The phrase identifies entities that manufacture platforms specifically designed for skateboarding that exhibit superior performance, durability, and overall quality. These manufacturers typically utilize high-grade materials, advanced construction techniques, and incorporate rider feedback to produce skate decks that enhance the skateboarding experience. As an example, a manufacturer known for its utilization of specific wood layering techniques and rigorous testing processes might be classified within this category.

Selection of a reliable manufacturer is crucial for skateboarders of all skill levels. A well-constructed platform improves board control, responsiveness, and safety, enabling riders to progress and execute tricks effectively. Historically, certain manufacturers have achieved prominence by consistently delivering products that meet the evolving demands of the skateboarding community, establishing a reputation for quality and innovation and contributing significantly to the sport’s advancement.

The following sections will explore key criteria for evaluating skateboard platforms, highlighting factors such as material composition, construction methods, shape variations, and brand reputation, providing a framework for understanding the nuances within the market.

Guidance From Established Skateboard Platform Manufacturers

This section offers guidance derived from the collective experience and best practices employed by leading skateboard platform manufacturers. This information serves to inform consumer choices and promote optimal product utilization.

Tip 1: Evaluate Wood Quality: Reputable manufacturers prioritize high-grade maple wood, often sourced from specific regions known for producing dense and durable timber. The quality of the wood directly impacts the deck’s strength, pop, and longevity.

Tip 2: Assess Construction Integrity: Manufacturers often employ specific pressing techniques and adhesive formulas to ensure a robust and consistent deck construction. Examine the uniformity of the plies and the overall finish for signs of careful craftsmanship.

Tip 3: Consider Deck Shape and Concave: Variations in deck shape and concave affect board feel and trick performance. Manufacturers offer a range of options to cater to different skateboarding styles and preferences. Understanding these nuances is key to selecting a suitable platform.

Tip 4: Pay Attention to Deck Size: Deck width influences stability and control. Wider decks generally offer greater stability, while narrower decks facilitate quicker turning. Select a deck width appropriate for shoe size and intended riding style.

Tip 5: Research Brand Reputation: Established manufacturers often have a track record of consistent quality and innovation. Reviews and feedback from experienced skateboarders can provide valuable insights into brand reliability.

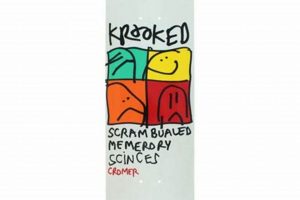

Tip 6: Inspect Graphics and Finishes: While primarily aesthetic, the quality of the graphics and finishes can indicate attention to detail. Durable, well-applied graphics resist wear and tear and contribute to the overall appearance of the skateboard.

Tip 7: Understand the Warranty: Leading manufacturers typically offer warranties against manufacturing defects. Review the warranty terms and conditions before purchasing to ensure adequate protection against potential issues.

Adherence to these recommendations, gleaned from the practices of experienced platform manufacturers, enhances product selection and fosters improved skateboarding performance. Informed decision-making ultimately contributes to a more enjoyable and successful skateboarding experience.

The subsequent section will delve into the maintenance and care of skateboard platforms, providing guidance on maximizing their lifespan and performance potential.

1. Wood Quality

Wood quality represents a foundational element in the assessment of skateboard deck manufacturers. The material’s properties directly influence the deck’s performance characteristics, including its structural integrity, responsiveness, and resistance to wear. Manufacturers recognized for superior skateboard platforms prioritize specific wood types, most notably hard rock maple, due to its high density and fiber strength. This choice results in a deck that exhibits greater popthe spring-like action enabling aerial maneuversand increased resistance to breakage under stress. Inferior wood quality leads to diminished performance, compromised safety, and reduced product lifespan. For instance, a manufacturer utilizing less dense or improperly seasoned wood will produce decks prone to delamination and premature failure, impacting the overall rider experience.

The source and treatment of the wood are equally critical. Reputable manufacturers often source maple from regions with controlled forestry practices, ensuring sustainable sourcing and consistent material quality. Seasoning processes, which involve carefully drying the wood to reduce moisture content, are essential for preventing warping and improving dimensional stability. In contrast, manufacturers employing subpar sourcing practices or inadequate seasoning methods may face challenges in maintaining consistent product quality. Furthermore, variations in grain orientation and ply construction methods contribute to the overall strength and stiffness of the skateboard deck. Precise alignment of wood grain patterns during manufacturing optimizes load distribution, enhancing the deck’s ability to withstand impact forces.

In summation, the selection of wood quality directly determines the product’s suitability for skateboarding. Rigorous material selection, meticulous seasoning practices, and optimized construction techniques distinguish those considered good skate deck brands. Skateboarders should consider wood quality as a key component of overall value, recognizing its contribution to performance, longevity, and safety. The choice between a quality wood and a cheaper alternative directly translates to the longevity and safety of the product.

2. Construction Method

Construction methods directly influence the durability, performance, and overall quality that define a reputable skateboard deck manufacturer. The processes employed to assemble a skateboard deck from individual plies of wood are critical in determining its structural integrity and responsiveness. Certain techniques and materials employed distinguish leading manufacturers from others in the industry.

- Pressing Techniques

Pressing techniques, including the use of hydraulic presses and specialized molds, play a critical role in shaping the deck and bonding the plies together. Manufacturers known for producing high-quality decks often utilize cold-pressing methods, which apply controlled pressure over extended periods, minimizing stress on the wood fibers. This approach results in a deck with improved strength and reduced risk of warping or delamination. In contrast, hot-pressing methods, while faster, can compromise the wood’s integrity, leading to a less durable product. Baker Skateboards, for instance, is known to use a specific pressing method to maintain the quality of the deck.

- Adhesive Formulation

The type of adhesive used to laminate the plies is another crucial aspect of the construction process. High-quality manufacturers prioritize water-resistant and flexible adhesives that maintain their bond strength under varying environmental conditions. Epoxy-based resins, for example, offer superior adhesion and impact resistance compared to cheaper alternatives like polyvinyl acetate (PVA) glues. The adhesive must effectively distribute stress throughout the deck structure, preventing ply separation and ensuring consistent performance over time. A company like Powell Peralta is known for proprietary adhesive formulas to enhance deck durability.

- Ply Orientation and Layup

The orientation and arrangement of the individual wood plies significantly impact the deck’s stiffness, pop, and torsional rigidity. Manufacturers often strategically orient the wood grain to maximize strength in key areas, such as the nose and tail. Cross-grain laminations, where the wood grain of adjacent plies runs perpendicular to each other, enhance the deck’s resistance to bending and twisting forces. A consistent and precise layup ensures uniform performance across the entire deck surface. Santa Cruz skateboards utilizes specific ply patterns to provide a durable and high-performing product.

- Curing Process

After pressing, the decks undergo a curing process to fully set the adhesive. This process ensures that the adhesive achieves its maximum strength and bonds effectively with the wood. The temperature and duration of the curing process must be carefully controlled to prevent over- or under-curing, both of which can negatively affect the deck’s durability. A manufacturer with quality control will often be able to provide the proper product.

In conclusion, construction methods represent a defining characteristic of a good skate deck manufacturer. The utilization of advanced pressing techniques, high-quality adhesives, strategic ply orientation, and controlled curing processes directly contributes to the production of skateboard decks that exhibit superior performance, durability, and overall value. These processes ensure that the product provides a stable and responsive platform for skateboarding, improving a skaters experiences.

3. Shape Variation

Shape variation, encompassing both the overall outline and the concave profile of a skateboard deck, is a critical differentiator among manufacturers recognized for product quality. A reputable skateboard deck manufacturer understands the effect of even minor shape alterations on a skateboarder’s performance and therefore offers diverse options to accommodate varying riding styles and preferences. The outline, from classic popsicle shapes to more directional forms, influences turning radius and stability, while the concave, the curvature across the width of the deck, affects foot lock-in and board feel. For example, a deeper concave provides enhanced grip and control for technical street skating, whereas a flatter concave might be favored for transition skating. Therefore, manufacturers who invest in research and development to produce a range of shapes demonstrate commitment to meeting the diverse needs of the skateboarding community.

The precise application of shape variation is also influenced by the manufacturer’s understanding of material properties and production techniques. Adjustments to the deck’s shape affect stress distribution within the wood, potentially impacting durability. A manufacturer renowned for quality carefully considers these factors, optimizing the shape not only for performance but also for long-term structural integrity. This can be exemplified by analyzing brands such as Anti Hero or Krooked, known for distinctive deck shapes that maintain structural soundness through specific wood layering and pressing processes. These details showcase expertise in integrating shape with the overall deck construction. Shape has to influence the deck durability.

Ultimately, the availability and execution of shape variations serve as a key indicator when evaluating skateboard deck manufacturers. A manufacturer’s dedication to providing thoughtfully designed and well-executed shapes directly enhances the rider’s ability to personalize their skateboarding experience and optimize their performance. Shape variations, therefore, are not merely aesthetic choices but integral components of the functional design that separate leading manufacturers from those offering generic or poorly executed products.

4. Size Availability

The range of sizes offered by a skateboard deck manufacturer directly correlates with its standing as a purveyor of high-quality products. Varied dimensions are crucial for accommodating the diverse needs of the skateboarding population, including individuals of different ages, foot sizes, and riding styles. A manufacturer limiting its size offerings restricts accessibility and reduces its ability to cater to the full spectrum of skaters. For example, a manufacturer exclusively producing decks narrower than 8 inches would exclude larger skaters seeking stability, while failing to offer smaller decks would disadvantage younger riders requiring greater maneuverability. Good skateboard deck brands ensure they cater for most skaters.

The significance of size availability extends beyond mere accommodation. It indicates a manufacturer’s commitment to understanding and responding to the nuanced demands of the market. A comprehensive size range reflects investment in tooling, design, and inventory management, demonstrating a proactive approach to customer satisfaction. Consider companies like Almost or Element, which maintain extensive size portfolios, indicating they have considered most if not all users. The size selection shows commitment.

Therefore, size availability is not simply a matter of offering more options; it is an indicator of a manufacturer’s overall dedication to quality and service. A manufacturer that prioritizes size availability signals a commitment to inclusivity and understanding, which in turn reflects positively on its reputation as a dependable platform provider. This commitment translates directly into enhanced customer satisfaction and loyalty, reinforcing the connection between expansive size offerings and good skate deck brands.

5. Graphic Durability

Graphic durability serves as a tangible indicator of a skateboard deck manufacturer’s commitment to overall product quality. The application of graphics onto a skateboard deck extends beyond mere aesthetics; it reflects the manufacturer’s investment in materials, processes, and quality control. Manufacturers recognized as producers of reliable skateboard platforms prioritize graphic durability, understanding that a quickly deteriorating graphic undermines the perceived value of the entire product. The process, whether screen printing, heat transfer, or digital printing, reveals dedication to detail and long-term product integrity. Companies with inferior processes show wear and tear, a sign the product is made cheaply.

The connection between graphic durability and a brand’s reputation stems from its direct impact on consumer perception. A deck with a vibrant, long-lasting graphic projects an image of quality and attention to detail, influencing purchasing decisions and fostering brand loyalty. Conversely, graphics that chip, fade, or peel prematurely create the impression of a low-quality product, eroding consumer trust and damaging the brand’s reputation. Consider, for example, brands like Real or Girl, which are known for their detailed and durable graphics that withstand considerable wear and tear. This durability enhances user satisfaction and promotes repeat purchases. However, companies without a proper process result in an inferior product.

In conclusion, graphic durability functions as a measurable attribute reflecting a skateboard deck manufacturer’s overall dedication to quality and customer satisfaction. A lasting graphic represents a commitment to craftsmanship, while a poorly executed one signals a lack of attention to detail. As such, skateboarders should consider graphic durability as a tangible indicator of a brand’s commitment to producing reliable and aesthetically pleasing products. A damaged graphic results in product and brand degradation.

6. Brand Reputation

Brand reputation functions as a distillation of customer experiences, manufacturing consistency, and overall product quality, directly influencing the perception of “good skate deck brands.” Positive brand perception is not arbitrarily assigned; rather, it accrues over time through the consistent delivery of reliable, durable, and well-designed skateboard platforms. This sustained performance generates a level of consumer trust that differentiates leading manufacturers from those with inconsistent or unreliable offerings. Instances such as Santa Cruz Skateboards, with a legacy of innovation and quality spanning decades, exemplify how brand reputation becomes synonymous with product excellence. The sustained excellence directly is tied to “good skate deck brands”.

The ramifications of brand reputation extend beyond mere consumer preference; it directly affects market share, pricing power, and the manufacturer’s ability to attract and retain talent. A manufacturer with a strong brand reputation benefits from increased consumer willingness to pay a premium for its products, reflecting the perceived value associated with the brand’s name. This advantage allows reputable manufacturers to invest further in research and development, fostering a cycle of innovation and continuous improvement. Conversely, manufacturers with negative or inconsistent brand reputations often struggle to compete, facing challenges in attracting customers and maintaining market share, resulting in loss of confidence.

Ultimately, brand reputation represents a critical, albeit intangible, asset for skateboard deck manufacturers. It serves as a shortcut for consumers seeking reliable and high-performing products, reducing the perceived risk associated with their purchase. While other factors such as price and aesthetics influence buying decisions, brand reputation functions as a foundational element, underpinning consumer confidence and driving long-term brand success, solidifying its position among “good skate deck brands.” Without a strong brand reputation, products will remain inferior.

Frequently Asked Questions

The following addresses common inquiries regarding the selection and attributes of high-quality skateboard decks, providing objective guidance for informed purchasing decisions.

Question 1: What distinguishes a superior skateboard deck from a standard model?

Superior skateboard decks are distinguished by material quality, construction precision, and shape consistency. Premium materials, such as hard rock maple, enhance durability and performance. Precise construction methods ensure structural integrity. Consistent shapes promote predictable handling. Collectively, these attributes contribute to an enhanced skateboarding experience.

Question 2: How does deck width influence skateboarding performance?

Deck width affects stability and maneuverability. Wider decks (8.25 inches and up) provide increased stability, suitable for transition skating and larger individuals. Narrower decks (8.0 inches and below) offer greater maneuverability, favored for technical street skating. The optimal width depends on skater size, style, and preference.

Question 3: What constitutes a durable skateboard deck graphic?

Graphic durability depends on the printing method and ink quality. Heat-transferred and screen-printed graphics using high-quality inks exhibit greater resistance to abrasion and fading. Multiple layers of clear coat protect the graphic from wear. Durability indicates the manufacturer’s commitment to long-term product value.

Question 4: Is brand reputation a reliable indicator of deck quality?

Brand reputation can serve as a reliable, albeit not definitive, indicator of deck quality. Established brands with a history of consistent performance and positive customer feedback often produce reliable products. However, emerging brands can also offer high-quality decks, warranting independent evaluation of materials and construction.

Question 5: How do pressing techniques impact deck strength and longevity?

Pressing techniques influence ply adhesion and deck shape. Cold-pressing methods, which apply pressure gradually, minimize stress on the wood, resulting in stronger and more durable decks. Hot-pressing methods, while faster, can compromise wood integrity. Knowledge of pressing methods aids in assessing deck quality.

Question 6: What role does concave play in skateboard deck performance?

Concave, the curvature across the deck’s width, affects foot lock-in and board feel. Deeper concave enhances grip and control, suitable for technical skating. Shallower concave provides a more mellow feel, favored for cruising and transition. Concave preference is a matter of personal preference and skating style.

In summation, informed skateboard deck selection requires careful consideration of material quality, construction methods, graphic durability, brand reputation, and shape characteristics. Evaluating these factors enables skateboarders to make optimal purchasing decisions.

The subsequent content will delve into the care and maintenance of skateboard decks, providing guidance on prolonging product lifespan and sustaining optimal performance.

Conclusion

This exploration elucidated key factors delineating competent skateboard platform manufacturers. Material selection, construction techniques, shape variations, graphic durability, and brand standing were examined. Each aspect contributes significantly to the overall performance and longevity of the product. A discerning approach to these characteristics is paramount when selecting skateboarding equipment.

Ultimately, a carefully considered selection process promotes safety and enhances the skateboarding experience. Prioritizing informed choices, predicated on objective evaluation, remains crucial for both novice and experienced skateboarders seeking optimal performance and enduring equipment. The quality of the deck significantly impacts the overall experience of the skateboarder.