassis play a crucial role in transmitting energy from the boot to the ice. A well-designed holder securely anchors the blade, preventing unwanted flex and optimizing energy transfer. Materials with high stiffness-to-weight ratios are often employed in the construction of these components to minimize energy loss through deformation. The blades attachment, if not properly connected, will mean the energy is lost when transferring down to the ice.

- Fit and Customization

A precise fit is paramount for efficient energy transfer. Excess space within the skate allows the foot to move independently, dissipating energy and reducing power. CCM Ribcor skates often feature heat-moldable materials that conform to the unique contours of the skater’s foot, minimizing slippage and maximizing contact. Customization options, such as adjustable tongues and ankle padding, further enhance fit and optimize energy transfer. A poor fit will inhibit a skaters agility, speed, and the power in their stride.

- Blade Quality and Sharpening

The quality and sharpness of the blade directly impact energy transfer efficiency. A dull blade requires more force to grip the ice, resulting in wasted energy. High-quality steel maintains its edge longer, reducing the frequency of sharpening and ensuring consistent performance. Proper blade sharpening optimizes the blade’s contact with the ice, maximizing grip and minimizing slippage. The blade should be sharpened by a professional who knows how to execute it properly, or performance may suffer, and injury could occur.

These facetsboot stiffness, blade holder design, fit, and blade qualityinteract synergistically to determine the overall energy transfer efficiency of the CCM Ribcor ice skate line. By optimizing these elements, CCM aims to provide skaters with a skate that maximizes power, speed, and agility. The efficiency of energy transfer directly translates to enhanced on-ice performance, giving players a competitive advantage. An understanding of these technologies will help users make an informed decision when buying Ribcor skates.

4. Boot stiffness variance

Boot stiffness variance within the CCM Ribcor ice skate line directly influences skating performance. The degree of rigidity in the boot determines the energy transfer efficiency and the level of support provided to the skater’s foot and ankle. Different positions and playing styles necessitate different levels of boot stiffness. For instance, forwards typically benefit from a stiffer boot to maximize power and acceleration, enabling them to generate speed and drive towards the net. Conversely, defensemen might prefer a slightly more flexible boot to enhance agility and mobility, allowing them to pivot quickly and cover more ground. A goalie will want stiffer boots to ensure maximum protection. Boot stiffness dictates how effectively the skater’s energy is transferred to the ice, and a variance is a key design aspect.

CCM addresses the variance in boot stiffness needs through a range of Ribcor models, each engineered with a specific stiffness profile. These profiles are often characterized numerically, allowing skaters to select a model that aligns with their performance requirements. Higher stiffness values indicate a more rigid boot, offering greater support and power transfer. Lower stiffness values suggest a more flexible boot, prioritizing agility and comfort. The boot’s construction materials and design contribute to its stiffness profile, with composite materials and reinforcement structures enhancing rigidity. Softer materials will increase flex, but sacrifice potential energy transfers.

Understanding the relationship between boot stiffness variance and skating style is crucial for selecting the appropriate CCM Ribcor ice skate. Factors such as skating frequency, skill level, and position should be considered. Beginner skaters often benefit from a more flexible boot that allows for greater ankle movement and control, while advanced skaters typically prefer a stiffer boot that maximizes power and responsiveness. Ultimately, the optimal boot stiffness is dependent on individual preferences and skating objectives, and the CCM Ribcor line provides a spectrum of options to accommodate diverse needs. The boot stiffness contributes directly to the quality and reliability of each stride and shot on the ice.

5. Blade steel composition

Blade steel composition is a critical determinant of performance and longevity in CCM Ribcor ice skates. The material properties directly influence edge retention, corrosion resistance, and overall durability, impacting the skater’s control, speed, and agility.

- Carbon Content

The carbon content of the steel dictates its hardness and ability to hold an edge. Higher carbon content generally results in a harder blade that retains its sharpness longer. However, excessive carbon can increase brittleness, making the blade more susceptible to chipping or cracking upon impact. CCM Ribcor blades often employ a balance of carbon to optimize edge retention without compromising durability.

- Alloy Composition

Alloying elements such as chromium, molybdenum, and vanadium are added to the steel to enhance its properties. Chromium improves corrosion resistance, preventing rust and maintaining blade integrity over time. Molybdenum increases toughness and wear resistance, extending the blade’s lifespan. Vanadium refines the grain structure of the steel, enhancing its strength and sharpness. The exact alloy composition varies depending on the specific CCM Ribcor model and intended performance characteristics.

- Heat Treatment

The heat treatment process significantly impacts the steel’s microstructure and mechanical properties. Hardening and tempering processes are employed to achieve the desired balance of hardness, toughness, and ductility. Proper heat treatment ensures that the blade retains its edge under the stresses of skating while resisting deformation or fracture. CCM utilizes controlled heat treatment techniques to optimize blade performance and durability.

- Surface Finish

The surface finish of the blade affects its glide and friction characteristics. A smooth, polished surface reduces friction with the ice, allowing for greater speed and efficiency. However, a certain degree of roughness is necessary to provide grip and control during turns and stops. CCM Ribcor blades typically feature a finely honed surface finish that balances glide with grip, optimizing performance in various skating maneuvers.

The interplay of carbon content, alloy composition, heat treatment, and surface finish determines the overall quality and performance of CCM Ribcor blades. Skaters should consider these factors when selecting skates, balancing the need for edge retention, durability, and glide characteristics to match their individual skating style and performance requirements. A higher quality blade steel composition should ensure long-lasting performance of CCM RIBCOR ice skates.

6. Customizable fit options

Customizable fit options are integral to CCM Ribcor ice skates, directly affecting comfort, performance, and injury prevention. The human foot varies significantly in shape and volume; therefore, a standardized skate fit is often suboptimal. Customizable fit options address these variations, providing a more personalized and secure fit. This is achieved through features like heat-moldable boots, adjustable tongues, and replaceable insoles, allowing skaters to tailor the skate to their specific foot morphology.

Heat-moldable boots exemplify this customization. When heated, the boot’s internal materials become pliable, conforming to the skater’s foot contours. This minimizes negative space within the skate, reducing friction and preventing blisters. Adjustable tongues offer another level of personalization, allowing skaters to modify the forward flex of the skate and optimize energy transfer. Replaceable insoles provide arch support and cushioning, accommodating different foot arch heights and improving overall comfort. For instance, a skater with high arches might benefit from aftermarket insoles offering increased support, mitigating foot fatigue and enhancing stability. The ability to customize the fit of CCM Ribcor skates extends beyond immediate comfort, influencing long-term performance and reducing the risk of common skating-related injuries such as lace bite and plantar fasciitis.

In summary, customizable fit options in CCM Ribcor ice skates are not merely ancillary features; they are essential components that enhance the skater’s experience. They address the inherent variability in foot anatomy, providing a personalized fit that optimizes comfort, performance, and injury prevention. While the specific customization options may vary across different Ribcor models, the underlying principle remains consistent: to provide skaters with a skate that adapts to their unique needs, facilitating a more efficient and enjoyable skating experience. Selecting the appropriate options can present a challenge for consumers unfamiliar with the technology, emphasizing the need for informed consultation during the purchase process.

7. Heat moldability features

Heat moldability features in CCM Ribcor ice skates represent a critical advancement in personalized fit and performance optimization. These features leverage thermo-reactive materials within the skate’s construction, enabling the boot to conform more precisely to the unique contours of the skater’s foot. This process, typically achieved through the application of controlled heat, results in a customized fit that minimizes negative space within the skate, thereby enhancing energy transfer efficiency and reducing the likelihood of friction-related discomfort. The presence of heat moldability is a direct response to the inherent variability in foot anatomy and the limitations of traditional, generic skate sizing.

The practical significance of heat moldability is evident in several key areas. Firstly, it addresses the issue of pressure points and hot spots that can develop during skating, leading to pain and reduced performance. By conforming to the foot’s shape, the heat-molded boot distributes pressure more evenly, minimizing discomfort and allowing for extended periods of skating. Secondly, the enhanced fit improves energy transfer by creating a more direct connection between the skater’s foot and the blade. This reduces wasted motion and maximizes the efficiency of each stride. A real-world example includes skaters with asymmetrical feet, where one foot is wider or has a higher arch than the other. Heat molding allows each skate to be customized to the individual foot, addressing fit discrepancies that would be impossible to resolve with off-the-shelf skates. Similarly, players recovering from foot injuries can benefit from heat molding, as it allows the skate to accommodate sensitive areas and provide a more supportive fit. For example, the CCM Ribcor 100K incorporates their heat-moldable SpeedForm technology to make sure maximum efficiency is achieved.

In conclusion, heat moldability features represent a significant contribution to the overall performance and comfort of CCM Ribcor ice skates. By enabling a customized fit, these features address the limitations of traditional skate sizing and provide skaters with a more optimized and personalized experience. While the effectiveness of heat molding depends on proper execution and individual foot characteristics, its impact on comfort, energy transfer, and injury prevention is undeniable. The integration of heat-moldable materials reflects a broader trend in skate design toward individualized performance and a recognition of the diverse needs of skaters. Further research and development in thermo-reactive materials are likely to enhance the effectiveness and durability of heat-moldable skates in the future.

Frequently Asked Questions

The following addresses common inquiries regarding CCM Ribcor ice skates, aiming to provide factual and concise information.

Question 1: What distinguishes CCM Ribcor ice skates from other product lines?

CCM Ribcor ice skates are engineered with a focus on quick release technology, ankle mobility maximization, and efficient energy transfer, differentiating them from lines that may prioritize support or other performance characteristics.

Question 2: How does boot stiffness influence performance in CCM Ribcor ice skates?

Boot stiffness directly affects energy transfer and support. Stiffer boots enhance power transmission but may limit agility, while more flexible boots offer increased mobility but less support. Selection depends on skating style and skill level.

Question 3: What role does blade steel composition play in CCM Ribcor ice skate performance?

Blade steel composition determines edge retention, corrosion resistance, and overall durability. Higher quality steel maintains sharpness longer and enhances glide characteristics.

Question 4: How do customizable fit options benefit the skater using CCM Ribcor ice skates?

Customizable fit options, such as heat-moldable boots, adjustable tongues, and replaceable insoles, provide a personalized fit, minimizing discomfort, enhancing energy transfer, and reducing the risk of injuries.

Question 5: What considerations are essential when selecting CCM Ribcor ice skates?

Key considerations include skating frequency, skill level, preferred skating style, boot stiffness, blade quality, and the availability of customizable fit options. Professional fitting is recommended.

Question 6: How does heat moldability enhance the fit of CCM Ribcor ice skates?

Heat moldability allows the boot to conform precisely to the skaters foot, minimizing negative space, distributing pressure evenly, and improving overall comfort and performance.

In summary, selecting CCM Ribcor ice skates requires careful consideration of individual needs and preferences. Understanding the interplay between key design elements, such as boot stiffness, blade composition, and fit options, is crucial for optimizing performance and comfort.

The following section provides a comparative analysis of available CCM Ribcor ice skate models.

Conclusion

This exploration of CCM Ribcor ice skates has elucidated key design elements and their impact on performance. Features such as quick release technology, variable boot stiffness, and heat-moldable construction contribute to a skate optimized for power transfer and personalized fit. Blade steel composition and customizable options further refine the skating experience, catering to a range of skill levels and preferences.

Understanding these factors enables informed purchasing decisions. The significance of selecting appropriate equipment cannot be overstated, influencing not only athletic performance but also the long-term comfort and safety of the skater. Continued advancements in materials and design suggest a trajectory toward increasingly specialized and performance-driven ice skate technology. Further research on ice skate technologies will allow more and more informed decisions and improve safety of the skates.