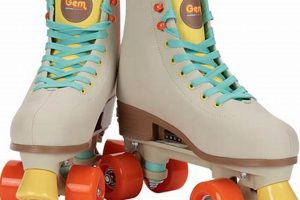

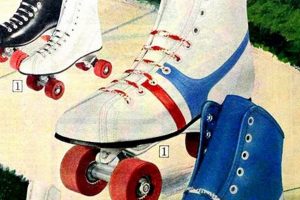

Footwear, known for its durable construction and distinctive aesthetic, has been adapted into recreational equipment. The result is a hybrid product that combines the resilience of a classic boot with the mobility of wheeled locomotion. These modified boots offer a unique skating experience.

This fusion offers enhanced ankle support and a robust platform, potentially improving stability and control for the user. Historically, the durable boot has been associated with counter-cultural movements and practical workwear, while skating represents freedom and recreation. The combination bridges these worlds.

The following sections will detail the construction specifics, customization options, performance characteristics, and target demographic for this particular type of wheeled footwear.

Guidance on Wheeled Boot Usage

The following recommendations are designed to maximize safety and performance when utilizing the specific wheeled boot design.

Tip 1: Secure Fastening is Paramount: Ensure all laces and straps are tightly secured before each use. Loose closures can compromise ankle support and increase the risk of instability during skating.

Tip 2: Controlled Environments for Initial Use: Beginners should practice in smooth, flat, obstacle-free areas. This allows for familiarization with the boot’s weight and maneuverability characteristics without the added complexity of uneven surfaces or obstacles.

Tip 3: Protective Gear is Non-Negotiable: Helmets, wrist guards, elbow pads, and knee pads are essential safety equipment. Impacts are inevitable, especially during the learning phase, and protective gear significantly reduces the risk of injury.

Tip 4: Wheel Maintenance is Critical: Regularly inspect wheels for wear and tear. Replace worn wheels promptly to maintain optimal grip and rolling efficiency. Additionally, ensure wheel bearings are properly lubricated for smooth operation.

Tip 5: Gradual Skill Progression is Advised: Avoid attempting advanced maneuvers until foundational skills, such as balancing, stopping, and turning, are mastered. This gradual approach reduces the risk of falls and injuries.

Tip 6: Be Aware of Surface Conditions: Avoid skating on surfaces with debris, cracks, or wet patches. These conditions can compromise traction and increase the likelihood of accidents.

Tip 7: Inspect Boot Integrity Regularly: Check the boot’s sole, stitching, and attachment points for any signs of damage. Compromised boot integrity can lead to failure during use. Address any issues promptly through repair or replacement.

Adherence to these guidelines will contribute to a safer and more enjoyable experience with the hybrid footwear.

The subsequent section will address common modifications and customization options for this type of product.

1. Boot Durability

The longevity and safety of wheeled boot adaptations are fundamentally linked to the inherent robustness of the boot component. High-quality materials and construction techniques are crucial for withstanding the stresses imposed by skating maneuvers.

- Material Composition

The type of leather or synthetic material used directly influences the boot’s resistance to abrasion, tearing, and environmental degradation. Full-grain leather, for example, offers superior durability compared to thinner, less processed alternatives. The material must withstand repeated flexing and impacts without compromising structural integrity.

- Stitching and Seam Reinforcement

The quality and density of stitching, particularly at stress points like the ankle and sole attachment, are paramount. Reinforced seams, using durable threads and techniques like double-stitching, prevent separation and failure under strain. Weak stitching is a common failure point in lower-quality adaptations.

- Sole Attachment Method

The method by which the sole is attached to the boot upper whether cemented, stitched, or a combination of both significantly impacts the overall durability. Stitched soles offer greater resistance to detachment compared to solely cemented constructions. A secure and robust sole attachment is vital for maintaining the boot’s structural integrity during skating activities.

- Hardware Quality

The durability of eyelets, buckles, and other hardware components contributes to the overall longevity of the wheeled boot. Corrosion-resistant materials and secure attachment methods prevent premature failure. Inferior hardware can compromise the boot’s functionality and shorten its lifespan.

The interplay of these factors determines the overall durability, influencing the longevity and safe performance of these specific wheeled boot design. Prioritizing robust materials and construction techniques is critical for ensuring a reliable and long-lasting product.

2. Wheel Composition

Wheel composition is a critical determinant of performance characteristics in wheeled boot applications. The material selected directly influences factors such as grip, speed, durability, and suitability for various surfaces. Polyurethane (PU) is the most common material, but variations in its formulation and hardness significantly impact the skating experience. For instance, a softer PU compound offers increased grip, making it suitable for indoor surfaces or beginners prioritizing stability. Conversely, a harder compound provides less friction, resulting in greater speed and is often preferred by experienced skaters on smoother outdoor terrains. The selection of an inappropriate wheel composition can lead to diminished control, increased risk of falls, and accelerated wear.

The durometer scale measures wheel hardness, with lower numbers indicating softer wheels and higher numbers representing harder ones. A wheel with a durometer of 78A would be considered soft and ideal for absorbing vibrations on rough surfaces, while an 85A or higher wheel would be better suited for smooth surfaces requiring speed and minimal energy loss. Furthermore, the wheel’s rebound characteristics, a measure of its ability to return energy after compression, also affect rolling efficiency. High-rebound wheels maintain momentum more effectively. A real-world example involves a skater using a hard wheel on a slick surface; the lack of grip could cause the skater to lose control. By contrast, using a soft wheel on a very smooth floor could create excessive drag.

Ultimately, wheel composition represents a crucial element impacting user experience and safety. Selecting the appropriate wheel material and durometer necessitates careful consideration of the intended skating environment, skill level, and desired performance characteristics. A mismatch between wheel composition and skating conditions not only reduces efficiency but also potentially jeopardizes user safety. Understanding this interrelation is paramount for both manufacturers and consumers involved with wheeled boot adaptations.

3. Ankle Support

Ankle support is a critical factor in wheeled boot design, significantly influencing stability, control, and injury prevention. The inherent dynamics of skating place considerable stress on the ankle joint, necessitating robust support mechanisms within the boot structure. The following details the multifaceted nature of ankle support in this specific application.

- Boot Height and Cuff Design

The height of the boot shaft and the design of the ankle cuff directly impact the degree of lateral support provided. Higher shafts and rigid cuffs restrict ankle movement, minimizing the risk of sprains and instability. Conversely, lower-cut designs offer greater flexibility but reduced support, potentially increasing vulnerability to injury. The trade-off between mobility and stability is a crucial consideration in boot design. For instance, a boot intended for aggressive skating maneuvers might prioritize flexibility, while a recreational model emphasizes stability. Real-world consequences of inadequate cuff support can manifest as ankle roll during sharp turns or landings.

- Lacing Systems and Closure Mechanisms

The lacing system and supplementary closure mechanisms, such as straps or buckles, play a pivotal role in securing the ankle within the boot. A well-designed system allows for precise adjustment and uniform pressure distribution, ensuring a snug and supportive fit. Inadequate lacing or poorly designed closures can result in ankle slippage and compromised stability. An example is a speed skating boot requiring a very tight lacing to allow maximum control, where roller derby may sacrifice tightness for agility

- Internal Padding and Ankle Reinforcement

Internal padding, particularly around the ankle area, contributes to both comfort and support. Strategically placed padding can cushion the ankle against impacts and prevent excessive movement within the boot. Additional reinforcement elements, such as molded plastic or carbon fiber inserts, further enhance stability. Failure to properly use padding can lead to discomfort and injury.

- Boot Stiffness and Torsional Rigidity

The overall stiffness of the boot’s construction significantly impacts its ability to resist torsional forces. A stiffer boot provides greater stability and control, particularly during lateral movements and landings. However, excessive stiffness can restrict ankle mobility and compromise comfort. The selection of appropriate boot stiffness depends on the intended skating style and user preferences. Boots designed for jumping or aggressive skating may require high torsional rigidity to prevent ankle injuries. In contrast, boots intended for recreational skating may prioritize flexibility for comfort.

The preceding facets of ankle support are intrinsically linked, collectively contributing to the overall performance and safety characteristics of wheeled boots. A comprehensive approach to ankle support design necessitates careful consideration of boot height, lacing systems, internal padding, and boot stiffness. Real-world application highlights the consequences of inadequate ankle support, including increased risk of sprains, instability, and diminished control. Thus, prioritizing robust ankle support mechanisms is essential for promoting safe and enjoyable skating experiences. The combination of these elements is what ultimately affect the durability of the boot as well.

4. Frame Material

The frame, serving as the interface between the boot and the wheels, significantly influences the performance characteristics of footwear adapted for wheeled mobility. Its material composition directly impacts weight, durability, responsiveness, and vibration absorption. The choice of material is, therefore, a critical engineering consideration.

- Aluminum Alloys

Aluminum alloys offer a favorable strength-to-weight ratio, making them a common choice for skating frames. They provide good responsiveness, allowing for efficient transfer of energy from the skater’s movements to the wheels. Different aluminum alloys, such as 6061 or 7005, offer varying levels of strength and corrosion resistance. An example is aircraft-grade aluminum which is known for its good strength and is suitable for use in skating frames to create durability.

- Steel

Steel frames are known for their high durability and affordability. However, they are significantly heavier than aluminum, which can impact agility and increase fatigue. Steel is often used in entry-level products where cost is a primary concern. A real-world example is that older or beginner model will often use the more affordable and durable steel.

- Composites (e.g., Carbon Fiber)

Composite materials, such as carbon fiber, offer exceptional stiffness and lightweight properties. These frames provide superior responsiveness and vibration damping, enhancing performance and comfort. However, they are typically more expensive than aluminum or steel. Competitive skaters often prefer frames made from composite materials because of these advantages. Example are those found in competitive roller skates, often with emphasis on speed

- Magnesium Alloys

Magnesium alloys provide a lighter alternative to aluminum while maintaining good strength. These frames offer excellent vibration absorption and responsiveness. However, magnesium is more susceptible to corrosion and requires specialized coatings. Magnesium is often use in sports equipment to enhance durability for long term use.

The selection of frame material represents a crucial trade-off between weight, durability, responsiveness, and cost. The optimal choice depends on the intended use of the boots, the skater’s skill level, and budget considerations. These factors must be considered to achieve ideal performance. The performance of all components is interlinked.

5. Braking System

The braking system integrated into wheeled boot adaptations is paramount for ensuring user safety and controlled deceleration. The efficacy and design of this system directly influence the maneuverability and hazard mitigation capabilities.

- Heel Brake Design

Heel brake systems, commonly found on recreational models, involve a brake pad positioned at the heel of one or both boots. Activation occurs by tilting the foot backward, applying pressure to the pad. This design offers intuitive operation for beginners but may limit maneuverability for advanced techniques. An example of this system is found in entry-level rollerblades, facilitating ease of use. The main drawback for this kind of braking system is it can be difficult to use effectively for individuals with limited flexibility.

- Toe Stop Integration

Toe stops, prevalent in quad skate configurations, involve a rubber or composite stopper mounted at the front of the boot. Braking is achieved by leaning forward and applying pressure to the toe stop. This system allows for precise control and is favored by skaters performing dance or jam skating maneuvers. The material composition of the stopper affects grip and wear. Harder composite provides more control, while softer material provides durability.

- Inline Brake Mechanisms

Inline brake mechanisms typically involve a brake pad mounted on a frame extension behind the rear wheels. Activation requires lifting the toe and applying pressure to the brake pad. The design can vary in terms of adjustability and pad replacement options. These are commonly used on recreational inline models and provide reliable stopping power. The braking effectiveness relies on maintaining proper technique to avoid instability during deceleration.

- Braking System Maintenance

Regular maintenance of braking systems is essential for ensuring consistent performance. This includes inspecting brake pads for wear, adjusting brake height, and replacing worn components. Neglecting maintenance can compromise braking effectiveness and increase the risk of accidents. The severity of these situations can lead to bodily harm and even injuries.

The braking system, irrespective of design, represents a critical safety component. Selection should align with user skill level and intended skating style, while consistent maintenance is imperative for optimal performance. Each system is a tradeoff between stopping power and maneuverability depending on the application. This combination is what ultimately impact performance.

6. Customization Options

Customization options significantly impact the appeal and functionality of wheeled footwear adapted from a durable boot. These modifications allow for personalization, performance enhancement, and adaptation to diverse skating styles and user needs. The ability to tailor specific aspects of the boot and its components directly affects both the aesthetic and functional aspects, influencing user satisfaction. An example is the exchange of standard wheels for high-rebound variants, enhancing speed and agility. The range of available alterations underscores the adaptability of the core design.

The practical implications of customization options are evident in areas such as comfort and safety. The ability to select appropriately sized and shaped inner linings can alleviate pressure points and improve fit. Furthermore, the addition of aftermarket ankle supports or reinforced toe caps can enhance protection against impacts. Frame selection presents another critical customization point. Different frame materials, such as aluminum or carbon fiber, alter the weight, stiffness, and responsiveness of the skates. This allows skaters to fine-tune the handling characteristics to suit their preferences and skill level. Another example is customization with different colored laces and accessories.

In summary, customization options are integral to optimizing the design, bridging the gap between mass-produced footwear and individualized skating experiences. Challenges exist in ensuring compatibility between aftermarket components and the base product. The freedom to personalize extends both form and function, ensuring it remains a key element in the design of wheeled boot modifications.

7. User Skill Level

The adoption of footwear adapted for wheeled mobility, particularly those based on durable boot designs, necessitates careful consideration of user skill level. Inexperience can lead to increased risk of injury and suboptimal performance, while advanced skills demand specific equipment attributes. The attributes that beginners should look for in terms of stability and control is crucial to understanding.

Beginner skaters often benefit from models prioritizing stability and control. Features such as lower wheel durometer, enhanced ankle support, and responsive braking systems facilitate learning fundamental skills. Conversely, advanced skaters may seek models with stiffer boots, lighter frames, and higher wheel durometers to maximize speed and agility. Real-world examples include rentals in skating rinks, which are frequently designed with beginner skill level in mind, balancing safety with usability. The use of highly modified equipment by professional skaters reflects the necessity of matching equipment to advanced capabilities.

Ultimately, aligning equipment characteristics with user skill level is paramount for ensuring both safety and enjoyment. Inadequate equipment can hinder skill development and increase the potential for accidents, while overly specialized equipment may be difficult for novice skaters to control. Acknowledging the interplay between user capabilities and equipment design is crucial for manufacturers, retailers, and end-users alike. The practical significance lies in mitigating risks and maximizing the potential benefits of wheeled boot usage across the spectrum of skill levels.

Frequently Asked Questions About Wheeled Boot Adaptations

The following addresses common inquiries regarding footwear which combine durable boot construction with wheeled mobility. These answers aim to provide clarity on usage, maintenance, and safety concerns.

Question 1: Is prior skating experience required to use wheeled boot designs?

Prior skating experience is beneficial, but not always essential. Beginner-friendly models prioritize stability and control, allowing novice skaters to learn basic skills. However, a foundational understanding of balance and coordination is advantageous. The design for users should consider all user skill level.

Question 2: What safety precautions should be taken when utilizing wheeled boots?

Wearing appropriate protective gear, including a helmet, wrist guards, elbow pads, and knee pads, is crucial. Skating in controlled environments, such as smooth, flat surfaces, is recommended, especially for beginners. Regular inspection of equipment for wear and tear is also vital. Ignoring the safety can lead to bodily injury.

Question 3: How should the braking system be maintained?

Brake pads should be inspected regularly for wear and replaced as needed. The braking mechanisms should be adjusted periodically to ensure optimal performance. Neglecting maintenance can compromise braking effectiveness and increase the risk of accidents.

Question 4: What is the typical lifespan of wheeled boots?

The lifespan depends on usage frequency, skating style, and maintenance practices. High-quality boots, properly maintained, can last for several years. However, heavy use or neglect can significantly shorten their lifespan. The boot sole is what determines durability.

Question 5: Can the wheels be replaced on wheeled boot adaptations?

Yes, the wheels are generally replaceable. The replacement process typically involves using specialized tools to remove and install new wheels. It is important to select wheels compatible with the boot’s frame and axle size. The performance relies on the correct size and design.

Question 6: Are these suitable for all types of skating?

The suitability depends on the specific design of the boots. Some models are designed for recreational skating, while others are optimized for aggressive skating, speed skating, or dance skating. Selecting a model appropriate for the intended use is essential. The design impacts the user skill levels.

In summary, wheeled boot adaptations require careful consideration of safety precautions, regular maintenance, and appropriate usage. Prior knowledge on what to look for in design for both beginners and experienced users is important to understand. These factors significantly impact the user experience and the longevity of the product.

The following section will discuss purchasing and retail considerations for these modified footwear options.

Doc Marten Roller Skates

This exploration has detailed key elements pertaining to footwear derived from a durable boot base and adapted for wheeled mobility. Examination of boot durability, wheel composition, ankle support, frame material, braking systems, customization options, and user skill level reveals the multifaceted nature of this product category. Understanding these factors is paramount for informed decision-making.

The integration of a robust boot design with wheeled locomotion presents both opportunities and challenges. Further research into material science, biomechanics, and user ergonomics will likely refine future iterations. The synthesis of style, functionality, and safety remains a central objective in the ongoing evolution of this hybrid footwear.