This specialized athletic footwear incorporates an integrated inflation mechanism. This feature allows the user to customize the fit of the skate to their individual foot shape, enhancing comfort and performance on the ice. This adjustment is achieved through the use of a pump that inflates internal bladders within the skate’s structure.

The principal advantage lies in the personalized fit, which contributes to increased stability and control during skating. This personalized fit can potentially reduce foot fatigue and enhance power transfer. These types of skates represent a significant development in sports equipment design, offering a blend of technology and ergonomic considerations. They once represented a notable innovation in the pursuit of enhanced athletic performance.

The subsequent sections will delve into the specific components and construction materials, fitting considerations, maintenance procedures, and a comparison with alternative skate designs. These aspects are pertinent to understanding the operational characteristics and optimal utilization of the equipment.

Optimization Strategies

The following recommendations aim to maximize the benefits and longevity of skates equipped with an internal inflation system.

Tip 1: Proper Inflation Technique: Avoid over-inflation. Over-inflation can compromise the structural integrity of the internal bladders and reduce comfort. Inflate in short bursts, checking the fit incrementally until a secure, comfortable feel is achieved.

Tip 2: Gradual Break-In Period: Allow for a gradual adaptation period. Initial use should involve shorter skating sessions to allow the foot to adjust to the customized fit. This minimizes the risk of blisters or discomfort.

Tip 3: Post-Use Deflation: Deflate the bladders after each use. This allows the materials to return to their original shape, potentially extending the lifespan of the internal inflation system.

Tip 4: Regular Inspection: Conduct routine inspections for signs of wear and tear. Examine the inflation mechanism, the bladders (if visible), and the overall structural integrity of the skate. Address any issues promptly.

Tip 5: Proper Storage: Store skates in a dry, well-ventilated environment. Avoid prolonged exposure to moisture or extreme temperatures, as these conditions can degrade the materials.

Tip 6: Blade Maintenance: Consistent blade care is essential. Regularly sharpen the blades to maintain optimal edge control and prevent premature wear.

Tip 7: Seek Professional Assistance: Consult a qualified skate technician for fitting adjustments or repairs. Attempting complex repairs without proper training can damage the equipment.

Adherence to these guidelines can significantly enhance the performance and extend the operational life of specialized ice skates.

The subsequent discussion will summarize the core findings and offer a concluding perspective on the overall value and application of these skates.

1. Customizable Fit

The integration of customizable fit within a skate represents a significant departure from traditional, static sizing models. The inflation mechanism allows the user to modulate the internal volume of the skate, thereby accommodating variations in foot shape and volume. The intended effect is a more secure and contoured fit, minimizing internal movement during skating maneuvers.

This adjustment capability is pertinent in instances where standard skate sizing fails to provide adequate support or results in discomfort due to pressure points. Consider a skater with slightly asymmetrical feet; the inflation system permits independent adjustment to each foot, addressing discrepancies that would otherwise necessitate compromises in fit. Similarly, a skater whose foot volume fluctuates with temperature or activity level can fine-tune the fit throughout a skating session.

The inherent flexibility of the integrated inflation system addresses limitations associated with fixed-size skates. Though not a complete substitute for professional skate fitting, it offers a degree of personalization that enhances comfort, stability, and potentially, skating performance. It is important to note that proper inflation technique is essential to avoid over-inflation, which can compromise the structural integrity of the boot or lead to discomfort.

2. Inflation Technology

Inflation technology, as incorporated within specialized ice skates, represents a targeted application of pneumatic principles to achieve a customized fit. This technology aims to enhance performance and comfort by allowing users to modulate the internal volume of the skate boot. Its integration within the skate structure necessitates careful consideration of materials, design, and operational parameters.

- Pneumatic Bladder System

The core of the inflation technology is the pneumatic bladder system. This system typically comprises one or more inflatable bladders strategically positioned within the skate boot. These bladders are constructed from a flexible, air-impermeable material capable of withstanding repeated inflation and deflation cycles. The bladders are interconnected via pneumatic lines to an external pump mechanism. Example: Bladders are strategically placed around the ankle to provide support.

- Inflation Mechanism

The inflation mechanism is responsible for delivering pressurized air into the bladder system. This mechanism typically consists of a hand-operated pump integrated into the skate’s construction. The pump draws air from the surrounding environment and forces it into the bladders, increasing their volume and exerting pressure on the user’s foot. The pump design must ensure precise control over the inflation pressure to prevent over-inflation and potential damage to the bladder system. Example: An integrated hand pump allowing user control

- Pressure Release Valve

A pressure release valve is an integral component of the inflation system, enabling the user to deflate the bladders and reduce the internal pressure within the skate boot. This valve typically consists of a spring-loaded mechanism that allows air to escape from the bladder system when activated. The valve design must ensure a controlled and gradual release of pressure to prevent sudden deflation and potential instability. Example: A small button or lever allows deflation

- Material Compatibility and Durability

The long-term performance of the inflation technology hinges on the material compatibility and durability of its components. The bladder material must be resistant to abrasion, puncture, and degradation from exposure to moisture and temperature variations. The pneumatic lines and valve components must be constructed from materials that maintain their integrity under repeated stress and prevent air leakage. The integration of the inflation system must not compromise the structural integrity of the skate boot itself. Example: Use of high-density polymers

The effective implementation of inflation technology hinges on the synergistic interplay of these components. By understanding their individual roles and the interdependencies, one can fully appreciate the capabilities of this type of skate. The success of integrating this technology into skating equipment lies in balancing customization with structural integrity and durability.

3. Performance Enhancement

Specialized ice skates are designed to augment a skater’s capabilities on the ice. The integration of specific design elements contributes to improved efficiency, control, and overall athletic performance. Focus remains on how specific features within this type of skate contribute to tangible improvements in the skater’s abilities.

- Optimized Energy Transfer

Efficient energy transfer is crucial for maximizing speed and agility. The customized fit minimizes foot slippage within the boot, ensuring that a greater proportion of the skater’s effort is directly translated into forward motion. This is particularly relevant during rapid acceleration or directional changes, where any loss of energy can negatively impact performance. Examples: During a hockey game where quick bursts of speed are required.

- Enhanced Ankle Support and Stability

Ankle support is critical for maintaining balance and preventing injuries. The inflatable bladders conform to the contours of the ankle, providing a secure and stable platform. This enhanced stability allows the skater to execute more complex maneuvers with greater confidence and control. It also reduces the risk of ankle sprains or other related injuries. Examples: Performing intricate figure skating routines.

- Improved Responsiveness and Control

The customized fit enhances the skater’s ability to feel and respond to subtle changes in ice conditions. The reduced space between the foot and the boot provides a more direct connection, allowing for quicker and more precise adjustments to maintain balance and control. This is particularly important in competitive skating, where split-second decisions can make the difference between success and failure. Examples: Navigating sharp turns during a speed skating race.

- Reduced Fatigue

By minimizing foot movement and providing enhanced support, the customized fit can help reduce muscle fatigue. This allows skaters to maintain a higher level of performance for longer periods of time. This is particularly beneficial during extended practice sessions or demanding competitions. Examples: During long hockey practices.

These interconnected factors highlight the potential for performance enhancement. They achieve this through a combination of optimized energy transfer, enhanced stability, and improved responsiveness. While individual results may vary, the integration of these design features represents a concerted effort to elevate skating performance through technological innovation.

4. Ankle Support

The correlation between ankle support and this model of ice skates is fundamental to their design and performance. Ankle support within a skate directly impacts stability, control, and injury prevention. The integration of the inflation mechanism directly addresses the need for customized ankle support, enabling users to modulate the internal fit of the boot around the ankle joint. This adjustable support is paramount because individual ankle anatomies vary, and standardized skate designs may not provide adequate support for all users. For example, a skater with a history of ankle instability may find the adjustable support particularly beneficial, as it allows for a tailored level of reinforcement during use.

The consequences of inadequate ankle support in skating can be significant. Insufficient support can lead to ankle sprains, reduced balance, and compromised skating technique. By enabling a customizable fit, this type of skate seeks to mitigate these risks. The inflation system allows for targeted pressure around the ankle, creating a more secure and stable platform. This enhanced stability translates to improved energy transfer during skating, allowing for more efficient strides and sharper turns. Consider a hockey player attempting a rapid change of direction; proper ankle support is essential to maintain balance and prevent injury during this maneuver. The absence of such support could result in a fall or a missed opportunity.

In summary, the adjustable ankle support provided by the inflatable system is a key design element. It contributes directly to user safety, skating performance, and overall comfort. While not a substitute for proper skating technique or professional medical advice, the customized fit offers a valuable tool for skaters seeking to enhance their stability and reduce the risk of ankle-related injuries. The practical significance is clear: enhanced ankle support translates directly into improved confidence and control on the ice.

5. Blade Quality

Blade quality is a critical determinant of performance characteristics. The steel alloy used in the blade’s construction, the precision of the blade’s edges, and the consistency of its curvature directly impact the skater’s ability to execute maneuvers, maintain speed, and control movement on the ice. A higher-quality blade will typically exhibit greater edge retention, reduced friction, and improved resistance to corrosion. For example, a skate with a blade crafted from high-carbon steel will maintain its edge sharpness for a longer duration compared to a skate with a blade made from a lower-grade steel, thus requiring less frequent sharpening and ensuring consistent performance. Proper blade quality also ensures balanced weight distribution to avoid potential for slips and injuries.

The relationship between the overall skate design and the blade is synergistic. While the customizable fit enhances comfort and stability, it is the blade that directly interacts with the ice surface. A well-designed boot will provide a stable platform for the foot and ankle, allowing the skater to apply force efficiently to the blade. However, if the blade itself is of inferior quality, the skater will be unable to fully realize the benefits of the boot’s design. For example, a poorly manufactured blade with inconsistent edges will cause the skater to experience a lack of control, even if the boot provides a perfect fit. This is particularly evident during demanding maneuvers such as crossovers or jumps, where precise edge control is essential.

In summary, blade quality plays an integral role in the overall performance and safety. The material composition, edge precision, and durability of the blade directly influence the skater’s ability to execute maneuvers, maintain control, and avoid injuries. While the inflatable system provides a customized fit for enhanced comfort and stability, its benefits can only be fully realized when paired with a blade of commensurate quality. Skaters should prioritize the quality of the blade as a key factor in their skate selection process, as it directly impacts their on-ice experience. Any compromise on blade quality has implications in performance level, and longevity of the skate.

6. Material Durability

Material durability in the context of specialized ice skates, encompassing both the outer boot and internal components, is crucial for longevity, performance consistency, and user safety. The rigors of ice skating, including exposure to moisture, repeated impacts, and constant flexing, place significant demands on the materials used in skate construction.

- Boot Construction Materials

The outer boot of these skates is typically constructed from synthetic composites, such as reinforced nylon or molded polymers. These materials are selected for their combination of rigidity, impact resistance, and water resistance. Rigidity provides the necessary support for the ankle and foot, while impact resistance protects against collisions with pucks, sticks, or other skaters. Water resistance prevents the absorption of moisture, which can degrade the structural integrity of the boot over time. For example, repeated exposure to moisture can cause the synthetic materials to delaminate or become brittle, leading to premature failure. High-end models incorporate carbon fiber reinforcements to enhance stiffness and reduce weight, improving energy transfer and responsiveness.

- Internal Liner Materials

The internal liner of the skate is responsible for providing comfort, cushioning, and moisture management. Common liner materials include closed-cell foams, which offer excellent cushioning and insulation, and moisture-wicking fabrics, which draw sweat away from the foot to prevent discomfort and odor. The durability of the liner is critical, as it is subject to constant friction and compression during skating. Over time, the foam can compress, reducing its cushioning properties, and the fabric can wear thin or tear. High-quality liners are often treated with antimicrobial agents to inhibit the growth of bacteria and fungi, further extending their lifespan. An example would be a liner that retains its shape after extensive usage.

- Inflation System Components

The inflation system relies on durable materials to maintain air pressure and withstand repeated cycles of inflation and deflation. The bladders are typically constructed from a flexible, air-impermeable polymer, such as polyurethane or thermoplastic elastomer. The pump mechanism consists of a series of valves and seals, which must maintain their integrity under pressure. Failure of any component in the inflation system can compromise the customized fit, reducing support and potentially leading to injury. It can become cracked from extreme hot or cold temperatures, leading to air leakage.

- Blade Mounting System

The connection between the boot and the blade is a critical area for durability. The blade is typically attached to the boot using rivets or screws, which must be securely fastened to prevent loosening or failure. The area around the blade mount is subject to significant stress during skating, particularly during sharp turns or jumps. Reinforcements, such as metal plates or additional layers of composite material, are often incorporated to strengthen this area and prevent cracking or deformation. Corrosion-resistant hardware is essential to prevent rusting or seizing of the fasteners. If the hardware rusts, it may lead to potential injuries.

In conclusion, material durability is an indispensable attribute. Each of these components plays a critical role in ensuring the overall performance, safety, and longevity of the product. Skaters should prioritize skates constructed from high-quality, durable materials, and to inspect their equipment regularly for signs of wear and tear. Adhering to proper maintenance procedures is essential to maximizing the lifespan of the skates and ensuring continued performance on the ice.

7. User Maintenance

User maintenance is integral to preserving the functionality, performance, and lifespan. The sophisticated design of these skates, incorporating an inflatable mechanism, necessitates diligent user care to prevent malfunctions and ensure optimal performance. Neglecting maintenance procedures can lead to compromised functionality, reduced comfort, and, ultimately, premature equipment failure.

Effective maintenance comprises several key areas: 1) Routine cleaning: After each use, the skates should be thoroughly dried to prevent corrosion of the blades and degradation of the boot materials. Excess moisture can compromise the integrity of the inflation system, potentially leading to leaks. 2) Inflation system care: The inflation mechanism should be inspected regularly for signs of damage or wear. Over-inflation should be avoided, as it can stress the internal bladders and reduce their lifespan. The pump and release valve should be kept clean and free of debris to ensure proper operation. 3) Blade maintenance: Sharpening the blades is crucial for maintaining edge control and gliding efficiency. The frequency of sharpening depends on the skater’s usage and the ice conditions. Regular honing can extend the time between professional sharpenings. 4) Storage practices: When not in use, the skates should be stored in a dry, well-ventilated environment. Avoid prolonged exposure to direct sunlight or extreme temperatures, which can damage the materials. Blade guards should be used to protect the blades from nicks and scratches.

Consistent user maintenance translates directly into extended equipment life and enhanced performance. By adhering to recommended cleaning, inspection, and storage protocols, skaters can safeguard their investment and ensure that their equipment remains in optimal condition. Ultimately, user maintenance is not merely a matter of prolonging the lifespan of the skates; it is an integral component of ensuring safety and maximizing the skating experience.

Frequently Asked Questions About Specialized Ice Skates

The following addresses common inquiries regarding the operation, maintenance, and performance of skates equipped with integrated inflation mechanisms.

Question 1: What is the appropriate inflation pressure for ice skates?

Inflation should proceed incrementally, ensuring a snug, secure fit without causing discomfort or restricting circulation. Over-inflation can compromise the structural integrity of the internal bladders. The optimal pressure is subjective and depends on individual foot morphology.

Question 2: How often should ice skate blades be sharpened?

Sharpening frequency depends on usage intensity and ice conditions. Signs indicating a need for sharpening include diminished edge control, reduced gliding efficiency, and a sensation of “slipping” on the ice. A qualified skate technician should perform sharpening to ensure proper edge geometry.

Question 3: What cleaning procedures are recommended for the skate equipment?

Following each use, the skates should be thoroughly dried to prevent corrosion and material degradation. A soft cloth can be used to remove moisture and debris from the boot and blade. The internal liner should be removed and allowed to air dry completely. Avoid using abrasive cleaners or harsh chemicals, as these can damage the skate’s components.

Question 4: What is the expected lifespan?

The lifespan depends on usage frequency, intensity, and adherence to maintenance protocols. With proper care, a high-quality pair can provide several seasons of reliable performance. However, components such as the inflation bladders and blade edges may require periodic replacement.

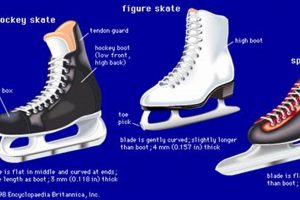

Question 5: Can specialized skates be used for all types of skating?

The suitability for different skating disciplines depends on the specific design. Some are optimized for hockey, while others are tailored for figure skating or recreational use. Consult the manufacturer’s specifications to ensure that the skates are appropriate for the intended application.

Question 6: What are the indicators of a malfunctioning inflation system?

Signs of malfunction include an inability to maintain pressure, uneven inflation, or audible air leaks. If any of these issues are detected, the skates should be inspected by a qualified technician. Attempting to repair the inflation system without proper training can cause further damage.

The information provided is intended for general guidance only. Consult a qualified skate technician or the manufacturer’s instructions for specific recommendations regarding operation and maintenance.

The subsequent section will offer a concluding summary of the key aspects discussed and provide a final perspective on the significance of specialized ice skates.

Conclusion

The preceding analysis has explored the design features, performance implications, and maintenance requirements associated with skates equipped with integrated inflation systems. These skates offer customizable fit, enhanced ankle support, and potential improvements in energy transfer. However, realizing these benefits requires careful attention to proper inflation techniques, consistent maintenance procedures, and consideration of material durability. The blades, inflation system, and boot construction all contribute to the overall performance and longevity.

The decision to adopt specialized ice skates necessitates a thorough assessment of individual needs, skating discipline, and budgetary constraints. While these skates offer advantages in terms of customized fit and performance enhancement, they also require a commitment to diligent maintenance. Whether for competitive athletics or recreational pursuits, the proper selection and care for specialized equipment are essential for maximizing performance and ensuring safety on the ice. Continued advancements in materials science and design methodologies may lead to further refinements in skate technology, but the fundamental principles of fit, blade quality, and maintenance will remain paramount.