A skateboarding platform manufactured by World Industries serves as the primary component for performing tricks and maneuvers. Constructed typically from multiple layers of laminated maple wood, these platforms provide the necessary rigidity and concave shape required for riders to control their movement. As an example, a skateboarder might choose a specific width and design based on their skating style and foot size, influencing the stability and responsiveness of the board.

The advent of skateboards significantly impacted youth culture and the development of extreme sports. The materials and construction techniques employed contribute to both performance and durability, affecting the longevity of the product and the rider’s experience. The graphics and branding on the underside often reflect trends and subcultures, contributing to the product’s appeal beyond its functional utility. Historical context reveals the evolution of these platforms from rudimentary wooden boards to sophisticated pieces of sporting equipment.

The following sections will delve into specific design features, material composition, and the impact of graphic design on consumer preference, providing a detailed examination of these platforms within the broader skateboarding industry.

Skate Platform Selection and Maintenance Recommendations

Proper selection and maintenance of a skateboarding platform are essential for performance, safety, and longevity. The following recommendations address key aspects to consider when choosing and caring for this equipment.

Tip 1: Deck Width Selection: Choose a platform width appropriate for shoe size and riding style. Narrower platforms (7.5″-8.0″) are generally favored for technical street skating, offering quicker response. Wider platforms (8.25″+) provide greater stability for vert or bowl skating.

Tip 2: Material Evaluation: Assess the material composition. North American maple is a commonly used and highly regarded material due to its combination of strength and flexibility. Avoid platforms constructed from unknown or low-quality wood, as these are prone to premature failure.

Tip 3: Graphic Protection: Protect the graphic layer from excessive wear. Applying a thin layer of clear coat or using a protective rail guard can help preserve the visual integrity of the platform and prevent splintering.

Tip 4: Hardware Inspection: Regularly inspect the mounting hardware (truck bolts) for tightness. Loose hardware can compromise the stability of the skateboard and increase the risk of accidents. Ensure all bolts are securely fastened before each use.

Tip 5: Storage Considerations: Store the platform in a dry environment. Exposure to moisture can warp the wood and weaken the adhesive bonds within the layers. Avoid leaving the skateboard in direct sunlight or extreme temperatures.

Tip 6: Concave Assessment: Evaluate the concave profile. The depth and shape of the concave affect foot placement and board feel. Experiment with different concave types to find the profile that best suits individual preferences and riding style.

Tip 7: Cleaning Protocols: Periodically clean the grip tape using a grip tape cleaner or a stiff brush. Remove dirt and debris to maintain optimal traction. Poor grip can significantly reduce control and increase the risk of slippage.

These recommendations provide a framework for informed decision-making regarding skateboard platform selection and maintenance. Adherence to these guidelines will promote both a more enjoyable and safer skateboarding experience.

The subsequent sections will explore specific manufacturing techniques and emerging technologies in the skateboard industry, further enhancing understanding of these crucial components.

1. Construction Materials

The selection of materials significantly influences the performance characteristics and durability of a World Industries skateboarding platform. The material composition directly impacts the board’s strength, flexibility, and overall responsiveness, crucial factors for skaters.

- North American Maple Plywood

North American maple is a common and highly regarded material for constructing skateboard platforms. Its inherent strength, combined with a degree of flexibility, allows for a resilient board capable of withstanding significant stress. Multiple plies of maple are laminated together with adhesive, creating a durable composite. The quality of the maple, including grain orientation and density, directly affects the board’s lifespan and performance capabilities within a World Industries product.

- Adhesive Type

The type of adhesive used to bond the maple plies is critical to the structural integrity of the skateboard platform. High-quality, water-resistant adhesives prevent delamination, ensuring the layers remain bonded even under harsh conditions. World Industries typically uses specific adhesive formulas designed to maintain their bond under repeated impact and stress. Inferior adhesives will result in the premature separation of the layers, rendering the platform unusable.

- Fiberglass or Carbon Fiber Reinforcements

Some skateboarding platforms incorporate fiberglass or carbon fiber reinforcements within the maple layup. These materials increase the board’s stiffness and pop, enhancing its responsiveness during ollies and other aerial maneuvers. World Industries may utilize these materials in specific models to target a particular riding style or performance characteristic. The strategic placement of these reinforcements adds durability and reduces the likelihood of warping or breaking under pressure.

- Resin Type and Impregnation

The type of resin used to seal and impregnate the wood plies in a skate platform is crucial for water resistance and overall durability. Epoxy or acrylic resins are typically chosen for their superior waterproofing properties. The resin seals the porous wood grain, preventing moisture absorption which can lead to warping and weakening of the board. In World Industries products, resin impregnation ensures consistent performance in varied environmental conditions.

The combination of these materials, along with the manufacturing processes employed, determines the ultimate quality and performance of a World Industries skateboarding platform. Careful selection and quality control throughout the construction process are paramount in producing a reliable and high-performing product.

2. Width Variations

Width variations in skateboarding platforms manufactured by World Industries are critical determinants of board performance and suitability for different skateboarding styles. The dimension, measured in inches, directly affects the board’s stability, responsiveness, and rider control. A narrower platform facilitates quicker turning and is often preferred for technical street skating, where precise foot placement and rapid maneuvers are paramount. Conversely, a wider platform offers increased stability, making it better suited for vert ramps, bowls, and larger transitions. World Industries recognizes this dichotomy by producing platforms in a range of widths to cater to diverse rider preferences and disciplines. For example, a skater performing flip tricks and grinds on street obstacles might opt for a board in the 7.75″ to 8.25″ range, whereas a transition skater would likely choose a board wider than 8.25″ for enhanced stability during aerials and coping maneuvers.

The impact of width variations extends beyond simply stability versus maneuverability. The platform’s width also influences the rider’s foot placement and overall feel. A wider platform provides more surface area for the feet, allowing for a more comfortable and stable stance, particularly beneficial for larger-footed riders. This increased surface area, however, can sometimes hinder rapid foot adjustments required for complex tricks. A narrower platform allows for quicker foot repositioning, at the expense of some stability. The choice of width is therefore a nuanced decision that involves balancing personal preference, physical attributes, and intended use. World Industries often indicates the intended use case for specific platform widths in their product descriptions, assisting consumers in making informed decisions.

In conclusion, width variations represent a fundamental design consideration in skateboarding platform manufacturing. By offering a spectrum of widths, World Industries caters to a broad range of skateboarding styles and rider preferences. Understanding the implications of platform width on stability, maneuverability, and foot placement is essential for selecting the appropriate equipment and maximizing performance. The challenges associated with selecting the optimal width highlight the importance of experimentation and personal assessment in the skateboarding discipline. This understanding reinforces the brand’s commitment to providing skaters with the tools necessary to express their individual style and progress in their chosen discipline.

3. Concave Design

Concave design in World Industries skateboarding platforms significantly influences the board’s handling and responsiveness. This curvature, pressed into the platform during manufacturing, affects foot placement, board feel, and overall control, making it a key determinant of rider performance.

- Radial Concave

Radial concave features a smooth, consistent curve from edge to edge. This design promotes a predictable and stable feel, facilitating easier transitions and consistent foot placement. World Industries platforms with radial concave are often preferred by beginners or skaters who favor a more traditional board feel. The subtle curvature allows for comfortable cruising and predictable control during basic maneuvers.

- Progressive Concave

Progressive concave exhibits a more pronounced curve near the edges of the platform, gradually flattening towards the center. This design provides enhanced grip and responsiveness during flip tricks, enabling skaters to exert more leverage and control over the board’s rotation. Certain World Industries models incorporate progressive concave to cater to technical street skaters who demand precision and responsiveness.

- W Concave

W concave includes a raised spine running lengthwise down the center of the board, creating two distinct concave areas on either side. This design provides increased arch support and enhances board feel, allowing skaters to maintain a locked-in position and exert greater control. World Industries platforms with W concave are often favored by downhill skaters or those who prioritize stability and control at higher speeds.

- Flat Concave

Flat concave, as the name suggests, offers a minimal curvature across the board’s surface. While it may seem counterintuitive, some skaters prefer this design because it provides a more direct feel and allows for greater freedom of movement. World Industries might offer select models with flat concave for skaters who value simplicity and a more traditional skateboarding experience. This design promotes a closer connection between the skater and the ground.

These concave variations demonstrate the nuanced approach World Industries takes in platform design. The choice of concave profile directly impacts the riding experience, influencing everything from board feel and responsiveness to stability and control. Understanding these differences allows skaters to select platforms that align with their individual preferences and skating styles, contributing to improved performance and enjoyment.

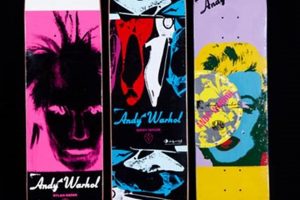

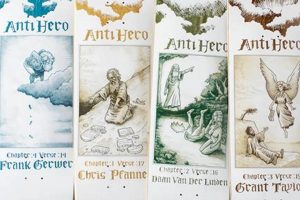

4. Graphic Application

Graphic application on skateboarding platforms manufactured by World Industries serves a function beyond mere aesthetics. The graphics are integral to the brand identity and influence consumer perception. The application process itself, often involving screen printing or heat transfer techniques, must ensure durability to withstand the wear and tear associated with skateboarding. Graphics on World Industries products frequently feature bold, cartoonish designs, reflecting the brand’s historical association with a particular era and style within skateboarding culture. These visual elements are strategically employed to appeal to specific demographics and reinforce the brand’s market positioning.

The application method impacts the graphic’s longevity and resistance to abrasion. Screen-printed graphics, while offering vibrant colors, may be more susceptible to scratching and fading compared to heat-transferred designs that are embedded deeper within the platform’s layers. World Industries, in its production processes, balances cost considerations with the need for visually appealing and durable graphics. Furthermore, limited edition graphics and artist collaborations create collectibility and contribute to brand exclusivity. The use of specific colors and imagery often serves to evoke nostalgia for older skateboarding eras, appealing to a segment of the market that values the brand’s heritage.

In summary, graphic application is a critical element of World Industries skateboarding platform design and marketing. It is not solely decorative but also contributes to brand identity, product durability, and consumer appeal. The brand’s strategic utilization of graphics has cemented its position within the skateboarding industry, reflecting its unique visual language and cultural influence. The interplay between aesthetic design and functional considerations demonstrates the importance of graphic application in the overall value proposition of these products.

5. Impact Resistance

Impact resistance is a critical performance characteristic of skateboarding platforms, directly influencing product lifespan and rider safety. For World Industries skateboard decks, this attribute is paramount, considering the stresses inherent in skateboarding activities. The deck’s ability to withstand repeated impacts, landings, and collisions dictates its functional longevity and the rider’s potential for injury.

- Material Composition and Layup

The primary factor determining impact resistance is the material composition and layup of the platform. World Industries typically utilizes multiple plies of North American maple, a wood known for its strength and flexibility. The grain orientation and the quality of the adhesive used in lamination are crucial. A higher number of plies and stronger adhesives increase the deck’s ability to absorb and distribute impact forces, reducing the likelihood of breakage. For example, a deck constructed with seven plies of high-grade maple will generally exhibit greater impact resistance than one with fewer plies or lower-quality wood. Certain models may incorporate fiberglass or carbon fiber layers to further enhance strength and stiffness, increasing the deck’s ability to withstand severe impacts.

- Deck Shape and Concave

The shape and concave of the platform contribute to its impact resistance. Decks with steeper concaves may be more prone to cracking under pressure due to the increased stress concentration at the edges. Conversely, a well-designed concave can distribute impact forces more evenly across the deck’s surface. World Industries decks are designed with specific concave profiles to balance board feel and structural integrity. The overall shape of the deck, including the nose and tail angles, also affects its ability to absorb impacts during landings. A more rounded shape may be less susceptible to chipping and cracking compared to a sharper, more angular design.

- Manufacturing Process and Quality Control

The manufacturing process and quality control measures implemented by World Industries directly influence the impact resistance of its products. Precise cutting, lamination, and pressing techniques are essential for ensuring consistent material properties and minimizing stress concentrations. Rigorous quality control checks are necessary to identify and reject decks with defects that could compromise their structural integrity. For instance, inconsistencies in wood grain or adhesive application can significantly reduce the deck’s ability to withstand impacts. A robust quality control system ensures that each deck meets specific performance standards and minimizes the risk of premature failure. Heat treating or other wood preparation techniques also impact the overall board structural integrity.

- Rider Weight and Style

The rider’s weight and skating style contribute significantly to the stress placed on the platform. Heavier riders and those who perform high-impact tricks will exert greater forces on the deck, increasing the risk of breakage. A rider who primarily skates street and performs frequent ollies and grinds will subject the platform to more repeated impacts compared to a cruiser skater who primarily rides flat ground. Therefore, the rider’s style and physical characteristics should be considered when selecting a World Industries deck to ensure it can withstand the anticipated stresses. A skater might need to purchase a thicker board to compensate for their weight or style for adequate impact resistance.

In conclusion, the impact resistance of World Industries skateboarding platforms is a multifaceted attribute determined by material composition, deck design, manufacturing processes, and the rider’s individual characteristics. By carefully considering these factors, skaters can select decks that provide the necessary durability and safety for their chosen style of riding. Continuous innovation in material science and manufacturing techniques is crucial for further enhancing the impact resistance and overall performance of these products.

6. Weight Distribution

Weight distribution is a critical factor influencing the performance characteristics of a World Industries skateboarding platform. The manner in which weight is distributed across the platform affects stability, responsiveness, and the ability to execute tricks effectively. Proper weight distribution is paramount for optimal control and maneuverability.

- Nose and Tail Weight Bias

The distribution of weight between the nose and tail of a World Industries platform directly influences its pop and rotational characteristics. A slightly heavier tail can enhance pop, facilitating higher ollies and more controlled flip tricks. Conversely, a more evenly balanced distribution can improve stability during grinds and slides. The specific weight bias is often a design consideration, tailored to suit different skateboarding styles. For instance, a platform intended for street skating may have a more pronounced tail weight bias compared to a cruiser board designed for general riding.

- Lateral Weight Distribution

Lateral weight distribution, referring to the balance of weight across the width of the platform, is crucial for stability and edge control. An uneven lateral distribution can lead to instability, making it difficult to maintain balance during turns and transitions. World Industries platforms are designed to ensure a symmetrical lateral weight distribution, promoting a predictable and consistent feel. Deviations from this symmetry can result from manufacturing defects or damage, negatively impacting performance. Proper truck mounting is essential to maintain lateral balance.

- Impact of Truck Placement

The placement of trucks relative to the platform’s center of gravity significantly impacts weight distribution and handling. Moving the trucks closer to the nose and tail can increase the board’s responsiveness, making it easier to perform quick turns and flip tricks. Conversely, positioning the trucks further apart can enhance stability, particularly at higher speeds. World Industries considers truck placement in relation to the platform’s design to optimize its overall performance characteristics. Slight variations in truck mounting position can alter the overall feel and responsiveness of the platform.

- Influence of Rider Stance

A skater’s stance affects the weight distribution on the skateboard. It depends on the rider stance like regular or goofy. Regular stance skater favors left foot to front while goofy favors the right foot at front. It affects balance and control on world industries skate deck. The stance dictates the initial weight distribution. Adjustments during riding dynamically shift the balance, essential for executing tricks and navigating obstacles. Adaptability in stance and weight manipulation are critical skills for effective board control.

These facets of weight distribution are integral to the design and performance of a World Industries skateboarding platform. Understanding how these elements interact allows skaters to select equipment that aligns with their individual style and skill level, ultimately enhancing their overall skateboarding experience. The complex relationship between weight distribution and performance underscores the importance of precision engineering and quality construction in these products.

7. Brand Heritage

The brand heritage of World Industries exerts a significant influence on the design, marketing, and consumer perception of its skateboarding platforms. Established in the late 1980s, World Industries rose to prominence during a period characterized by a distinct visual style and a rebellious attitude within skateboarding culture. The brand’s early adoption of cartoonish and often provocative graphics, coupled with its association with influential skaters, shaped its identity and created a lasting impact. Consequently, current World Industries skateboarding platforms are often designed to evoke a sense of nostalgia, reflecting the brand’s historical aesthetic and appealing to skaters who appreciate its legacy. The presence of iconic characters and logos from the brand’s past directly contributes to the perceived value and collectibility of its skate decks. For instance, the re-release of decks featuring classic graphics has proven successful in attracting both longtime fans and new consumers drawn to the brand’s historical significance.

Brand heritage serves as a tangible component of a World Industries skateboarding platform, influencing purchasing decisions and brand loyalty. The perceived authenticity and connection to a specific era within skateboarding history are key factors differentiating World Industries products from competitors. Marketing campaigns often leverage this heritage, emphasizing the brand’s long-standing presence and its role in shaping skateboarding culture. The designs applied to decks often reference specific moments or figures from the brand’s past, creating a sense of continuity and reinforcing its identity. Furthermore, collaborations with artists or skaters who have ties to the brand’s history further enhance the value and appeal of its products.

In conclusion, the brand heritage of World Industries is inextricably linked to its skateboarding platforms. It dictates design choices, marketing strategies, and consumer perceptions. The brand’s ability to effectively leverage its history creates a competitive advantage and ensures continued relevance within the skateboarding market. This emphasis on heritage, however, presents challenges. World Industries must balance its connection to the past with the need to innovate and adapt to evolving trends within skateboarding. The brand’s continued success hinges on its ability to honor its legacy while simultaneously maintaining its relevance in a dynamic and competitive industry.

Frequently Asked Questions

This section addresses common inquiries regarding skateboarding platforms manufactured by World Industries. It provides concise and informative answers to assist consumers in making informed purchasing and usage decisions.

Question 1: What materials are typically used in World Industries skateboard deck construction?

World Industries decks are typically constructed using multiple plies of North American maple. Select models may incorporate fiberglass or carbon fiber reinforcements to enhance strength and performance.

Question 2: How does deck width influence skateboarding performance?

Deck width impacts stability and maneuverability. Narrower decks (7.5″-8.0″) offer quicker response, while wider decks (8.25″+) provide greater stability, particularly for transition skating.

Question 3: What is concave, and how does it affect board feel?

Concave refers to the curvature of the deck’s surface. Variations in concave affect foot placement, board feel, and control. Common types include radial, progressive, and W concave, each offering distinct performance characteristics.

Question 4: How should a World Industries skateboard deck be maintained to prolong its lifespan?

Proper maintenance includes regular hardware inspections, cleaning of the grip tape, and storage in a dry environment. Protecting the graphic layer and avoiding excessive exposure to moisture are also recommended.

Question 5: Are World Industries decks suitable for all skateboarding skill levels?

World Industries offers decks designed for various skill levels, from beginners to experienced skaters. Selection should be based on individual skill, preferred riding style, and board specifications.

Question 6: How do the graphics on a World Industries deck influence its value?

Graphics contribute to brand identity and can influence consumer preference. Limited edition graphics or those featuring iconic designs may increase the deck’s collectibility and perceived value.

Key takeaways emphasize the importance of material selection, deck dimensions, concave design, proper maintenance, and the influence of graphics on perceived value. These factors collectively determine the performance and longevity of a World Industries skateboard deck.

The subsequent sections will examine emerging trends and technologies in the skateboard industry, providing further insight into the future of skateboarding platforms.

Conclusion

This exposition has detailed various facets of the World Industries skate deck, emphasizing critical aspects such as construction materials, width variations, concave design, graphic application, impact resistance, weight distribution, and brand heritage. Each element contributes significantly to the overall performance, durability, and market appeal of the product. A comprehensive understanding of these factors is essential for informed decision-making within the skateboarding community.

Continued research and development within the skateboard industry are necessary to further optimize these platforms. Industry stakeholders must prioritize innovation in materials science and manufacturing processes to enhance safety, longevity, and performance. Ongoing engagement with the evolving needs of skateboarders remains paramount for sustained progress and relevance within the sport.