A foundational component for skateboarding, it represents an undecorated or unfinished wooden platform. Typically constructed from multiple layers of maple veneer pressed together, this item serves as the base upon which trucks, wheels, and grip tape are mounted. An example includes a seven-ply maple deck lacking any graphics, ready for customization.

Its significance lies in its versatility. It provides skateboarders with the opportunity to personalize their equipment through custom artwork, stickers, or grip tape designs. Historically, these unmodified platforms were the standard before the widespread adoption of pre-printed graphics, emphasizing rider creativity and individuality. The blank surface also offers economic advantages, being generally more cost-effective than decorated alternatives.

With this foundational understanding established, subsequent discussion will delve into topics such as the different wood types used in their manufacture, the various deck shapes and sizes available, and methods for customization and artistic expression on the surface.

Guidance on Undecorated Skate Platforms

The following guidelines provide insights for individuals selecting and utilizing unadorned skateboard platforms, focusing on maximizing performance and customization potential.

Tip 1: Assess Wood Quality: Prioritize platforms constructed from high-grade maple veneer. Consistent wood grain and minimal imperfections indicate durability and resistance to warping.

Tip 2: Consider Deck Dimensions: Select the platform width based on shoe size and intended riding style. Wider platforms offer increased stability, while narrower platforms facilitate quicker turning.

Tip 3: Inspect Concavity: Evaluate the depth and angle of the concave. A steeper concave provides enhanced foot grip and board feel, while a mellow concave offers greater foot freedom.

Tip 4: Prepare the Surface: Before applying grip tape or artwork, lightly sand the surface to promote adhesion and prevent air bubbles. Use fine-grit sandpaper for optimal results.

Tip 5: Utilize Appropriate Grip Tape: Choose grip tape with a grit level suitable for the intended riding conditions. Coarser grit provides greater traction, while finer grit offers more subtle control.

Tip 6: Seal Finished Artwork: After applying custom graphics, consider applying a sealant to protect the design from wear and tear. Clear acrylic sprays are commonly used for this purpose.

Tip 7: Monitor for Damage: Regularly inspect the platform for cracks, chips, or delamination. Promptly address any damage to prevent further degradation and potential injury.

Adhering to these recommendations will assist in selecting, preparing, and maintaining an unadorned skateboard platform, maximizing its performance and longevity.

The subsequent sections will address advanced customization techniques and explore the evolving trends in skateboard platform design.

1. Maple Ply Construction

Maple ply construction is intrinsically linked to the structural integrity and performance characteristics of an undecorated skateboard platform. The process, involving the layering and pressing of thin sheets of maple veneer, forms the foundation upon which the platform’s strength, flexibility, and responsiveness depend. The quality of the maple used and the precision of the pressing process directly affect the deck’s ability to withstand the stresses of skateboarding. A poorly constructed platform, even if visually similar, will exhibit reduced pop, increased susceptibility to breakage, and a shorter lifespan. For instance, a deck manufactured with lower-grade maple or inconsistent pressing will delaminate more easily under impact, leading to premature failure.

The number of plies and the grain orientation within each layer also contribute to the overall performance. Typically, seven plies are used, providing a balance between weight and strength. Alternating the grain direction of each ply enhances resistance to torsional forces and distributes stress more evenly across the deck’s surface. This design allows for controlled flex, enabling riders to execute maneuvers effectively. Consider the difference between a mass-produced deck using readily available materials versus one constructed with carefully selected, vertically laminated maple – the latter consistently provides better resilience and a more predictable riding experience.

In summary, maple ply construction is not merely a manufacturing method but a critical determinant of a skateboard platform’s performance and durability. Understanding the nuances of this construction process is essential for both manufacturers seeking to produce high-quality platforms and riders seeking equipment that can withstand the demands of skateboarding. The inherent challenge lies in balancing cost-effectiveness with the need for high-grade materials and precise manufacturing techniques, ultimately impacting the final product’s longevity and the rider’s experience. This understanding is pivotal to the broader discussion of skateboard platform design and optimization.

2. Concave Depth Variance

Concave depth variance, a significant characteristic of a skateboard platform, directly influences its functionality. The degree of curvature across the width of the platform’s surface affects the rider’s foot placement, board feel, and ability to execute various maneuvers. A deeper concave provides a more pronounced pocket for the feet, enhancing grip and facilitating flip tricks. Conversely, a shallower concave offers increased foot freedom and a more relaxed riding experience. Because the plain skate deck lacks pre-existing graphics that might visually mask the concave, the shape is readily apparent and easily assessed by the rider. This allows for a more discerning selection process based purely on the functional characteristics of the platform. For example, a street skater may opt for a deeper concave for improved flick control, whereas a transition skater might prefer a flatter profile for greater stability on ramps.

The absence of graphics on a plain skate deck further emphasizes the importance of concave depth variance. With no visual distractions, the rider is acutely aware of the subtle nuances in the platform’s shape. This heightened sensitivity allows for a more precise connection between the rider’s intentions and the board’s response. Moreover, the blank surface encourages customization of grip tape patterns, which can further enhance the functional benefits of a particular concave depth. Riders often use grip tape to create custom pockets or ridges, tailoring the platform’s feel to their specific riding style. Therefore, understanding and appreciating concave depth variance is vital in selecting a blank deck that best complements individual preferences and skill levels.

In summary, concave depth variance is a fundamental element in the overall performance of an undecorated skateboard platform. Its direct influence on foot placement, board feel, and maneuverability, amplified by the absence of distracting graphics, underscores its significance in platform selection. A clear comprehension of concave profiles enables riders to choose a plain skate deck that aligns precisely with their needs, optimizing their skateboarding experience. The challenges related to concave depth variance lie in the subjective nature of rider preference and the variability in manufacturing tolerances. Therefore, hands-on assessment and careful inspection are crucial when selecting an unadorned platform.

3. Surface Preparation Methods

Surface preparation methods are a crucial precursor to customizing a plain skate deck. These methods directly impact the adhesion and longevity of any subsequent graphic applications, be it paint, stickers, or grip tape. A raw, untreated wooden platform presents a surface that is often too smooth or too rough for optimal bonding. Contaminants like oils from manufacturing processes or handling can also impede adhesion. Effective surface preparation removes these impurities and creates a textured surface that promotes a strong mechanical bond. Neglecting this step often results in premature peeling, cracking, or bubbling of applied materials. As an example, attempting to apply grip tape directly to a freshly manufactured deck without prior cleaning and sanding may lead to air pockets and uneven adhesion, compromising the skater’s control and safety.

The specific techniques employed for surface preparation vary depending on the intended customization. Light sanding with fine-grit sandpaper is a common practice to create a slightly roughened surface for improved grip tape application or for creating a receptive base for paint. Cleaning with isopropyl alcohol removes residual oils and debris. For more complex graphic applications, such as screen printing, a primer might be applied to seal the wood and create a uniform surface for the ink. Furthermore, proper sealing prevents moisture absorption, which can cause warping or delamination of the deck over time. The practical significance of understanding these methods is evident in the final aesthetic and functional quality of the customized platform. A well-prepared surface ensures that artwork remains vibrant and intact, and that grip tape provides consistent traction.

In conclusion, surface preparation methods are not merely preparatory steps but integral components in the customization process of a plain skate deck. They serve to optimize adhesion, enhance the visual appeal of applied graphics, and prolong the lifespan of the customized platform. Challenges lie in selecting the appropriate methods for specific materials and avoiding over-preparation, which can damage the wood. This understanding connects to the broader theme of skateboard customization, highlighting the importance of proper technique and material selection in achieving desired results.

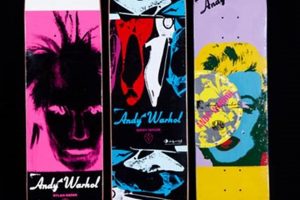

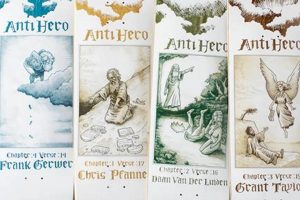

4. Customization Art Mediums

The selection of customization art mediums directly influences the aesthetic and functional outcome of personalizing a plain skate deck. The undecorated surface serves as a blank canvas, allowing for diverse artistic expression. Choice of medium, ranging from spray paint to acrylic markers, dictates the durability, vibrancy, and detail achievable. For instance, utilizing enamel paints may produce a resilient, weather-resistant finish ideal for outdoor use, but requires meticulous application to prevent drips or uneven coverage. Conversely, applying fine-tipped paint markers offers greater precision for intricate designs but may lack the expansive coverage of spray paint. Each medium’s unique properties contribute distinctly to the final appearance and longevity of the custom graphic.

Furthermore, the interaction between the chosen medium and the wood’s surface characteristics warrants consideration. Porous wood can absorb paint unevenly, leading to inconsistent color saturation. Pre-sealing the plain skate deck mitigates this effect, creating a uniform base for the artwork. Grip tape application also demands specific mediums; applying adhesive-backed stencils with spray paint necessitates a careful selection of paints that resist bleeding under the tapes edges. The integration of these artistic elements enhances not only the visual appeal but also the rider’s personal connection to the equipment. For example, a skater may choose to immortalize a significant event or idea through custom graphics, thereby transforming the deck into a meaningful art piece beyond its functional purpose.

In summary, customization art mediums constitute a pivotal component in the personalization of a plain skate deck. The understanding of each medium’s characteristics, its interaction with the wooden surface, and their practical implications directly impacts the artistic outcome and the board’s usability. Challenges in this domain involve balancing artistic expression with durability requirements and mastering the application techniques of various mediums. This understanding seamlessly integrates into the broader theme of skateboard customization, emphasizing the symbiotic relationship between art, function, and individual expression within skateboarding culture.

5. Structural Integrity Monitoring

Structural integrity monitoring is a vital practice concerning undecorated skateboard platforms, ensuring rider safety and maximizing the lifespan of the equipment. The practice encompasses regular inspection and assessment of the platform’s physical condition to detect potential weaknesses or damage that could compromise its functionality. The absence of pre-applied graphics on a plain skate deck facilitates easier visual inspections, as flaws are not obscured.

- Crack Detection

Crack detection is the identification of fractures within the deck’s maple plies. Small hairline cracks, often initiated by repeated stress or impact, can propagate and lead to catastrophic failure. Visual inspection, coupled with a flex test (assessing the deck’s give under pressure), can reveal such damage. For example, a crack near the truck mounting holes poses a significant risk of the trucks detaching during use.

- Delamination Assessment

Delamination involves the separation of the individual maple veneer layers composing the deck. This phenomenon weakens the platform’s structural rigidity and compromises its ability to absorb impact. Inspecting the edges of the plain skate deck for peeling or bubbling is crucial. Delamination often occurs after exposure to moisture or extreme temperature fluctuations.

- Impact Damage Evaluation

Impact damage, typically resulting from collisions or forceful landings, can create localized weaknesses within the deck. These weaknesses manifest as dents, compression marks, or splintering. Assessing the severity and extent of the damage is essential to determine whether the platform remains safe for use. For instance, a significant dent near the center of the deck may indicate compromised core strength.

- Hardware Integrity Verification

Hardware integrity verification involves inspecting the truck mounting bolts, nuts, and washers for signs of wear, corrosion, or loosening. Loose hardware can create stress points and contribute to premature deck failure. Ensuring proper tightness and replacing worn hardware are critical aspects of maintaining structural integrity. Regular tightening of the truck mounting hardware should be conducted to reduce the risk of potential integrity issues.

These facets of structural integrity monitoring underscore the need for proactive assessment and maintenance of plain skate decks. Regular inspections and prompt replacement of damaged components are essential for ensuring rider safety and prolonging the useful life of the platform. Without graphics obscuring the surface, inspection is greatly simplified. Neglecting structural integrity can have serious consequences, potentially leading to injury or equipment failure. It is important to remember, monitoring structural Integrity protects not just the boarder but also the community around them.

Frequently Asked Questions

This section addresses common inquiries regarding the characteristics, usage, and maintenance of undecorated skateboard platforms. The following questions and answers aim to provide clarity and facilitate informed decision-making for skateboarders and enthusiasts.

Question 1: What advantages does a plain skate deck offer over a pre-printed graphic deck?

Undecorated platforms afford complete customization. Riders can apply personally designed artwork, allowing for unique expression. Additionally, these platforms are often more cost-effective, providing a blank canvas without the added expense of pre-existing graphics.

Question 2: Are plain skate decks constructed from the same materials as graphic decks?

Yes, typically. Both utilize laminated maple veneer, with variations existing in wood grade and pressing techniques. The absence of graphics does not inherently affect the construction materials.

Question 3: How should a plain skate deck be prepared for grip tape application?

Surface preparation is critical. Light sanding with fine-grit sandpaper creates a textured surface for optimal grip tape adhesion. Cleaning with isopropyl alcohol removes any residual oils or contaminants.

Question 4: What types of art mediums are suitable for customizing a plain skate deck?

A range of mediums can be employed, including spray paint, acrylic markers, paint pens, and stencils. Each medium offers distinct properties regarding durability, color vibrancy, and application precision. Appropriate sealant application following customization enhances art preservation.

Question 5: How can the structural integrity of a plain skate deck be maintained?

Regular inspection is essential. Examine the platform for cracks, delamination, and impact damage. Pay close attention to the edges and truck mounting areas. Promptly address any damage to prevent further degradation and potential safety hazards.

Question 6: Does the absence of graphics impact the performance of the skateboard?

No. The presence or absence of graphics does not inherently affect the riding characteristics. Performance is primarily determined by the deck’s shape, concave, materials, and construction quality. The skater’s personal preference is crucial for performance.

In conclusion, plain skate decks provide a versatile and cost-effective foundation for skateboarding. Proper selection, preparation, and maintenance contribute to an enhanced riding experience. Careful assessment of these platforms, coupled with appropriate customization techniques, allows for both personalized aesthetics and sustained performance.

The following section will provide a guide in choosing a right grip tape for plain skate deck.

Conclusion

The preceding discourse has illuminated the multifaceted nature of the plain skate deck. The absence of pre-applied graphics transforms this platform into a versatile foundation for both functional riding and artistic expression. Careful consideration of wood quality, concave profiles, and surface preparation techniques ensures optimal performance and customization potential. Routine monitoring for structural degradation, coupled with appropriate maintenance, extends the usable lifespan of the deck, promoting rider safety.

The continued exploration of materials science and manufacturing innovation promises further advancements in plain skate deck design. The skateboarding community’s ongoing engagement with this foundational element will undoubtedly drive future refinements, enhancing both the riding experience and the opportunities for individual artistic statement. Independent skateboarding shops and the support they get play a significant role on how “plain skate deck” is received in a specific skateboarding community.