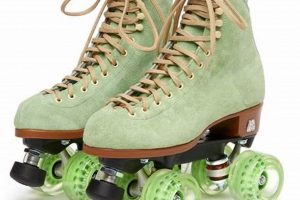

Adhesive-backed decorations designed for application to wheeled footwear, particularly those used in roller skating, serve both aesthetic and functional purposes. These decals, available in a diverse range of sizes, shapes, and materials, offer a means of personalizing equipment. As an illustration, a skater might use vibrant, weather-resistant appliques to distinguish their roller skates from others.

The addition of these embellishments provides more than mere visual appeal. They offer a degree of protection to the underlying surface, mitigating scratches and minor abrasions. Historically, these decorations have reflected trends in art, music, and popular culture, serving as a visual record of individual expression within the skating community. The application of these emblems allows individuals to assert their unique identity and affiliations.

The subsequent discussion will address the types of materials commonly used in their manufacture, methods of application and removal, and considerations for selecting appropriate designs based on durability and intended use. Examination of design trends and vendor options will also be addressed.

Guidelines for Roller Skate Embellishment

The following are recommendations for the selection, application, and maintenance of decorative appliques for roller skates, intended to maximize aesthetic appeal and longevity.

Tip 1: Material Selection: Prioritize vinyl compositions for enhanced weather resistance and durability. Opt for laminated finishes to protect against abrasion and UV degradation.

Tip 2: Surface Preparation: Thoroughly clean and degrease the target surface before application. Isopropyl alcohol is recommended for removing residues that may impede adhesion.

Tip 3: Application Technique: Employ a squeegee or similar tool to ensure uniform pressure and eliminate air bubbles during application. Begin at one edge and gradually work across the surface.

Tip 4: Design Considerations: Select patterns and graphics that complement the overall aesthetic of the roller skates. Avoid overly intricate designs that may be prone to peeling or damage.

Tip 5: Edge Sealing: Apply a thin bead of clear sealant around the edges to prevent moisture penetration and lifting. This is particularly important in high-wear areas.

Tip 6: Removal Procedures: Use a heat gun or hairdryer on low setting to soften the adhesive before peeling. Clean any residual adhesive with an appropriate solvent, such as citrus-based cleaner.

Tip 7: Maintenance Protocols: Regularly inspect the applied embellishments for signs of wear or damage. Promptly address any issues to prevent further degradation.

Adherence to these guidelines will contribute to a more professional appearance and extend the lifespan of the roller skate adornments.

The subsequent section will delve into available design resources and customization options.

1. Material Durability

The longevity and visual appeal of applied roller skate decorations are directly contingent upon the intrinsic properties of the substrate material. Premature degradation of the material undermines the aesthetic purpose of the decoration and potentially compromises surface protection afforded by the applied film. Inferior materials, exhibiting poor resistance to abrasion, UV radiation, and moisture, are susceptible to cracking, fading, and peeling, necessitating frequent replacement and increased maintenance. For example, a roller skate decoration constructed from calendared vinyl, lacking a protective laminate, will exhibit significantly reduced durability compared to a cast vinyl product with UV-resistant over laminate.

The selection of robust and appropriate materials, such as high-performance polymeric films, directly impacts the decoration’s ability to withstand the rigors of roller skating. Factors such as impact resistance, tensile strength, and flexibility must be carefully considered to ensure the decoration maintains its structural integrity under dynamic stress. Furthermore, the chemical composition of the material should exhibit compatibility with both the adhesive backing and the surface of the roller skate to prevent delamination or discoloration. An illustration of this is the use of a solvent-based adhesive on a polycarbonate skate boot; the solvent may cause the polycarbonate to degrade leading to failure of the decoration.

In conclusion, the emphasis on material durability within the context of roller skate embellishments is not merely an aesthetic consideration but a practical imperative for maximizing the product’s lifecycle and safeguarding the underlying equipment. Compromising on material quality results in diminished performance, increased operational costs, and potential damage to the skates themselves. Therefore, prioritizing the selection of high-durability materials is paramount for achieving a cost-effective and visually appealing customization solution.

2. Adhesive Strength

Adhesive strength represents a critical determinant of the performance and longevity of decorative appliques on roller skates. Insufficient adhesive strength leads to premature detachment, rendering the embellishment ineffective. The dynamic nature of roller skating, involving constant movement, vibrations, and exposure to environmental factors, places significant stress on the adhesive bond. Consequently, a robust adhesive foundation is essential to maintain the integrity of the applied decoration. For instance, an inadequate adhesive formulation may fail to withstand temperature fluctuations, resulting in peeling or bubbling. Similarly, exposure to moisture can weaken the adhesive bond, leading to detachment during use.

Selection of an appropriate adhesive necessitates consideration of the substrate material of both the roller skate and the applique itself. Incompatibility between the adhesive and either surface can result in compromised bond strength. Surface preparation, including thorough cleaning and degreasing, is also paramount. Contaminants such as dirt, oils, or waxes impede proper adhesion. Furthermore, the application technique directly impacts the effectiveness of the adhesive. Applying uniform pressure during installation ensures complete contact between the adhesive and the target surface, minimizing air pockets and maximizing bond strength. As an example, an experienced applicator will utilize a squeegee to ensure even distribution of pressure across the surface, promoting optimal adhesion.

In conclusion, adhesive strength is a foundational component of effective roller skate embellishments. Its contribution to the product’s overall performance is undeniable, directly impacting durability, aesthetics, and user satisfaction. Proper material selection, meticulous surface preparation, and skilled application are key to maximizing adhesive performance and ensuring the long-term integrity of the decoration. The challenges in balancing permanent adhesion with potential removal needs can often be solved by using a medium to high tack adhesive.

3. Design Complexity

The level of intricacy in the design of adhesive decorations for roller skates directly impacts their durability and ease of application. Complex designs, characterized by numerous fine lines, sharp angles, and small, detached elements, exhibit a heightened susceptibility to tearing, peeling, and damage during both the application process and subsequent use. This vulnerability arises from the increased surface area exposed to potential sources of abrasion and the reduced structural integrity resulting from intricate cuts and perforations. A real-world example can be observed in the application of a detailed mandala-style graphic to a skate boot; the thin lines are prone to catching on surfaces, leading to premature failure and detracting from the overall aesthetic.

The feasibility of applying a particular design to a roller skate also depends significantly on its complexity. Intricate patterns require meticulous alignment and careful handling to avoid distorting or tearing the adhesive material during installation. The presence of small, isolated elements necessitates precise placement and increases the risk of trapping air bubbles, which can further compromise adhesion and visual appeal. Conversely, simpler designs, featuring larger, more cohesive shapes, offer a more forgiving application process and are less prone to damage. Consider a comparison between a solid geometric shape and a design composed of several small, separate stars; the former is invariably easier to apply and maintain on a dynamic surface like a roller skate.

In summary, design complexity represents a crucial consideration in the creation and application of adhesive decorations for roller skates. Balancing aesthetic preferences with practical limitations is essential to ensure both visual appeal and long-term durability. By prioritizing simpler, more robust designs, manufacturers and users can mitigate the risks associated with intricate patterns and maximize the longevity and functionality of the applied embellishment. Failure to account for the impact of design complexity can result in compromised adhesion, premature degradation, and ultimately, a less satisfactory user experience.

4. Application Technique

The longevity and aesthetic appeal of adhesive decorations on roller skates are critically dependent on the application technique employed. Improper application, irrespective of material quality or design sophistication, can lead to premature failure of the decorative element. Air entrapment, misalignment, and inadequate surface contact compromise adhesion and increase vulnerability to environmental factors. For example, applying a decorative element without proper surface cleaning can result in immediate adhesion issues, leading to edge lifting and eventual detachment. The application method is thus a significant variable in the success of customizing roller skates with adhesive ornamentation.

Specific techniques, such as utilizing a squeegee or roller to apply uniform pressure, are vital in minimizing air pockets and ensuring consistent contact between the adhesive backing and the skate surface. Pre-cleaning the application surface with isopropyl alcohol or a similar degreasing agent removes contaminants that impede adhesion. Furthermore, temperature considerations play a role; applying the decoration in a controlled temperature range optimizes adhesive performance. Conversely, attempting to apply a decoration in extreme temperatures can compromise the adhesive’s bonding properties. A demonstrable instance of proper technique involves the careful positioning of the decorative element, followed by a controlled, squeegee-assisted application, progressing from the center outwards to displace air.

In summary, the application technique represents a pivotal factor in the integration of adhesive decorations with roller skates. Prioritizing proper surface preparation, utilizing appropriate tools, and adhering to recommended environmental conditions maximize adhesive performance and extend the lifespan of the applied decoration. Failure to emphasize this aspect undermines the potential benefits of high-quality materials and intricate designs. The practical implications of understanding this connection lead to enhanced durability, improved aesthetics, and greater user satisfaction, thereby contributing to a more cost-effective and visually appealing customization outcome.

5. Weather Resistance

Weather resistance constitutes a critical performance attribute for adhesive decorations intended for roller skates. The operating environment of these adornments inherently involves exposure to variable climatic conditions, necessitating robust material properties capable of withstanding degradation induced by environmental stressors.

- UV Radiation Degradation

Prolonged exposure to ultraviolet (UV) radiation leads to photochemical degradation of polymeric materials. This manifests as discoloration, embrittlement, and eventual disintegration of the adhesive decoration. UV-resistant coatings or base materials are essential to mitigate this effect and maintain visual integrity. For instance, without UV protection, a vibrant colored applique will fade rapidly when used outdoors.

- Moisture Permeation and Hydrolysis

The ingress of moisture through the adhesive layer can compromise bond strength and induce hydrolysis, particularly in certain adhesive formulations. This weakens the adhesion, leading to peeling and detachment. Waterproof materials and sealants are necessary to prevent moisture penetration and preserve adhesion integrity. As an example, a skate design using paper adhesive is susceptible to peeling off due to moisture.

- Temperature Cycling Effects

Fluctuations in temperature induce thermal expansion and contraction in both the adhesive decoration and the underlying skate surface. This differential expansion generates stress on the adhesive bond, potentially leading to cracking, bubbling, or detachment. Materials with similar coefficients of thermal expansion and adhesives with high temperature resistance are desirable to minimize these effects. Example is the changing weather affecting skates outdoor.

- Abrasion and Environmental Contaminants

Exposure to particulate matter, road debris, and other environmental contaminants subjects the surface of the adhesive decoration to abrasion and chemical attack. Protective laminates or coatings are required to resist scratching, staining, and chemical degradation. This maintains the visual appearance and extends the lifespan of the embellishment. Without these, surfaces can be ruined and look unappealing.

These facets collectively underscore the importance of weather resistance in the selection and application of adhesive decorations for roller skates. Failure to address these environmental vulnerabilities results in diminished aesthetic appeal, reduced lifespan, and ultimately, a compromised user experience. The careful selection of materials and application techniques designed to withstand these environmental stressors is paramount for achieving a durable and visually appealing customization solution.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, application, and maintenance of adhesive decals for roller skates. This aims to provide clarity on best practices and dispel prevalent misconceptions.

Question 1: What materials offer the greatest durability for roller skate decorations?

Polymeric vinyl films, particularly those incorporating UV-resistant laminates, exhibit superior durability. These materials resist fading, cracking, and peeling, prolonging the lifespan of the decoration.

Question 2: How should the surface of roller skates be prepared prior to applying adhesive emblems?

Thorough cleaning with isopropyl alcohol is recommended to remove grease, dirt, and other contaminants. A clean surface promotes optimal adhesion and prevents premature detachment.

Question 3: What techniques are most effective for applying adhesive decorations to roller skates?

The use of a squeegee or roller facilitates uniform pressure distribution, minimizing air pockets and ensuring complete contact between the adhesive and the skate surface. Starting from the center and working outwards is advised.

Question 4: How can the edges of adhesive roller skate embellishments be sealed to prevent moisture penetration?

Applying a thin bead of clear sealant around the edges creates a barrier against moisture ingress, mitigating the risk of edge lifting and adhesive failure. Silicone-based sealants are often suitable.

Question 5: What is the recommended procedure for removing adhesive decals from roller skates without damaging the underlying surface?

Applying heat from a hairdryer or heat gun softens the adhesive, enabling easier removal. Residual adhesive can be removed with a citrus-based cleaner or similar solvent. Caution should be exercised to avoid overheating and damaging the skate.

Question 6: How frequently should applied decorations be inspected and maintained?

Regular inspections, ideally conducted weekly, allow for the early detection of wear, damage, or edge lifting. Prompt attention to these issues prevents further degradation and prolongs the decoration’s lifespan.

In summation, successful application and maintenance of roller skate adornments hinge on meticulous material selection, surface preparation, and application techniques. Adherence to these guidelines optimizes both aesthetic appeal and long-term performance.

The succeeding section will address sourcing options and vendor considerations.

Conclusion

This exploration of roller skate stickers has underscored the importance of material durability, adhesive strength, design complexity, application technique, and weather resistance in achieving optimal performance and longevity. These factors, when carefully considered, contribute to a cost-effective and visually appealing means of personalizing roller skates. Failure to address these critical elements can result in premature degradation, compromised aesthetics, and increased maintenance demands.

The informed selection and application of roller skate stickers represents a deliberate investment in both self-expression and equipment protection. By prioritizing quality materials and proper techniques, skaters can ensure their personalized embellishments withstand the rigors of use, contributing to a more rewarding and visually compelling skating experience. Continued adherence to best practices will maximize the value and impact of these decorative elements.