The foundation of skateboarding is a specially constructed platform designed to withstand significant stress and impact. Typically crafted from multiple layers of laminated wood, often maple, it provides the rider with a surface for performing maneuvers. The dimensions and concave shape influence board feel and responsiveness. For example, a wider platform may offer more stability, while a deeper concave can enhance foot lock-in during tricks.

This component is crucial for executing various skateboarding techniques, influencing both the rider’s control and the durability of the board. The selection of materials and construction methods directly impacts its lifespan and performance. Throughout the history of skateboarding, innovations in design and manufacturing have continually enhanced the capabilities of this fundamental element.

With a solid understanding of this core piece of equipment, the subsequent sections will delve deeper into the specific characteristics that differentiate models, the materials used in their creation, and the factors skaters consider when making purchasing decisions.

Selecting a Durable Platform

Choosing the appropriate skateboard platform is essential for both performance and longevity. Several factors warrant careful evaluation to ensure a suitable match for individual needs and skating styles.

Tip 1: Evaluate Wood Quality: The grade and type of wood used in construction significantly impact durability. North American maple is widely regarded as a premium material due to its strength and resilience. Inspect the layers for consistent grain and minimal imperfections.

Tip 2: Consider Layer Count: The number of plies, typically seven, contributes to overall stiffness and impact resistance. A higher ply count may offer increased durability but can also affect board feel.

Tip 3: Assess Concave Shape: The curvature of the platform’s surface influences foot placement and trick execution. Experiment with different concave profiles to determine the optimal feel for one’s riding style.

Tip 4: Check for Manufacturing Defects: Thoroughly inspect the platform for any signs of delamination, warping, or inconsistencies in the lamination process. These flaws can compromise structural integrity and shorten its lifespan.

Tip 5: Verify Dimensions: The width and length of the platform should align with rider’s foot size and preferred skating discipline. Wider platforms generally provide increased stability, while narrower platforms may offer greater maneuverability.

Tip 6: Consider Weight Rating: Some manufacturers provide weight recommendations for their platforms. Adhering to these guidelines can help prevent premature failure due to excessive stress.

Tip 7: Investigate Glue Quality: The adhesive used to bond the layers plays a crucial role in preventing delamination. Seek platforms that utilize high-quality, waterproof glues for enhanced durability.

By carefully considering these factors, skaters can make informed decisions and select a skateboard platform that delivers optimal performance, durability, and longevity.

The subsequent section will provide further insights into maintaining the skateboard platform and maximizing its lifespan through proper care and storage.

1. Wood Ply Composition

The arrangement of wood plies is fundamental to the structural integrity and performance characteristics of a skateboard platform. This composition directly influences its strength, flexibility, and overall responsiveness, making it a critical consideration for both manufacturers and skaters.

- Ply Orientation and Grain Direction

The orientation of the wood grain within each ply is strategically arranged to maximize strength and prevent cracking. Typically, alternating grain directions in adjacent plies create a cross-laminated structure, distributing stress and enhancing resistance to warping or delamination. Deviations from this practice can significantly compromise the platform’s lifespan.

- Wood Species Selection

While maple is the predominant wood species utilized, variations in maple type, such as North American hard rock maple, impact the platform’s density and stiffness. Denser woods generally provide greater strength and pop, while less dense woods may offer more flexibility. The choice of wood species directly influences the board’s overall performance profile.

- Adhesive Type and Application

The adhesive used to bond the plies together is crucial for preventing delamination under stress. High-quality, waterproof adhesives are essential for maintaining structural integrity during impacts and exposure to moisture. Improper adhesive application or the use of inferior glues can result in premature failure.

- Pressing Techniques and Curing Process

The method used to press and cure the wood plies significantly impacts the final product. Precise pressure application and controlled curing times ensure consistent bonding and minimize internal stresses within the platform. Variations in these processes can lead to inconsistencies in shape, concave, and overall performance.

In summation, wood ply composition is not merely a superficial detail but rather a complex engineering consideration that profoundly affects the functionality and durability of the skateboard platform. Understanding these aspects allows skaters to make informed decisions regarding equipment selection, optimizing their performance and extending the lifespan of their boards.

2. Concave Profile

The curvature molded into the surface fundamentally dictates board feel, maneuverability, and trick performance. Its subtle contours are instrumental in establishing the rider’s interface with the board, influencing both control and execution.

- Radial Concave

Characterized by a consistent, curved shape from edge to edge, radial concave provides a predictable and uniform feel. This profile often appeals to skaters prioritizing stability and controlled transitions. Its consistent curvature aids in maintaining foot placement during slides and grinds, fostering a sense of groundedness on the board.

- Progressive Concave

Featuring a gradual increase in curvature towards the edges, progressive concave enhances foot lock-in and responsiveness. The steeper edge curves provide added leverage for ollies and flip tricks, enabling quicker and more precise board control. This profile is often favored by technical skaters seeking increased responsiveness.

- W Concave

Defined by a subtle ridge running lengthwise down the center of the board, W concave enhances foot stability and promotes directional control. The central spine provides a tactile reference point for foot placement, aiding in maintaining balance during slides and downhill runs. This profile is commonly found on longboards and cruisers, prioritizing stability at higher speeds.

- Flat Concave

Devoid of any significant curvature, flat concave offers a spacious and unrestricted platform for foot placement. This profile promotes a loose and unrestricted feel, allowing for fluid foot movements and transitions. It’s often favored by skaters who prioritize board walking and freestyle maneuvers, granting freedom of movement and adaptability.

In summary, the selected curvature directly influences a skater’s connection and command. It is integral to boards overall performance and handling attributes. Each profile presents specific advantages, catering to diverse skating disciplines and individual preferences. Selecting one that suits a rider’s style will enhance skills and provide a better experience.

3. Dimensional Stability

Dimensional stability, in the context of the skateboard platform, refers to its ability to maintain its original shape and size over time, resisting deformation under varying environmental conditions and stress loads. This property is paramount for consistent performance and longevity.

- Moisture Resistance

Wood, the primary material, is hygroscopic, meaning it readily absorbs and releases moisture from the surrounding atmosphere. Fluctuations in moisture content cause expansion and contraction, potentially leading to warping, cracking, or delamination. Dimensionally stable platforms are treated or constructed to minimize moisture absorption, ensuring consistent shape and performance regardless of humidity levels. An example is the use of waterproof glues and sealants during manufacture.

- Temperature Sensitivity

Extreme temperature variations can also induce dimensional changes. High temperatures may cause the wood to soften and become more susceptible to bending, while low temperatures can make it brittle and prone to fracture. Dimensionally stable platforms are engineered to withstand a range of temperatures without significant deformation, maintaining their structural integrity in diverse climates. Careful selection of wood density and drying processes minimizes this effect.

- Load Bearing Capacity

The platform must resist deformation under the rider’s weight and the impact forces generated during tricks. Repeated stress can lead to permanent bending or sagging, altering the concave shape and negatively impacting performance. Dimensionally stable platforms are constructed with high-quality materials and precise lamination techniques to maximize their load-bearing capacity and prevent permanent deformation. Reinforcement with composite materials is a design adaptation to support higher load requirements.

- Material Creep

Creep is the tendency of a solid material to deform permanently under sustained stress. Over time, even relatively small loads can cause noticeable bending or sagging. Dimensionally stable platforms are made from materials that exhibit minimal creep, ensuring that the shape and concave remain consistent throughout the board’s lifespan. The selection of high-grade maple with specific grain orientations is critical to minimizing this phenomenon.

In summary, dimensional stability is a critical attribute, directly influencing its performance and lifespan. By mitigating the effects of moisture, temperature, load, and creep, manufacturers can create durable products that provide consistent performance under a wide range of conditions.

4. Impact Resistance

Impact resistance is a crucial attribute, directly influencing the lifespan and performance capability. The ability to withstand sudden and forceful impacts, characteristic of skateboarding activities, determines the platform’s structural integrity and rider safety. Insufficient impact resistance leads to premature failure, compromised performance, and potential injury.

The construction process fundamentally dictates its capacity to absorb impact. High-quality materials, such as North American maple, combined with precise lamination techniques, create a robust structure capable of dissipating energy from landings, grinds, and other maneuvers. A failure in any layer of the ply due to low-quality material or manufacturing error drastically reduces the impact resistance, causing breakage and increasing the risk of accidents. For example, a drop from a significant height places substantial stress on the platform, testing its capacity to absorb the force without fracturing. Similarly, repeated impacts during street skating can gradually weaken it, eventually leading to catastrophic failure if the initial impact resistance is inadequate.

Understanding the relationship between construction techniques and impact resistance is practically significant for both manufacturers and skaters. Manufacturers can optimize materials and processes to produce stronger, more durable platforms. Skaters can make informed purchasing decisions, selecting products that align with their skating style and the demands of their chosen terrain. In conclusion, impact resistance is a defining characteristic, necessitating careful consideration of materials and construction to ensure a safe and durable skating experience.

5. Grip Tape Compatibility

Grip tape compatibility represents a crucial, yet often overlooked, aspect of skateboard platform design. It determines the effectiveness with which the abrasive surface adheres to the wood, directly influencing rider control, trick execution, and overall safety.

- Surface Texture and Adhesion

The texture of the platforms upper surface significantly impacts grip tape adhesion. A smooth, consistent surface provides optimal contact for the adhesive backing, ensuring a secure bond. Irregularities, such as deep pores or uneven finishes, can reduce surface area contact, compromising adhesion and leading to premature peeling or bubbling. This is evident when attempting to apply grip tape to older, worn surfaces, where adhesion is often suboptimal.

- Material Composition and Chemical Compatibility

The type of sealant or finish applied to the platform can influence chemical compatibility with grip tape adhesives. Certain coatings may react negatively with adhesives, weakening the bond or causing the grip tape to deteriorate. For instance, some urethane-based clear coats may create a slippery barrier, hindering adhesion. Manufacturers often recommend specific grip tape types to ensure compatibility with their platform’s surface treatment.

- Dimensional Stability and Grip Tape Application

Dimensional stability plays a vital role in maintaining proper adhesion. Warping or twisting of the platform can create stress points, causing the grip tape to lift or tear. Applying grip tape to a dimensionally unstable platform exacerbates these issues, leading to uneven wear and reduced grip. This is particularly noticeable in boards exposed to extreme temperature or humidity fluctuations.

- Edge Sealing and Longevity

Proper edge sealing is crucial for preventing moisture from penetrating between the grip tape and the platform. Moisture can weaken the adhesive bond and cause the grip tape to peel, especially along the edges. Effective edge sealing techniques, such as trimming the grip tape precisely to the platform’s edge or using edge sealant products, significantly extend the grip tape’s lifespan and maintain optimal grip.

These factors collectively underscore the importance of considering grip tape compatibility during both the manufacturing and usage phases. A well-prepared surface ensures optimal adhesion, enhancing rider control and prolonging the life of both the grip tape and the skateboard platform.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions regarding skateboard platforms. Accurate information facilitates informed purchasing decisions and promotes optimal equipment maintenance.

Question 1: What constitutes a “real” skateboard platform, as opposed to a lower-quality alternative?

A genuine skateboard platform typically comprises seven plies of North American maple, laminated with waterproof glue, and pressed to a standardized shape and concave. Lower-quality alternatives often utilize inferior wood species, weaker adhesives, or inconsistent manufacturing processes, resulting in reduced durability and performance.

Question 2: How does the concave profile impact skateboarding performance?

The concave profile influences foot placement, board feel, and trick execution. Deeper concaves generally provide enhanced foot lock-in and responsiveness, while shallower concaves offer more board feel and flexibility. The ideal concave profile depends on individual preferences and skating style.

Question 3: What is the expected lifespan of a skateboard platform, and how can it be extended?

The lifespan varies depending on usage frequency, skating style, and environmental conditions. Regular street skating subjects the platform to greater stress than casual cruising. To extend lifespan, avoid prolonged exposure to moisture, store in a dry environment, and consider using rail guards to protect the edges.

Question 4: Is there a correlation between platform weight and performance?

Weight can influence board feel and maneuverability. Lighter platforms generally offer quicker response and easier flipping, while heavier platforms may provide increased stability at higher speeds. The optimal weight is subjective and depends on individual preferences.

Question 5: How does the width of the platform affect the riding experience?

Wider platforms offer more stability and are often preferred for transition skating and vert ramps. Narrower platforms provide greater maneuverability and are suitable for technical street skating. Rider foot size and personal preference are key factors in determining the appropriate width.

Question 6: What are the signs that a skateboard platform needs replacement?

Signs include delamination (ply separation), cracking, excessive warping, and a loss of pop (reduced springiness). Any of these indicators suggests that the platform’s structural integrity has been compromised and replacement is advisable.

In summary, selecting and maintaining a quality skateboard platform requires careful consideration of its materials, construction, and compatibility with one’s individual needs and skating style. Prioritizing these factors maximizes performance, safety, and equipment longevity.

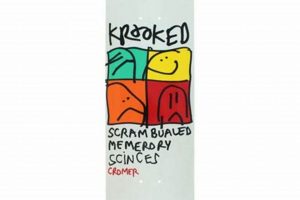

The following section provides a comparative analysis of different skateboard platform brands and models, highlighting their strengths, weaknesses, and suitability for various skating disciplines.

In Conclusion

This exploration of the real skate deck has underscored its foundational role in skateboarding. From its multi-layered construction and carefully engineered concave to its essential properties of impact resistance and grip tape compatibility, each element contributes to the rider’s experience and the board’s overall performance. Understanding these characteristics enables informed decision-making, promoting safety, skill development, and equipment longevity.

As skateboarding continues to evolve, so too will the design and materials used in the construction of the real skate deck. Further research and development will undoubtedly lead to enhanced performance and durability. Skaters are therefore encouraged to remain informed about these advancements, ensuring that their equipment aligns with their individual needs and the demands of their chosen discipline. Investing in a quality platform is an investment in both the sport and the skater’s personal progression.