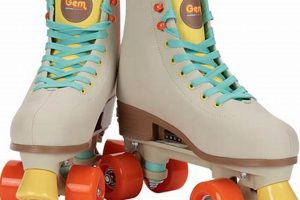

The term identifies a specific type of recreational footwear designed for gliding across surfaces. These devices consist of a boot or shoe attached to a frame that holds wheels. The configuration of the wheel assembly aims to provide stability and control for the user, enabling various maneuvers. Examples include models used in roller derby, artistic skating, and casual recreational use.

The construction of such equipment impacts user experience significantly. Features contributing to enhanced control and stability are desirable. Historically, the evolution of these products reflects advancements in materials science and engineering, leading to improved performance and safety. Their popularity has varied over time, influenced by trends and the emergence of new forms of wheeled recreation.

Understanding the features that provide stability and control is crucial. The following sections will explore specific aspects of design, materials, and maintenance, offering further insight into maximizing performance and longevity of this type of equipment.

Maximizing Performance and Longevity

Optimal use requires adherence to certain guidelines. These tips aim to improve the user experience and extend the lifespan of the equipment.

Tip 1: Wheel Maintenance is Paramount. Regularly inspect wheels for wear and tear. Uneven wear patterns indicate the need for rotation. Clean wheels periodically to remove debris that hinders performance and increases friction.

Tip 2: Bearing Care Impacts Smoothness. Bearings should be cleaned and lubricated routinely. Dirty or dry bearings create resistance, diminishing glide efficiency and potentially causing damage. Proper maintenance will ensure smooth rotation.

Tip 3: Frame Inspection Prevents Accidents. Periodically examine the frame for cracks or loose components. A compromised frame can lead to instability and increase the risk of injury. Tighten any loose screws or bolts immediately.

Tip 4: Boot Security Enhances Control. Ensure the boot or shoe is securely fastened to the frame. Loose connections reduce control and responsiveness. Proper lacing or strap adjustment is essential for stability.

Tip 5: Surface Selection Affects Wheel Life. Skating on rough surfaces accelerates wheel wear. Choose smooth, clean surfaces whenever possible to prolong wheel life and maintain optimal performance.

Tip 6: Storage Conditions Matter. Store equipment in a cool, dry place away from direct sunlight. Extreme temperatures and humidity can damage materials and shorten the lifespan of components.

Tip 7: Consider Wheel Durometer. Different wheel durometers (hardness) are suited to different surfaces and skating styles. Select a durometer appropriate for the intended use to optimize grip and roll.

Implementing these practices ensures a safer and more enjoyable skating experience, while also protecting the investment in the equipment. Consistent maintenance is crucial for both performance and longevity.

The following sections will delve into the specifics of component selection and troubleshooting common issues, offering a more in-depth understanding of the equipment.

1. Wheel Durometer

Wheel durometer, a measurement of a wheel’s hardness, plays a critical role in the performance of these devices. The selection of an appropriate durometer significantly impacts the skater’s grip, speed, and overall control. Understanding this relationship is essential for optimizing the skating experience.

- Grip vs. Roll Characteristics

Softer wheels (lower durometer numbers) offer increased grip, particularly on slick or uneven surfaces. This increased grip allows for more precise maneuvers and enhanced stability. Harder wheels (higher durometer numbers) provide faster roll speeds, ideal for smooth surfaces and straight-line skating. The trade-off between grip and roll is a fundamental consideration in wheel selection.

- Surface Dependence

The optimal durometer is heavily dependent on the skating surface. Indoor surfaces, typically smooth and polished, often benefit from harder wheels. Outdoor surfaces, which can be rough and variable, generally require softer wheels to maintain adequate grip and absorb vibrations. Surface conditions dictate the necessary balance between grip and roll performance.

- Skating Style Considerations

Different skating styles demand different durometer characteristics. Artistic skaters may prefer softer wheels for enhanced grip during intricate routines. Speed skaters prioritize harder wheels for maximum velocity. Recreational skaters often seek a middle ground, balancing grip and roll for a versatile experience. Style-specific requirements influence the optimal wheel selection.

- Wear and Longevity

Softer wheels tend to wear down more quickly than harder wheels, especially on abrasive surfaces. Harder wheels, while more durable, can provide a harsher ride and less grip. The expected lifespan of the wheels is an important factor to consider, particularly for frequent skaters. Balancing performance with durability is a practical consideration.

The choice of wheel durometer represents a compromise between competing performance characteristics. Selecting the correct durometer, matched to the skating surface and style, is crucial for maximizing the potential and enjoyment derived from the equipment, and directly influences stability, maneuverability, and overall skating experience.

2. Bearing Precision

Bearing precision, typically denoted by the ABEC (Annular Bearing Engineers’ Committee) rating, significantly influences the performance characteristics of wheeled recreational equipment. Higher ABEC ratings (e.g., ABEC-7, ABEC-9) indicate tighter tolerances and greater manufacturing accuracy. Consequently, equipment with higher precision bearings exhibit reduced friction, leading to enhanced roll speed and smoother gliding. The integration of high-precision bearings within such equipment translates directly to improved performance, allowing for greater speed and efficiency with less exertion.

The practical impact of bearing precision is evident in various skating disciplines. For speed skating, where minimizing friction is paramount, high-ABEC-rated bearings are crucial for achieving competitive speeds. In artistic skating, smoother rolling facilitates precise execution of complex maneuvers. Conversely, for recreational use, lower ABEC ratings may suffice, prioritizing durability and cost-effectiveness over peak performance. The selection of appropriate bearing precision is dependent on the specific application and performance requirements. Neglecting bearing maintenance, regardless of precision rating, will degrade performance significantly. Debris accumulation and inadequate lubrication increase friction and reduce roll speed, negating the benefits of high-precision bearings. Proper maintenance, including cleaning and lubrication, is essential for preserving the performance of even the highest-rated bearings.

In summary, bearing precision directly impacts the speed and smoothness of these devices. While higher precision bearings offer performance advantages, appropriate selection should align with the intended use and skating style. Furthermore, consistent maintenance is indispensable for realizing and sustaining the benefits of precision bearings, ensuring the equipment functions optimally over its lifespan and continues to provide the intended skating experience.

3. Plate Material

The plate, forming the chassis upon which wheels and trucks are mounted, is a fundamental component influencing performance. Material selection directly affects weight, strength, responsiveness, and vibration dampening, impacting the overall user experience.

- Aluminum Alloys: A Balance of Strength and Weight

Aluminum alloys are frequently used due to their favorable strength-to-weight ratio. They offer a durable and relatively lightweight platform, enhancing maneuverability and reducing fatigue. Examples include aircraft-grade aluminum, providing high tensile strength for demanding applications. The choice of specific alloy influences the plate’s ability to withstand stress and maintain structural integrity.

- Magnesium: Ultra-Lightweight Options

Magnesium plates offer even lower weight compared to aluminum, further enhancing agility. However, magnesium is generally less durable and may be more susceptible to corrosion. Its application is typically limited to specialized models where weight reduction is a primary concern, often at the expense of long-term durability. Protective coatings are crucial for mitigating corrosion risks.

- Nylon or Composite Materials: Vibration Dampening and Cost-Effectiveness

Nylon or composite plates provide excellent vibration dampening, resulting in a smoother and more comfortable ride. These materials are also generally more cost-effective than metals. However, they may lack the stiffness and strength of metal plates, potentially affecting responsiveness and power transfer. These are commonly found in entry-level models.

- Steel: Durability and Affordability

Steel plates offer exceptional durability and are generally more affordable than aluminum or magnesium. However, steel’s higher weight can reduce maneuverability and increase fatigue. This material is typically found in older or less expensive models where robustness is prioritized over performance. Rust prevention is crucial for maintaining the integrity of steel plates.

The selection of a plate material involves balancing factors such as weight, strength, cost, and vibration dampening. The optimal choice depends on the intended use and performance requirements. Material selection fundamentally influences the overall riding characteristics and durability of the equipment.

4. Boot Stiffness

Boot stiffness, a critical design parameter, significantly influences the performance characteristics of equipment designed for gliding across surfaces. The degree of boot stiffness directly affects energy transfer from the skater to the wheels and the responsiveness of the overall system. A stiffer boot provides enhanced support and reduces energy loss during maneuvers, resulting in more precise control and increased efficiency. Conversely, a more flexible boot offers greater comfort but may compromise stability and power transfer, particularly during demanding activities. This fundamental connection between boot stiffness and performance necessitates careful consideration during equipment selection.

For instance, in disciplines such as artistic skating and roller derby, where precise movements and rapid changes in direction are paramount, stiffer boots are generally preferred. The enhanced support and responsiveness enable skaters to execute intricate routines and maintain stability during aggressive gameplay. Conversely, for recreational skating, a moderately stiff boot may offer a more comfortable compromise, providing adequate support without sacrificing flexibility. Boot stiffness can also contribute to injury prevention. A sufficiently stiff boot provides ankle support, reducing the risk of sprains and other common skating-related injuries. The specific needs and skill level of the skater should guide the selection of an appropriately stiff boot.

In summary, boot stiffness plays a crucial role in the overall performance and safety of skating equipment. Its influence on energy transfer, responsiveness, and ankle support underscores its importance as a key design consideration. Understanding the relationship between boot stiffness and skating discipline enables informed decisions, optimizing performance, comfort, and safety. Balancing the need for support with the need for flexibility remains a central challenge in boot design, directly impacting the user’s experience and potential.

5. Truck Adjustability

Truck adjustability directly impacts the maneuverability and stability characteristics of roller skates. The capacity to modify truck settings allows skaters to tailor the equipment’s response to their specific skating style and performance objectives. This feature is critical for optimizing control and achieving desired handling characteristics.

- Kingpin Adjustment and Turning Radius

The kingpin, a central bolt within the truck assembly, controls the angle at which the trucks pivot. Adjusting the kingpin tension alters the turning radius. Loosening the kingpin facilitates tighter turns, enhancing agility. Tightening the kingpin increases stability, particularly at higher speeds. This adjustment is frequently employed in roller derby, where skaters require both maneuverability and stability during gameplay.

- Cushion (Bushing) Durometer and Responsiveness

Cushions, also known as bushings, are resilient components that dampen truck movement. The durometer (hardness) of the cushions influences the responsiveness of the trucks. Softer cushions allow for easier turning and a more fluid feel. Harder cushions provide greater resistance and stability. This adjustment is crucial for artistic skating, where precise and controlled movements are essential for executing complex routines.

- Truck Angle and Stability

The angle of the truck relative to the boot affects the skate’s overall stability. Lower truck angles generally provide greater stability, while higher truck angles enhance maneuverability. This adjustment is less common but can be beneficial for skaters with specific balance requirements or skating styles. Speed skaters, for example, often prefer lower truck angles for increased stability at high speeds.

- Pivot Cup Material and Truck Movement

The pivot cup, a small receptacle that houses the truck’s pivot point, impacts the smoothness of truck movement. Different materials, such as urethane or nylon, offer varying degrees of friction and durability. Selecting the appropriate pivot cup material can optimize truck movement and prevent binding, enhancing the overall skating experience. A well-maintained pivot cup ensures consistent and predictable truck response.

The ability to adjust the trucks empowers skaters to fine-tune the equipment to their individual preferences and skating requirements. This customization is essential for maximizing performance, enhancing control, and achieving a comfortable and enjoyable skating experience. Without truck adjustability, skaters are limited to the factory settings, potentially hindering their ability to fully realize their skating potential.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, maintenance, and performance characteristics of recreational wheeled footwear. The information presented aims to provide clarity and enhance understanding of the equipment.

Question 1: What differentiates recreational wheeled footwear from other types of skating equipment?

Recreational wheeled footwear, specifically those employing a four-wheel configuration arranged in pairs, distinguishes itself through its design intended primarily for general use and maneuverability on varied surfaces. This contrasts with inline skates, designed for speed and efficiency on smooth, prepared surfaces, and ice skates, specialized for use on ice rinks.

Question 2: How often should bearings be cleaned and lubricated?

Bearing maintenance frequency depends significantly on usage and environmental conditions. Under typical recreational use, cleaning and lubrication every 1-3 months is advisable. More frequent maintenance may be required if skating occurs in dusty or wet environments to prevent premature wear and performance degradation.

Question 3: What is the significance of wheel durometer, and how does it affect performance?

Wheel durometer, measured on the A scale, indicates the hardness of the wheel material. Lower durometer values (e.g., 78A) signify softer wheels, providing greater grip on slick surfaces but reduced roll speed. Higher durometer values (e.g., 95A) denote harder wheels, optimizing speed on smooth surfaces while diminishing grip. Selection should align with skating environment and desired performance characteristics.

Question 4: How does boot stiffness influence skating performance and comfort?

Boot stiffness directly affects energy transfer and ankle support. Stiffer boots enhance responsiveness and power transfer but may reduce comfort over extended periods. Softer boots offer greater flexibility and comfort but may compromise stability and control. Boot selection should consider the intended skating style and prioritize either performance or comfort.

Question 5: What role does plate material play in the overall quality of the equipment?

The plate material, typically aluminum or nylon composite, dictates weight, strength, and vibration dampening properties. Aluminum plates offer a balance of durability and lightweight construction, whereas nylon composite plates prioritize vibration absorption and affordability. The choice affects maneuverability and overall riding comfort.

Question 6: How does truck adjustability impact the handling characteristics?

Truck adjustability, achieved through kingpin tension adjustment, alters the turning radius. Loosening the kingpin facilitates tighter turns, whereas tightening it enhances stability at higher speeds. Truck adjustability enables customization of handling characteristics to suit individual skating styles and preferences.

Proper maintenance, informed component selection, and an understanding of the interplay between various features are essential for maximizing the lifespan and performance of wheeled recreational footwear.

The subsequent sections will explore troubleshooting common issues encountered during use, providing practical guidance for resolving technical difficulties.

Conclusion

This exploration has detailed critical aspects of the recreational equipment, focusing on performance, maintenance, and customization. The intricacies of wheel durometer, bearing precision, plate materials, boot stiffness, and truck adjustability have been examined to underscore their contribution to overall functionality and user experience. Consistent maintenance and informed component selection are vital for optimizing both performance and longevity of the equipment.

Continued advancement in materials science and engineering promises further refinement of these designs, potentially enhancing both safety and performance. A thorough understanding of these elements empowers informed decision-making, ensuring users can maximize the capabilities of their equipment and enjoy a safe and fulfilling skating experience.