Equipment designed for a specific style of skating incorporates features that enhance performance in skate parks and on urban terrain. This specialized gear prioritizes durability and maneuverability. The construction typically includes a robust frame, smaller wheels for grind clearance, and a supportive boot. These elements facilitate complex tricks and withstand the impacts associated with this demanding activity.

This category of skating allows practitioners to express creativity and physical prowess. The design considerations focus on enabling grinds, slides, and jumps on various surfaces. Historically, evolution in design stemmed from a desire for greater control and resilience. The result is specialized equipment that bolsters confidence and expands the possibilities for advanced maneuvers.

The following sections will delve into the specific components of this type of skating equipment, analyzing the roles of the frame, wheels, and boot in achieving optimal performance. Furthermore, the discussion will explore the criteria to consider when selecting the appropriate gear, ensuring both safety and suitability for the rider’s skill level and intended use.

Essential Considerations for Selecting Aggressive Inline Skates

Choosing appropriate equipment requires careful evaluation of several factors. Focusing on specific components and understanding their impact on performance and safety is crucial.

Tip 1: Frame Material: Opt for a robust frame constructed from high-density plastic or aluminum. This choice ensures durability under the stresses of grinding and impact. Aluminum frames provide greater rigidity but may be more expensive.

Tip 2: Wheel Diameter and Durometer: Smaller wheel diameters (54-60mm) facilitate grinding. Higher durometer ratings (88A-90A) offer increased speed and longevity on hard surfaces. Consider a balance between roll speed and grip according to the skate environment.

Tip 3: Bearing Quality: Invest in ABEC-rated bearings (ABEC 5 or higher) for smooth and efficient rolling. Proper bearing maintenance, including cleaning and lubrication, is essential for optimal performance.

Tip 4: Boot Support and Fit: Secure and supportive boot design is crucial to prevent ankle injuries. Ensure a snug fit that allows for proper articulation without restricting movement. Consider heat-moldable liners for a customized fit.

Tip 5: Grind Blocks and Plates: Inspect the grind blocks or plates for wear and replace them when necessary. These components directly impact the ability to perform grinds and slides effectively. Select blocks constructed from durable materials such as UHMW (Ultra-High Molecular Weight) plastic.

Tip 6: H-Block Configuration: The H-block configuration influences grinding stability. Evaluate the size and shape of the H-block to match skating style and preference. A wider H-block generally provides greater stability for beginners, while a narrower one allows for more maneuverability.

Tip 7: Anti-Rocker or Freestyle Setup: Consider anti-rocker wheels (smaller, harder wheels in the center) for enhanced grindability or a freestyle setup (no center wheels) for maximum freedom of movement. The optimal setup depends on individual skating style and terrain.

Selecting suitable equipment provides the foundation for progression and injury prevention. Focusing on durability, performance, and proper fit will yield the best results.

The subsequent sections explore maintenance procedures and further enhance the lifespan of skating equipment.

1. Frame Rigidity

Frame rigidity, in the context of equipment utilized for demanding activities, directly impacts the energy transfer from the skater to the wheels. A frame exhibiting greater rigidity allows for a more immediate response to directional changes and forceful landings. Conversely, a flexible frame absorbs energy, leading to a less precise and potentially less stable skating experience. Therefore, frame construction materials and design significantly influence the user’s ability to perform advanced techniques and maintain control in dynamic situations. For instance, a frame constructed from aircraft-grade aluminum will offer superior rigidity compared to one made from lower-density plastic. This difference is discernible when executing grinds or landing jumps, where minimal frame flex translates to greater stability.

The materials used in frame construction and the structural design contribute significantly to the overall rigidity. A frame engineered with reinforcing ribs or a thicker cross-section will inherently exhibit greater resistance to deformation. Furthermore, the interface between the frame and the boot is a crucial point of consideration. A secure and well-fitted interface ensures that the skater’s movements are efficiently transmitted to the frame, minimizing energy loss and maximizing responsiveness. The rigidity of a frame also has implications for wear and tear. A more rigid frame is less prone to bending or cracking under stress, extending the lifespan of the equipment. Regular inspection of the frame for signs of damage is essential to ensure continued safe and optimal performance.

In summary, frame rigidity is a critical determinant of performance characteristics in specialized skating equipment. It directly affects responsiveness, stability, and energy transfer, thereby influencing the skater’s control and execution of tricks. A greater awareness of the impact of frame rigidity allows for better selection and care of equipment, ultimately leading to enhanced performance and safety. Frame rigidity in this equipment plays a pivotal role in the equipment and skating performance that will allow the user to excel. Selecting the correct frame rigidity is key to mastering skills and safety.

2. Wheel Durometer

Wheel durometer, a measure of hardness, is a significant factor influencing performance characteristics in equipment designed for rigorous activity. The selection of appropriate wheel durometer impacts grip, speed, and wear resistance, all critical considerations for users. The following points delineate key aspects of wheel durometer relevant to performance and durability.

- Grip and Surface Adhesion

Lower durometer ratings (e.g., 78A-85A) indicate softer wheels, which offer enhanced grip on smooth surfaces. This characteristic is beneficial for controlled movements and stability. However, softer wheels tend to wear more rapidly on abrasive surfaces. Higher durometer wheels provide less grip, but greater speed. The correct rating would depend on surface and desired outcome.

- Speed and Rolling Resistance

Higher durometer ratings (e.g., 88A-90A+) signify harder wheels, characterized by lower rolling resistance and increased speed. These wheels are suitable for smooth surfaces where grip is less critical. A lower durometer wheel increases rolling resistance.

- Impact Absorption and Vibration Damping

Softer wheels, corresponding to lower durometer ratings, provide better impact absorption and vibration damping. This can be advantageous on uneven surfaces. Conversely, harder wheels transmit more impact force, potentially leading to discomfort or fatigue over extended periods.

- Wear Resistance and Durability

Harder wheels, indicated by higher durometer ratings, generally exhibit greater wear resistance, resulting in extended lifespan. Softer wheels wear faster, particularly when subjected to aggressive use or abrasive surfaces. The conditions are often associated with intense activity.

The selection of wheel durometer requires a careful evaluation of the intended use environment and the user’s performance priorities. Balancing grip, speed, impact absorption, and durability is essential to optimize the skating experience and maximize equipment longevity. Selection should be based on the expected environment and the intended use.

3. Boot Support

Boot support forms a critical foundation for controlled movement and injury prevention in specialized equipment. The demands placed upon the lower extremities necessitate a design that provides both stability and freedom of motion. Insufficient support compromises performance, while excessive rigidity limits the execution of complex maneuvers.

- Ankle Stability and Injury Prevention

Adequate ankle support minimizes the risk of sprains and fractures during high-impact landings and rapid directional changes. A well-structured boot restricts excessive lateral movement, maintaining proper alignment and reducing stress on ligaments. Equipment utilizing reinforced ankle cuffs and supportive liners demonstrably enhances stability. Failure to provide adequate ankle stabilization elevates the incidence of lower extremity injuries.

- Energy Transfer and Responsiveness

The boot acts as a conduit for transmitting force from the skater to the frame and wheels. A supportive boot efficiently transfers energy, resulting in improved responsiveness and control. Conversely, a flexible boot dissipates energy, leading to reduced power and diminished precision. This relationship is particularly evident when executing grinds, where precise control is paramount. Rigid boots can limit range of motion.

- Customization and Fit

An adaptable boot design allows for customization to accommodate individual foot shapes and preferences. Heat-moldable liners, adjustable straps, and replaceable cuffs enhance the fit and comfort, optimizing performance. A secure and comfortable fit eliminates slippage and pressure points, reducing the risk of blisters and discomfort. The absence of customization options compromises both performance and comfort.

- Impact Absorption and Cushioning

Effective boot support incorporates cushioning materials to absorb impact forces during landings and other high-stress maneuvers. Strategically placed padding reduces the strain on joints and muscles, mitigating fatigue and enhancing overall comfort. Shock-absorbing insoles and liner materials further contribute to impact attenuation. Inadequate cushioning increases the likelihood of discomfort and injury. Liner material provides comfortable support.

The interplay between ankle stability, energy transfer, customization, and impact absorption defines the effectiveness of boot support. These elements collectively contribute to the user’s control, comfort, and safety. A holistic approach to boot design, encompassing these facets, optimizes the performance and longevity within this specialized skating activity. Consideration of boot support is a foundational element when choosing appropriate equipment.

4. Grind Plates

Grind plates are integral components of equipment used in activities involving sliding along surfaces. Their presence directly enables the execution of grinds, a fundamental aspect of this sport. The design and material composition of grind plates are critical factors influencing performance and durability. In this context, a causal relationship exists between the properties of grind plates and the rider’s ability to perform tricks. A durable grind plate, constructed from materials with high abrasion resistance, extends the lifespan of the equipment. For instance, a rider attempting a prolonged slide on concrete will exert significant force on the grind plate. A plate made from low-quality plastic would degrade rapidly, whereas a plate manufactured from UHMW (Ultra-High Molecular Weight) polyethylene would withstand the abrasion more effectively. This difference directly affects the rider’s ability to execute the trick consistently and safely.

The importance of grind plates extends beyond mere functionality; they are a defining characteristic of this type of equipment. Without them, the capacity to perform grinds is severely limited. The size, shape, and placement of grind plates influence stability and control during slides. Smaller grind plates may offer increased maneuverability, while larger plates provide a more stable platform. The recess, or lack thereof, contributes to the control that a rider can achieve during tricks. The appropriate grind plate configuration is determined by individual skating style and preferred terrain. The correct configuration enables riders to explore their own limits of skill and safety and may also influence trick execution.

Understanding the relationship between grind plates and specialized equipment is of practical significance for both riders and manufacturers. Riders benefit from a greater awareness of how grind plate design impacts performance, enabling them to select equipment that aligns with their skill level and skating style. Manufacturers can leverage this understanding to optimize grind plate designs, enhancing the durability, functionality, and overall value of their products. Ultimately, a focus on grind plate design contributes to the advancement of this activity, facilitating more creative and challenging tricks. Grind plates are a key element of safety and trick performance that enable the rider to explore the limits of what is possible.

5. Bearing Precision

Bearing precision, measured by the ABEC (Annular Bearing Engineering Committee) scale, dictates the rotational efficiency and smoothness of wheels on specialized skating equipment. Higher ABEC ratings (e.g., ABEC 5, ABEC 7, ABEC 9) signify tighter tolerances and reduced friction. In the context of this skating discipline, this translates to enhanced speed, reduced energy expenditure, and greater control. For example, a skater attempting a complex trick requiring sustained momentum will benefit from higher-precision bearings, which maintain rotational speed more effectively than lower-rated bearings. The impact of bearing precision is most pronounced during transitions between maneuvers and in maintaining speed across varied surfaces. The absence of quality bearings can negatively affect the skate’s ability to perform and the skater’s ability to safely execute tricks.

The practical significance of bearing precision extends to maintenance and durability. Higher-quality bearings, manufactured with tighter tolerances and superior materials, are generally more resistant to wear and contamination. Regular cleaning and lubrication are essential for all bearings, but the impact of neglect is more severe on lower-precision bearings, which are more susceptible to performance degradation due to dirt and friction. Selecting bearings appropriate for intended use is also crucial. Bearings subjected to repeated high-impact forces, common in aggressive skating, should be chosen with impact resistance in mind, not only ABEC rating. A well-maintained set of high-precision bearings can contribute significantly to the overall performance and longevity of skating equipment.

In summary, bearing precision is a critical determinant of performance characteristics in specialized equipment. It directly affects speed, efficiency, and control, thereby influencing the skater’s ability to execute tricks and navigate varied terrain. While ABEC ratings provide a useful benchmark, consideration of material quality and intended use is equally important. Regular maintenance ensures optimal performance and extends bearing lifespan. The correct bearing precision improves performance and allows for a longer equipment lifespan.

Frequently Asked Questions

This section addresses common inquiries regarding equipment selection, maintenance, and performance characteristics for aggressive inline skating. The information provided aims to offer clarity and promote informed decision-making.

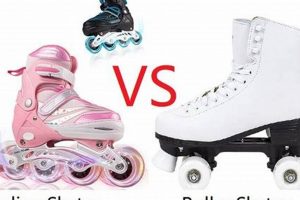

Question 1: What differentiates aggressive inline skates from recreational inline skates?

Aggressive inline skates are designed for park and street skating, featuring reinforced boots, smaller wheels, and grind plates. Recreational inline skates prioritize comfort and speed for distance skating.

Question 2: How does wheel durometer impact aggressive skating performance?

Wheel durometer affects grip, speed, and wear resistance. Lower durometer wheels offer greater grip, while higher durometer wheels provide increased speed and durability on hard surfaces.

Question 3: What is the significance of the ABEC rating in aggressive skate bearings?

ABEC ratings indicate bearing precision. Higher ABEC ratings signify tighter tolerances and reduced friction, contributing to smoother and faster rolling. However, material quality and impact resistance are also crucial factors.

Question 4: How often should aggressive inline skates be maintained?

Maintenance frequency depends on usage intensity. Regular cleaning and lubrication of bearings, inspection of grind plates, and tightening of hardware are recommended after each session.

Question 5: What safety gear is essential for aggressive inline skating?

A helmet, knee pads, elbow pads, and wrist guards are essential for minimizing injury risk. Mouthguards and padded shorts are also advisable for advanced maneuvers.

Question 6: How do I choose the right size aggressive inline skates?

Proper fit is crucial for comfort and control. Measure foot length and consult the manufacturer’s sizing chart. Consider heat-moldable liners for a customized fit. A snug fit that allows for toe movement is recommended.

Understanding the nuances of aggressive inline skating equipment enables skaters to optimize their performance and ensure their safety. Careful consideration of the factors outlined above is paramount.

The subsequent section explores advanced techniques and training methodologies that maximize the benefits derived from appropriate equipment selection.

The Enduring Significance of Optimized Equipment

This exploration has underscored the critical relationship between carefully selected components and enhanced performance within the domain of equipment designed for a demanding activity. From the frame’s rigidity to the wheel’s durometer and bearing precision, each element contributes uniquely to the skater’s experience. The understanding of these factors is essential for achieving a balance between maneuverability, durability, and safety.

Continued refinement in materials science and design will undoubtedly yield further advancements in this area. Riders and manufacturers should maintain a commitment to innovation, pursuing equipment configurations that push the boundaries of performance while prioritizing rider well-being. A thorough understanding of all aspects is crucial to excel.

![Best Chicago Skates Inline Skates: [Year] Guide & More! How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Chicago Skates Inline Skates: [Year] Guide & More! | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-470-300x200.jpg)