Affordable skateboard platforms represent an accessible entry point for individuals interested in skateboarding, as well as a cost-effective option for experienced skaters who require replacement boards. These products often feature simplified construction, alternative materials, or bulk purchasing strategies to reduce the overall price point without necessarily sacrificing functionality. For example, a beginner might opt for a deck made from a standard maple laminate rather than a more exotic wood blend.

The availability of budget-friendly options expands participation in skateboarding, making it a more inclusive activity. Furthermore, economical platforms allow skaters to experiment with different board shapes and sizes without a significant financial commitment. Historically, skateboard construction relied on readily available materials, leading to naturally lower costs. This tradition continues with contemporary manufacturers focusing on efficient production methods to offer competitive pricing.

The subsequent sections will delve into specific considerations when selecting economical skateboard platforms, including material composition, construction techniques, and optimal use cases for budget-conscious consumers.

Considerations for Economical Skateboard Platform Acquisition

The following tips provide guidance when sourcing affordable skateboard platforms. Adherence to these recommendations can assist in securing a functional and reliable product without exceeding budget constraints.

Tip 1: Material Assessment: Evaluate the type of wood used in deck construction. Maple is a common and durable option, but variations in ply count and grade influence overall resilience. Lower-cost options may utilize fewer or thinner plies.

Tip 2: Construction Integrity: Inspect the lamination quality. Delamination, or separation of the wood plies, compromises structural integrity and shortens the lifespan of the platform. Visual inspection can often reveal potential weaknesses.

Tip 3: Size and Shape Compatibility: Ensure the dimensions of the deck align with intended use and personal preference. A narrower deck is typically preferred for technical street skating, while a wider deck provides stability for transition riding.

Tip 4: Hardware Compatibility: Confirm that the deck is compatible with standard truck mounting patterns. Non-standard hole patterns may limit hardware choices or necessitate modification.

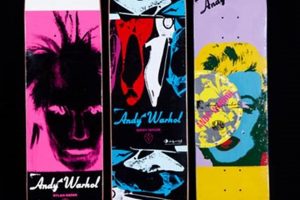

Tip 5: Graphic Durability: Consider the application method of the graphic. Screen-printed graphics tend to be more durable than heat-transferred graphics, which are susceptible to peeling or fading. Functionality should outweigh aesthetic considerations when prioritizing value.

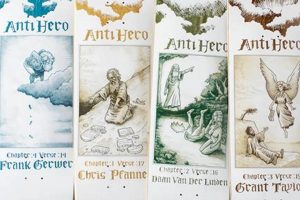

Tip 6: Brand Reputation: Research the manufacturer’s reputation for quality control and customer service. Established brands may offer more consistent products, even within their budget lines.

Tip 7: Clearance and Discount Opportunities: Monitor online retailers and local skate shops for clearance sales or discounted decks. End-of-season sales frequently offer significant savings.

Prioritizing material evaluation, construction integrity, and hardware compatibility allows for the acquisition of a functional and reliable skateboard platform at a reduced cost. Careful consideration of these factors mitigates the risk of purchasing substandard equipment.

The subsequent section will explore specific retail outlets and online marketplaces that specialize in affordable skateboard equipment, offering potential avenues for cost-effective procurement.

1. Material Quality

Material quality constitutes a critical determinant in the performance and longevity of economical skateboard platforms. The selection of materials directly influences the deck’s structural integrity, flexibility, and resistance to wear. Lower-priced skateboard platforms often utilize less expensive wood species or lower grades of maple, which may exhibit reduced durability and a higher susceptibility to cracking or delamination. Consequently, skaters who opt for affordable options must understand the potential trade-offs between cost savings and long-term product performance.

For example, decks constructed from imported maple may be less dense and more prone to warping compared to those made from Canadian or North American maple. Similarly, a deck with fewer plies (layers of wood) will generally be more flexible but less resistant to impact damage than a deck with a higher ply count. Understanding these relationships allows consumers to make informed decisions, balancing their budgetary constraints with their performance requirements. A skater primarily performing flatground tricks may find a lower-grade material acceptable, while a skater engaging in more aggressive street skating will likely require a more robust platform.

Ultimately, while the allure of “skate decks for cheap” is undeniable, it is imperative to recognize that material quality directly impacts the overall value proposition. Skaters should prioritize understanding the materials used in construction and the potential implications for durability and performance. While cost savings are attractive, compromising excessively on material quality can result in a shorter lifespan and potentially higher replacement costs in the long run, negating the initial savings.

2. Construction Methods

The correlation between construction methods and the affordability of skateboard platforms is significant. Production techniques directly influence manufacturing costs, and therefore, the price point of the final product. Economical platforms often utilize simplified or automated construction processes to reduce labor expenses and increase production volume. For example, a deck produced using a single-mold pressing technique, as opposed to individual pressing of each ply, streamlines manufacturing but may result in a less refined concave or overall shape consistency. Another cost-saving measure involves employing adhesives with shorter curing times, potentially affecting the long-term bond strength between plies.

The choice of pressing method, adhesive type, and even the precision of cutting tools contribute to both the cost and quality of the deck. Decks constructed with less stringent quality control measures may exhibit minor imperfections, such as uneven glue lines or slight variations in deck thickness. While these imperfections may not significantly impair the functionality of the board, they contribute to the lower price. A premium deck, conversely, typically undergoes more rigorous inspection and utilizes advanced pressing techniques to ensure consistent shape and optimal performance characteristics. For instance, some high-end manufacturers use computer-controlled machinery to precisely align the wood grain of each ply, maximizing strength and pop.

In summary, the methods employed in the construction of skateboard platforms are a primary determinant of their affordability. While simplified processes can reduce manufacturing costs, it is crucial to recognize that these techniques may also impact the overall quality and durability of the product. Understanding the interplay between construction methods and price allows consumers to make informed decisions, balancing their budgetary constraints with their performance expectations. The pursuit of economical skateboard platforms necessitates a careful assessment of the construction techniques utilized and their potential effects on the deck’s long-term reliability.

3. Ply Count

The number of plies, or layers of wood, comprising a skateboard deck significantly influences its cost and performance characteristics. Variations in ply count represent a key factor differentiating budget-friendly options from higher-priced alternatives. Lower ply counts often correlate with reduced manufacturing costs, contributing to the availability of economical skateboard platforms.

- Reduced Material Usage

A lower ply count directly translates to less material used in the deck’s construction. This reduction in raw material consumption lowers the overall manufacturing cost, making the deck more accessible at a lower price point. For example, a seven-ply deck will invariably be more expensive to produce than a six-ply deck, assuming similar wood quality.

- Altered Deck Flexibility

Decreasing the number of plies generally increases the deck’s flexibility. While some skaters prefer a more flexible board, a lower ply count may reduce the deck’s overall stiffness and responsiveness, potentially affecting trick execution and board control. This increased flex can lead to quicker fatigue and a shortened lifespan, particularly with repeated high-impact use.

- Impact on Deck Durability

A lower ply count can compromise the deck’s structural integrity and durability. With fewer layers of wood to absorb impact, the deck becomes more susceptible to cracking, chipping, and delamination. Economical decks with reduced ply counts may not withstand the same level of abuse as more robust, higher-ply counterparts, requiring more frequent replacement.

- Weight Considerations

A reduced ply count generally results in a lighter deck. While some skaters value the reduced weight for enhanced maneuverability, particularly in technical street skating, this weight reduction often comes at the expense of durability and overall board feel. The lighter weight may not provide the same level of stability and control as a heavier, higher-ply deck.

In conclusion, the ply count is a critical factor in determining the cost and performance of a skateboard deck. While reducing the ply count can contribute to lower prices, it also affects the deck’s flexibility, durability, and weight. Skaters seeking economical options must carefully weigh the benefits of a lower price against the potential trade-offs in performance and longevity. Selecting a deck with a ply count appropriate for the intended use and skating style is crucial for optimizing both cost-effectiveness and skateboarding experience.

4. Shape Variations

Shape variations in skateboard platforms represent a crucial factor influencing both performance characteristics and manufacturing costs, thereby directly impacting the availability of economical options. The complexity of the deck’s geometry contributes significantly to production expenses, making simplified shapes more prevalent within the realm of “skate decks for cheap”.

- Standardization and Reduced Tooling Costs

Simplified deck shapes, such as those with minimal concave or symmetrical designs, necessitate less complex tooling and manufacturing processes. This standardization reduces the initial investment required for production, enabling manufacturers to offer these decks at lower prices. An asymmetrical shape, requiring specialized molds and potentially more manual labor, increases the cost accordingly.

- Material Optimization in Simplified Shapes

Standard shapes often allow for more efficient use of raw materials. Less intricate designs minimize waste during the cutting and pressing stages, contributing to lower material costs. Conversely, decks with complex contours necessitate more precise cutting techniques and may result in a higher proportion of unusable material, increasing overall expenses.

- Influence of Shape on Performance and Skill Level

Certain shape variations are more conducive to specific skating styles or skill levels. Deeper concave and more aggressive shapes are generally favored by experienced skaters for technical tricks. Simplified shapes, while potentially less optimized for advanced maneuvers, provide a more stable and forgiving platform for beginners, aligning with the target market for more affordable options.

- Shape Trends and Market Demand

The prevalence of certain shapes can fluctuate based on current skateboarding trends. Mass-produced, popular shapes can often be found at lower prices due to economies of scale and increased competition. Niche or unconventional shapes, produced in smaller quantities, typically command a premium price due to their limited availability and specialized appeal.

In conclusion, shape variations play a significant role in determining the cost of skateboard platforms. Simplified shapes facilitate streamlined manufacturing processes, minimize material waste, and cater to a broader range of skill levels, contributing to the availability of more affordable options. Conversely, complex shapes necessitate more specialized tooling and production techniques, resulting in higher prices. The relationship between shape and cost allows skaters to balance their performance requirements with their budgetary constraints.

5. Graphic Application

The method of graphic application on skateboard platforms directly influences production costs, subsequently impacting the availability of “skate decks for cheap.” Simpler graphic application techniques, such as heat transfer, are generally less expensive than more durable methods like screen printing. Heat transfer involves applying a pre-printed design to the deck using heat and pressure. This process is relatively quick and requires less specialized equipment, reducing overall manufacturing expenses. Conversely, screen printing requires creating stencils for each color in the design and applying ink directly to the deck. This method is more labor-intensive and requires skilled technicians, contributing to higher production costs. The choice of graphic application thus becomes a key factor in determining the final retail price. For instance, a deck featuring a complex, multi-colored screen-printed graphic will typically command a higher price than a deck with a single-color heat-transferred design, even if other factors such as wood quality and construction are similar. The prevalence of heat-transferred graphics on budget-friendly options underscores this direct connection.

The durability of the graphic also plays a role in the perceived value and longevity of the skateboard platform. Heat-transferred graphics are generally more susceptible to wear and tear, fading, and peeling compared to screen-printed graphics. This lower durability can be a significant consideration for skaters who prioritize aesthetics and board appearance. Manufacturers offering “skate decks for cheap” may choose heat transfer to minimize costs, acknowledging that the graphic may not withstand prolonged use or aggressive skating. As a result, the graphic integrity becomes a trade-off between cost savings and aesthetic longevity. A practical example involves comparing two decks: one with a vibrant, screen-printed graphic that remains intact for months with regular use, and another with a heat-transferred graphic that begins to fade and peel within weeks. This difference in graphic longevity impacts the overall value proposition for consumers, influencing their purchase decisions based on their priorities.

In summary, the selection of graphic application methods is intrinsically linked to the price point of skateboard decks. Heat transfer provides a cost-effective means of applying graphics, contributing to the availability of “skate decks for cheap.” However, this cost savings often comes at the expense of graphic durability. Skaters must therefore consider the trade-offs between cost, aesthetics, and longevity when selecting a skateboard platform. The choice of graphic application technique underscores the broader theme of balancing cost and quality within the market for affordable skateboarding equipment. While a visually appealing graphic can enhance the user experience, understanding the underlying application method enables informed purchase decisions based on individual needs and priorities.

6. Brand Reputation

Brand reputation serves as a crucial, albeit sometimes overlooked, factor in the landscape of economically priced skateboard platforms. It provides a valuable, if not definitive, indicator of product quality, consistency, and customer support, influencing purchasing decisions within the “skate decks for cheap” market segment.

- Consistency of Quality

Established brands, even those offering budget lines, often maintain a baseline standard of quality control. This consistency stems from established manufacturing processes and a commitment to upholding their brand image. Conversely, lesser-known or unbranded “skate decks for cheap” may exhibit significant variability in quality, making purchasing decisions riskier. A known brand, for example, might use a standardized maple ply and construction method across its budget and premium lines, ensuring a minimum level of performance. A no-name brand might source materials from varying suppliers, leading to inconsistencies.

- Warranty and Customer Support

Reputable brands typically offer warranties or guarantees on their products, providing recourse for defects or manufacturing flaws. This assurance is often absent in the “skate decks for cheap” market, leaving consumers with limited options in case of product failure. For example, a well-known brand might offer a limited warranty against delamination, while an unbranded product likely offers no such protection.

- Material Sourcing and Production Ethics

Established brands are often subject to greater scrutiny regarding their sourcing practices and production ethics. Consumers may prioritize brands that adhere to sustainable forestry practices or fair labor standards, even when seeking affordable options. The origins and production methods of “skate decks for cheap” from unknown sources are often opaque, raising ethical concerns. A recognizable brand is more likely to be transparent about its supply chain.

- Resale Value and Brand Recognition

While not a primary concern for all purchasers of “skate decks for cheap”, brand recognition can influence resale value and overall consumer satisfaction. A deck from a known brand, even if purchased at a discount, may retain some residual value in the secondary market. Furthermore, brand recognition can offer a sense of assurance and confidence in the product’s performance. This factor is less relevant for users who simply need a low-cost, functional deck.

In conclusion, while the allure of ultra-low-priced skateboard platforms is undeniable, the absence of a reputable brand can introduce significant risks regarding product quality, customer support, and ethical considerations. Consumers operating within the “skate decks for cheap” market should carefully weigh the potential benefits of choosing a recognizable brand, even if it entails a slightly higher initial investment, to mitigate potential issues and ensure a more satisfactory skateboarding experience. Brand reputation, therefore, serves as a valuable heuristic in navigating the complexities of affordable skateboard equipment.

7. Retail Location

The selection of a retail location significantly impacts the availability and price of affordable skateboard platforms. Different retail channels employ varied business models, influencing pricing strategies and the overall cost of “skate decks for cheap.”

- Online Marketplaces

Online marketplaces, such as dedicated skateboard retailers and general e-commerce platforms, often offer competitive pricing due to lower overhead costs. Reduced expenses related to physical storefronts, staffing, and utilities enable online vendors to offer discounts and promotions. The increased competition among sellers in the online space further drives down prices, creating opportunities to acquire economical skateboard platforms. For instance, comparing prices across multiple online retailers can often yield significant savings compared to purchasing from a local skate shop.

- Local Skate Shops

Local skate shops provide a curated selection of skateboard platforms, often catering to a specific community or skating style. While local shops may not always offer the lowest prices, they provide valuable services such as expert advice, personalized recommendations, and opportunities to physically inspect the product before purchase. These added benefits may justify a slightly higher price point for some consumers. Moreover, local shops sometimes offer package deals or loyalty programs that can reduce the overall cost. A local shop might offer a discount on a deck when purchased with trucks and wheels, effectively lowering the cost of the platform.

- Big Box Retailers

Large retail chains, while not typically specializing in skateboarding equipment, may offer entry-level skateboard platforms at competitive prices. These retailers leverage their large purchasing power to secure bulk discounts from manufacturers, allowing them to offer lower prices to consumers. However, the selection of skateboard platforms at big box retailers is often limited, and the quality of the available options may be lower compared to products offered by specialized retailers. A big box retailer might carry a basic, low-cost skateboard designed for casual use, but it might not offer the same performance or durability as a deck from a dedicated skate brand.

- Factory Direct Outlets

Factory direct outlets or online stores represent a potential avenue for securing “skate decks for cheap” by eliminating the middleman. Manufacturers selling directly to consumers can offer lower prices by bypassing retail markups. However, these outlets may have limited product selection or offer products with slight cosmetic imperfections. A skateboard manufacturer might have an online outlet store selling decks with minor graphic errors or discontinued models at significantly reduced prices.

In conclusion, the retail location plays a crucial role in determining the availability and price of affordable skateboard platforms. Online marketplaces and factory direct outlets often offer the lowest prices, while local skate shops provide added value through expert advice and personalized service. Big box retailers may offer entry-level options at competitive prices, but the selection and quality may be limited. Consumers seeking “skate decks for cheap” should carefully consider the trade-offs between price, product quality, and the added benefits offered by different retail channels.

Frequently Asked Questions

The following section addresses common inquiries and concerns regarding the acquisition and utilization of affordable skateboard platforms. The information presented aims to provide clarity and guidance for consumers seeking cost-effective options.

Question 1: What compromises are typically made to reduce the price of skateboard decks?

Reduced pricing often stems from the utilization of less expensive wood types, simplified construction techniques, lower ply counts, and basic graphic applications. Material sourcing, manufacturing location and quality control processes are additional factors.

Question 2: How does a lower price affect the durability of a skateboard deck?

Lower-priced decks frequently exhibit reduced durability due to the factors listed above. They may be more susceptible to cracking, chipping, and delamination, resulting in a shorter lifespan. Skate style and usage are also a factor for durability.

Question 3: Are economical skateboard decks suitable for all skill levels?

Entry-level decks may be appropriate for beginners or casual skaters. More experienced skaters, particularly those performing demanding tricks, may require higher-quality decks to withstand the increased stress and impact.

Question 4: What is the typical lifespan of an affordable skateboard deck?

Lifespan varies greatly depending on frequency of use, skating style, and deck construction. A lower-priced deck used infrequently for basic cruising may last longer than a higher-priced deck subjected to daily, aggressive street skating. Always consider usage and skate style.

Question 5: How can the likelihood of a skateboard deck purchase be maximized to ensure durability within a limited budget?

Careful inspection before purchase can identify potential weaknesses. Assessing wood quality, lamination, and graphic application are important. Researching brand reputation and sourcing from reputable retailers are also key.

Question 6: What are the potential safety concerns associated with using low-quality skateboard decks?

Deck failure during use poses a significant safety risk. Cracking or delamination can lead to loss of control, potentially resulting in injuries. Regular inspection and prompt replacement of damaged decks are crucial for mitigating these risks. Replacement and inspections are important for safety.

In summary, acquiring an economical skateboard platform necessitates a careful assessment of potential trade-offs between cost and performance. Understanding the factors that influence durability and safety is essential for making informed purchasing decisions.

The subsequent section will provide information for sourcing the necessary components to assemble a complete skateboard setup, addressing considerations for budget-conscious consumers.

Considerations for Economical Skateboard Platform Acquisition

This discourse has explored the nuanced landscape of affordable skateboard platforms, delineating key aspects impacting both cost and performance. Material composition, construction methodologies, graphic application techniques, brand reputation, and retail location were examined as crucial determinants influencing the value proposition of “skate decks for cheap.” Understanding these factors empowers consumers to make informed decisions, balancing budgetary constraints with functional requirements.

The pursuit of affordable skateboarding equipment necessitates a judicious approach. While the allure of reduced pricing is undeniable, a comprehensive assessment of potential trade-offs is paramount. Prudent selection based on the criteria outlined herein enables individuals to engage in skateboarding without compromising safety or significantly diminishing the overall experience. Future research should focus on long-term performance analysis of cost-effective materials and manufacturing processes.