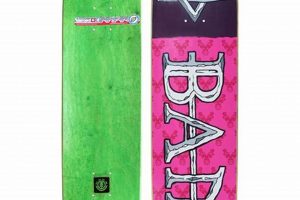

An unfinished wooden platform intended for skateboarding is a fundamental component for those seeking customization. Typically constructed from multiple layers of laminated maple, this product provides a foundation upon which skaters can apply their own graphics, finishes, and hardware. It offers a clean slate, contrasting with pre-decorated alternatives available commercially.

The appeal of these platforms lies in the opportunity for individual expression and control over the final product. Historically, skaters have sought ways to personalize their equipment, and these items fulfill that need. The benefits include cost savings for budget-conscious individuals, as well as the ability to create unique and personalized boards that reflect specific riding styles or aesthetic preferences.

Subsequent discussions will delve into the selection criteria for quality materials, techniques for applying graphics and finishes, and the optimal hardware configurations to complete a customized skateboarding experience. Further exploration will address the nuances of concave shapes, sizes, and their impact on performance.

Guidance for Working with Unfinished Skate Platforms

This section provides essential guidance for individuals seeking to customize skateboards using unmodified platforms. Proper preparation and execution are crucial for achieving optimal performance and durability.

Tip 1: Material Inspection: Prior to customization, meticulously examine the platform for any structural imperfections, such as delamination or warping. Compromised materials will negatively impact performance and longevity. Select platforms constructed from high-quality, consistently layered maple.

Tip 2: Surface Preparation: Ensure a smooth and receptive surface by sanding the platform with progressively finer grit sandpaper. Start with a coarser grit to remove imperfections and finish with a fine grit for a polished surface. This process is essential for proper graphic adhesion.

Tip 3: Graphic Application: Employ high-quality paints, inks, or transfer methods designed specifically for skateboard applications. Consider the long-term durability and UV resistance of chosen materials. Multiple thin layers are preferable to a single heavy coat, preventing cracking and peeling.

Tip 4: Sealing and Finishing: Apply a clear coat sealant to protect the graphics and the wood from environmental factors and wear. Polyurethane-based sealants are recommended for their durability and resistance to abrasion. Allow sufficient drying time between coats.

Tip 5: Hardware Installation: Use precision tools to accurately drill mounting holes for trucks and other hardware. Inaccurate drilling can compromise the structural integrity of the platform. Ensure all hardware is securely fastened and properly aligned.

Tip 6: Edge Sealing: Pay close attention to sealing the edges of the platform. This prevents moisture from penetrating the layers of wood, which can lead to warping and delamination. Multiple coats of sealant are recommended for the edges.

Tip 7: Environmental Considerations: Work in a well-ventilated area and utilize appropriate personal protective equipment, such as respirators and gloves, when sanding, painting, and applying sealants. Adhere to all safety guidelines provided by the manufacturers of the chosen materials.

Adhering to these guidelines will result in a customized skateboard that not only reflects individual style but also performs reliably and withstands the rigors of regular use. Careful attention to detail throughout the customization process is paramount.

The subsequent sections will explore specific design considerations and advanced customization techniques for achieving truly unique and professional-grade skateboards.

1. Wood Grain

Wood grain, referring to the alignment and pattern of wood fibers, is a critical determinant of the structural integrity and performance characteristics of the skateboard platform. The orientation and quality of the grain directly influence the platform’s strength, flexibility, and resistance to stress.

- Grain Orientation and Strength

The direction of the wood grain in each ply significantly affects the platform’s resistance to bending and breakage. Vertically oriented grain, aligned along the length of the platform, provides maximum stiffness and load-bearing capacity. Conversely, horizontally oriented grain offers greater flexibility. A combination of orientations in alternating plies is employed to achieve a balanced strength and flex profile.

- Grain Density and Durability

Denser wood grain, characterized by tighter spacing between growth rings, indicates slower growth and generally corresponds to higher wood density and increased durability. Platforms constructed from maple with dense, consistent grain patterns are more resistant to impact and wear, contributing to a longer lifespan.

- Grain Consistency and Uniformity

Variations in grain pattern within a single platform can create weak points and inconsistencies in performance. Uniform grain patterns across all plies promote even stress distribution and minimize the risk of localized failure. Careful selection of maple with consistent grain is essential for ensuring structural reliability.

- Impact on Flex Characteristics

Wood grain directly affects the flex characteristics of the platform, influencing its responsiveness and feel. Platforms with predominantly vertical grain tend to be stiffer and more responsive, while those with horizontal grain exhibit greater flexibility and shock absorption. The choice of grain orientation is dictated by the intended riding style and desired performance attributes.

Ultimately, a thorough understanding of wood grain is paramount in evaluating and selecting an appropriate skateboarding platform. The careful consideration of grain orientation, density, consistency, and its influence on flex characteristics will contribute significantly to the platform’s performance, durability, and overall suitability for its intended use.

2. Concave Depth

Concave depth, a critical geometric characteristic of the skateboard platform, directly influences rider control and responsiveness. Within the context of the unfinished platform, concave depth represents a foundational design element, predetermining the potential range of performance characteristics. A deeper concave provides a more pronounced pocket for the feet, enhancing grip and facilitating aggressive maneuvers such as flip tricks and slides. Conversely, a shallower concave offers a flatter, more stable platform suitable for cruising and controlled riding. The absence of pre-defined graphics allows for visual assessment and, to a limited extent, tactile evaluation of the concave before customization begins.

The impact of concave depth is exemplified by the contrast between street skateboarding and vert riding. Street skaters often prefer steeper concaves to maximize board feel and control during technical tricks performed on flat ground and obstacles. Vert riders, while also benefiting from enhanced grip, may opt for shallower concaves to promote stability and reduce foot fatigue during extended sessions on ramps. The selection of a platform with a specific concave depth, therefore, represents a crucial decision point for skaters seeking to optimize their equipment for a particular discipline.

In conclusion, concave depth serves as a fundamental parameter within the overall design of a skateboard platform. Its influence on rider control, stability, and overall board feel underscores its importance in the selection process. A comprehensive understanding of concave variations and their implications is essential for skaters seeking to create customized setups tailored to their specific riding styles and performance requirements.

3. Ply Construction

Ply construction, the method of layering thin sheets of wood to form a solid composite, is integral to the structural integrity and performance characteristics of the skateboard platform. The unfinished platform derives its strength and flexibility from the arrangement, type, and adhesive bonding of these plies. Typically comprised of seven to nine layers of maple veneer, the oriented layering process contributes to dimensional stability and resistance to warping. Variations in ply thickness, grain direction, and wood species directly influence the platforms flex, pop, and overall durability. Insufficient ply adhesion or inconsistencies in material quality compromise structural integrity, leading to premature failure under stress. An example is delamination, where the layers separate, rendering the platform unusable.

The arrangement of plies is carefully engineered. Cross-grain layering, where adjacent plies have their wood grain oriented perpendicularly, significantly enhances the platform’s resistance to torsional forces. This construction method minimizes splitting and improves overall strength. The adhesive used to bond the plies must possess high shear strength and environmental resistance to withstand the repeated stresses of skateboarding. Furthermore, the uniformity of ply thickness is critical. Inconsistencies result in uneven stress distribution, potentially leading to localized weaknesses. Manufacturers employ hydraulic presses and controlled curing processes to ensure consistent bonding and optimal ply integration. A notable example is the use of epoxy resins in high-end platforms to enhance water resistance and durability.

In summation, ply construction dictates the platform’s structural properties and longevity. A thorough understanding of this process is essential for evaluating platform quality and predicting performance characteristics. The selection of appropriate materials and precise manufacturing techniques are paramount in producing durable and reliable skateboard platforms. The inherent challenges in maintaining consistent material quality and controlling the lamination process underscore the importance of rigorous quality control measures within the skateboard manufacturing industry. Further advancements in ply construction may involve the incorporation of alternative materials, such as fiberglass or carbon fiber, to enhance strength-to-weight ratios and improve overall performance.

4. Shape Symmetry

Shape symmetry, pertaining to the balanced proportions and mirroring of a skateboard platform’s outline and features around a central axis, is a significant factor influencing stability, predictability, and rider control. The unfinished platform, prior to customization, presents an unadulterated opportunity to assess and potentially modify this symmetry to suit specific riding preferences. Deviations from symmetry can introduce inconsistencies in performance, particularly during rotational maneuvers and switch stance riding.

- Nose and Tail Similarity

The degree to which the nose and tail of the platform mirror each other directly impacts a rider’s ability to perform tricks in either direction with equal ease. Symmetrical nose and tail designs allow for seamless transitions between regular and switch stances, enhancing versatility. Asymmetrical designs, conversely, may favor one stance over the other, affecting performance on more technical tricks.

- Edge Curvature Consistency

Uniform curvature along both edges of the platform promotes predictable turning characteristics. Variations in edge curvature can result in inconsistent grip and turning radii, making it difficult for riders to maintain control during high-speed maneuvers. The unfinished platform allows for precise evaluation of this curvature and, if necessary, modification to achieve optimal symmetry.

- Concave Symmetry

A symmetrically distributed concave enhances foot placement and provides a consistent feel across the platform. Asymmetrical concave designs can lead to imbalances in foot pressure and reduced control, particularly during technical tricks. A thorough inspection of the unfinished platform allows for verification of concave symmetry before graphic application or hardware installation.

- Truck Hole Alignment

Precise symmetry in the placement of truck mounting holes is critical for proper truck alignment and balanced weight distribution. Misaligned truck holes can induce unwanted steering bias and negatively impact stability. Accurate drilling based on symmetrical measurements from a central reference point is imperative when preparing an unfinished platform.

The principles of shape symmetry apply universally across various skateboarding disciplines, influencing performance in street, park, and vert riding. While subtle asymmetries may be intentionally incorporated into some platform designs to achieve specific performance characteristics, maintaining overall symmetry remains a fundamental consideration for ensuring stability, predictability, and rider control. Assessment of shape symmetry on a skateboarding platform is a factor to consider.

5. Surface Smoothness

The surface quality of the unmodified skateboard platform constitutes a critical determinant of subsequent customization success and overall aesthetic appeal. A smooth, uniform surface is essential for optimal adhesion of graphics, paints, and other decorative finishes. Irregularities, such as scratches, dents, or raised wood fibers, impede proper bonding, leading to premature peeling, cracking, or uneven coverage. The absence of a prepared surface necessitates meticulous sanding and preparation prior to any artistic or protective treatment. The unmodified state, therefore, presents both an opportunity for personalized aesthetics and a challenge in achieving professional-grade results.

Consider, for instance, the application of heat-transfer graphics. Imperfections in the surface texture create air gaps, preventing complete contact between the transfer medium and the wood. This results in incomplete image transfer and a visually compromised final product. Similarly, when applying multiple layers of paint, a rough surface will amplify imperfections, creating a textured finish rather than the desired smooth, glossy appearance. Professional skateboard manufacturers employ specialized sanding equipment and multi-stage finishing processes to ensure a uniformly smooth surface, optimizing the final graphic adhesion and durability.

In conclusion, the initial surface smoothness of an unfinished skateboard platform directly influences the quality and longevity of subsequent customizations. Adequate preparation, including sanding and surface treatment, is paramount to achieving a professional finish. This underscores the importance of scrutinizing the initial state of the platform and implementing appropriate surface preparation techniques. The degree to which this preparatory step is executed determines the ultimate visual and functional integrity of the customized skateboard.

Frequently Asked Questions About Unfinished Skate Platforms

This section addresses common inquiries regarding the selection, preparation, and customization of skateboards using unmodified platforms. Information presented aims to provide clarity and informed guidance.

Question 1: What wood type is optimal for an unfinished skateboard platform?

North American maple is widely considered the standard due to its strength, flexibility, and consistent grain structure. Other hardwoods may be used, but maple provides a balanced performance profile.

Question 2: How does concave depth affect skateboarding performance?

Concave depth influences foot grip and control. Deeper concaves enhance board feel and are suited for technical tricks. Shallower concaves offer increased stability for cruising and controlled riding.

Question 3: Is sanding required before applying graphics to an unfinished platform?

Yes. Sanding creates a smooth, receptive surface, promoting optimal adhesion of graphics, paints, and sealants. Progressive grit sandpaper is recommended to achieve a uniformly smooth finish.

Question 4: What type of sealant is recommended for protecting customized graphics?

Polyurethane-based sealants provide a durable, abrasion-resistant finish that protects graphics from wear and environmental factors. Multiple thin coats are preferable to a single thick coat.

Question 5: How does ply construction impact the strength and durability of the platform?

The number of plies, their arrangement, and the adhesive used to bond them directly influence the platform’s strength and resistance to warping. Seven-ply maple is a common configuration. Cross-grain layering enhances torsional strength.

Question 6: How critical is symmetry in platform shape?

Shape symmetry affects stability and predictability, especially during rotational maneuvers. Symmetrical nose and tail designs allow for seamless transitions between regular and switch stances.

Key takeaway: Careful selection and preparation of the platform are essential for achieving optimal performance and durability in a customized skateboard.

The subsequent section will delve into advanced customization techniques and innovative design considerations for achieving truly unique skateboard platforms.

Skate Deck Blank

This exploration has comprehensively examined the unmodified skateboard platform, underscoring the significance of material selection, structural integrity, and surface preparation. Factors such as wood grain orientation, concave depth, ply construction, shape symmetry, and surface smoothness have been identified as critical determinants of both performance and customization potential. The deliberate consideration of these elements is paramount for those seeking to construct reliable and aesthetically personalized skateboarding equipment.

The enduring appeal of the unadorned platform lies in its capacity to empower individual expression and tailor equipment to specific needs. A sustained commitment to understanding these core principles will foster continued innovation within the skateboarding community, ultimately elevating both the art and the science of board design and construction.

![Get the Best True Skate Deck Template [Free] How to Skateboard: A Beginner's Guide to Your First Board & Tricks Get the Best True Skate Deck Template [Free] | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/03/th-113-300x200.jpg)