Components designed to be affixed to the chassis of inline skates, these circular objects facilitate movement across surfaces. They are typically constructed from polyurethane and manufactured in various sizes, durometers (hardness), and profiles to cater to different skating styles and terrains. A typical example involves swapping out worn or damaged components to maintain optimal performance.

These elements are crucial for ensuring a smooth, efficient, and safe skating experience. Replacing worn or damaged ones improves grip, reduces vibration, and enhances overall control. This extends the lifespan of the skates themselves, offering a cost-effective alternative to purchasing new equipment. Historically, the development of more durable and performance-oriented compositions has significantly impacted the evolution of inline skating as both a recreational activity and a competitive sport.

The following discussion will delve into the key factors to consider when selecting new rolling components, including size, durometer, profile, and bearing compatibility, providing a comprehensive guide for users seeking to optimize their skating performance and equipment longevity.

Essential Guidance on Roller Component Exchange

The subsequent points offer critical advice for individuals undertaking the replacement process. Implementing these recommendations will contribute to improved performance, enhanced safety, and extended equipment lifespan.

Tip 1: Wheel Size Considerations: Selecting the correct diameter is paramount. The skate frame dictates the maximum acceptable dimension. Exceeding this limit will impede functionality. Consult the skate manufacturer’s specifications or existing components for accurate measurements.

Tip 2: Durometer (Hardness) Selection: The durometer, measured on the A scale, influences grip and speed. Lower values offer increased grip, suitable for slippery surfaces. Higher values prioritize speed, ideal for smooth terrain. Assess prevailing skating conditions to determine the optimal hardness rating.

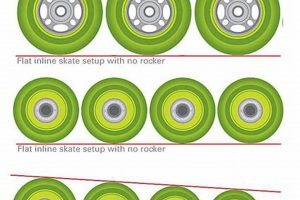

Tip 3: Profile (Shape) Evaluation: The profile dictates the contact patch with the skating surface. Rounded profiles enhance maneuverability, while flat profiles maximize speed and stability. Consider the intended skating style recreational, aggressive, speed skating to guide profile selection.

Tip 4: Bearing Compatibility Verification: Bearings are integral to rotational efficiency. Ensure compatibility between the bearing size (typically 608 or 688) and the hub diameter of the chosen replacement parts. Incompatible bearings will compromise performance and potentially damage the equipment.

Tip 5: Regular Inspection for Wear: Periodic examination of each component is crucial. Uneven wear patterns indicate potential alignment issues or bearing problems. Premature replacement of worn items prevents performance degradation and safety hazards.

Tip 6: Rotational Maintenance: Rotating positions regularly distributes wear evenly across all components. This practice extends the overall lifespan and maintains consistent performance characteristics.

Tip 7: Surface Suitability Considerations: Different compositions exhibit varying levels of performance across diverse surfaces. Rough asphalt will necessitate a more durable formulation compared to smooth indoor surfaces. Select materials appropriate for the intended environment.

Adhering to these recommendations will optimize skating performance, extend component longevity, and enhance overall safety. Prioritizing these aspects contributes to a more enjoyable and effective skating experience.

The following section will address common inquiries and misconceptions regarding the installation and maintenance of replacement components, providing further clarity and practical guidance.

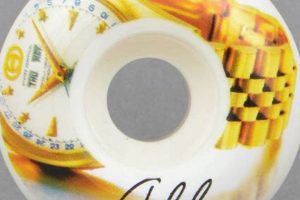

1. Durometer (hardness)

Durometer, a measure of a material’s resistance to indentation, is a critical specification for inline skate replacement wheels. It is typically expressed on the A scale, ranging from softer compounds around 74A to harder compounds reaching 90A and beyond. A direct correlation exists between durometer and performance characteristics. Softer compounds provide increased grip, particularly on slick surfaces, at the expense of rolling speed. Conversely, harder compounds offer lower rolling resistance and thus higher speed, but with reduced grip. For example, a skater using 78A wheels on a polished indoor surface would experience superior control compared to using 85A wheels. However, on rough asphalt, the 85A wheels would offer a smoother, faster ride.

The selection of an appropriate durometer necessitates careful consideration of the intended skating environment and style. Aggressive skaters performing tricks often favor harder compounds for durability and slide characteristics. Speed skaters prioritize the lowest possible rolling resistance, opting for the hardest available compositions. Recreational skaters typically gravitate towards a moderate durometer, such as 82A or 84A, balancing grip and speed for general-purpose use. Ignoring durometer specifications can lead to compromised performance, increased fatigue, and even potential safety hazards. Utilizing wheels with insufficient grip on a wet surface, for instance, dramatically increases the risk of falls.

In summary, the durometer rating is a fundamental attribute of inline skate replacement wheels that profoundly influences performance. The optimal choice depends heavily on individual skating style, surface conditions, and desired balance between grip and speed. Understanding the relationship between durometer and these factors empowers skaters to select the most appropriate components, thereby maximizing performance, safety, and enjoyment. Further research into specific material formulations and construction techniques can provide even greater insight into fine-tuning rolling performance.

2. Wheel Size (diameter)

The diameter of an inline skate wheel, typically measured in millimeters (mm), is a primary determinant of performance characteristics. Selecting the appropriate diameter is crucial for optimizing speed, maneuverability, and stability. The skate frame design dictates the maximum wheel size that can be accommodated; exceeding this limit renders the skates unusable.

- Speed and Rolling Efficiency

Larger diameter wheels generally possess lower rolling resistance, translating to higher top speeds and improved energy efficiency. A larger circumference covers more ground per rotation, requiring less effort to maintain momentum. For instance, speed skaters commonly employ 100mm or 110mm wheels to maximize velocity during competitions. Conversely, smaller wheels require more rotations to cover the same distance, resulting in reduced speed and increased effort.

- Maneuverability and Agility

Smaller diameter wheels facilitate quicker turns and enhanced agility. The reduced wheelbase improves responsiveness, making them suitable for environments requiring frequent directional changes. Aggressive skaters performing tricks in skate parks often prefer smaller wheels, typically ranging from 55mm to 72mm, due to their increased maneuverability and ability to navigate tight spaces. Larger wheels, while faster, are less responsive and may impede agility in confined areas.

- Stability and Control

Larger diameter wheels offer increased stability, particularly at higher speeds. The extended contact patch provides greater surface area for grip, reducing the likelihood of instability or loss of control. Recreational skaters often benefit from larger wheels (e.g., 80mm to 90mm) to enhance stability and confidence. Smaller wheels, while more maneuverable, can feel less stable at elevated speeds, especially on uneven surfaces.

- Frame Compatibility and Clearance

The skate frame is designed to accommodate a specific range of wheel diameters. Attempting to install wheels exceeding the frame’s capacity will result in interference with the boot or frame itself, rendering the skates unusable. It is imperative to consult the skate manufacturer’s specifications or measure the existing wheels to determine the appropriate replacement size. Installing smaller-than-recommended wheels may compromise performance and stability.

The selection of wheel diameter for inline skates represents a trade-off between speed, maneuverability, and stability. Skaters must carefully evaluate their skating style, environment, and frame compatibility to determine the optimal size. Factors such as skating surface, intended use (recreational, speed, aggressive), and personal preferences should all be considered to ensure a safe and enjoyable skating experience.

3. Bearing Compatibility

Bearing compatibility is a critical consideration when selecting inline skate replacement wheels. Mismatched bearing and wheel combinations can lead to compromised performance, premature wear, and potential safety hazards. Understanding the standards and nuances of bearing compatibility is essential for ensuring proper functionality and longevity of skating equipment.

- Standard Bearing Sizes and Wheel Hubs

The most prevalent bearing size for inline skates is the 608 bearing, characterized by an 8mm inner diameter, a 22mm outer diameter, and a 7mm width. Some skates, particularly those designed for speed or recreational use, may utilize 688 bearings, which are smaller and lighter. Inline skate replacement wheels are manufactured with hubs designed to accommodate either 608 or 688 bearings. Attempting to install a bearing into an incompatible hub size will result in either a loose fit or an inability to insert the bearing completely, both of which negatively impact performance. For example, trying to fit a 608 bearing into a wheel hub designed for 688 bearings will leave the bearing loose and unstable.

- Bearing Spacers and Alignment

Bearing spacers are small cylindrical components that sit between the two bearings within a wheel hub. They ensure proper alignment and prevent over-tightening of the axle nut, which can damage the bearings and impede rotation. Bearing spacers are typically designed to work with specific bearing sizes. Incompatible spacers can lead to misalignment, increased friction, and reduced bearing lifespan. Skates that requires 8mm bearing spacers should be utilized, otherwise the skate wheel performance can decrease its performance or damaged. Replacement wheels should be selected with consideration for existing spacer dimensions.

- Axle Diameter and Wheel Compatibility

The axle diameter is the diameter of the bolt that holds the wheel onto the skate frame. Most inline skates utilize an 8mm axle diameter, which is compatible with 608 bearings. However, some frames may use different axle sizes. Ensuring that the axle diameter is compatible with both the bearings and the wheel hub is crucial for secure and functional wheel attachment. Failure to match axle and wheel dimensions can result in instability and potential wheel detachment during use.

- Wheel Core Material and Bearing Seat

The material composition and design of the wheel core, the central portion of the wheel that houses the bearings, influence bearing fit and performance. A poorly designed or manufactured core can result in an uneven bearing seat, leading to vibration, increased friction, and premature bearing wear. High-quality replacement wheels feature precisely machined cores that provide a snug and secure fit for the bearings, maximizing performance and longevity.

Proper bearing compatibility is essential for achieving optimal performance and safety when replacing inline skate wheels. By carefully considering bearing size, spacer dimensions, axle diameter, and wheel core design, skaters can ensure a secure and functional wheel assembly that enhances skating efficiency and extends equipment lifespan. Selecting the correct components and adhering to established maintenance practices are crucial for realizing the full potential of inline skating equipment.

4. Profile (shape)

The profile, or shape, of an inline skate replacement wheel refers to the cross-sectional curvature of the wheel’s contact surface. This geometrical characteristic significantly influences rolling resistance, maneuverability, and grip. Consequently, the profile is a critical design element that directly affects skating performance and suitability for different skating disciplines. A pronounced, rounded profile reduces the contact patch with the skating surface, facilitating quicker turns and enhanced agility. Conversely, a flatter, more square profile maximizes the contact patch, increasing grip and stability at the expense of maneuverability. For instance, speed skaters favor wheels with elliptical profiles to minimize rolling resistance and maximize speed on straightaways, while hockey players benefit from rounded profiles that enable rapid changes in direction on the rink.

The selection of an appropriate wheel profile must align with the intended skating environment and style. In environments demanding frequent directional changes, such as roller hockey rinks or slalom courses, a rounded profile is advantageous. The reduced contact area allows for smoother transitions between edges and enhanced responsiveness. Conversely, when prioritizing stability and speed on relatively straight paths, a flatter profile is preferred. This increased contact area maximizes grip and minimizes energy loss due to deformation of the wheel. The choice of profile affects the skater’s ability to control the skates, with rounder wheels promoting maneuverability and flatter wheels offering stability. Additionally, the wheel’s durometer interacts with its profile, influencing the overall grip characteristics. A softer wheel with a rounded profile will provide maximum grip and maneuverability, while a harder wheel with a flatter profile will maximize speed and stability.

In conclusion, the wheel profile is a critical factor influencing the performance of inline skate replacement wheels. Its selection must be carefully considered in relation to the skater’s style, the skating environment, and the desired balance between maneuverability, stability, and speed. Different profiles cater to different skating disciplines, with rounded profiles favoring agility and flatter profiles optimizing stability and speed. Understanding the interaction between profile, durometer, and skating environment is essential for selecting the most appropriate replacement wheels and maximizing skating performance.

5. Material Composition

The material composition of inline skate replacement wheels is a primary determinant of their performance, durability, and overall suitability for various skating conditions. The selection of appropriate materials directly impacts grip, rolling resistance, wear resistance, and vibration absorption, making it a critical consideration for skaters seeking to optimize their equipment.

- Polyurethane (PU) Formulation

Polyurethane is the dominant material used in the construction of these components, owing to its versatile properties and ability to be tailored for specific applications. Variations in the chemical composition of the PU affect its hardness, rebound characteristics, and resistance to abrasion. For example, formulations with a higher proportion of isocyanates typically yield harder, more durable wheels suitable for aggressive skating, while those with a greater concentration of polyols provide enhanced grip and vibration damping for recreational use. The precise formulation is a proprietary aspect of wheel manufacturing and directly influences the final product’s performance profile.

- Core Material and Design

The core, typically made from reinforced plastics like nylon or fiberglass, provides structural support to the wheel and affects its rolling efficiency. The core’s stiffness and design impact energy transfer during skating. A stiffer core will enhance responsiveness and speed, while a more flexible core can improve comfort by absorbing vibrations. For instance, wheels intended for speed skating often incorporate lightweight, rigid cores to minimize energy loss, whereas recreational wheels may utilize more compliant cores to enhance ride quality. The interface between the core and the PU layer is also crucial, as poor bonding can lead to delamination and premature wheel failure.

- Additives and Reinforcements

Various additives are incorporated into the PU matrix to modify its properties. These may include pigments for coloration, UV stabilizers to prevent degradation from sunlight exposure, and reinforcing agents such as silica or carbon black to enhance abrasion resistance. For example, the addition of carbon black can significantly improve the wheel’s ability to withstand wear on rough surfaces, extending its lifespan. The type and concentration of these additives are carefully controlled to achieve the desired performance characteristics without compromising the PU’s inherent properties.

- Bearing Seat Precision

The bearing seat, the area within the wheel core where the bearings are housed, requires precise tolerances to ensure proper bearing alignment and smooth rotation. High-quality materials and manufacturing processes are essential for maintaining the dimensional accuracy of the bearing seat. Imperfections in this area can lead to increased friction, vibration, and premature bearing failure. For example, wheels with poorly machined bearing seats may exhibit noticeable vibrations at higher speeds, diminishing skating efficiency and comfort. The selection of durable core materials that resist deformation under stress is critical for preserving the integrity of the bearing seat over time.

In summary, the material composition of inline skate replacement wheels represents a complex interplay of factors that directly influence their performance and longevity. The selection of appropriate PU formulations, core materials, additives, and manufacturing processes is crucial for achieving the desired balance of grip, speed, durability, and comfort. Skaters should consider these factors when selecting replacement wheels to ensure optimal performance and a satisfying skating experience.

6. Core Construction

The core, an integral component within inline skate replacement wheels, provides structural integrity and dictates the wheel’s performance characteristics. Its construction directly influences energy transfer, rolling efficiency, and overall durability. Understanding the nuances of core design and materials is essential for informed wheel selection.

- Core Material Composition

Core materials typically consist of rigid polymers such as nylon, polycarbonate, or composites incorporating fiberglass. The material’s stiffness dictates the wheel’s responsiveness and resistance to deformation under load. A stiffer core translates to more efficient energy transfer during push-off, resulting in increased speed and reduced energy loss. For example, speed skating wheels often employ high-modulus carbon fiber cores to maximize stiffness, while recreational wheels may utilize more flexible nylon cores to enhance vibration absorption and comfort. The material choice represents a trade-off between performance and ride quality.

- Core Design and Geometry

The core’s geometry, including spoke patterns, ribbing, and overall shape, significantly impacts its structural integrity and weight distribution. Open-core designs, characterized by large cutouts, reduce weight but may compromise stiffness. Solid-core designs, offering greater structural support, are typically heavier. Spoke patterns, such as star-shaped or multi-spoke configurations, distribute stress and improve load-bearing capacity. The design must balance weight reduction with structural integrity to optimize performance. For instance, aggressive skating wheels often feature reinforced cores with minimal cutouts to withstand the impact forces associated with jumps and grinds.

- Core-Urethane Bond Interface

The interface between the core and the polyurethane (PU) tire is a critical area of concern. Proper bonding is essential to prevent delamination, where the PU separates from the core under stress. Surface preparation techniques, adhesive selection, and molding processes play a crucial role in achieving a strong and durable bond. Premature delamination can lead to wheel failure and potential safety hazards. High-quality wheels undergo rigorous testing to ensure the integrity of the core-urethane bond, often involving cyclical loading and environmental exposure.

In summary, core construction is a multifaceted aspect of inline skate replacement wheel design. The interplay between material selection, geometric design, and bonding techniques dictates the wheel’s performance characteristics and durability. Selecting wheels with appropriate core construction is paramount for optimizing skating efficiency, ensuring longevity, and maintaining safety across various skating disciplines.

7. Surface Condition

The condition of the skating surface exerts a profound influence on the performance and longevity of inline skate replacement wheels. Surface characteristics dictate friction levels, wear rates, and vibration transmission, thereby necessitating careful consideration when selecting appropriate components.

- Surface Roughness and Abrasion

Rough surfaces, such as coarse asphalt or concrete, accelerate wear on inline skate wheels due to increased abrasion. Softer durometer wheels, while providing enhanced grip, exhibit a higher rate of material loss on abrasive surfaces compared to harder durometer wheels. Conversely, smoother surfaces, like polished concrete or wood floors, minimize abrasion, allowing for the utilization of softer wheels to maximize grip and maneuverability. For instance, wheels designed for indoor rink skating typically feature softer durometers than those intended for outdoor street skating.

- Debris and Contamination

The presence of debris, including dirt, pebbles, and other foreign objects, can significantly impact wheel performance and lifespan. Debris can become embedded in the wheel’s polyurethane matrix, increasing rolling resistance and accelerating wear. Moreover, contaminants can damage bearings, leading to reduced rotational efficiency and potential failure. Skating surfaces prone to debris accumulation necessitate more frequent wheel cleaning and maintenance to mitigate these effects. The presence of sharp objects can also cause cuts or gouges in the wheel’s surface, compromising its structural integrity and safety.

- Surface Moisture and Grip

Wet or damp surfaces dramatically reduce wheel grip, increasing the risk of slippage and loss of control. The presence of a water film between the wheel and the skating surface diminishes friction, making it challenging to maintain balance and execute precise maneuvers. Wheels with specific tread patterns or formulations designed to displace water can improve grip on wet surfaces. However, even with specialized wheels, caution is advised when skating in wet conditions. In freezing condition the skates will not work at all, consider avoid skates to save your safety.

- Surface Uniformity and Vibration

Uneven surfaces, characterized by cracks, bumps, or other irregularities, increase vibration and impact forces transmitted to the skater. This can lead to discomfort, fatigue, and accelerated wear on both the wheels and the skater’s joints. Utilizing wheels with shock-absorbing properties or larger diameters can help mitigate the effects of uneven surfaces. Suspension systems incorporated into the skate frame can also further dampen vibrations and improve ride quality. Regular inspection and maintenance of skating surfaces are crucial for minimizing the risk of injury and equipment damage.

The interrelationship between surface condition and inline skate replacement wheel selection underscores the importance of matching equipment to the environment. Considering surface roughness, debris levels, moisture conditions, and uniformity ensures optimal performance, longevity, and safety. Proper maintenance and regular wheel inspection are essential for mitigating the negative effects of adverse surface conditions and maximizing the lifespan of skating equipment.

Frequently Asked Questions

The following addresses commonly encountered inquiries regarding rolling components for inline skates. Each question aims to provide clear and concise information to enhance understanding and inform decision-making.

Question 1: How frequently should rolling components be exchanged?

Replacement frequency depends on usage intensity, skating surface conditions, and the quality of the components themselves. Regular inspection is recommended, with replacement occurring when significant wear, cracking, or performance degradation is observed. A general guideline suggests replacement every 3-12 months for frequent skaters.

Question 2: Is it necessary to replace all components simultaneously, or can they be exchanged individually?

While individual replacement is permissible, replacing all components concurrently ensures uniform performance and wear characteristics across all positions. Replacing a single worn unit alongside newer ones can lead to uneven wear patterns and compromised handling.

Question 3: What is the significance of the durometer rating on inline skate replacement wheels?

The durometer rating, typically measured on the A scale, indicates the hardness of the wheel’s polyurethane material. Higher ratings signify greater hardness, lower rolling resistance, and reduced grip, while lower ratings offer enhanced grip at the expense of speed. Selection should align with skating style and surface conditions.

Question 4: Can components from different manufacturers be interchanged without compatibility issues?

Interchangeability is generally feasible, provided the diameter, width, and bearing compatibility are consistent. However, variations in urethane formulation, core design, and manufacturing tolerances may influence performance characteristics. It is advisable to consult compatibility charts or seek expert guidance to ensure proper fit and function.

Question 5: What maintenance procedures prolong the lifespan of inline skate replacement wheels?

Regular cleaning to remove dirt and debris, periodic rotation to distribute wear evenly, and proper storage in a cool, dry environment are essential maintenance practices. Avoiding skating on excessively rough surfaces and promptly addressing any bearing issues will also contribute to extended lifespan.

Question 6: Is professional installation required, or can the replacement process be executed independently?

The replacement process can typically be performed independently with basic tools and mechanical aptitude. However, improper installation can lead to performance issues or equipment damage. If unfamiliar with the procedure, seeking assistance from a qualified technician is recommended.

Understanding these key aspects facilitates informed decision-making when selecting and maintaining rolling components, ultimately contributing to a more enjoyable and efficient skating experience.

The subsequent section will delve into advanced topics, including performance optimization strategies and emerging technologies in rolling component design.

Concluding Remarks

The preceding analysis has provided a comprehensive overview of the factors influencing the selection, maintenance, and performance of inline skate replacement wheels. Core considerations include wheel size, durometer, profile, material composition, and bearing compatibility, all of which contribute to a cohesive skating experience. Neglecting these variables can lead to diminished performance, accelerated wear, and compromised safety.

Ultimately, the informed selection and responsible maintenance of inline skate replacement wheels are essential for maximizing skating efficiency, extending equipment lifespan, and ensuring a safe and enjoyable experience. It is imperative to continually evaluate equipment needs, adapt to evolving technologies, and prioritize safety to derive the full benefits of the sport. The investment in quality components and diligent maintenance practices represents a commitment to both performance excellence and personal well-being.