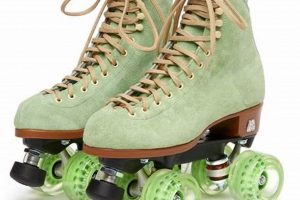

Vintage-inspired quad roller skates, often characterized by high-top boots, vibrant color schemes, and classic wheel configurations, represent a nostalgic connection to the sport’s golden era. These skates frequently incorporate features reminiscent of earlier designs, such as traditional lacing systems, durable leather or synthetic uppers, and a focus on maneuverability and agility. Examples include skates replicating the styles popular in the 1970s and 1980s, featuring bold stripes, padded collars, and resilient toe stops.

The significance of these revived skate designs lies in their appeal to both seasoned roller derby athletes and newcomers seeking a blend of performance and aesthetic. Their construction often prioritizes comfort and control, allowing skaters to execute complex maneuvers with confidence. Furthermore, the historical resonance of these skates adds a layer of cultural appreciation to the sport, fostering a sense of community and shared heritage among participants. The durability and repairability associated with these skates contribute to their enduring value.

This analysis provides a foundation for exploring specific aspects of skate selection, maintenance, and the impact of various design elements on overall performance. Subsequent discussions will address considerations for choosing the optimal skate type, essential maintenance procedures to ensure longevity, and the influence of wheel composition and bearing quality on skating experience.

Essential Considerations for Vintage-Inspired Quad Roller Skates

Proper selection and maintenance of skates embodying the aesthetic of roller derby’s past are crucial for optimal performance and longevity. Attention to specific features and diligent upkeep can significantly enhance the skating experience.

Tip 1: Boot Material Assessment: Leather or durable synthetic uppers are preferred for their resilience and ability to mold to the wearer’s foot over time. Inspect stitching and reinforcement points for signs of quality construction.

Tip 2: Plate and Chassis Evaluation: The skate plate, typically aluminum or nylon, should be robust and properly aligned. Examine mounting points for secure attachment to the boot. Consider the angle of the kingpin, as this influences turning radius and stability.

Tip 3: Wheel Durometer Selection: Wheel hardness, measured in durometers, affects grip and roll. Softer wheels (lower durometer) provide greater grip on smooth surfaces, while harder wheels (higher durometer) offer faster roll on slick surfaces. Choose based on typical skating environment.

Tip 4: Bearing Maintenance: Regular cleaning and lubrication of wheel bearings are essential for smooth, efficient roll. Remove bearings periodically, clean with solvent, and lubricate with a suitable bearing oil or grease.

Tip 5: Toe Stop Adjustment: The toe stop’s height and angle influence braking and stability during stops and starts. Adjust the toe stop to a comfortable position that allows for controlled deceleration without obstructing movement.

Tip 6: Lacing Technique: Proper lacing ensures a secure and comfortable fit. Tighten laces firmly from the toe to the ankle, paying attention to pressure points. Utilize different lacing patterns to accommodate foot shape and desired level of support.

Tip 7: Routine Inspection: Conduct regular inspections of all skate components, including wheels, bearings, plates, and boots. Address any signs of wear or damage promptly to prevent further deterioration and ensure safety.

Prioritizing these considerations ensures the longevity, performance, and safety of vintage-inspired quad roller skates, allowing skaters to fully appreciate the blend of nostalgia and functionality they offer.

Attention will now turn to a discussion of customizing these skates and how to enhance their performance through personalized modifications.

1. Boot Construction

Boot construction in skates directly impacts performance, comfort, and durability. The materials used, the stitching techniques employed, and the overall design determine how well the skate transfers energy from the skater’s body to the wheels. In skates that evoke a vintage aesthetic, high-top designs are common, providing ankle support crucial for roller derby maneuvers. Leather, a material often associated with a vintage look, offers durability and molds to the skater’s foot over time, enhancing comfort and control. Conversely, synthetic materials may offer lighter weight and different levels of water resistance. Poor boot construction can result in ankle instability, reduced power transfer, and premature wear, affecting the skater’s ability to execute complex movements and potentially leading to injury. A well-constructed boot provides a secure and responsive platform, optimizing performance and extending the lifespan of the skates.

The stitching patterns used to assemble the boot contribute significantly to its structural integrity. Reinforcement at stress points, such as the toe area and around the ankle, prevents tearing and prolongs the boot’s lifespan. The lacing system also plays a crucial role, allowing skaters to customize the fit and level of support. A poorly designed lacing system can lead to uneven pressure distribution, causing discomfort and hindering performance. Consider, for example, the differences between a simple, straight lacing pattern and a more intricate crisscross pattern; the latter typically provides greater ankle support and a more secure fit. The internal padding and lining of the boot also contribute to comfort and impact absorption, particularly important in the high-impact environment of roller derby.

In summary, boot construction is a fundamental element influencing the overall effectiveness and longevity of the skates. Paying close attention to the materials, stitching, lacing system, and internal padding during skate selection ensures a comfortable, supportive, and durable platform for optimal performance. Neglecting these aspects can result in compromised performance, increased risk of injury, and a shorter lifespan for the skates. The proper boot construction connects directly to the skater’s control, power, and overall enjoyment of the sport. This underscores the importance of careful assessment when choosing skates designed with vintage aesthetics in mind.

2. Plate Material

The plate material in roller derby skates significantly affects maneuverability, stability, and power transfer. In the context of skates styled after historical designs, the choice of plate material balances aesthetic authenticity with modern performance requirements.

- Aluminum Plate Characteristics

Aluminum plates offer a high strength-to-weight ratio, providing rigidity for efficient energy transfer during acceleration and directional changes. Different aluminum alloys are used, with variations in hardness and tensile strength. For instance, 7075 aluminum is known for its high strength, making it suitable for skaters requiring maximum responsiveness. Its use may deviate from historical accuracy but enhances performance.

- Nylon Plate Characteristics

Nylon plates, sometimes reinforced with fiberglass, provide a lighter weight alternative to aluminum. While less rigid, nylon offers greater vibration absorption, potentially improving comfort during extended skating sessions. These were common in some historical periods and offer a more authentic feel for skaters prioritizing nostalgia over peak performance. However, they can flex under high stress, reducing responsiveness.

- Kingpin Angle Influence

The angle of the kingpin, which connects the plate to the trucks and wheels, influences turning radius and stability. Steeper angles offer tighter turns, favored by agile skaters. Shallower angles provide greater stability at higher speeds. The plate material influences how accurately and consistently the kingpin angle can be maintained under stress. Aluminum plates generally offer greater precision in this regard.

- Impact on Skate Responsiveness

The stiffness of the plate directly impacts the responsiveness of the skate. A stiffer plate, typically aluminum, transfers energy more efficiently, allowing for quicker reactions to skater input. This is critical for rapid maneuvers and precise control. A more flexible plate, like nylon, may offer a more forgiving feel, but can sacrifice responsiveness in critical situations. The choice of plate material must align with the skater’s skill level and skating style.

The selection of plate material in skates therefore represents a compromise between historical accuracy, performance demands, and skater preference. While an aluminum plate might offer superior performance characteristics for modern roller derby, a nylon plate could better capture the feel of earlier skate designs, appealing to those prioritizing aesthetic authenticity. Understanding these trade-offs is crucial when selecting skates that blend retro style with functional performance.

3. Wheel Durometer

Wheel durometer, a measurement of a wheel’s hardness, is a critical factor in determining the performance characteristics of roller derby skates, including those designed with a retro aesthetic. The durometer rating directly affects grip, roll speed, and overall maneuverability. Understanding this measurement is essential for selecting wheels that complement both the skate’s design and the skater’s style.

- Durometer Scale Overview

The durometer scale, typically using the “A” scale for roller derby wheels, ranges from softer (e.g., 78A) to harder (e.g., 99A and above). Lower numbers indicate greater softness and increased grip, while higher numbers indicate greater hardness and enhanced roll speed. The choice of durometer is contingent upon the skating surface and desired performance characteristics.

- Grip vs. Roll Trade-off

Softer wheels (lower durometer) provide increased grip on smoother surfaces, allowing for quicker stops and more controlled turns. This is advantageous for skaters prioritizing agility. Harder wheels (higher durometer) offer less grip but enhanced roll speed, making them suitable for skaters seeking to maximize velocity and maintain momentum. The selection process inherently involves a trade-off between these two attributes.

- Surface Considerations

The skating surface directly influences the optimal wheel durometer. Slick surfaces, such as polished concrete, generally benefit from harder wheels to maximize roll speed. Conversely, rougher surfaces, such as sport court or unpolished concrete, require softer wheels to provide adequate grip and prevent slippage. Adaptation to the specific surface conditions is paramount for optimal performance.

- Impact on Retro Skate Performance

In the context of skates emulating historical designs, the choice of wheel durometer can either enhance or detract from the intended aesthetic and performance. While a harder wheel may offer superior roll speed for modern competitive play, a softer wheel might better replicate the feel of earlier skate models, prioritizing a more traditional skating experience. Selection should be guided by the skater’s preference for authenticity versus contemporary performance.

The interplay between wheel durometer and surface conditions determines the effectiveness of skate performance. While harder wheels excel on smooth, slick surfaces by providing less friction and more speed, softer wheels compensate for the irregularities of rougher surfaces, providing greater grip and control. Therefore, a nuanced understanding of durometer and its connection to skate surfaces remains essential for skaters of all skill levels who appreciate vintage-inspired designs.

4. Bearing Precision

Bearing precision is a fundamental, albeit often overlooked, aspect of skate performance. In the realm of skates designed to evoke the aesthetics of roller derby’s past, the integration of high-precision bearings can significantly enhance functionality, bridging the gap between vintage appearance and contemporary performance capabilities. The following points delineate the importance of bearing precision within the context of these skates.

- ABEC Rating System

The Annular Bearing Engineering Committee (ABEC) rating system, while not a definitive measure of overall bearing quality, provides a standardized metric for gauging bearing tolerances. Higher ABEC ratings (e.g., ABEC-7, ABEC-9) indicate tighter manufacturing tolerances, potentially resulting in smoother roll and reduced friction. Skates designed with a vintage look can benefit from the incorporation of higher ABEC-rated bearings to deliver a more efficient skating experience, even while maintaining a retro aesthetic.

- Material Composition and Durability

Bearing materials, such as steel or ceramic, influence durability and resistance to wear. Ceramic bearings, though typically more expensive, offer increased hardness and reduced friction compared to steel counterparts. In skates intended to replicate older designs, the choice of bearing material can be strategically balanced. Steel bearings may align more closely with historical accuracy, while ceramic bearings can augment performance without significantly altering the skate’s external appearance. The internal components are crucial in performance, regardless of external appearances.

- Lubrication and Maintenance

Proper lubrication is paramount for maintaining bearing precision and extending bearing lifespan. Regular cleaning and lubrication with appropriate bearing oil or grease minimizes friction and prevents corrosion. Skates featuring vintage-inspired designs are not exempt from this requirement; diligent maintenance of the bearings is essential for preserving optimal roll characteristics, irrespective of the skate’s external style.

- Impact on Roll Efficiency

Bearing precision directly affects roll efficiency, dictating how smoothly and efficiently the wheels rotate. Bearings with tighter tolerances and proper lubrication minimize energy loss due to friction, allowing skaters to maintain speed with less effort. Integrating high-precision bearings into retro-styled skates can yield a tangible improvement in performance, enabling skaters to achieve greater speed and endurance without compromising the skate’s vintage appeal.

The integration of high-precision bearings within skates contributes to enhancing the skater experience. By carefully considering ABEC ratings, material composition, and maintenance practices, skaters can optimize the performance of their vintage-inspired equipment, achieving a harmonious balance between aesthetic appeal and functional capability. Ignoring bearing precision can negate the benefits of other high-quality components, resulting in suboptimal performance and diminished skating enjoyment.

5. Toe Stop Design

The design of the toe stop is a crucial element influencing safety, agility, and braking effectiveness in roller derby skates, especially those styled to emulate retro designs. Toe stops facilitate rapid stops, controlled starts, and contribute significantly to balance and stability during dynamic maneuvers. In the context of skates fashioned after vintage models, the design and adjustability of the toe stop may deviate from contemporary standards, requiring careful consideration. A poorly designed or improperly adjusted toe stop can compromise a skater’s ability to execute fundamental movements, potentially increasing the risk of falls and injuries. The component’s importance directly relates to the ability of the skater to control their movements, influencing overall performance and safety.

Historically, toe stops consisted primarily of natural rubber or early synthetic compounds, offering varying levels of grip and durability. Modern toe stops incorporate advancements in materials science, utilizing specialized polymers that provide enhanced grip and resistance to wear. The size, shape, and adjustability of the toe stop also influence its functionality. Larger toe stops offer a broader contact surface, providing increased stability and braking power, while smaller toe stops allow for greater maneuverability and reduced weight. Adjustable toe stops enable skaters to customize the height and angle of the contact point, optimizing performance based on individual skating style and preference. For example, a jammer might prefer a smaller, more agile toe stop, while a blocker may opt for a larger, more stable one. The threads can wear off over time with constant use, which needs to be changed. This will save time from falling during game or practices.

Ultimately, the toe stop represents a crucial interface between the skater and the skating surface, with its design influencing a range of essential performance attributes. When considering skates that embody a vintage aesthetic, evaluating the toe stop’s design and adjustability is paramount. Balancing historical accuracy with functional requirements is critical to ensure that skaters can effectively utilize their skates while maintaining safety and control. The toe stop’s impact extends beyond simple braking, affecting a skater’s confidence and ability to execute complex maneuvers, thus underscoring its fundamental importance within the broader context of skate design.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, maintenance, and performance characteristics of skates designed to emulate the aesthetic of roller derby’s past.

Question 1: What distinguishes “retro roller derby skates” from modern alternatives?

These skates are generally distinguished by design elements reminiscent of earlier eras, such as high-top boots, traditional lacing systems, and vibrant color schemes. Performance characteristics may differ, with modern skates often prioritizing lightweight materials and advanced wheel technologies. Skates styled after historical designs may emphasize aesthetic authenticity over peak performance.

Question 2: How does boot material impact the performance of “retro roller derby skates”?

Boot material affects comfort, durability, and energy transfer. Leather boots offer durability and conform to the foot over time but may require a break-in period. Synthetic boots can provide lighter weight and varying levels of water resistance. The optimal material depends on individual preferences and intended usage.

Question 3: What are the key considerations when selecting a plate for “retro roller derby skates”?

Plate material influences maneuverability and responsiveness. Aluminum plates offer rigidity and efficient energy transfer, while nylon plates provide lighter weight and greater vibration absorption. The kingpin angle also affects turning radius and stability. The selected plate should align with the skater’s skill level and skating style.

Question 4: How does wheel durometer affect the performance of “retro roller derby skates”?

Wheel durometer dictates grip and roll characteristics. Softer wheels (lower durometer) provide greater grip on smooth surfaces, while harder wheels (higher durometer) offer faster roll on slick surfaces. The choice of durometer should be based on the typical skating environment and desired performance balance.

Question 5: What maintenance procedures are essential for preserving the longevity of “retro roller derby skates”?

Regular cleaning and lubrication of wheel bearings are crucial for smooth roll. Inspection of boot stitching, plate mounting points, and toe stop condition is also necessary. Prompt repair of any signs of wear or damage prevents further deterioration and ensures safety.

Question 6: Can “retro roller derby skates” be used in modern competitive roller derby?

While skates styled after historical designs can be used, competitive performance may be limited by certain design characteristics. Modern skates often incorporate advanced materials and technologies optimized for agility, speed, and impact resistance. Skaters should evaluate their individual needs and priorities when selecting equipment for competitive play.

Selection of “retro roller derby skates” requires careful evaluation of design, materials, and performance characteristics. Proper maintenance is essential for preserving functionality and ensuring safety.

The next section will delve into the topic of customization and upgrades, exploring options for enhancing the performance and aesthetic of “retro roller derby skates.”

Retro Roller Derby Skates

This exploration has dissected various facets of skates designed with a vintage aesthetic, emphasizing the significance of boot construction, plate material, wheel durometer, bearing precision, and toe stop design. Each component contributes uniquely to the overall skating experience, impacting performance, safety, and longevity. Understanding the interplay between these elements allows for informed decision-making during skate selection and maintenance.

The sustained interest in skates styled after roller derby’s past underscores a continuing appreciation for the sport’s heritage. Whether prioritizing historical accuracy or modern performance enhancements, a comprehensive understanding of the aforementioned factors ensures that skaters can effectively utilize and maintain their equipment. Continued innovation in materials and design will undoubtedly further refine the capabilities of skates, regardless of their aesthetic origins. Therefore, diligent research and informed choices remain paramount for all participants seeking to engage with roller derby, either competitively or recreationally.