Skateboarding equipment frequently incorporates a laminated wood platform. These platforms, crucial for performing tricks and maneuvers, come in various sizes and constructions to suit different skating styles and rider preferences. The construction and design influence the board’s performance characteristics.

The quality and materials used in constructing these platforms directly impact durability, pop (the board’s ability to spring upwards), and overall control. Historical context reveals a progression in manufacturing techniques, leading to enhanced strength and responsiveness. This evolution has allowed for increasingly complex maneuvers and greater skater confidence.

The subsequent sections will delve into specific aspects of these platforms, including their construction, materials, and the influence of graphics and concave on performance. Understanding these features allows skaters to make informed choices when selecting equipment.

Selecting Suitable Primitive Skate Decks

This section provides guidance on choosing appropriate skateboarding platforms, focusing on aspects that affect performance and longevity.

Tip 1: Consider Deck Width. Deck width significantly impacts stability and control. Wider decks generally offer more stability, advantageous for beginners or skaters focused on transition skating. Narrower decks facilitate quicker rotations, preferred by street skaters.

Tip 2: Evaluate Deck Length. Deck length influences the board’s maneuverability. Shorter decks are easier to flip and spin, while longer decks provide increased stability and foot space. Match deck length to skating style and personal preference.

Tip 3: Assess Concave Depth. Concave refers to the curvature of the deck’s surface between the edges. Deeper concave enhances foot lock-in, promoting greater control during tricks. Shallower concave provides a more subtle feel, favored by some for comfort.

Tip 4: Examine Material Quality. High-quality maple wood is a standard material for skateboard decks due to its strength and flexibility. Multi-layered construction increases durability and prevents warping. Inquire about the wood grade and pressing process.

Tip 5: Inspect Graphic Application. Graphic application affects the deck’s longevity. Heat-transfer graphics are generally more durable than screen-printed graphics, resisting wear and tear from skateboarding activities.

Tip 6: Account for Wheelbase. Wheelbase, the distance between the trucks, impacts turning radius and stability. A shorter wheelbase results in tighter turns, while a longer wheelbase enhances stability at higher speeds.

Tip 7: Acknowledge Rider Weight and Shoe Size. Rider weight and shoe size should influence deck selection. Heavier riders may require thicker decks for enhanced durability. Larger shoe sizes necessitate wider decks for optimal foot placement.

Selecting the correct skateboard platform involves considering various factors, including width, length, concave, material, and individual rider characteristics. Understanding these elements leads to an informed decision, enhancing skateboarding performance and enjoyment.

The following sections will address maintenance procedures and common issues associated with these platforms, providing comprehensive information for skateboarders of all skill levels.

1. Construction Materials

The selection and quality of construction materials are foundational to the performance and durability of skateboarding platforms. These materials dictate the board’s strength, flexibility, and responsiveness, directly impacting a skater’s ability to execute maneuvers and withstand the rigors of skateboarding.

- Maple Wood Composition

North American maple is the predominant material utilized in skateboard deck construction. Its tight grain structure and natural flexibility offer an optimal balance between strength and responsiveness. The number of maple plies (typically seven) and their orientation contribute significantly to the deck’s overall performance. Lower quality maple or alternative wood types reduce deck lifespan and compromise performance, potentially leading to premature breakage or decreased pop. An example of this is using birch or other softer woods which have a more tendency to warp over time.

- Glue Adhesives

The adhesive used to laminate the maple plies together plays a vital role in maintaining deck integrity. High-quality epoxy-based glues provide superior bonding strength and water resistance, preventing delamination under stress or exposure to moisture. Inferior glues can result in ply separation, compromising the deck’s structure and rendering it unusable. A clear example is the use of solvent-based glues on decks in the past that were prone to cracking under the pressure of skating.

- Resin Infusion Techniques

Modern manufacturing processes incorporate resin infusion techniques to enhance deck strength and reduce weight. Epoxy resins are forced into the maple plies under pressure, creating a stronger, more durable composite material. This method also minimizes the risk of air pockets and voids within the deck, improving overall performance. Some manufacturers even use carbon fiber reinforcement with resin infusion techniques to add even more strength to key stress areas like the nose and tail of a board.

- Ply Orientation and Grain Direction

The orientation of the maple plies and their grain direction are meticulously engineered to optimize deck strength and flexibility. Alternating the grain direction of each ply enhances resistance to warping and cracking. Careful attention to ply alignment ensures consistent performance and prevents premature failure. Specific layups and composite arrangements of each ply can be experimented with in certain models to provide added strength or snap.

In summary, the composition, bonding, and engineering of construction materials directly correlate to the overall quality and performance characteristics of skateboard platforms. Understanding these nuances enables skaters to make informed choices, selecting equipment that meets their specific needs and enhances their skateboarding experience. These material attributes will ultimately play a part in how the skater experiences their ride and what tricks they can and cannot do.

2. Deck Dimensions

Deck dimensions are a critical factor in skateboard platform selection, significantly influencing handling, stability, and suitability for various skating styles. Specific measurements, including width, length, and wheelbase, directly affect a skater’s ability to perform tricks and navigate different terrains.

- Deck Width and Foot Placement

Deck width determines the surface area available for foot placement. Wider decks offer increased stability, particularly beneficial for beginners or skaters focused on vert and transition skating. Narrower decks facilitate quicker rotations, advantageous for street skating and technical flip tricks. Width is generally measured in inches and ranges from approximately 7.5″ to 9.0″ or wider. Proper foot placement is essential for balance and control; inadequate deck width can hinder progression and increase the risk of injury. An example of this is a skater with a larger shoe size attempting to use a narrower deck, resulting in less stability.

- Deck Length and Maneuverability

Deck length affects the overall maneuverability and responsiveness of the platform. Shorter decks are generally easier to flip and spin, favored for technical street skating. Longer decks provide increased stability at higher speeds, often preferred for transition and downhill skating. Deck length is also measured in inches, typically ranging from 28″ to 33″. The relationship between deck length and skater height is critical; shorter skaters may find longer decks cumbersome, while taller skaters may struggle with the limited foot space of shorter decks. An example of where Deck Length plays a major role is that of a street skater using a deck that is far too long making kickflips more difficult.

- Wheelbase and Turning Radius

Wheelbase, the distance between the inner mounting holes of the trucks, impacts the turning radius and stability. A shorter wheelbase results in a tighter turning radius, ideal for navigating confined spaces and executing quick turns. A longer wheelbase enhances stability at higher speeds, preferred for cruising and transition skating. Wheelbase is measured in inches and generally falls within the range of 13″ to 15″. Adjusting the wheelbase can fine-tune the board’s handling characteristics to suit specific skating styles or personal preferences. An example is increasing the wheelbase to add stability at high speeds in transition skating.

- Nose and Tail Dimensions and Pop

The dimensions and angles of the nose and tail influence the “pop,” the board’s ability to spring off the ground for ollies and other aerial maneuvers. Steeper angles and larger surface areas generally provide more leverage for generating pop. The shape and dimensions of the nose and tail are often asymmetrical, with the nose being slightly longer and wider than the tail. Skaters often have a preference for a particular nose and tail design to maximize pop and control. An example of how Nose and Tail play a major role is that steeper angles on these areas are often favored in the vert skating area to get the deck more vertical on its ascent.

Understanding the interplay of these dimensional factors is crucial for selecting a skateboard platform that aligns with individual skating style and skill level. Optimizing deck dimensions enhances performance, control, and overall skateboarding experience. A skater should experiment with varying dimensions to determine the optimal configuration for their specific needs.

3. Concave Design

Concave design significantly influences the performance characteristics of skateboarding platforms. The curvature across the width of the deck affects foot placement, control, and the execution of various skateboarding maneuvers. Understanding concave design is essential for selecting a skateboarding platform that aligns with individual preferences and skating styles.

- Radial Concave

Radial concave features a consistent, rounded curve across the deck’s width. This design provides a predictable and stable platform for foot placement, offering a balanced feel suitable for various skating styles. Radial concave is a common choice for beginners due to its forgiving nature and ease of control. For example, a skater learning basic ollies may benefit from the stability afforded by radial concave. Decks with a more mellow concave are favored by some as they will allow you to have a wider range of foot placements in all kinds of skating.

- Progressive Concave

Progressive concave exhibits a gradual increase in curvature from the center of the deck towards the edges. This design offers enhanced edge control and responsiveness, facilitating more technical tricks and maneuvers. Skaters often choose progressive concave for its ability to lock their feet into the deck during flip tricks. Decks utilizing a progressive concave may allow a skater to feel more comfortable with quick and technical flip tricks, like a nollie heel.

- W Concave

W concave incorporates a raised spine or “W” shape along the center of the deck. This design enhances torsional stiffness and provides additional foot support, improving control during slides and transition skating. The W concave effectively creates pockets for the skater’s feet, increasing board feel and responsiveness. Decks utilizing a W concave may be more appealing to a longboarder looking for more foot support during slides.

- Flat Concave

Flat concave decks lack any significant curvature, presenting a completely flat surface across the deck’s width. This design offers maximum foot freedom and a unique board feel, favored by some for its minimalist approach. Flat concave decks often require more precise foot placement and control due to the absence of defined edges. Some skaters might opt for these types of boards to provide added room for skating in all kinds of terrain.

The selection of an appropriate concave design hinges on individual skating style and preferences. Experimentation with different concave types allows skaters to identify the design that best complements their technique and enhances their overall skateboarding experience. Selecting the best concave for a skater’s particular tastes and needs is essential to enjoying and progressing the art of skateboarding.

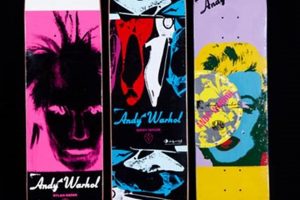

4. Graphic Durability

Graphic durability, referring to a skateboard deck’s capacity to resist wear and maintain its visual integrity over time, is a significant factor in the perceived quality and longevity of skateboarding platforms. The graphics applied to skateboarding platforms are more than mere decoration; they contribute to brand identity and individual expression. The method of graphic application directly correlates to its resistance to abrasion, impact, and environmental factors, impacting the deck’s aesthetic appeal and, indirectly, its perceived value. A deck with a readily chipping or fading graphic can be viewed as inferior, irrespective of its structural integrity. Consider, for example, two identical decks in terms of material and construction. One utilizes a heat-transfer graphic, the other a screen-printed graphic. After a period of regular use, the heat-transfer graphic will likely show less wear and tear compared to the screen-printed graphic.

Several methods are employed in applying graphics to skateboarding platforms, each with varying degrees of durability. Heat-transfer graphics, where the design is fused onto the deck’s surface using heat and pressure, generally exhibit greater resistance to scratching and peeling compared to screen-printed graphics. Screen printing, while offering vibrant colors and intricate designs, often involves a layer of ink applied to the surface, making it more susceptible to abrasion from skateboarding activities. Some manufacturers employ additional protective coatings or clear coats to enhance graphic durability. The type of ink used, the number of layers applied, and the quality of the clear coat all contribute to the graphic’s ability to withstand wear. For example, decks used primarily for street skating, where frequent contact with rough surfaces is expected, benefit significantly from more robust graphic application methods.

In conclusion, graphic durability is an important consideration in skateboarding platform selection. It directly impacts the deck’s aesthetic appeal and, to some extent, its perceived value. While graphic durability does not directly affect the structural integrity of the deck, it contributes to the overall user experience and influences the skater’s satisfaction with the product. Skaters should consider the graphic application method when selecting a deck, particularly if aesthetics and long-term visual appeal are a priority. Neglecting graphic durability can lead to premature wear and diminished enjoyment of the skateboarding platform over time. It should also be understood that even the most durable graphics will eventually show signs of wear and tear; such wear and tear can be considered a badge of honor to some skaters and a sign of the skater’s commitment to the sport.

5. Wood Grain Orientation

Wood grain orientation in skateboard decks, specifically within primitive skate decks, plays a crucial role in determining structural integrity, flex characteristics, and overall performance. The direction of wood fibers within each ply of maple laminate affects its resistance to bending and breaking forces. Proper alignment of these grain patterns significantly enhances a deck’s ability to withstand the stresses of skateboarding, particularly during high-impact maneuvers. Misaligned grain can lead to weakened points and increased susceptibility to splintering or catastrophic failure. For instance, if the grain of an inner ply runs perpendicular to the dominant longitudinal axis of the deck, it can act as a stress concentrator, initiating cracks under pressure. The consequence of poor grain orientation translates directly into a reduction in the lifespan and reliability of the platform.

Manufacturers of primitive skate decks often employ specific grain orientation techniques, alternating the direction of the grain in each ply to create a balanced and resilient composite structure. This cross-ply lamination approach distributes stress evenly across the deck, mitigating the risk of localized failures. Skateboard decks commonly feature a longitudinal grain orientation in the outer plies to provide maximum strength along the length of the board, resisting bending during ollies and other tricks. Inner plies are frequently oriented with a combination of longitudinal and transverse grains to control flex and torsional rigidity. In the practical realm, this knowledge allows skaters and retailers to inspect decks for visible grain anomalies, such as knots or irregular patterns, which may indicate compromised strength. A trained eye can identify subtle cues related to grain alignment, allowing for informed purchasing decisions. Some custom deck builders will showcase their ply orientations to showcase their board strength and value.

In summary, wood grain orientation is an essential, often overlooked, aspect of primitive skate deck construction. Its influence on strength, flex, and durability cannot be overstated. While visual inspection can offer some indication of grain quality, the internal grain orientation remains largely hidden, making it paramount to select decks from reputable manufacturers known for their adherence to quality control standards. The challenges associated with verifying internal grain orientation underscore the importance of trusting established brands that prioritize material selection and manufacturing processes aimed at optimizing wood grain alignment. The understanding of wood grain alignment and its connection to primitive skate decks adds another aspect to the art and science of understanding what goes into these simple but technical boards that can be ridden around a skatepark, street, or even a vert ramp.

6. Pressing Technique

Pressing technique, in the context of primitive skate decks, is a critical manufacturing process influencing the board’s structural integrity, shape consistency, and overall performance. Variations in pressing methodologies directly impact deck durability, pop, and the skater’s riding experience. The selection and execution of a specific pressing technique are paramount to achieving desired deck characteristics.

- Cold Press vs. Hot Press

Cold pressing involves bonding maple plies at room temperature using adhesives and pressure. This method generally results in a more flexible deck with a softer feel, preferred by some skaters for its forgiving nature. Hot pressing, conversely, utilizes elevated temperatures to accelerate the curing process of the adhesive. This technique typically yields a stiffer, more responsive deck with enhanced pop. The choice between cold and hot pressing depends on the desired performance characteristics and target skating style. An example would be a transition skater preferring a deck with hot pressing so as to enhance the pop so they can land the lip tricks with more ease.

- Single Deck Press vs. Multi-Deck Press

Single deck pressing involves molding one deck at a time, allowing for greater control over individual deck characteristics. This method is often used for high-end or custom decks, where precise shape and concave are crucial. Multi-deck pressing, on the other hand, molds several decks simultaneously, increasing production efficiency and reducing manufacturing costs. While multi-deck pressing can maintain consistent quality, it may sacrifice some of the individualized attention afforded by single deck pressing. An example of single press decks are boards which are custom built by small brands or artists that focus solely on specific shapes.

- Pneumatic Press vs. Hydraulic Press

Pneumatic presses utilize air pressure to apply force during the molding process. These presses offer relatively lower force compared to hydraulic presses, resulting in decks with more subtle concave and less pronounced features. Hydraulic presses, which employ fluid pressure, generate significantly higher force, allowing for the creation of decks with deep concave and complex shapes. The choice between pneumatic and hydraulic pressing depends on the complexity of the desired deck shape and the required level of pressure. An example of these deck’s are decks being pressed with intricate concave shapes and steep nose and tail angles.

- Concave Depth and Pressing Time

Concave depth, the curvature of the deck between the edges, is directly influenced by the pressing technique and the duration of the pressing cycle. Deeper concave requires longer pressing times and higher pressure to achieve the desired shape. Over-pressing can lead to excessive stress on the maple plies, compromising deck strength. Under-pressing, conversely, can result in inconsistent concave and reduced board feel. Proper calibration of pressing time and pressure is essential for achieving optimal concave depth and maintaining deck integrity. The result of improperly pressed concave in a deck can result in a skater losing the grip of their shoe and potentially having them slip out while doing a trick.

In conclusion, the pressing technique employed in the manufacturing of primitive skate decks is a multifaceted process with significant implications for deck performance and durability. The selection of appropriate pressing methods, whether cold or hot, single or multi-deck, pneumatic or hydraulic, directly influences the deck’s shape, concave, and overall riding experience. Careful consideration of concave depth and pressing time ensures optimal deck characteristics and prevents premature failure. These considerations, when combined, affect the overall characteristics of the primitive skate decks and directly have a link to the skater’s personal tastes and needs.

7. Shape Variation

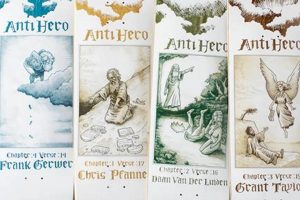

Shape variation in primitive skate decks exerts a direct influence on performance characteristics and rider suitability. The nuanced contours of a deck, encompassing nose and tail profiles, sidecut, and overall geometry, dictate how a skateboard interacts with different terrains and maneuver types. Specific shapes are designed to optimize certain skating styles, demonstrating a clear cause-and-effect relationship between shape and performance. For example, a square tail paired with a pointed nose, a shape commonly observed in directional decks, facilitates enhanced grip and responsiveness in transition skating, while a symmetrical twin-tip shape enables easier switch riding and technical flip tricks in street skating.

The importance of shape variation as a component of primitive skate decks lies in its capacity to tailor the riding experience to individual preferences and skill levels. A deck with a pronounced concave and steep kicktails will provide greater leverage for ollies and flip tricks, benefiting experienced skaters seeking technical precision. Conversely, a flatter deck with mellow kicktails offers a more forgiving platform for beginners, promoting stability and control. Understanding shape variation allows skaters to make informed choices, selecting decks that complement their specific needs and enhance their progress. The shapes of some of these boards can go beyond regular concave and include gas pedals, rails, and other interesting features.

The practical significance of understanding shape variation extends beyond individual skater preference, impacting the broader skateboarding industry. Manufacturers leverage shape variation to differentiate their products and cater to diverse market segments. This understanding enables the creation of specialized decks optimized for specific disciplines, contributing to the evolution of skateboarding as a whole. Recognizing the subtleties of shape allows both skaters and retailers to navigate the complex landscape of skateboard decks, ensuring optimal equipment selection and maximizing the potential for individual expression and performance. A few examples of these decks include the shapes created by Welcome Skateboards and Pizza Skateboards, which offer shapes unlike the industry standards of the past.

Frequently Asked Questions

The following addresses commonly asked questions concerning the construction, selection, and maintenance of skateboarding platforms, specifically within the realm of primitive skate decks.

Question 1: What defines a “primitive” skate deck in terms of construction?

A “primitive” designation does not inherently imply a specific construction method. It generally refers to the brand or artistic style associated with the deck. Construction typically involves seven plies of maple, but variations exist. Prospective buyers should focus on material quality and pressing technique rather than relying solely on the “primitive” label as an indicator of quality.

Question 2: How does deck width affect skateboarding performance?

Deck width influences stability and maneuverability. Wider decks offer increased stability, while narrower decks facilitate quicker rotations. The optimal width is contingent on skater size, foot placement preference, and intended skateboarding style.

Question 3: What is the significance of concave in a skate deck?

Concave refers to the curvature across the width of the deck. Deeper concave enhances foot lock-in and control, while shallower concave provides a more subtle feel. Concave selection is largely a matter of personal preference and skating style.

Question 4: How can one assess the quality of a skate deck’s graphic?

Graphic quality is generally determined by the application method. Heat-transfer graphics typically exhibit greater durability than screen-printed graphics. Visual inspection for imperfections or inconsistencies in the graphic application may indicate potential weaknesses.

Question 5: What are the recommended storage practices for skate decks to prevent damage?

Skate decks should be stored in a dry, temperature-controlled environment to prevent warping or delamination. Avoid prolonged exposure to direct sunlight or excessive humidity. Storage in a flat position is recommended to maintain deck shape.

Question 6: What are common indicators of a damaged or worn-out skate deck?

Indicators of damage include cracks, splintering, delamination, and excessive flex. Reduced pop and inconsistent board feel also suggest that a deck may need replacement. The presence of these issues compromises performance and safety.

Understanding these aspects allows for informed decision-making in the selection and maintenance of skateboarding equipment, enhancing both performance and longevity.

The following sections delve into common skateboarding techniques and best practices for skill development, ensuring a comprehensive guide for skateboarders of all levels.

Primitive Skate Decks

This exploration has elucidated the multifaceted nature of skateboarding platforms, specifically primitive skate decks. Construction materials, dimensional attributes, concave profiles, graphic application techniques, wood grain alignment, pressing methodologies, and shape variations collectively determine a deck’s performance and longevity. Comprehension of these elements empowers informed equipment selection.

The deliberate choice of appropriate equipment is paramount to skill progression and injury prevention. Skateboarders are encouraged to critically evaluate deck characteristics and prioritize quality craftsmanship. Continued innovation in deck design promises further advancements in skateboarding performance and accessibility.