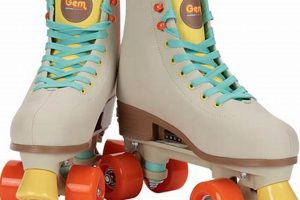

This specific product refers to a type of recreational equipment designed for gliding movement over surfaces. Characterized by boots attached to a frame with four wheels, this particular model is intended for both indoor and outdoor use. It caters to individuals interested in activities ranging from casual skating to more advanced maneuvers at skate parks or roller rinks. The defining feature is its construction, materials, and intended use-case, which balances performance and accessibility for a broad spectrum of users.

This particular item’s significance lies in offering an accessible entry point to the world of roller skating. Its design blends durability with comfort, appealing to beginners while still providing sufficient performance characteristics for experienced skaters. Historically, similar products have contributed to the popularization of roller skating as a recreational and competitive activity, providing a foundation for skill development and community engagement. The enduring appeal reflects the intrinsic enjoyment derived from the activity and the product’s role in facilitating that experience.

The following discussion will delve into specific attributes, covering elements such as wheel composition, boot construction, and frame materials. Subsequent sections will also address proper maintenance, safety considerations, and comparisons to similar skating equipment, ultimately providing a complete understanding of this recreational item.

Enhancing the Skating Experience

Optimizing enjoyment and longevity involves understanding key aspects of operation and maintenance.

Tip 1: Wheel Maintenance: Regularly inspect wheel bearings for debris and lubrication. Properly maintained bearings ensure smooth rolling and reduce wear.

Tip 2: Boot Care: Clean the boot exterior after each use to remove dirt and prevent material degradation. Use appropriate cleaning agents for the boot material.

Tip 3: Frame Inspection: Routinely check the frame for any signs of damage, such as cracks or bends. A damaged frame compromises stability and safety.

Tip 4: Proper Fit: Ensure a snug and comfortable fit to prevent blisters and maintain control. Avoid overly tight or loose fits.

Tip 5: Secure Fastenings: Double-check all straps, buckles, and laces before each use. Secure fastenings are crucial for stability and preventing falls.

Tip 6: Surface Awareness: Select appropriate skating surfaces to minimize wear on wheels and enhance control. Avoid rough or uneven terrain when possible.

Tip 7: Gradual Skill Progression: Develop skills progressively to avoid injury. Start with basic maneuvers and gradually increase complexity.

Adhering to these guidelines contributes to extended product lifespan, improved performance, and a safer skating experience.

The succeeding section will address frequently asked questions related to this equipment, further enhancing user understanding.

1. Wheel Durometer

Wheel durometer, a measure of a wheel’s hardness, significantly affects the performance characteristics of this skating equipment. The durometer rating, typically expressed on the A scale, indicates the wheel’s resistance to indentation. Lower durometer values correspond to softer wheels, offering increased grip and shock absorption. Conversely, higher durometer values denote harder wheels, promoting greater speed and reduced rolling resistance. For instance, skaters primarily using the product on smooth indoor surfaces, such as rinks, may favor wheels with a higher durometer (e.g., 95A or higher) to maximize speed. Those skating on rougher outdoor terrain might benefit from a lower durometer (e.g., 78A-85A) for enhanced grip and comfort.

The selection of an appropriate durometer impacts various aspects of skating. Harder wheels translate to a faster roll but may result in a less comfortable ride and reduced control on uneven surfaces. Softer wheels provide better traction and absorb vibrations but can exhibit slower speeds and increased wear. Consider a scenario where a skater intends to perform complex maneuvers at a skate park; a medium-range durometer (e.g., 85A-90A) might provide a balance of speed and grip necessary for executing tricks safely and effectively. This underscores the need to assess intended use and skating environment when choosing the wheel durometer.

In summary, wheel durometer is a critical factor influencing the performance and suitability of this equipment. Proper selection depends on the skater’s skill level, intended use, and the characteristics of the skating surface. Misalignment between wheel durometer and skating conditions can lead to compromised performance, reduced comfort, or accelerated wheel wear. Therefore, understanding the durometer scale and its implications is essential for optimizing the skating experience and ensuring longevity of the equipment.

2. Boot Material

The selection of boot material directly influences the performance, comfort, and durability of this skating equipment. The boot provides structural support to the skater’s ankle and foot, transmitting forces to the frame and wheels. Consequently, the material properties of the boot are paramount. Common materials include vinyl, leather, and synthetic composites, each offering a distinct balance of attributes. For example, vinyl boots, often found on entry-level models, provide affordability and ease of maintenance but typically offer less support and breathability compared to leather or composite alternatives.

Leather boots, historically prevalent, provide a combination of support, flexibility, and breathability. Their ability to mold to the skater’s foot over time contributes to a personalized fit. However, leather requires regular maintenance to prevent drying and cracking. Synthetic composites, increasingly common in contemporary designs, offer a balance of durability, support, and weight reduction. These materials can be engineered to provide specific performance characteristics, such as enhanced stiffness for improved power transfer or increased flexibility for greater maneuverability. Consider a scenario where a skater prioritizes long-distance comfort; a boot constructed from a breathable synthetic composite with strategically placed padding might be preferable to a rigid leather boot. Conversely, a skater engaging in aggressive skating disciplines might require a boot with a reinforced composite shell for maximum support and protection.

In summary, the boot material constitutes a critical determinant of the overall skating experience. Selecting a material that aligns with the skater’s skill level, intended use, and environmental conditions is essential for optimizing performance, comfort, and longevity. Neglecting to consider the boot material’s properties can result in compromised support, accelerated wear, or diminished comfort, underscoring the importance of careful evaluation during the purchasing process.

3. Frame Strength

Frame strength is a critical factor influencing the performance, safety, and longevity of these roller skates. As the structural foundation connecting the boot to the wheels, the frame bears the skater’s weight and endures significant stresses during use. The integrity of the frame directly impacts stability, maneuverability, and the ability to withstand impacts.

- Material Composition and Impact Resistance

The materials used in frame construction directly affect its ability to withstand impacts and maintain structural integrity. Aluminum alloys are commonly employed due to their high strength-to-weight ratio, offering a balance of durability and maneuverability. Steel frames, while heavier, provide superior impact resistance, making them suitable for aggressive skating styles. Plastic frames, often found on entry-level models, offer cost-effectiveness but possess lower impact resistance, limiting their suitability for demanding applications. A frame constructed from a high-grade aluminum alloy will demonstrably better withstand the stresses associated with jumps, grinds, and other aggressive maneuvers compared to a frame made from a lower-grade material or plastic. The choice of material directly impacts the skater’s confidence and the product’s long-term reliability.

- Frame Geometry and Stress Distribution

The geometric design of the frame plays a crucial role in distributing stresses and preventing premature failure. Frames with reinforced stress points, such as around the wheel mounting areas and at the boot attachment points, are better equipped to withstand high loads. The frame’s profile also influences its torsional rigidity, affecting the skater’s ability to transfer energy efficiently and maintain control during turns. A well-designed frame will minimize flex under load, ensuring consistent wheel contact with the skating surface and maximizing power transfer. Conversely, a poorly designed frame may exhibit excessive flex, leading to instability and reduced performance.

- Manufacturing Process and Quality Control

The manufacturing process employed in creating the frame directly affects its overall strength and reliability. Frames produced using precision casting or machining techniques typically exhibit higher dimensional accuracy and material density compared to those manufactured using less precise methods. Rigorous quality control procedures, including non-destructive testing, are essential for identifying defects and ensuring that each frame meets specified strength requirements. A frame produced with meticulous attention to detail and subjected to stringent quality control measures will exhibit a significantly lower risk of failure under stress compared to one manufactured with less rigorous processes.

- Frame Length and Wheelbase

The length of the frame and the resulting wheelbase (distance between the axles of the front and rear wheels) influence stability and maneuverability. Shorter frames offer increased agility and responsiveness, making them suitable for tight turns and quick maneuvers. Longer frames provide greater stability at higher speeds, making them advantageous for speed skating and long-distance cruising. The appropriate frame length depends on the skater’s intended use and skill level. A shorter frame might be preferred by a skater focused on artistic skating, while a longer frame might be chosen by a skater participating in speed competitions.

In summary, frame strength is a multifaceted attribute that profoundly impacts the performance and safety of these roller skates. The material composition, geometric design, manufacturing process, and frame length all contribute to its overall integrity and ability to withstand the stresses of skating. Skaters should carefully consider these factors when selecting equipment to ensure that the frame is appropriately suited to their intended use and skill level. Compromising on frame strength can lead to reduced performance, increased risk of injury, and premature equipment failure.

4. Bearing Precision

Bearing precision, measured by the Annular Bearing Engineering Committee (ABEC) scale or similar ISO standards, significantly influences the performance characteristics of “rock gt 50 roller skates.” Bearings facilitate wheel rotation, and their precision directly correlates to rolling efficiency, speed, and the overall skating experience. Higher ABEC ratings (e.g., ABEC-7 or ABEC-9) signify tighter tolerances and smoother operation, reducing friction and enabling faster, more effortless gliding. This is particularly relevant for skaters seeking to maximize speed and minimize energy expenditure. Conversely, lower ABEC ratings (e.g., ABEC-1 or ABEC-3) indicate looser tolerances and increased friction, resulting in slower speeds and requiring more effort to maintain momentum. An example of this cause-and-effect relationship can be seen comparing experienced skater who need to do some trick. A trick that requires much energy will make the different for skater with high or low ABEC.

The practical significance of understanding bearing precision extends to maintenance and replacement considerations. Higher-precision bearings, while offering superior performance, may also be more susceptible to contamination and require more frequent cleaning and lubrication to maintain optimal efficiency. Lower-precision bearings, while slower, tend to be more durable and require less maintenance. The choice between high and low bearing ABEC ratings in this model also reflects a balance between performance requirements and maintenance demands. Some skaters will buy another bearing or do some modifications for performance improvement.

In summary, bearing precision is a critical determinant of the performance and maintenance requirements of “rock gt 50 roller skates.” Understanding the ABEC rating and its implications allows skaters to make informed decisions based on their skill level, skating style, and willingness to invest in maintenance. The correct bearing allows you to skate with less energy.

5. Skate Type

The classification of “rock gt 50 roller skates” within a specific skate type is paramount to understanding its intended application and performance characteristics. Skate type dictates design features, component selection, and overall suitability for particular skating disciplines. Recreational skates, artistic skates, speed skates, and aggressive skates each exhibit distinct attributes tailored to their respective purposes. The “rock gt 50 roller skates” model likely aligns most closely with recreational or possibly artistic skate categories, given its implied design for general use rather than specialized competitive purposes. The practical significance of this classification lies in managing user expectations and ensuring the product meets the specific demands of the intended activity.

If classified as a recreational skate, the “rock gt 50 roller skates” model would prioritize comfort, ease of use, and versatility across various skating surfaces. Such a configuration would emphasize a supportive boot, moderately sized wheels with a balanced durometer for both indoor and outdoor use, and a durable frame capable of withstanding general wear and tear. Conversely, should the model lean towards artistic skating, the design would incorporate features that enhance maneuverability and precision, such as a shorter frame, adjustable toe stops, and a more responsive boot. The alignment with a specific skate type directly influences the product’s value proposition and its target audience. For example, marketing a recreational skate to aggressive skaters would lead to dissatisfaction due to the product’s inherent limitations in handling the stresses of ramps, grinds, and other high-impact maneuvers.

In summary, skate type serves as a crucial contextual element for interpreting the design and functionality of “rock gt 50 roller skates.” Accurate classification is essential for aligning product capabilities with user expectations and ensuring suitability for the intended skating discipline. Challenges arise when ambiguity exists regarding the skate type, potentially leading to misapplication and diminished user satisfaction. Clarifying the intended application through explicit categorization and detailed specifications is, therefore, paramount to effective product positioning and user guidance.

Frequently Asked Questions About rock gt 50 roller skates

This section addresses common inquiries regarding this skating equipment, providing objective information to enhance understanding and facilitate informed decision-making.

Question 1: What is the recommended maintenance schedule for these roller skates?

Regular maintenance is essential for optimal performance and longevity. It is advised to clean the wheels and bearings after each use, particularly after skating in dusty or dirty conditions. Inspect the frame and boot for any signs of damage or wear and tear, and address any issues promptly. Lubricate the bearings every few weeks, depending on usage frequency. The boot should be cleaned and conditioned periodically to maintain its integrity.

Question 2: What is the maximum weight capacity of these roller skates?

The maximum weight capacity is typically specified by the manufacturer and should be consulted before use. Exceeding the stated weight limit can compromise the structural integrity of the skates, leading to potential damage and safety hazards. Refer to the product documentation or manufacturer’s website for the precise weight capacity.

Question 3: What type of wheel is best suited for outdoor use with these roller skates?

For outdoor use, wheels with a lower durometer rating (e.g., 78A-85A) are generally recommended. Softer wheels provide better grip and shock absorption on uneven surfaces, enhancing comfort and control. Softer durometer provides for the vibration reduction and smooth feeling during the activity.

Question 4: How are the bearings replaced in these roller skates?

Replacing the bearings requires specialized tools and a degree of mechanical aptitude. The process involves removing the wheels from the frame, extracting the old bearings using a bearing press or similar tool, and then pressing the new bearings into place. It is essential to ensure that the bearings are properly seated and aligned to avoid damage or premature wear. If unsure, consult a qualified skate technician.

Question 5: What is the appropriate boot size for optimal comfort and performance?

The ideal boot size depends on individual foot measurements. It is recommended to measure the length and width of the foot and consult the manufacturer’s sizing chart. A snug but comfortable fit is desired, allowing for adequate support without restricting circulation. Wear the type of socks typically used for skating during the fitting process. Do not rely on the size of your usual footwear as the skate sizes can vary.

Question 6: Are replacement parts readily available for these roller skates?

The availability of replacement parts depends on the manufacturer and the specific model of the skates. Common replacement parts, such as wheels, bearings, and toe stops, are generally accessible through online retailers and specialty skate shops. However, more specialized components may require contacting the manufacturer directly. Researching parts availability before purchasing is recommended.

In summary, proper maintenance, adherence to weight limits, appropriate wheel selection, and accurate sizing are critical factors for safe and enjoyable use of these roller skates. The more technical issues of bearing replacement, please ask professional or watch on the internet for the safety.

The following section will provide a comparative analysis of similar skating equipment, highlighting the strengths and weaknesses of “rock gt 50 roller skates” relative to its competitors.

Concluding Assessment

The preceding analysis has explored the multifaceted attributes of “rock gt 50 roller skates,” encompassing aspects such as wheel durometer, boot material, frame strength, bearing precision, and skate type classification. Furthermore, it has addressed common maintenance concerns and provided guidance on informed purchasing decisions. The investigation reveals that optimal utilization necessitates a comprehensive understanding of these elements and their interdependencies, facilitating tailored selection based on intended use and user proficiency.

Ultimately, the enduring value of “rock gt 50 roller skates,” or any comparable skating equipment, resides in its capacity to provide a safe, engaging, and physically beneficial recreational outlet. Continued advancements in materials science and design engineering will undoubtedly shape the evolution of this equipment, further enhancing performance and accessibility. Careful consideration of the factors outlined herein will empower consumers to make informed choices, maximizing both enjoyment and the long-term value of their investment in the pursuit of this activity.

![Best Ladies Roller Skates [Gear]: Roll in Style! How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Ladies Roller Skates [Gear]: Roll in Style! | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-546-300x200.jpg)