A platform for riding and performing tricks, constructed primarily from synthetic polymers, offers an alternative to traditional wood-based counterparts. These platforms provide a surface upon which individuals propel themselves using one foot while balancing with the other, often incorporating features such as grip tape for enhanced traction. For example, cruisers utilizing this material are frequently seen navigating urban environments.

The utilization of polymers in the construction of these riding platforms presents several advantages. Increased durability and resistance to environmental factors, such as moisture, are often observed. This resistance contributes to a longer lifespan compared to some conventional materials. Furthermore, the manufacturing process can allow for greater flexibility in design and customization, impacting both the aesthetic and functional aspects. The emergence of these decks reflects an evolution in skateboarding technology, driven by the desire for enhanced performance and longevity.

Given the unique properties and benefits associated with platforms made from synthetic polymers, a deeper examination of their composition, manufacturing methods, and performance characteristics is warranted. The following sections will explore these aspects in detail, providing a comprehensive overview of their role within the skateboarding landscape.

Considerations for Selecting a Polymer-Based Skate Platform

The following guidelines offer important considerations for evaluating a riding platform constructed from synthetic polymers.

Tip 1: Assess Material Composition. Determine the specific type of polymer utilized in construction. Different polymers offer varying degrees of flexibility, impact resistance, and weight. Understanding the material composition provides insight into the platform’s performance characteristics.

Tip 2: Evaluate Deck Flexibility. A suitable degree of flexibility is crucial for control and comfort. A platform that is too rigid may transmit excessive vibrations, while one that is too flexible may feel unstable. Experiment with different flex patterns to find a suitable match for riding style.

Tip 3: Inspect Surface Texture. The surface texture, often enhanced with grip tape, affects traction and control. Ensure the grip tape is properly applied and provides adequate adhesion, especially in wet conditions. Examine the quality and durability of the grip surface.

Tip 4: Consider Dimensional Stability. Platforms should resist warping or deformation under varying temperature and humidity conditions. Inquire about the manufacturing process and quality control measures implemented to ensure dimensional stability over time.

Tip 5: Evaluate Weight and Portability. The overall weight of the platform affects maneuverability and ease of transport. Consider the trade-off between weight, durability, and other performance characteristics based on intended usage.

Tip 6: Research Brand Reputation. Investigate the manufacturer’s reputation and read reviews from other users. This provides valuable insights into the platform’s reliability, quality, and overall user experience. Look for brands with a proven track record of producing high-quality skateboarding equipment.

Tip 7: Examine Manufacturing Processes. The manufacturing process impacts the structural integrity and overall quality. Look for information about the techniques used to mold or shape the platform, as well as the quality control measures in place.

Selecting a suitable polymer-based riding platform requires careful evaluation of various factors, including material composition, flexibility, surface texture, dimensional stability, weight, and brand reputation. These considerations ensure optimal performance, durability, and rider satisfaction.

The final section will delve into the future trends and potential innovations within the realm of polymer-based skateboarding equipment.

1. Durability

Durability, in the context of riding platforms constructed from synthetic polymers, directly impacts the longevity and overall value of the product. The resistance to wear, tear, and environmental factors is a crucial determinant of its service life.

- Impact Resistance

Polymer-based platforms exhibit varying degrees of resistance to impacts, such as those encountered during landings and collisions. The specific polymer used, along with any reinforcement techniques, influences the ability to withstand sudden force without cracking or fracturing. For instance, a platform using high-density polyethylene (HDPE) may demonstrate greater resistance to impact than one using polypropylene (PP). The implications extend to rider safety and the frequency of replacement.

- Abrasion Resistance

The surface of the riding platform is constantly subjected to abrasion from footwear and the riding surface. The choice of polymer and surface treatments determines the resistance to scratching, scuffing, and general wear. A platform with poor abrasion resistance will exhibit visible damage and reduced performance over time. Materials like polyurethane (PU) blends offer increased resistance to abrasion compared to other polymers, prolonging the platform’s lifespan.

- Environmental Degradation

Exposure to sunlight, moisture, and temperature fluctuations can cause degradation in some polymers, leading to warping, cracking, or discoloration. The incorporation of UV stabilizers and appropriate material selection mitigates these effects. A platform susceptible to environmental degradation will exhibit reduced structural integrity and aesthetic appeal. Certain polymers, such as those containing stabilizers, are specifically formulated to withstand prolonged exposure to harsh environmental conditions.

- Material Fatigue

Repeated stress and strain can lead to material fatigue, even in durable polymers. The design of the platform, including the distribution of stress points and the overall thickness, affects its resistance to fatigue. A platform prone to fatigue may exhibit premature failure. Finite element analysis (FEA) is often employed to optimize the design and minimize stress concentrations, thereby extending fatigue life.

The interplay between impact resistance, abrasion resistance, environmental degradation, and material fatigue determines the overall durability. The selection of appropriate polymers, coupled with optimized design and manufacturing processes, enhances the platform’s ability to withstand the rigors of skateboarding and contributes to a longer service life.

2. Water Resistance

Water resistance is a critical attribute of platforms made from synthetic polymers, dictating their suitability for use in diverse environmental conditions and influencing their long-term structural integrity. Unlike traditional wood-based platforms, polymers offer inherent resistance to moisture absorption, mitigating issues such as warping, delamination, and rot.

- Hydrophobic Properties of Polymers

Most polymers exhibit inherent hydrophobic properties due to their molecular structure. This characteristic limits the absorption of water, preventing the material from becoming saturated and compromising its structural integrity. For example, platforms made from high-density polyethylene (HDPE) or polypropylene (PP) demonstrate minimal water absorption compared to wood-based alternatives. This resistance is especially important in humid climates or when the platform is used on wet surfaces, ensuring consistent performance and extending its lifespan.

- Prevention of Warping and Swelling

Wood is susceptible to warping and swelling when exposed to moisture, altering its shape and affecting its performance. Polymer-based platforms resist these deformations, maintaining their original shape and dimensional stability even after prolonged exposure to water. This is crucial for maintaining consistent control and predictability during use. The dimensional stability of a polymer platform ensures that the wheel mounts remain aligned and the platform’s flex characteristics remain consistent, enhancing the rider’s experience.

- Resistance to Mold and Mildew Growth

Damp environments encourage the growth of mold and mildew on organic materials like wood, leading to degradation and potential health hazards. Polymers resist mold and mildew growth, ensuring a hygienic and durable riding surface. This resistance is beneficial for riders who frequently use their platforms in damp or humid environments. The absence of mold and mildew also contributes to the platform’s aesthetic appeal and reduces the need for specialized cleaning and maintenance.

- Longevity and Reduced Maintenance

The water resistance of polymer-based platforms translates to increased longevity and reduced maintenance requirements. Unlike wood platforms that require regular sealing and protection from moisture, polymer platforms generally require minimal upkeep. This reduces the overall cost of ownership and ensures that the platform remains in optimal condition for an extended period. Riders can spend less time on maintenance and more time riding, maximizing the value and enjoyment derived from their equipment.

The inherent water resistance of platforms constructed from synthetic polymers provides a significant advantage over traditional materials. This attribute contributes to increased durability, dimensional stability, hygiene, and reduced maintenance, making polymer-based platforms a practical choice for a wide range of riding conditions and environments.

3. Flexibility Control

Flexibility control, as a design parameter of platforms constructed from synthetic polymers, significantly influences performance characteristics. The ability to tailor the flex pattern of a polymer-based riding surface affects rider stability, responsiveness, and comfort. An excessively flexible platform may compromise stability, while an overly rigid one can transmit excessive vibrations. The intended riding style and skill level dictate the optimal degree of flexibility. For example, cruising platforms often exhibit greater flexibility to absorb bumps and enhance comfort, whereas platforms designed for technical tricks necessitate a more rigid construction for precise control. The manipulation of polymer composition, platform geometry, and reinforcement techniques allows for precise flexibility control, leading to specialized platforms catering to diverse skateboarding disciplines.

Achieving appropriate flexibility involves careful consideration of material properties and structural design. The selection of specific polymers, such as high-density polyethylene (HDPE) or polypropylene (PP), influences the inherent flexibility of the platform. Furthermore, the incorporation of reinforcement elements, such as fiberglass or carbon fiber, allows for localized stiffening or softening of the platform. For instance, a platform with carbon fiber inserts near the truck mounts will exhibit increased rigidity in that area, enhancing responsiveness during turns. Ribbing patterns on the underside of the platform also affect flexibility, with strategically placed ribs providing increased stiffness in specific directions. These design choices directly affect the riding experience, enabling riders to fine-tune their equipment to match their preferences and abilities.

In summary, flexibility control is a key engineering aspect of platforms made from synthetic polymers, impacting rider comfort, stability, and performance. By manipulating material composition and structural design, manufacturers can tailor the flex pattern of these platforms to suit specific riding styles and skill levels. This level of customization distinguishes polymer-based platforms and contributes to their growing popularity within the skateboarding community. However, challenges remain in accurately predicting and controlling flexibility across diverse environmental conditions and with prolonged use, highlighting the need for continued research and development in this area.

4. Manufacturing Cost

The cost of manufacturing represents a significant factor in the viability and market penetration of riding platforms constructed from synthetic polymers. The economic feasibility of producing these alternatives to traditional wood-based platforms directly influences their accessibility to consumers and their competitive positioning within the skateboarding market. The use of injection molding, compression molding, or other polymer processing techniques necessitates specific equipment and expertise, which contributes to the overall production expenses. Material costs, including the price of raw polymers and any reinforcing additives, also play a substantial role. A lower manufacturing cost can translate into a more affordable product, potentially attracting a broader customer base and driving sales volume. For instance, platforms utilizing recycled polymers may offer a cost advantage compared to those using virgin materials, while still maintaining acceptable performance characteristics.

Several factors can influence the manufacturing cost of riding platforms fabricated from synthetic polymers. The complexity of the platform’s design, including the presence of intricate features or customized shapes, directly affects tooling costs and production cycle times. Automation of the manufacturing process can reduce labor expenses but requires a substantial initial investment in equipment. The scale of production also impacts per-unit costs, with larger production runs typically resulting in economies of scale. Consider the example of a small-scale manufacturer producing limited quantities of customized platforms versus a large-scale manufacturer producing mass-market platforms; the latter likely benefits from significantly lower per-unit manufacturing costs. Furthermore, variations in polymer prices and availability can influence production expenses, requiring manufacturers to carefully manage their supply chains.

In summary, manufacturing cost is a critical consideration for the development and commercialization of riding platforms constructed from synthetic polymers. Efficient manufacturing processes, strategic material sourcing, and optimized designs contribute to lower production expenses, enhancing the affordability and competitiveness of these platforms within the skateboarding market. However, minimizing manufacturing costs should not compromise the quality, durability, or performance of the platform. Balancing cost considerations with product performance is essential for achieving long-term success in this market segment. Technological advancements in polymer processing and material science may further reduce manufacturing costs and enhance the performance characteristics of polymer-based platforms in the future.

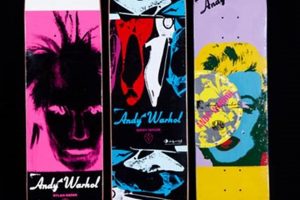

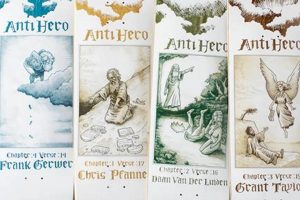

5. Design Versatility

The inherent malleability of polymers grants a significant degree of design freedom in the creation of riding platforms, often referred to as synthetic platforms. This characteristic enables manufacturers to deviate from traditional shapes and structural configurations, fostering innovation in both aesthetics and functional performance. For example, integrated grip patterns can be directly molded into the surface, eliminating the need for applied grip tape and resulting in a more streamlined appearance. Similarly, complex concave profiles can be easily replicated across large production runs, ensuring consistent performance characteristics. The versatility in design extends to incorporating integrated features, such as LED lighting or storage compartments, which would be difficult or impossible to achieve with conventional materials.

The functional advantages arising from design versatility are numerous. Optimized aerodynamic profiles can enhance speed and stability, while strategically placed flex zones can improve shock absorption and responsiveness. Consider the development of platforms with variable thickness profiles, allowing for increased strength in high-stress areas and reduced weight in less critical regions. Moreover, the ability to mold intricate internal structures provides opportunities for weight reduction without compromising structural integrity. These advancements contribute to enhanced performance and rider comfort. The absence of grain structure, inherent in wood, further allows for uniform material properties and predictable behavior, essential for reliable performance.

In conclusion, the design versatility afforded by polymers offers significant advantages in the development of riding platforms. The ability to mold intricate shapes, integrate functional features, and optimize structural characteristics translates to improved performance, enhanced aesthetics, and increased customization options. While challenges remain in optimizing material properties and ensuring long-term durability, the inherent design flexibility of polymers promises continued innovation in the realm of synthetic riding platforms.

Frequently Asked Questions About Plastic Skate Decks

The following section addresses common inquiries regarding riding platforms constructed from synthetic polymers, providing concise and informative responses.

Question 1: What are the primary advantages of a riding platform made of plastic compared to one made of wood?

Platforms constructed from synthetic polymers typically exhibit increased resistance to water damage, warping, and cracking. The manufacturing process allows for greater design flexibility and customization.

Question 2: Are riding platforms made of plastic as durable as those made of wood?

Durability varies depending on the specific polymer used and the manufacturing process. High-quality polymers, such as reinforced nylon or polyurethane blends, can provide comparable or even superior durability compared to traditional wood.

Question 3: How does the flexibility of a platform constructed from plastic compare to that of a wood platform?

The flexibility can be tailored by adjusting the polymer composition, platform thickness, and internal structure. Manufacturers can engineer platforms with varying degrees of flex to suit different riding styles and preferences.

Question 4: Are riding platforms made of plastic environmentally friendly?

The environmental impact depends on the type of polymer used and the manufacturing process. Platforms constructed from recycled polymers or bio-based plastics offer a more sustainable alternative. Proper disposal and recycling practices are crucial.

Question 5: How does the cost of a riding platform made of plastic compare to that of a wood platform?

The cost varies depending on the materials used, the manufacturing process, and the brand. In some cases, synthetic platforms can be more affordable than high-quality wood platforms, while others may be more expensive.

Question 6: What are some common applications for riding platforms constructed from plastic?

Synthetic platforms are used in a variety of skateboarding disciplines, including cruising, carving, freestyle, and downhill. Their durability and water resistance make them particularly suitable for use in diverse environmental conditions.

In summary, riding platforms constructed from synthetic polymers offer distinct advantages and disadvantages compared to traditional wood platforms. The choice between the two depends on individual preferences, riding style, and environmental considerations.

The next section will explore the potential future trends and innovations within the realm of polymer-based skateboarding equipment.

Conclusion

This exploration has examined riding platforms constructed from synthetic polymers, commonly referred to as “plastic skate deck.” It outlined material composition, manufacturing considerations, performance characteristics, durability, water resistance, flexibility control, manufacturing costs, and design versatility. These factors collectively determine the suitability and performance of a “plastic skate deck” across various skateboarding disciplines.

The selection of a riding platform requires careful consideration of individual needs and riding conditions. Further research and development in polymer science and manufacturing processes may yield more sustainable and high-performance “plastic skate deck” options in the future. The continued evaluation of both performance and environmental impact remains crucial for responsible innovation within this sector of skateboarding equipment.