Skateboard decks manufactured by Element are constructed from multiple layers of maple wood, pressed together to form a durable platform for skateboarding. These decks serve as the foundation upon which trucks, wheels, and grip tape are mounted, enabling riders to perform various maneuvers.

The structural integrity and design aesthetics of the platform directly influence a skateboarder’s control and performance. A quality platform can improve board feel, responsiveness, and longevity, making it a crucial component for both novice and experienced riders. The brand’s history within the skateboarding industry contributes to its reputation for producing reliable and visually appealing equipment.

The following sections will delve into the specific characteristics, construction techniques, and design variations present within the brand’s product line, providing a detailed overview for prospective purchasers and enthusiasts alike. These topics will cover materials, shape, size, and graphic elements.

Guidance on Platform Selection

Optimal selection of a skateboarding platform requires careful consideration of several key factors to ensure suitability for the intended riding style and skill level.

Tip 1: Assess Riding Style: Different styles, such as street, park, or vert, demand specific platform characteristics. Street skating typically benefits from a narrower width for enhanced maneuverability, while vert skating often necessitates a wider platform for increased stability.

Tip 2: Evaluate Platform Width: Platform width should correlate with foot size and riding preference. Wider platforms provide more stability, while narrower platforms enhance responsiveness. Experimentation is recommended to determine the optimal width.

Tip 3: Examine Platform Concave: Concave refers to the curvature of the platform’s surface. Deeper concave offers greater foot lock-in, facilitating flip tricks, while shallower concave provides a more mellow feel. Choice depends on personal preference and technical requirements.

Tip 4: Consider Platform Length: Platform length influences wheelbase and overall control. Shorter platforms are generally more responsive, whereas longer platforms offer increased stability at higher speeds.

Tip 5: Inspect Material Quality: High-quality maple wood is a standard material for skateboard platforms due to its durability and flex. Ensure the platform consists of multiple plies of maple for optimal strength and resilience.

Tip 6: Analyze Graphic Design: While aesthetics are subjective, the graphic design can indicate the brand’s attention to detail and commitment to quality. Durable graphics suggest a higher quality manufacturing process.

Tip 7: Check for Construction Integrity: Thoroughly inspect the platform for any signs of warping, delamination, or unevenness. Such defects can compromise the platform’s performance and longevity.

Careful attention to these factors can significantly improve the skateboarding experience, enhancing control, stability, and overall performance. Selecting a compatible platform is essential for safe and effective skateboarding.

The subsequent section will explore specific models and their suitability for various skill levels and riding environments.

1. Construction Materials

The composition of materials in skateboarding platforms is directly correlated to their performance characteristics, durability, and overall lifespan. The choice of wood, adhesive, and manufacturing processes employed by this brand significantly impacts the rider’s experience.

- Maple Wood Composition

The brand predominantly utilizes North American maple in the construction of its decks. The number of plies, typically seven, and the grade of maple influence the deck’s strength and flexibility. Higher-grade maple results in a more resilient and responsive platform. Lesser-grade maple or alternative wood combinations may compromise structural integrity.

- Adhesive Properties

The adhesive used to bond the maple plies together is crucial in preventing delamination and maintaining structural cohesion. High-quality epoxy resins offer superior bonding strength and water resistance compared to lower-grade adhesives. Proper application and curing processes are essential for ensuring long-term durability and resistance to environmental factors.

- Pressing Techniques

The method of pressing the maple plies influences the platform’s shape, concave, and overall consistency. Heat and pressure application during the pressing process determine the density and uniform distribution of the wood fibers. Advanced pressing techniques can enhance the deck’s pop and responsiveness, while inferior methods may result in warping or inconsistent concave profiles.

- Quality Control Measures

Rigorous quality control checks throughout the manufacturing process are essential for identifying and addressing defects in materials or construction. Inspection for voids, delamination, and dimensional inaccuracies ensures that only platforms meeting the brand’s standards are released to the market. Failure to implement adequate quality control can result in compromised performance and premature failure of the platform.

The selection and processing of construction materials are paramount to the performance and longevity of the platform. The brand’s adherence to high-quality maple, robust adhesives, and precise manufacturing techniques contributes to its reputation for producing durable and reliable skateboarding equipment. Comparisons to decks using alternative materials or inferior construction techniques highlight the significance of these material considerations.

2. Deck Shape

Deck shape is a critical determinant of skateboard performance, influencing maneuverability, stability, and rider feel. The geometry of an “element skate decks” deck is carefully considered during design and manufacturing to cater to various skating styles and rider preferences.

- Concave Profile

Concave refers to the curvature of the deck’s surface between the edges. Deeper concave provides increased foot lock-in, enhancing control during flip tricks and technical maneuvers. Shallower concave offers a more mellow feel, preferred by some for cruising and less aggressive riding styles. Different “element skate decks” models feature varying concave depths to suit specific needs.

- Nose and Tail Geometry

The shape and angle of the nose and tail affect pop height, board control, and responsiveness. Steeper nose and tail angles generally result in higher ollies and more immediate board reaction. “element skate decks” often incorporate distinct nose and tail shapes to optimize performance for particular types of tricks or terrain.

- Width and Length Dimensions

Deck width influences stability and foot placement, with wider decks generally preferred for vert skating and narrower decks for street skating. Deck length impacts the wheelbase and overall maneuverability. “element skate decks” are available in a range of widths and lengths to accommodate different foot sizes, riding styles, and personal preferences.

- Wheelbase Configuration

The wheelbase, or distance between the trucks, affects the board’s turning radius and stability. A shorter wheelbase provides quicker turning and responsiveness, while a longer wheelbase offers increased stability at higher speeds. “element skate decks” provide specific wheelbase measurements, enabling riders to fine-tune their setup for optimal performance.

The interplay between concave, nose and tail geometry, width, length, and wheelbase collectively defines a deck’s handling characteristics. The brand recognizes the importance of deck shape and offers a variety of designs to cater to the diverse needs of skateboarders. Understanding these characteristics allows riders to select a platform that aligns with their individual style and skill level.

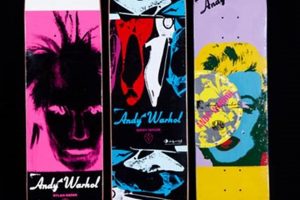

3. Graphic Application

The application of graphics to skateboard decks is not merely an aesthetic consideration but an integral component of product branding and durability. For Element, the graphic application process reflects a commitment to both visual appeal and long-term performance. The selection of inks, application techniques, and protective coatings directly affects a deck’s resistance to wear, fading, and chipping, particularly under the stresses of skateboarding. Therefore, the method used for graphic application is crucial for maintaining the integrity and market value of Element decks.

Specific examples illustrate the importance of this process. Heat transfer graphics, commonly used on decks, offer vibrant colors and intricate designs. However, the longevity of heat transfers depends heavily on the quality of the materials and the precision of the application. Screen-printed graphics, another popular option, provide excellent durability and resistance to abrasion, making them suitable for decks intended for intense use. Element often employs multi-layer screen printing techniques to achieve complex designs while ensuring a robust finish. The choice between these, or other graphic application methods, depends on factors such as design complexity, cost considerations, and the desired level of durability.

In summary, graphic application is a significant aspect of Element’s deck manufacturing, influencing both the aesthetic appeal and the functional lifespan of the product. The challenge lies in balancing visually engaging designs with the need for resilient graphics that can withstand the rigors of skateboarding. By investing in high-quality materials and advanced application techniques, Element aims to deliver decks that maintain their visual appeal and structural integrity over time, reinforcing brand identity and customer satisfaction.

4. Size Variations

The dimensions of skateboard platforms, specifically width and length, are critical factors influencing board control and rider stability. These size variations within Element’s product line cater to diverse skating styles and individual physical attributes, directly affecting a skater’s ability to execute tricks and maneuvers. For instance, a wider platform typically offers enhanced stability for vert skating or larger riders, while a narrower platform facilitates quicker rotations for technical street skating. Conversely, mismatched dimensions can impede progression and potentially increase the risk of injury.

Consider the practical implications of deck width. A skater with larger feet might find a narrower platform uncomfortable and less stable, making it difficult to maintain balance and control. Conversely, a smaller skater on an overly wide platform could struggle to generate sufficient leverage for performing flip tricks. Element’s range of platform widths acknowledges these diverse needs, providing options from approximately 7.75 inches to 8.5 inches or more. Similarly, variations in length affect the wheelbase and overall responsiveness of the skateboard. Shorter platforms are often favored for their maneuverability, while longer platforms provide enhanced stability at higher speeds.

Ultimately, the proper selection of platform size is paramount for optimizing performance and ensuring rider comfort. The range of size options offered by Element allows skaters to fine-tune their setup according to their individual needs and preferences. Failure to consider these size variations can significantly impact the overall skateboarding experience, hindering progression and potentially leading to discomfort or injury. Understanding the relationship between deck dimensions and rider attributes is, therefore, crucial for making informed purchasing decisions and maximizing performance.

5. Concave Depth

Concave depth, the curvature of a skateboard platform between its edges, significantly influences a rider’s board feel and control. The selection of concave depth is a critical factor for skateboarders, impacting trick execution and overall riding experience.

- Foot Lock-In and Control

Deeper concave provides a more pronounced pocket for a rider’s feet, increasing foot lock-in and enhancing control during flip tricks and technical maneuvers. This increased connection allows for more precise board manipulation. For Element, this can translate to certain deck models being favored by street skaters who prioritize technical performance.

- Board Feel and Responsiveness

The extent of concave affects the responsiveness of a deck. Deeper concave generally offers a quicker, more reactive feel, while flatter concave provides a more mellow and predictable ride. This difference can influence the selection process based on individual preferences and riding style. Riders should understand this choice when selecting Element decks.

- Riding Style Compatibility

Different concave depths are often preferred for specific riding styles. Street skaters may favor deeper concave for technical tricks, while transition skaters may prefer a shallower concave for stability and flow. Element offers a range of concave options to accommodate various disciplines within skateboarding. The deck choice will vary based on intended use.

- Brand-Specific Concave Design

Each skateboard brand often develops its own unique concave profiles, which can become a defining characteristic of their decks. Element’s concave designs are influenced by their team riders and the types of skating they represent. Understanding a brand’s concave philosophy can assist riders in selecting a deck that aligns with their preferences and performance goals. Therefore, Element’s concave is specific to the boards that the company manufactures.

The interplay between concave depth, riding style, and personal preference underscores its importance in selecting an Element skateboard platform. Riders should consider their skill level, intended use, and desired board feel when evaluating the concave characteristics of different models. Making an informed decision can significantly improve performance and enjoyment while skateboarding.

6. Durability Testing

Durability testing for skateboard platforms is a critical process ensuring structural integrity and longevity. These tests simulate the stresses encountered during typical skateboarding activities. The resilience of “element skate decks” directly impacts rider safety and product value.

- Impact Resistance Testing

Drop tests and impact simulations assess a deck’s ability to withstand sudden forces from landings and collisions. Accelerometers and strain gauges measure the force threshold before structural failure. “element skate decks” undergo these tests to verify their resistance to common skateboarding impacts, reducing the risk of breakage.

- Flexural Strength Testing

Flexural testing measures a deck’s resistance to bending under load. This simulates the stress experienced during ollies, grinds, and other maneuvers. Load cells and deflection sensors provide data on the deck’s stiffness and load-bearing capacity. “element skate decks” are evaluated to ensure they maintain their shape and responsiveness over time.

- Delamination Resistance Testing

Delamination testing evaluates the bond strength between the layers of wood in the deck. This process involves subjecting the deck to moisture, temperature fluctuations, and mechanical stress. “element skate decks” are tested to ensure the adhesive maintains its integrity, preventing separation of the plies and extending the deck’s lifespan.

- Fatigue Testing

Fatigue testing simulates repetitive stress cycles to assess the long-term durability of the deck. This involves subjecting the deck to repeated bending and loading cycles, mimicking the cumulative stress of regular skateboarding. “element skate decks” undergo fatigue testing to identify potential weak points and ensure they can withstand prolonged use.

These durability tests are fundamental to the manufacturing of “element skate decks”. They provide data-driven insights into product performance, allowing for design improvements and quality control measures. The implementation of these tests contributes to the brand’s reputation for producing reliable and long-lasting skateboard equipment.

7. Brand Reputation

The reputation of a skateboard deck manufacturer directly influences consumer trust, product value, and market position. For “element skate decks”, a positive brand image is essential for maintaining a competitive advantage and fostering customer loyalty.

- Historical Performance and Legacy

A brand’s historical performance in producing durable and reliable equipment contributes significantly to its reputation. Element’s legacy within the skateboarding community, built on years of producing platforms that meet the demands of both amateur and professional riders, shapes consumer perception. Previous successes create an expectation of continued quality.

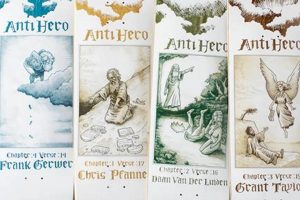

- Endorsements and Sponsorships

Endorsements from respected skateboarders and sponsorships of prominent skateboarding events enhance brand visibility and credibility. Element’s association with well-known athletes lends legitimacy to its products, signaling quality and performance to potential customers. These endorsements serve as a form of social proof.

- Product Quality and Innovation

Consistent product quality and a commitment to innovation are critical for sustaining a positive brand reputation. Element’s dedication to utilizing high-grade materials and incorporating advanced construction techniques reinforces its commitment to providing superior platforms. This continuous improvement fosters customer confidence.

- Customer Service and Community Engagement

Responsive customer service and active engagement with the skateboarding community build trust and loyalty. Addressing customer concerns promptly and participating in community events demonstrate a commitment to customer satisfaction and foster a sense of connection. These interactions contribute to a positive brand image.

These factors collectively contribute to the brand’s overall standing within the skateboarding industry. Positive attributes lead to increased sales, greater customer loyalty, and a stronger market position. Conversely, a negative reputation can erode consumer trust and negatively impact the brand’s long-term viability. For “element skate decks”, maintaining a strong brand reputation is paramount to its continued success.

Frequently Asked Questions About Platform Selection

The following section addresses common inquiries regarding the selection, maintenance, and usage of skateboard platforms, providing information to assist users in making informed decisions.

Question 1: What factors determine the appropriate platform width for a skateboarder?

Platform width selection depends on foot size, riding style, and personal preference. Wider platforms generally offer greater stability, while narrower platforms enhance maneuverability. Experimentation is recommended to determine the optimal width for individual needs.

Question 2: How does concave depth affect skateboard performance?

Concave depth influences foot lock-in and board feel. Deeper concave provides increased control during flip tricks, while shallower concave offers a more mellow ride. The appropriate concave depth varies based on riding style and personal preference.

Question 3: What materials are typically used in the construction of a skateboard platform?

Skateboard platforms are commonly constructed from multiple plies of maple wood, bonded together with adhesive. High-quality maple provides durability and flex, while the adhesive prevents delamination.

Question 4: How can platform durability be assessed prior to purchase?

Platform durability can be assessed by inspecting for signs of warping, delamination, or unevenness. Checking for consistent ply construction and a smooth finish indicates higher quality manufacturing.

Question 5: What is the significance of the nose and tail shape on a skateboard platform?

The nose and tail shape influence pop height and board control. Steeper angles generally result in higher ollies and more immediate board reaction. Different shapes cater to specific trick types and riding styles.

Question 6: How does the wheelbase affect the performance of a skateboard platform?

The wheelbase, or distance between the trucks, affects the turning radius and stability of the board. A shorter wheelbase provides quicker turning, while a longer wheelbase offers increased stability at higher speeds.

In summary, the appropriate selection of a skateboard platform requires careful consideration of individual needs, riding style, and preferences. Factors such as width, concave depth, materials, and wheelbase all contribute to the overall performance and riding experience.

The next section will explore platform maintenance and storage to maximize product lifespan.

Conclusion

This exploration of skateboard platforms has highlighted key considerations for optimal performance and durability. Factors such as construction materials, deck shape, graphic application, size variations, concave depth, durability testing, and brand reputation significantly influence the selection and lifespan of skateboarding equipment. Understanding these elements enables informed purchasing decisions and promotes enhanced riding experiences.

Continued advancements in skateboard technology and manufacturing processes promise to further refine platform design and performance. A commitment to quality and innovation remains essential for manufacturers seeking to meet the evolving demands of the skateboarding community. Prioritizing rider safety, product reliability, and environmental sustainability will ensure the continued growth and responsible development of the skateboarding industry.