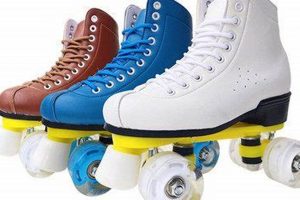

Specialized footwear is essential for the fast-paced, full-contact sport of roller derby. These items of sporting equipment are designed to provide the agility, stability, and protection necessary for participants to excel. For example, features such as low-cut boots, durable wheels, and responsive plates distinguish them from recreational models.

This particular kind of equipment significantly impacts athletic performance, contributing to enhanced maneuverability and control on the track. The design of these items has evolved significantly over time, reflecting the changing demands of the sport and advancements in materials technology. This evolution has led to improvements in safety and responsiveness.

The following sections will examine the specific components of this vital equipment, including the boot, plate, wheels, and bearings. The article will also cover selection criteria, maintenance practices, and the role of protective gear in maximizing skater safety and performance.

Roller Derby Footwear

Selecting appropriate skating equipment is crucial for performance and safety. This section provides key considerations for choosing and maintaining suitable apparatus.

Tip 1: Boot Selection: Prioritize a snug, supportive fit. A properly fitted boot enhances ankle stability and responsiveness. Consider heat-moldable options for a customized fit.

Tip 2: Plate Material: Aluminum plates offer greater durability and responsiveness compared to nylon. The plate’s angle influences turning ability; experiment to find the optimal angle.

Tip 3: Wheel Durometer: Wheel hardness (durometer) affects grip and roll. Softer wheels (lower durometer) provide more grip on slick surfaces, while harder wheels (higher durometer) offer faster roll on smooth surfaces. Choose durometer based on the track surface.

Tip 4: Bearing Maintenance: Regularly clean and lubricate bearings to maintain optimal roll. Dirty or dry bearings reduce speed and increase energy expenditure.

Tip 5: Toe Stop Adjustment: Properly adjusted toe stops are essential for starts, stops, and strategic maneuvers. Adjust the height to allow for controlled engagement with the track surface.

Tip 6: Equipment Inspection: Before each session, thoroughly inspect all components for signs of wear or damage. Replace worn parts immediately to prevent accidents.

Tip 7: Professional Fitting: Consult with a knowledgeable retailer or experienced skater for professional fitting advice. A well-fitted set enhances performance and reduces the risk of injury.

Adhering to these guidelines can significantly improve the skating experience, leading to enhanced performance and increased longevity of the equipment.

The next section will address the relationship between this equipment and the broader context of roller derby gameplay and strategy.

1. Boot Fit

Boot fit is a foundational element of well-functioning equipment, directly influencing skater performance and safety. An improperly fitted boot can compromise stability, reduce agility, and increase the risk of injury. For example, a boot that is too large allows the foot to move excessively within the confines of the boot, resulting in reduced power transfer during acceleration and turning. Conversely, a boot that is too small can cause discomfort, restrict blood flow, and lead to blisters or other foot ailments. In both scenarios, the skater’s ability to perform effectively is demonstrably diminished.

The connection between boot fit and roller derby performance extends beyond mere comfort. A snug, supportive fit enhances ankle stability, crucial for maintaining balance during high-speed maneuvers and contact situations. A properly fitted boot allows for quicker and more precise responses to changes in direction, contributing to improved agility on the track. Custom-molded boots, or those with heat-moldable features, offer a tailored fit that maximizes these benefits. Ignoring the importance of a proper boot fit can lead to chronic instability, increasing the likelihood of ankle sprains and other lower extremity injuries. The strategic selection of materials also play a critical role when choosing a set of these skates, with the wrong boot material affecting your skating.

In summary, the boot fit is not merely a matter of personal preference but a fundamental aspect of equipment functionality. Achieving an optimal fit is essential for maximizing performance, minimizing the risk of injury, and ensuring the longevity of the skater’s participation in the sport. Careful consideration of boot size, shape, and support features is paramount during the selection process. Furthermore, routine evaluation of boot condition and fit throughout the skater’s career is necessary to maintain performance and safety standards. The boot aspect when picking skates is just as important as any other feature of the skate. Proper boot fit is a major component of these skates.

2. Plate Material

The plate, a critical component of roller derby equipment, serves as the chassis connecting the boot to the wheels. Its material composition directly impacts the skate’s performance characteristics, influencing factors such as responsiveness, durability, and weight. The choice of plate material, therefore, is a significant consideration for skaters seeking to optimize their equipment for the demands of the sport.

- Aluminum Alloy Plates

Aluminum alloy plates offer a balance of strength, rigidity, and weight, making them a popular choice for competitive roller derby. The stiffness of aluminum allows for efficient energy transfer during acceleration and turning, providing a more responsive feel compared to less rigid materials. Furthermore, aluminum’s durability enables it to withstand the stresses of high-impact collisions and aggressive skating styles. Several grades of aluminum are utilized, with higher-grade alloys offering increased strength-to-weight ratios. Examples include 7075 aluminum, known for its exceptional strength, and 6061 aluminum, offering a good balance of strength and weldability. Choosing an aluminum plate also affects skate maneuverability.

- Nylon Plates

Nylon plates, typically composed of reinforced polymers, represent a more economical alternative to aluminum. While generally lighter than aluminum, nylon plates exhibit greater flex, resulting in reduced responsiveness. This increased flex can absorb some vibrations, offering a more comfortable ride on rough surfaces, but at the expense of energy transfer efficiency. Nylon plates are often preferred by beginner skaters or those prioritizing comfort over ultimate performance. They are more susceptible to damage from high-impact collisions or repeated stress, potentially limiting their lifespan compared to aluminum options. However, the relatively inexpensive nature of the nylon plate means its easily replaced.

- Magnesium Plates

Magnesium plates are known for being extremely light weight but provide rigidity as well. While they are not as popular, these skates can offer benefits that skaters seek.

- Plate Angle and Truck Design

Beyond the base material, the geometry of the plate particularly the angle of the kingpin and the design of the trucks significantly impacts handling characteristics. Plates with steeper kingpin angles generally offer increased maneuverability, allowing for tighter turns and quicker transitions. However, steeper angles may also reduce stability at high speeds. The design of the trucks, including the cushion (or bushing) durometer and configuration, also plays a crucial role in determining the skate’s responsiveness and feel. Experimentation with different truck setups and cushion durometers is often necessary to achieve optimal performance for individual skating styles and preferences. The best plate will be one designed for your skating style.

The selection of plate material involves a trade-off between factors such as cost, weight, durability, and responsiveness. While aluminum plates offer superior performance characteristics for competitive skaters, nylon plates provide a more accessible option for beginners or those prioritizing comfort. Ultimately, the optimal choice depends on the individual skater’s skill level, skating style, and budget. Regardless of the material chosen, proper maintenance and inspection of the plate are crucial for ensuring safe and reliable performance of the equipment.

3. Wheel Durometer

Wheel durometer, a measure of wheel hardness, is a critical determinant of performance when selecting equipment. The durometer scale, typically ranging from 0A to 101A (with some manufacturers exceeding this range), dictates the wheel’s grip, roll, and durability characteristics. In roller derby, the interaction between the wheel and the track surface directly affects a skater’s agility, speed, and stopping ability. A softer wheel (lower durometer) deforms more readily, increasing contact area with the track and providing greater grip. This is advantageous on slick surfaces or for skaters prioritizing maneuverability and control. Conversely, a harder wheel (higher durometer) deforms less, reducing rolling resistance and maximizing speed on smooth, grippy surfaces. Choosing an inappropriate durometer can negatively impact performance. For instance, using excessively hard wheels on a slippery track reduces grip, leading to uncontrolled sliding and diminished acceleration. In contrast, excessively soft wheels on a grippy surface can create excessive drag, hindering speed and causing premature wear.

The selection of wheel durometer is highly dependent on track conditions and individual skating style. Skaters competing on polished concrete or plastic-coated tracks often benefit from harder wheels to maximize speed and glide. Those skating on rougher surfaces or those who prioritize quick stops and agile maneuvers may opt for softer wheels. Some skaters employ a combination of different durometer wheels to achieve a customized balance of grip and roll. Furthermore, body weight and skating technique influence the optimal durometer choice. Heavier skaters may require harder wheels to prevent excessive compression and maintain roll efficiency, while lighter skaters can often benefit from the increased grip of softer wheels. For example, jam skaters often benefit from a softer wheel to maximize grip and allow for more agile movement. Blocking players, who are more concerned about their ability to make quick turns, benefit more from using harder wheels.

Ultimately, understanding the relationship between wheel durometer and track conditions is paramount for optimizing performance and safety. Experimentation with different durometers and careful assessment of track surfaces are essential steps in selecting the appropriate wheels. Furthermore, regular inspection of wheel wear and timely replacement of worn wheels are crucial for maintaining consistent grip and roll. In conclusion, wheel durometer is not merely a preference but a critical variable that can significantly impact the overall performance of roller derby equipment. Understanding the characteristics of these skates is important.

4. Bearing Precision

Bearing precision, measured by the Annular Bearing Engineering Committee (ABEC) scale or similar ISO standards, significantly affects the performance of roller derby roller skates. Bearings facilitate the rotational movement of the wheels around the axle. Higher ABEC ratings (e.g., ABEC 7, ABEC 9) indicate tighter tolerances and smoother rolling, reducing friction and increasing speed. In roller derby, where bursts of speed and rapid changes in direction are essential, bearings with higher precision can provide a competitive advantage. The reduction in friction allows skaters to maintain momentum with less effort, conserving energy throughout a bout. A skater using skates with ABEC 9 bearings may experience a noticeable increase in glide compared to one using ABEC 3 bearings, assuming all other factors (wheel durometer, track surface, skater weight) are equal. In practical terms, this can translate to faster acceleration during jams and improved agility when maneuvering through blockers. For example, a skater may notice they have more speed using high quality bearings, even with low quality plates.

However, the benefits of high-precision bearings are contingent on proper maintenance and environmental conditions. Bearings are susceptible to contamination from dirt, dust, and moisture, which can increase friction and degrade performance. Regular cleaning and lubrication are necessary to maintain the benefits of high-precision bearings. Some skaters choose to use bearings with sealed or shielded designs to minimize contamination. Furthermore, the demands of roller derby place significant stress on bearings. Impacts from collisions and frequent changes in direction can cause wear and tear, eventually reducing precision and performance. High-quality bearings constructed from durable materials are more resistant to these stresses and maintain their performance characteristics over a longer period. The specific demands on bearings are great when using them for roller derby. They have to be durable and maintain stability.

In summary, bearing precision is a critical factor influencing the performance of roller derby equipment. Higher precision bearings can provide a measurable advantage in terms of speed and efficiency, but their benefits are realized only with proper maintenance and when paired with other high-quality components. The selection of bearings should be based on a skater’s budget, skill level, and the environmental conditions in which they typically skate. While high-precision bearings may offer a performance edge, they are not a substitute for proper skating technique or regular maintenance. Bearings are an important part of a skaters skates and greatly affect skate performance.

5. Toe Stop

The toe stop is an indispensable component of roller derby equipment, serving as a primary mechanism for braking, controlled falls, and strategic maneuvers. Its design and adjustment directly influence a skater’s agility and responsiveness on the track. For instance, during a fast-paced jam, a skater may use the toe stop to execute a quick stop or pivot, effectively altering their trajectory to evade a blocker or gain positional advantage. The toe stop functions as a pivot point, enabling rapid changes in direction that would be impossible with only wheel-based control. The component also provides stability when starting from a stationary position, allowing skaters to generate initial momentum without slippage. Proper toe stop engagement is paramount to ensuring a successful pivot.

Furthermore, the toe stop’s material composition affects its performance and longevity. Natural rubber toe stops offer excellent grip and shock absorption, while harder, synthetic materials provide greater durability and resistance to wear. Adjustment is key; the height of the toe stop relative to the wheels determines the degree of leverage and braking force applied. A lower toe stop allows for quicker engagement but may increase the risk of accidental contact with the track during normal skating. Conversely, a higher toe stop requires greater force to engage but provides more clearance for maneuverability. An appropriate toe stop and adjustment is key for skaters.

In summary, the toe stop is an integral safety and performance feature in roller derby. Its effectiveness hinges on proper selection, adjustment, and maintenance. A skater’s proficiency in using the toe stop translates directly to enhanced control, agility, and strategic capability. Selecting the wrong stop type can affect the skaters overall skating ability.

6. Wheelbase Length

Wheelbase length, the distance between the front and rear axles, is a critical geometric parameter affecting the maneuverability and stability of roller derby roller skates. This measurement influences turning radius, responsiveness, and overall handling characteristics. The optimal wheelbase length is dependent on skater size, skating style, and positional requirements within the sport.

- Agility and Maneuverability

A shorter wheelbase enhances agility, allowing for tighter turns and quicker changes in direction. This configuration is advantageous for jammers, who require exceptional maneuverability to evade blockers and score points. Shorter wheelbases enable rapid transitions and the ability to navigate confined spaces on the track. For example, a jammer might prefer a shorter wheelbase to quickly dart through a pack of blockers. The wheelbase measurement has an effect on a player’s playing style.

- Stability and Speed

A longer wheelbase promotes stability, particularly at higher speeds. This configuration is beneficial for blockers, who prioritize maintaining a stable platform for defensive maneuvers and delivering forceful hits. The increased distance between axles reduces the likelihood of instability and provides a more predictable feel. Blockers need a lot of stability, and the type of skate and skate parts are important to the player’s success. Wheelbase is important for stability.

- Skater Size and Anthropometry

Wheelbase length should be proportional to the skater’s size and foot length. Skaters with larger feet generally benefit from longer wheelbases to maintain balance and control. Conversely, skaters with smaller feet may find shorter wheelbases more comfortable and responsive. A mismatch between wheelbase length and foot size can compromise skating efficiency and increase the risk of injury. Matching the right skate to a player is essential to their success.

- Plate Mounting Position

The mounting position of the plate on the boot influences the effective wheelbase length. Moving the plate forward or backward alters the weight distribution and affects turning characteristics. Experimentation with plate positioning can fine-tune the skate’s handling to suit individual preferences and skating styles. Some players are fine with how the plate is mounted, but others would prefer customization. Customization is one of the keys to a player’s success with their skates.

In conclusion, wheelbase length is a crucial factor in determining the performance characteristics of roller derby roller skates. The optimal wheelbase length is contingent on a variety of factors, including skating style, positional requirements, and skater size. Careful consideration of these factors is essential for maximizing performance and minimizing the risk of injury. Customization of skates is a major piece of player success.

Frequently Asked Questions

The following section addresses common inquiries regarding specialized footwear for the sport of roller derby. The information presented aims to clarify key aspects of equipment selection, maintenance, and performance optimization.

Question 1: What differentiates these specialized skates from recreational models?

Roller derby roller skates are engineered for the high-impact, agile movements characteristic of the sport. Distinguishing features include durable construction, specialized wheel compounds, and responsive plate designs. Recreational skates typically lack the robustness and performance characteristics required for competitive roller derby.

Question 2: How often should bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage and environmental conditions. Generally, bearings should be cleaned and lubricated every 2-4 weeks with regular use. Signs of reduced roll or increased noise indicate the need for immediate maintenance.

Question 3: What is the significance of wheel durometer?

Wheel durometer, a measure of hardness, affects grip and roll. Softer wheels (lower durometer) offer greater grip, while harder wheels (higher durometer) provide faster roll. Selection depends on track surface and skater preference.

Question 4: How should one determine the appropriate boot size?

Boot fit is crucial for comfort and performance. The boot should fit snugly, providing adequate support without restricting circulation. A professional fitting by a knowledgeable retailer is recommended.

Question 5: What are the relative advantages of aluminum versus nylon plates?

Aluminum plates offer superior strength, rigidity, and responsiveness compared to nylon plates. Nylon plates are generally more economical and lighter, but may lack the durability and performance characteristics required for competitive skating.

Question 6: How does toe stop adjustment affect skating performance?

Toe stop height and angle influence braking power, agility, and stability. Adjustments should be made to accommodate individual skating style and preference. A low toe stop provides quicker engagement, while a higher toe stop offers greater clearance for maneuverability.

Proper equipment selection and maintenance are paramount for maximizing performance and minimizing the risk of injury. Skaters are encouraged to seek expert advice and prioritize safety at all times.

The subsequent section will explore protective gear and safety considerations for roller derby participants.

Conclusion

The preceding analysis has detailed the multifaceted aspects of roller derby roller skates, emphasizing the significance of component selection and maintenance. From boot fit to wheelbase length, each element contributes to performance and safety on the track. The interplay between these factors necessitates a comprehensive understanding for skaters seeking optimal functionality.

Given the potential for injury inherent in roller derby, a continued focus on technological advancements and proper equipment practices remains crucial. This investment in skater well-being will contribute to the sustained growth and evolution of the sport.