Equipment used for gliding across frozen surfaces designed and retailed by a specific outdoor and recreation company, facilitates recreational and athletic winter activities. These implements, typically featuring a blade attached to a supportive boot, enable users to move efficiently and gracefully on ice.

The availability of such winter sporting goods from established retailers contributes significantly to accessibility and participation in ice skating. This can promote physical fitness, social engagement, and enjoyment of outdoor winter environments. Historically, advancements in materials and design have improved comfort, performance, and safety for skaters of all skill levels.

The following sections will delve into specific models, construction materials, sizing considerations, and maintenance procedures relevant to selecting and using appropriate gear for optimal ice skating experiences.

Selection and Maintenance Guidance

The following recommendations address crucial aspects of choosing and maintaining ice skating equipment to optimize performance and longevity.

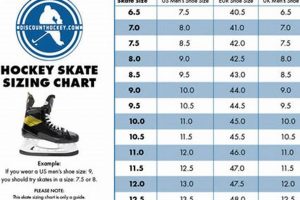

Tip 1: Size Assessment: Accurate foot measurement is paramount. Consult the manufacturer’s sizing chart and consider sock thickness to ensure a snug, supportive fit. Excessively large equipment compromises control and increases the risk of injury.

Tip 2: Blade Material Evaluation: Assess the blade material. Carbon steel offers superior edge retention but requires more frequent maintenance. Stainless steel resists corrosion but may not hold an edge as effectively.

Tip 3: Proper Lacing Technique: Employ a consistent lacing pattern, ensuring even pressure distribution. Over-tightening restricts circulation and can cause discomfort. Under-tightening diminishes support and control.

Tip 4: Regular Blade Sharpening: Schedule professional blade sharpening at regular intervals, dependent on usage frequency. Dull blades impede gliding efficiency and increase the likelihood of falls.

Tip 5: Post-Use Drying Protocol: Thoroughly dry the blades after each use to prevent rust formation. Use a soft cloth and consider applying a thin layer of protective oil.

Tip 6: Boot Care: Clean the boot exterior with a damp cloth to remove dirt and debris. Allow the boots to air dry completely before storing. Avoid direct heat, which can damage the materials.

Optimal equipment selection and diligent maintenance practices extend the life of ice skating gear and contribute to a safer and more enjoyable skating experience.

The subsequent section will address storage strategies to further protect this winter sporting equipment during the off-season.

1. Blade Material

The selection of blade material represents a critical factor in the overall performance and durability of ice skating equipment, directly impacting maneuverability, edge control, and maintenance requirements. The following points examine specific facets of blade material in the context of such skating equipment.

- Carbon Steel Composition

Carbon steel blades are known for their superior hardness and edge retention capabilities. This characteristic enables more precise turns and enhanced control on the ice. However, carbon steel is susceptible to corrosion if not properly maintained, necessitating diligent drying and protective oiling after each use. Improper care can lead to rust formation, compromising the blade’s integrity and performance.

- Stainless Steel Composition

Stainless steel offers inherent resistance to corrosion, reducing the maintenance burden compared to carbon steel. While stainless steel blades generally do not maintain an edge as sharply as carbon steel, they remain a viable option for recreational skaters who prioritize ease of maintenance and durability over peak performance edge control.

- Hardness and Tempering

The hardness of the steel, typically measured using Rockwell scales, dictates its resistance to wear and its ability to hold a sharp edge. Blades designed and retailed must undergo a tempering process to achieve the correct balance of hardness and flexibility. Overly hard blades are prone to chipping, while excessively soft blades lose their edge quickly.

- Blade Geometry and Profile

The curvature and shape of the blade influence the skater’s ability to execute turns, accelerate, and maintain balance. Different blade profiles cater to varying skating styles, from figure skating to hockey. The selection of blade geometry should align with the intended use and skill level of the skater using such skates.

Considering the inherent properties and maintenance requirements of different blade materials ensures the selection of equipment that aligns with individual skating needs and skill levels. Proper blade maintenance, irrespective of the material, is essential for maximizing performance, safety, and the longevity of the gear purchased.

2. Boot Support

The structural integrity of the boot component within ice skating equipment is paramount, directly influencing user safety, performance, and overall comfort. The boot provides a stable platform for the foot and ankle, transmitting force to the blade and facilitating precise movements on the ice.

- Ankle Stabilization

The primary function of boot support is to stabilize the ankle joint. Insufficient support increases the risk of sprains and other injuries, particularly during dynamic movements such as turns and jumps. Designs from established manufacturers typically incorporate reinforced ankle padding and rigid outer shells to provide substantial lateral and medial support.

- Energy Transfer Efficiency

A well-designed boot optimizes energy transfer from the skater’s leg muscles to the blade. A stiff boot minimizes energy loss due to flexing or twisting, allowing for more efficient propulsion and control. This is particularly critical for skaters engaged in advanced techniques or competitive disciplines.

- Customization and Fit

Individual foot anatomy varies significantly, and the effectiveness of boot support hinges on achieving a proper fit. Some manufacturers offer heat-moldable boots that can be customized to conform to the unique contours of the user’s foot. Adjustable lacing systems and strategically placed padding further enhance fit and comfort.

- Material Composition and Durability

The materials used in boot construction, such as leather, synthetic polymers, and composite materials, influence both support characteristics and durability. High-quality materials resist deformation and degradation over time, maintaining their structural integrity and providing consistent support throughout the lifespan of the equipment.

In the context of ice skating equipment, a properly supportive boot contributes to a safer and more efficient skating experience. The integration of advanced materials, customizable features, and ergonomic designs reflects the ongoing evolution of skating equipment aimed at optimizing performance and minimizing injury risk.

3. Size accuracy.

Precise sizing is crucial when selecting skating equipment to ensure user safety, comfort, and optimal performance. The proper fit facilitates control, enhances stability, and minimizes the risk of injury. This discussion highlights the significance of accurate sizing when purchasing ice skating gear.

- Performance Enhancement

Accurate sizing directly contributes to enhanced skating performance. A boot that fits snugly and securely allows for efficient energy transfer from the skater’s leg to the blade. Excess space within the boot results in energy loss and reduced control, hindering the skater’s ability to execute precise movements. An appropriately sized pair allows skaters to maintain better balance, execute turns with greater accuracy, and achieve higher speeds with less effort.

- Injury Prevention

Improperly sized can significantly increase the risk of foot and ankle injuries. Boots that are too large allow the foot to move excessively, leading to blisters, chafing, and instability. Conversely, boots that are too small can compress the foot, causing discomfort, numbness, and potential long-term damage. Proper sizing mitigates these risks by providing a secure and supportive fit that minimizes movement and distributes pressure evenly across the foot.

- Comfort and Enjoyment

Comfort plays a vital role in the overall skating experience. Well-fitted boots eliminate pressure points and allow for natural foot movement, enhancing comfort and reducing fatigue. This, in turn, allows skaters to enjoy longer sessions on the ice without discomfort or pain. Ill-fitting boots can quickly detract from the experience, leading to frustration and decreased enjoyment of the sport.

- Longevity of Equipment

Selecting the correct size extends the lifespan of the product. Boots that are subjected to undue stress from improper fit are more likely to break down or wear out prematurely. By ensuring a proper fit, the equipment is used as intended, reducing stress on the materials and components, and preserving the integrity of the product over time. This represents an investment in long-term performance and value.

Size determination is essential for a satisfactory skating experience. Prioritizing accurate sizing during the selection process ensures greater performance, safety, and comfort for the user, while also potentially extending the life of the equipment.

4. Lacing System

The lacing system is an integral component influencing the performance and fit of ice skates distributed by L.L.Bean. This system’s primary function is to secure the boot to the wearer’s foot, thereby directly affecting ankle support, energy transfer, and overall control on the ice. A well-designed system distributes pressure evenly across the foot, minimizing discomfort and preventing slippage within the boot. Conversely, an inadequate system can lead to compromised stability, reduced maneuverability, and an elevated risk of injury. For instance, a system that fails to adequately tighten around the ankle may allow excessive lateral movement, predisposing the wearer to sprains or strains.

L.L.Bean offers models featuring varying lacing configurations to accommodate diverse user preferences and skill levels. Traditional lacing, utilizing eyelets along the boot, provides a customizable fit but requires manual adjustment. Speed lacing systems, incorporating hooks or loops, facilitate quicker adjustments and enhanced security. The specific materials used in the lacing system, such as durable nylon or waxed cotton, influence the system’s resistance to wear and its ability to maintain tension throughout a skating session. Proper lacing technique is essential; overtightening can restrict circulation, while insufficient tension compromises support.

The efficacy of the lacing system directly correlates with the skater’s ability to execute complex maneuvers and maintain balance. Selection of an appropriate lacing system, coupled with diligent maintenance and proper lacing technique, is critical for maximizing the performance and safety of L.L.Bean ice skating equipment. Challenges may arise in balancing comfort and support, necessitating careful consideration of individual foot morphology and skating style. The integration of advanced materials and ergonomic designs reflects ongoing efforts to optimize lacing systems for enhanced user experience.

5. Edge sharpness.

Edge sharpness represents a critical factor in the performance and safety of ice skates, directly influencing a skater’s ability to control movement and execute maneuvers. Proper edge maintenance is essential for optimal functionality of skating equipment.

- Influence on Gliding Efficiency

Sharp edges allow the blade to grip the ice surface, facilitating efficient propulsion and directional control. Dull edges, conversely, cause the blade to slip, reducing gliding efficiency and requiring more effort to maintain speed and direction. Regular sharpening is therefore necessary to maintain the intended performance characteristics of such equipment.

- Impact on Maneuverability

Sharp edges are crucial for executing precise turns, stops, and other complex skating maneuvers. A well-defined edge enables the skater to carve into the ice, providing the necessary grip and control for agile movements. Conversely, rounded or damaged edges impair the skater’s ability to perform such maneuvers effectively, increasing the risk of falls and loss of control.

- Safety Considerations

Edge sharpness directly impacts safety on the ice. Dull edges increase the likelihood of slipping, particularly when attempting sudden stops or changes in direction. Maintained edges provide enhanced control and stability, reducing the risk of accidents and injuries. Routine edge inspection and sharpening are thus paramount for ensuring safe usage.

- Maintenance Procedures

Maintaining appropriate edge sharpness requires periodic sharpening by a qualified professional. The frequency of sharpening depends on usage frequency and the type of ice surface encountered. Regular inspection for nicks, burrs, and other damage is also essential. Protective blade guards should be used when off the ice to prevent accidental dulling or damage. Proper maintenance ensures continued safe and effective performance.

The functionality and safety hinges on the condition of the blade edges. Consistent maintenance is required to ensure they perform as designed, delivering an optimal skating experience and minimizing the risk of accidents. Attention to edge sharpness contributes directly to user satisfaction and the overall effectiveness of winter sporting equipment.

6. Rust prevention.

Maintaining the integrity and performance of ice skates necessitates diligent rust prevention measures. The metallic components, particularly the blades, are susceptible to corrosion when exposed to moisture, which can compromise structural integrity and skating efficiency.

- Material Selection and Rust Susceptibility

The blade material dictates its inherent resistance to rust. Carbon steel blades, while offering superior edge retention, are more prone to corrosion than stainless steel. Understanding the material composition is therefore crucial for implementing appropriate preventative measures. Skates with carbon steel blades require more intensive post-use care to mitigate rust formation.

- Post-Use Drying Procedures

Thorough drying of the blades after each use is paramount. Moisture left on the blade surface accelerates the corrosion process. A soft, absorbent cloth should be used to remove all traces of water. Particular attention should be paid to the area where the blade attaches to the boot, as moisture can accumulate in this crevice.

- Protective Coatings and Lubricants

Application of a thin layer of rust-inhibiting oil or silicone-based lubricant can provide a protective barrier against moisture and oxidation. These coatings should be applied after drying the blades and reapplied periodically, especially during periods of prolonged storage. Selecting a lubricant specifically formulated for metals prevents damage to the blade and ensures smooth gliding.

- Storage Environment Considerations

The storage environment significantly influences rust formation. Skates should be stored in a dry, well-ventilated location. Avoid storing them in damp environments, such as equipment bags or basements, where humidity can accelerate corrosion. Use of moisture-absorbing desiccants, such as silica gel packets, can further reduce humidity levels within the storage container.

Effective rust prevention protocols are essential for prolonging the lifespan and maintaining the performance of ice skates. By understanding the factors that contribute to corrosion and implementing appropriate preventative measures, owners can ensure that their investment remains in optimal condition, providing safe and enjoyable skating experiences for years to come.

Frequently Asked Questions

The following section addresses common inquiries regarding ice skating equipment distributed by a particular outdoor and recreation company. The information provided is intended to clarify usage, maintenance, and safety aspects.

Question 1: What are the recommended procedures for drying the blades?

Following each use, blades should be thoroughly dried with a soft, absorbent cloth. Special attention should be paid to the area where the blade meets the boot. The application of a rust-inhibiting lubricant is also recommended.

Question 2: How often should blades be professionally sharpened?

The frequency of sharpening depends on usage. A general guideline is to sharpen after every 20-40 hours of skating. Blades should be inspected regularly for nicks or dull spots. A qualified professional should perform sharpening to maintain the correct blade profile.

Question 3: What type of storage environment is recommended during the off-season?

Skates should be stored in a dry, well-ventilated location, away from direct sunlight and extreme temperatures. The use of blade guards during storage is essential to prevent damage and maintain edge sharpness. A desiccant can be placed in the storage container to absorb moisture.

Question 4: How do size selection practices ensure a proper fit?

Foot measurements should be taken while wearing skating socks. Consult the manufacturer’s sizing chart for guidance. It is preferable to try on the equipment in person to ensure a snug, supportive fit without excessive pressure points. Professional fitting assistance is recommended.

Question 5: What materials are commonly used in the construction of skate boots and how do these affect the performance?

Skate boots may be constructed from leather, synthetic materials, or a combination thereof. Leather offers durability and support but requires proper maintenance. Synthetic materials are often lighter and more water-resistant. Boot stiffness influences ankle support and energy transfer; stiffer boots are generally preferred for advanced skating.

Question 6: Are there specific cleaning guidelines for removing dirt and debris from the boot exterior?

The boot exterior can be cleaned with a damp cloth and mild soap. Abrasive cleaners should be avoided, as they can damage the materials. Allow the boots to air dry completely before storing. Remove the liners for separate drying to prevent moisture buildup and odor.

Proper maintenance, including drying, sharpening, and storage practices, is essential for prolonging the life of ice skating equipment. Accurate sizing and appropriate cleaning procedures contribute to user comfort and safety.

The next section will address advanced techniques in ice skate care and performance optimization.

Conclusion

This discourse has addressed critical aspects of equipment offered by a prominent outdoor and recreation retailer. Blade material, boot support, sizing accuracy, lacing systems, edge sharpness, and rust prevention are all crucial considerations in the selection, maintenance, and usage of ice skating equipment. Adherence to recommended guidelines promotes safety, optimizes performance, and extends the functional lifespan of this winter sporting gear.

The longevity and efficacy of such equipment are directly proportional to the commitment to diligent care and maintenance practices. Appropriate selection and responsible stewardship not only enhance individual skating experiences but also contribute to the sustainability of resources associated with winter recreation.