A recreational platform utilized for skateboarding, characterized by graphics often featuring depictions of a popular Italian culinary dish, serves as both a functional piece of sporting equipment and a medium for artistic expression. These platforms, typically constructed from laminated maple wood, provide the foundation for performing tricks and navigating various terrains within the skateboarding discipline.

The popularity of such graphically themed equipment stems from its ability to resonate with a broad audience, combining the cultural appeal of skateboarding with the universally recognized image of a readily consumed food item. Historically, skateboard graphics have evolved from simple logos to elaborate artworks, reflecting trends and subcultures. The utilization of food-related imagery offers a playful and accessible aesthetic, further enhancing the sport’s approachability.

Understanding the composition, construction, and graphic design elements of these platforms is crucial for selecting appropriate equipment. Further discussion will delve into specific design features, materials used in construction, and the impact of graphics on the overall user experience within the skateboarding community.

Skate Platform Selection and Maintenance Guidance

The following guidelines provide key considerations for selecting and maintaining a skateboarding platform featuring specific graphic designs. Adherence to these principles can prolong the lifespan of the equipment and enhance the overall skateboarding experience.

Tip 1: Layer Evaluation. Inspect the platform’s laminated wood construction to confirm the absence of delamination. Any visible separation between layers indicates structural weakness and potential for failure under stress.

Tip 2: Concavity Assessment. Examine the platform’s curvature, or concavity, as it influences board feel and trick execution. Higher concavity provides increased grip, while flatter platforms offer greater stability.

Tip 3: Graphic Integrity. Assess the durability of the graphic application. Screen-printed graphics are typically more resistant to wear than heat-transferred designs. Consider the graphic’s positioning to minimize abrasion during grinds and slides.

Tip 4: Hardware Compatibility. Ensure compatibility between the platform’s mounting holes and the intended truck hardware. Mismatched hardware can compromise stability and lead to premature wear.

Tip 5: Regular Cleaning. Remove dirt and debris from the platform’s surface using a soft brush and mild soap solution. Accumulated grime can diminish grip and accelerate wear on the graphic.

Tip 6: Storage Considerations. Store the platform in a cool, dry environment to prevent warping or damage from exposure to moisture or extreme temperatures.

Tip 7: Impact Mitigation. While skateboarding involves inherent risks, minimizing direct impact to the platform, particularly on edges and tail/nose, can reduce the likelihood of cracking or chipping.

By observing these recommendations, skateboarders can optimize the performance and longevity of their equipment. Subsequent sections will address advanced customization options and safety precautions within the skateboarding discipline.

1. Maple Ply Lamination

Maple ply lamination is a fundamental process in the creation of durable and high-performing skateboarding platforms, including those featuring pizza-themed graphics. The quality and method of lamination directly impact the deck’s strength, flexibility, and overall lifespan, influencing the user’s experience.

- Grain Orientation and Strength

Maple veneers are stacked with alternating grain directions. This cross-grain arrangement enhances the platform’s resistance to warping and cracking under stress. A poorly laminated platform, even with visually appealing graphics, may fail prematurely due to inadequate strength.

- Adhesive Quality and Bond Integrity

The adhesive used to bond the maple plies is critical. High-quality epoxy resins create a strong, water-resistant bond that withstands repeated impacts and temperature fluctuations. Inadequate adhesive can lead to delamination, compromising the structural integrity and rendering the pizza-themed graphic irrelevant.

- Pressing Techniques and Density

During lamination, hydraulic presses apply controlled pressure to compress the maple veneers and ensure uniform bonding. Precise pressure settings are crucial for achieving optimal density and flex. Insufficient pressure can result in air pockets and weak spots, leading to decreased performance and durability of the platform.

- Ply Count and Deck Thickness

The number of maple plies, typically seven, and the overall deck thickness directly influence the platform’s rigidity and responsiveness. A thinner deck may offer increased flexibility for technical tricks, while a thicker deck provides greater stability for larger features. Regardless of thickness, proper lamination is essential to prevent ply separation and maintain the platform’s structural integrity throughout its lifespan.

The relationship between maple ply lamination and any skate platform, including those with pizza graphics, is one of fundamental necessity. Without proper lamination techniques, the visual appeal of the graphic is secondary to the platform’s inherent structural weaknesses. A well-laminated platform provides the foundation for both performance and durability, ensuring the longevity of the equipment and the user’s skateboarding experience.

2. Concave Configuration

Concave configuration, referring to the curvature across the width of a skateboard platform, significantly influences a skater’s control and maneuverability. Regarding pizza-themed skate platforms, the concave’s shape dictates the foot’s contact area, impacting grip and responsiveness. A steeper concave creates a more pronounced pocket for the feet, facilitating enhanced board feel and enabling quicker responses during trick execution. Conversely, a mellow concave provides a flatter surface, offering greater stability at higher speeds. The choice of concave is therefore not merely aesthetic but directly affects the functionality of the platform.

The practical significance of understanding concave configuration is evident in trick-oriented skateboarding. A skater performing flip tricks, such as kickflips or heelflips, relies on the concave to provide leverage and control over the board’s rotation. A poorly chosen concave can hinder trick execution, leading to missed attempts and potential injuries. Furthermore, concave configuration plays a crucial role in locking into grinds and slides. A well-defined concave provides a secure point of contact for the skater’s feet, ensuring stability during these maneuvers. Skateboard manufacturers typically offer a range of concave options to cater to different riding styles and preferences, recognizing the pivotal role it plays in performance.

In summary, concave configuration is a critical design element that directly impacts the functionality and performance of a skate platform, including those with pizza-themed graphics. While the graphic design contributes to the board’s aesthetic appeal, the concave configuration is instrumental in determining how the platform performs under various skateboarding conditions. Selecting the appropriate concave is paramount for maximizing control, stability, and trick execution, and therefore represents a fundamental consideration for skateboarders of all skill levels.

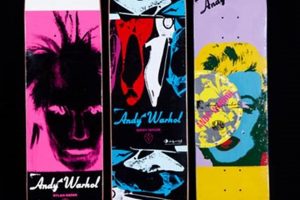

3. Graphic Application

The graphic application on a “pizza skate deck” is not merely an aesthetic addition but a critical component affecting brand identity, product appeal, and potentially, the deck’s lifespan. The process involves transferring a designed image, often pizza-related, onto the deck’s surface, requiring techniques that ensure durability and visual clarity. Poor graphic application leads to premature wear, fading, or chipping, undermining the deck’s aesthetic value and potentially reflecting negatively on the manufacturer’s quality standards. Real-world examples demonstrate the impact: decks with high-quality, multi-layered graphic applications retain their visual appeal longer, maintaining market value and brand recognition, whereas those with cheaper, single-layer applications degrade quickly, becoming visually unappealing and reducing the product’s longevity.

Different methods exist for graphic application, each with varying implications for durability and cost. Screen printing, while relatively inexpensive, often lacks the resolution and longevity of heat transfer or direct digital printing. Heat transfer involves applying a pre-printed graphic onto the deck using heat and pressure, creating a durable bond. Direct digital printing allows for complex, high-resolution images to be applied directly onto the deck’s surface, but can be more costly. For “pizza skate decks,” where the graphic is central to the product’s identity, manufacturers must weigh the cost-benefit of each method, considering the desired lifespan and target market. Furthermore, clear coat applications over the graphic can provide an additional layer of protection against abrasion and UV damage, enhancing the graphic’s longevity and preserving the deck’s overall appearance.

In conclusion, graphic application is an integral aspect of the pizza skate deck. Its quality directly correlates with the product’s visual appeal, durability, and brand perception. Challenges arise in balancing cost-effectiveness with the need for a robust, long-lasting graphic. The selection of appropriate application methods, coupled with protective clear coats, ensures that the deck maintains its aesthetic value and withstands the rigors of skateboarding, reinforcing the deck’s appeal and reflecting positively on the manufacturer. This careful consideration connects directly to the broader themes of product quality, brand identity, and consumer satisfaction within the skateboarding industry.

4. Wheelbase Options

Wheelbase, the distance between the inner mounting holes of the front and rear trucks on a skate deck, directly influences the maneuverability and stability of any skateboard, including those with themed graphics. A shorter wheelbase generally results in a more responsive and easily turned platform, suitable for technical street skating. Conversely, a longer wheelbase provides increased stability at higher speeds, favored by transition skaters and those navigating larger terrain. The selection of an appropriate wheelbase depends on the intended riding style, skill level, and physical characteristics of the skater.

The interplay between wheelbase and deck graphic, such as a pizza design, is primarily aesthetic. The graphic itself does not affect the functional properties of the wheelbase; however, the target demographic for a particular graphic might influence the deck manufacturer’s decision regarding wheelbase options. For instance, a smaller pizza-themed deck with a shorter wheelbase may appeal to younger skaters or those focused on technical tricks, while a larger deck with a longer wheelbase and the same graphic could target older skaters or those seeking stability for cruising or park riding. In practice, wheelbase selection considers performance demands first, followed by graphic selection to align with marketing strategies.

In summary, wheelbase options represent a critical functional element in skateboard design. While the presence of a themed graphic, such as a pizza motif, is an aesthetic consideration, the wheelbase profoundly affects the deck’s performance characteristics. Manufacturers must carefully consider the intended use and target demographic when determining the wheelbase options offered for a particular deck design, balancing aesthetic appeal with functional performance to meet the diverse needs of the skateboarding community.

5. Truck Compatibility

Truck compatibility is a critical consideration when selecting a skateboard platform, regardless of graphic design. The proper alignment and secure attachment of trucks to the deck ensure safe and optimal performance. This holds true for decks featuring a “pizza skate deck” theme, where aesthetic appeal must be secondary to functional integration.

- Mounting Hole Patterns

Standardized mounting hole patterns are prevalent across skateboard decks and trucks, typically adhering to the New School or Old School configurations. Mismatched hole patterns necessitate drilling new holes, compromising the deck’s structural integrity and potentially voiding any warranty. Verifying compatibility before purchase is essential to avoid such complications for any skate platform, including one with a specific culinary graphic.

- Deck Width and Truck Axle Length

The width of the skateboard deck should correspond to the axle length of the trucks. Overhanging or undersized trucks can negatively impact stability and turning radius. An appropriately sized truck ensures that the wheels align correctly with the deck’s edges, providing optimal leverage and control. Careful matching of deck width and truck axle length is crucial for safe and effective skateboarding, irrespective of any graphic design.

- Truck Height and Wheel Clearance

Truck height, relative to the deck, influences wheel clearance and the risk of wheelbite (where the wheels rub against the deck during turns). Taller trucks necessitate riser pads to increase clearance, while lower trucks may require smaller wheels to prevent wheelbite. Proper wheel clearance is vital for smooth and uninterrupted riding. Ignoring this compatibility aspect can lead to hazardous conditions and hinder performance on all decks.

In conclusion, truck compatibility is a non-negotiable aspect of skateboard assembly. Regardless of the visual appeal of a “pizza skate deck,” ensuring that the trucks are correctly matched to the deck’s mounting pattern, width, and desired wheel size is paramount for safety and performance. Neglecting these compatibility factors can render the deck unusable or, worse, create a hazardous riding situation, overshadowing any aesthetic value the graphic may possess. The integration of functional considerations with aesthetic preferences is crucial in skateboarding equipment selection.

6. Durability Factors

The longevity and performance of a “pizza skate deck” are intrinsically linked to a complex interplay of durability factors that dictate its ability to withstand the stresses inherent in skateboarding. Material selection, construction techniques, and environmental conditions exert considerable influence on the deck’s resistance to damage and its overall lifespan. Premature failure can result from inadequate attention to these factors, leading to compromised performance, potential injury, and reduced product value. Examples include delamination caused by substandard adhesive, cracking due to low-quality wood, or graphic degradation from inadequate sealing. The practical significance lies in understanding these factors to inform both manufacturing processes and consumer purchasing decisions, thus maximizing the lifespan and utility of the skateboarding platform.

Examining specific durability factors provides further insight. Impact resistance is crucial, requiring high-density maple plies and a robust pressing process to distribute force effectively. Flexural strength determines the deck’s ability to withstand bending forces without permanent deformation, influenced by grain orientation and lamination quality. Water resistance prevents swelling and warping, achieved through waterproof adhesives and protective coatings. Abrasion resistance protects the graphic and deck surface from wear caused by sliding and grinding. These factors interact synergistically, meaning a weakness in one area can compromise the entire structure. Real-world applications include utilizing epoxy resins for superior bonding, implementing cross-grain lamination for enhanced strength, and applying UV-resistant clear coats to protect graphics, all aimed at mitigating potential points of failure and extending the usable life of the skate platform.

In conclusion, durability factors are not merely peripheral considerations but foundational elements determining the overall value and performance of a “pizza skate deck.” Addressing these factors necessitates a holistic approach, from material selection and manufacturing processes to the application of protective coatings. Challenges remain in balancing cost-effectiveness with the demand for increased durability, requiring ongoing innovation in materials and manufacturing techniques. Understanding and prioritizing these factors ensures a higher quality product, enhanced user safety, and reduced environmental impact through increased product lifespan, contributing positively to the skateboarding industry as a whole.

7. Artistic Expression

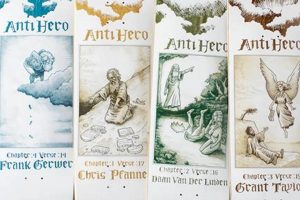

The surface of a skate deck provides a canvas for artistic expression, and the integration of pizza-related imagery onto these platforms serves as a prominent example. This phenomenon manifests in various forms, ranging from photorealistic depictions of pizza slices to abstract interpretations of the culinary item. The cause lies in the desire for self-identification and the expression of personal interests within the skateboarding subculture. A skate deck featuring a pizza design becomes a visual statement, communicating the rider’s affinities and potentially sparking conversations within the community. The importance of artistic expression as a component of a “pizza skate deck” stems from its ability to transform a functional object into a personalized artifact, elevating its value beyond mere utility. Real-life examples include professional skateboarders collaborating with artists to create limited-edition decks featuring unique pizza-themed designs, thereby enhancing both the deck’s collectibility and its symbolic representation of a shared cultural interest. The practical significance of this understanding lies in recognizing the skate deck as not only a piece of sporting equipment but also as a medium for artistic and cultural communication.

Further analysis reveals that the artistic style employed in pizza skate deck designs varies widely, reflecting diverse artistic influences and target demographics. Some designs emulate classic pizza parlor aesthetics, incorporating elements such as checkered patterns and vintage typography. Others adopt a more contemporary approach, utilizing bold colors, geometric shapes, and digital illustration techniques. The choice of artistic style influences the deck’s overall aesthetic appeal and its ability to resonate with specific sub-segments within the skateboarding community. Practical applications of this understanding include targeted marketing strategies that align specific pizza skate deck designs with the preferences of particular rider groups, thereby maximizing sales and brand engagement. Additionally, understanding the interplay between artistic expression and consumer preferences can inform the development of innovative and visually compelling deck designs that capture emerging trends within both the skateboarding and culinary worlds.

In conclusion, artistic expression is an integral element of the “pizza skate deck,” transforming it from a purely functional item into a personalized medium for self-expression and cultural communication. The challenges lie in continually innovating and adapting artistic styles to reflect evolving trends and consumer preferences. This connection links to the broader theme of skateboarding as a culture that values individuality and creative expression, where the skate deck serves as a canvas for conveying personal identity and engaging in a visual dialogue within the community. The merging of culinary imagery with the art of skateboarding highlights the dynamic and multifaceted nature of contemporary subcultures and the ways in which individuals express themselves through the objects they choose to associate with.

Frequently Asked Questions

This section addresses common inquiries regarding platforms used for skateboarding that feature graphics thematically related to pizza. The information presented aims to clarify key aspects and dispel potential misconceptions.

Question 1: What materials are typically used in the construction of a pizza skate deck?

The primary material is generally laminated maple wood, consisting of multiple plies bonded together with adhesive. Some manufacturers may incorporate alternative materials, such as composites or bamboo, to modify the deck’s performance characteristics.

Question 2: How does the graphic application process affect the durability of the deck?

The method used to apply the graphic influences its resistance to wear and tear. Screen-printed graphics tend to be more durable than heat-transferred designs, while clear coat applications can provide an additional layer of protection.

Question 3: Does the pizza theme have any impact on the deck’s performance?

No. The graphic design is purely aesthetic and does not affect the functionality or performance of the skateboard platform. Performance is determined by factors such as deck shape, concave, and material composition.

Question 4: Are there specific truck sizes recommended for a pizza skate deck?

Truck size should be chosen based on the width of the deck. The axle length of the trucks should align with the deck’s width to ensure proper wheel alignment and stability. Consult a sizing guide for precise measurements.

Question 5: How should a pizza skate deck be properly maintained?

Regular cleaning with a soft brush and mild soap solution is recommended to remove dirt and debris. Avoid prolonged exposure to moisture or extreme temperatures. Inspect the deck regularly for signs of damage, such as cracks or delamination.

Question 6: Where can pizza skate decks be purchased?

These platforms are available at many skateboarding shops, both brick-and-mortar and online retailers. Selection may vary depending on the retailer and current inventory.

Understanding these points will enable a more informed selection and care of skateboarding equipment featuring such designs.

The subsequent section will explore advanced customization options available for enhancing the performance and aesthetic appeal of skate platforms.

In Summation

This discourse has explored the “pizza skate deck” from multiple perspectives, encompassing its material construction, graphic application, and functional elements such as wheelbase and truck compatibility. An understanding of maple ply lamination, concave configuration, and durability factors is crucial for both manufacturers and consumers seeking to optimize performance and longevity. The aesthetic dimension, specifically the artistic expression inherent in the pizza theme, has also been examined, revealing its role in personal identification and cultural communication within the skateboarding community.

As a functional piece of sporting equipment and a canvas for personal expression, the platform featuring this specific thematic design merits careful consideration. Evaluating its attributes, from structural integrity to artistic value, is paramount. Continued innovation in materials and manufacturing processes, coupled with a discerning approach to product selection, will shape the future of these platforms within the skateboarding landscape.