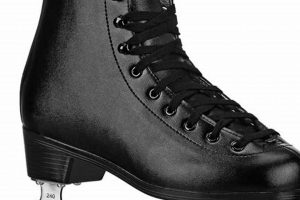

The subject of this exploration refers to footwear specifically designed for gliding across ice surfaces. These items typically feature a rigid boot attached to a blade, enabling movement on ice. For example, individuals participating in ice hockey, figure skating, or recreational skating utilize these specialized boots.

These specific ice-gliding implements are renowned within the skating world for their performance, durability, and technological advancements. Their historical significance in the development of ice sports is considerable, and their continued innovation provides benefits to both professional athletes and recreational users. They represent a commitment to quality and performance in the realm of ice sports equipment.

The following sections will delve into specific aspects of these specialized skates, including construction materials, blade technology, fitting considerations, and the models commonly used in various disciplines of ice skating.

Considerations for Ice Skate Selection and Maintenance

The following points offer practical guidance on selecting and maintaining high-performance ice skates to ensure optimal performance and longevity.

Tip 1: Proper Sizing is Crucial: Ill-fitting ice skates can lead to discomfort, blisters, and impaired performance. Professional fitting at a reputable retailer is recommended to accurately determine the correct size and boot shape.

Tip 2: Blade Sharpness Affects Performance: Maintaining a sharp blade edge is essential for efficient gliding and precise turns. Regular sharpening, performed by a qualified technician, is recommended to prevent slippage and improve control.

Tip 3: Boot Support is Sport-Specific: The level of ankle support required varies based on the skating discipline. Hockey skates prioritize agility and responsiveness, while figure skates demand rigid support for jumps and landings. Choose a model designed for the intended use.

Tip 4: Lacing Technique Impacts Comfort and Performance: The lacing pattern and tension distribution influence boot fit and ankle stability. Experiment with different lacing techniques to achieve a secure and comfortable fit that maximizes performance.

Tip 5: Regular Cleaning Prevents Corrosion: After each use, wipe down the blades with a dry cloth to remove moisture and prevent rust. Blade guards should be used when walking on surfaces other than ice to protect the edges.

Tip 6: Proper Storage Extends Lifespan: Store ice skates in a dry, well-ventilated area to prevent moisture buildup and odor. Remove the insoles after each use to allow them to dry thoroughly.

Tip 7: Professional Maintenance is Advised: Periodic professional maintenance, including blade alignment and boot inspection, can identify and address potential issues before they escalate into major problems.

Adhering to these recommendations will contribute to enhanced skating performance, improved comfort, and extended equipment lifespan.

The next section will explore the advanced technologies incorporated into contemporary high-performance ice skates.

1. Blade Material

The performance of specialized footwear for ice sports is intrinsically linked to the composition of its blade. The material properties dictate crucial factors such as edge retention, glide efficiency, and resistance to corrosion. Certain models utilize high-carbon steel, selected for its ability to maintain a sharp edge over extended use, thereby enhancing a skater’s control and precision. In contrast, lower-grade materials may dull more rapidly, necessitating more frequent sharpening and potentially compromising performance. The steel grade affects durability and resistance to nicks and scratches from ice debris.

The selection of blade material represents a trade-off between cost, performance, and maintenance requirements. Higher-end models often incorporate specialized coatings or treatments to further enhance glide and protect against corrosion. For instance, some blades feature a chrome finish or a titanium coating, which can increase surface hardness and reduce friction. The manufacturing process and tempering of the steel also contribute significantly to its overall quality and longevity. Skaters involved in demanding disciplines such as figure skating or ice hockey often prioritize blades made from premium materials to ensure optimal performance and responsiveness.

Understanding the characteristics of various blade materials is essential for informed decision-making when selecting footwear. Selecting inappropriate blade material can lead to subpar performance and increased maintenance costs. The connection between blade material and overall performance underscores its fundamental role in the design and functionality. The interplay of these aspects must be considered in order to yield the desired result.

2. Boot Stiffness

Boot stiffness, a critical characteristic of specialized footwear, directly influences performance. The rigidity of the boot shell dictates the level of support provided to the ankle and lower leg, consequently affecting energy transfer and responsiveness. A stiffer boot provides enhanced support, enabling skaters to execute powerful strides and maintain stability during complex maneuvers. Conversely, a softer boot offers greater flexibility and range of motion but may compromise support and control at high speeds or during demanding technical elements.

The selection of boot stiffness hinges upon the skater’s skill level, skating discipline, and personal preferences. Beginner skaters typically benefit from moderately stiff boots that offer a balance of support and flexibility, facilitating skill development and minimizing the risk of injury. Advanced skaters, particularly those involved in disciplines such as figure skating or ice hockey, often require stiffer boots that provide the necessary support for executing complex jumps, spins, and high-speed maneuvers. The stiffness rating, typically expressed on a numerical scale, allows skaters to make informed decisions based on their individual needs and performance goals. For example, a hockey player seeking maximum power and agility might choose a boot with a high stiffness rating, while a recreational skater might opt for a more flexible boot offering greater comfort.

Understanding the connection between boot stiffness and performance is crucial for optimizing skating technique and minimizing the risk of injury. Proper boot selection, considering the skater’s skill level and skating discipline, can significantly enhance performance and overall enjoyment. Ultimately, selecting the appropriate boot stiffness level contributes to enhanced stability, efficient power transfer, and reduced fatigue, leading to a more satisfying skating experience.

3. Heat Molding

Heat molding is a customization process applicable to select models of specialized footwear for ice sports. This procedure enhances the fit and comfort by conforming the boot to the unique contours of an individual’s foot, leading to improved performance and reduced discomfort.

- Customized Fit Enhancement

Heat molding allows the composite materials of the boot to become more pliable when exposed to elevated temperatures. This pliability facilitates the molding process, wherein the boot conforms to the specific shape of the skater’s foot. The result is a more personalized fit that minimizes pressure points and hot spots, thereby reducing the likelihood of blisters and discomfort during extended use. An example includes the use of a convection oven or specialized heating equipment to uniformly heat the boot before the skater inserts their foot to mold it.

- Improved Performance Metrics

A precisely fitted boot translates to improved energy transfer and responsiveness. By eliminating excessive space within the boot, heat molding ensures that the skater’s movements are directly translated to the blade, enabling more efficient strides, tighter turns, and enhanced control. This direct connection is crucial for athletes who require immediate and precise responses from their equipment, such as hockey players or figure skaters. An example of this effect is a skater experiencing improved acceleration due to less energy being wasted on boot movement.

- Materials and Process Variations

The effectiveness of heat molding depends on the materials used in the boot’s construction. Some composite materials are more amenable to heat molding than others, exhibiting greater pliability and retaining their shape more effectively after cooling. The molding process also varies depending on the boot model and the retailer’s equipment. Common methods include using a convection oven, a specialized skate oven, or even hot water. An example is a high-end model utilizing a carbon fiber composite shell which requires precise temperature control during the molding process.

- Longevity and Repeat Molding Potential

While heat molding offers significant benefits, the number of times a boot can be effectively molded is limited. Repeated heat molding can weaken the composite materials, potentially compromising the boot’s structural integrity and performance. Moreover, the customization achieved through heat molding may not be fully reversible, meaning that the boot may not be suitable for subsequent users with different foot shapes. Therefore, the process should be undertaken with careful consideration and, ideally, under the guidance of a qualified professional. An example could be an issue such as repeatedly using the same skate on different days.

In conclusion, heat molding is a valuable customization technique available for select models of specialized footwear. The benefits of improved fit, enhanced performance, and reduced discomfort must be weighed against the potential limitations and risks associated with the process. When executed correctly, heat molding can significantly enhance the skating experience.

4. Lacing System

The lacing system is an integral component of specialized footwear, directly impacting fit, performance, and safety. In the context of these ice skates, the lacing system is responsible for securing the foot within the boot, optimizing energy transfer, and providing critical ankle support.

- Ankle Support and Stability

The lacing system’s primary function is to provide adjustable ankle support. By tightening the laces, a skater can control the degree of flexion and extension allowed at the ankle joint. This is particularly crucial in disciplines such as figure skating and ice hockey, where rapid changes in direction and demanding maneuvers place significant stress on the ankle. For example, a figure skater performing a jump will tighten the laces to maximize ankle stability, while a hockey player might loosen the upper laces for greater agility. An inadequate lacing system can compromise ankle stability, increasing the risk of injury.

- Customizable Fit and Comfort

The lacing system enables a customizable fit, accommodating variations in foot shape and volume. Skaters can adjust lace tension across different zones of the foot to achieve a secure and comfortable fit. For example, a skater with a narrow foot might tighten the laces more in the midfoot region to prevent slippage, while a skater with a wider foot might loosen the laces in that area. Proper lacing minimizes pressure points and prevents blistering, enhancing comfort during prolonged use. The quality of the laces themselves (material, thickness, and texture) also contributes to ease of adjustment and overall comfort.

- Energy Transfer and Responsiveness

A well-executed lacing system maximizes energy transfer from the skater’s foot to the blade. By securing the foot firmly within the boot, the lacing system prevents energy loss due to foot slippage or movement within the boot. This results in more efficient strides, sharper turns, and improved overall responsiveness. For example, a tightly laced boot allows a skater to generate more power during a push-off, resulting in greater acceleration. Conversely, a loosely laced boot can lead to energy loss and reduced performance.

- Lace Material and Construction

The choice of lace material and construction directly influences the lacing system’s durability and performance. High-quality laces are typically made from durable synthetic materials that resist fraying and stretching. Waxed laces provide increased friction, helping to maintain lace tension and prevent slippage. Some models incorporate specialized eyelets or lace locks that further enhance security and prevent loosening during skating. An example of a common issue is when the lace is worn or broken after long skating hours. Properly designed and maintained laces contribute to the overall effectiveness and reliability of the skating footwear.

The lacing system represents a critical interface between the skater and the equipment, directly impacting comfort, performance, and safety. Selecting footwear with a well-designed and durable lacing system, and employing proper lacing techniques, is essential for optimizing the skating experience and minimizing the risk of injury.

5. Ankle Support

Ankle support, a pivotal element in specialized ice footwear, directly influences a skater’s stability, performance, and injury prevention. Within designs by a specific manufacturer of ice implements, the level of ankle support varies across different models, catering to diverse skill levels and skating disciplines. Insufficient ankle support can lead to instability, increasing the risk of sprains or other injuries, while excessive support can restrict movement and hinder agility. The specific construction of the boot, including the materials used and the height of the boot cuff, contributes significantly to the overall level of ankle support. For instance, a high-end model designed for figure skating may feature a significantly stiffer boot and higher cuff to provide the necessary support for executing complex jumps and landings. By contrast, a recreational model may prioritize comfort and flexibility with a softer boot and lower cuff. The precise design aims to balance support and mobility based on the intended use.

The cause-and-effect relationship between ankle support and performance is readily apparent. Increased ankle stability translates to more efficient energy transfer from the skater’s leg to the blade, enabling more powerful strides and sharper turns. This is particularly crucial in ice hockey, where players require explosive acceleration and rapid changes in direction. For example, a hockey player wearing boots with inadequate ankle support may experience a loss of power and control, impacting their ability to effectively compete. Conversely, sufficient ankle support allows the player to confidently execute demanding maneuvers without compromising stability. Furthermore, the lacing system complements the boot’s inherent support structure, allowing skaters to customize the fit and fine-tune the level of ankle support based on their preferences and the demands of the activity.

Understanding the connection between ankle support and specific models is of practical significance for skaters of all levels. Choosing the appropriate level of support based on skill level, skating discipline, and individual needs can significantly enhance performance, minimize the risk of injury, and improve overall skating enjoyment. Manufacturers invest heavily in research and development to optimize ankle support designs, utilizing advanced materials and construction techniques to achieve the optimal balance between support, comfort, and performance. By understanding the principles of ankle support and its relationship to specific footwear designs, skaters can make informed decisions that contribute to a safer and more rewarding skating experience.

6. Fit Precision

Fit precision is a critical determinant of performance, comfort, and safety in ice skates manufactured by a specific brand. The manufacturer emphasizes anatomical accuracy in boot design to minimize negative space and maximize energy transfer between the skater’s foot and the blade. Improper fit can lead to blisters, reduced agility, and increased risk of ankle injuries. For example, if the heel is not securely locked in place, the skater will experience slippage, diminishing power and control. A skater’s ability to execute precise turns and powerful strides is directly compromised by inadequacies in fit. This manufacturer uses sophisticated foot scanning technology and a range of boot widths and volumes to achieve a more precise fit for individual skaters, addressing the anatomical variations across different foot shapes.

The implementation of heat-moldable materials further enhances fit precision. These materials allow retailers to customize the boot’s shape to the skater’s foot, eliminating pressure points and maximizing comfort. A figure skater, for instance, might benefit from heat molding to achieve a snug fit around the ankle, improving stability during landings. In hockey, a close-fitting boot can enhance responsiveness and agility, allowing players to react quickly to changes in the game. This level of customization addresses the limitations of standardized sizing and ensures that the skate functions as an extension of the skater’s body. This tight connection to a skater’s body promotes efficient strides, which means energy is not loss to slippage during power transfer to the ice.

Achieving optimal fit requires a combination of professional fitting, heat molding where applicable, and careful lace adjustment. Retailers specializing in these specialized skates play a crucial role in assessing a skater’s foot and recommending the appropriate boot model and size. Challenges remain in ensuring consistent fit across all models and sizes, and ongoing research into foot biomechanics and boot construction is essential. By prioritizing fit precision, the manufacturer aims to deliver skates that optimize performance and protect skaters from injury.

Frequently Asked Questions

The following section addresses common inquiries regarding specialized ice implements, designed to provide clarity on various aspects of their selection, use, and maintenance.

Question 1: How does one determine the appropriate size for these ice skates?

The selection of an appropriate size necessitates a professional fitting at a reputable retailer. Foot length and width measurements, combined with consideration of boot volume, are crucial for optimal fit.

Question 2: What is the recommended frequency for blade sharpening?

Blade sharpening frequency depends on usage intensity and ice conditions. Professional sharpening is generally recommended every 10-20 hours of skating.

Question 3: How should moisture be managed to prevent rust formation on the blades?

Following each use, blades should be thoroughly wiped with a dry cloth. Blade guards should be used when walking on surfaces other than ice to minimize moisture exposure and physical damage.

Question 4: What factors should influence the selection of boot stiffness?

Boot stiffness selection is contingent upon skating discipline and skill level. Hockey skates typically prioritize agility, while figure skates emphasize ankle support. Beginners generally benefit from moderate stiffness.

Question 5: Can these ice skates be heat molded multiple times?

Repeated heat molding can compromise the structural integrity of the boot. The number of heat molding cycles should be limited, and professional guidance is advised.

Question 6: What are the key indicators that new laces are required?

Fraying, stretching, or breakage of laces necessitates immediate replacement. Worn laces can compromise ankle support and increase the risk of injury.

Adhering to these guidelines promotes safe and efficient skating, extends the lifespan of the equipment, and maximizes the overall skating experience.

The next section provides insights into the technology used to manufacture these ice skates.

Conclusion

This exploration has illuminated the multifaceted aspects of ice skates from a particular manufacturer, emphasizing performance, materials, fit precision, and maintenance considerations. The analysis has underscored the interplay between design features and a skater’s proficiency, highlighting how these elements directly impact efficiency, stability, and safety on the ice. Proper selection and diligent maintenance of these specialized implements are demonstrably crucial for optimizing both recreational enjoyment and competitive success.

The ongoing evolution of ice sport footwear technology necessitates a continued commitment to research and innovation. Skaters and retailers must remain informed about the latest advancements in materials science and boot construction to ensure optimal equipment performance and mitigate the risk of injury. The future of ice sports relies, in part, on the quality and availability of equipment that enables athletes to push the boundaries of their abilities safely and effectively.