A type of recreational equipment, these skates combine the mobility of traditional roller skates with the speed and efficiency of inline designs. The defining characteristic is the ability to separate the skate component from the shoe or boot, offering convenience and versatility. For example, an individual might wear specialized footwear and then attach the skate frame when desired for skating.

The significance of this design lies in its adaptability. Users can transition between walking and skating without the need to carry an extra pair of shoes. This offers benefits for commuters, recreational users, and individuals seeking a more versatile footwear option. Historically, designs aimed at combining footwear and skating have sought to improve portability and ease of use, with advancements in materials and mechanisms continually refining the functionality.

The subsequent sections will delve into the construction materials, attachment mechanisms, various models available, user considerations, and maintenance requirements of this specialized skating equipment. These aspects are important for understanding the functionality and practical applications.

Considerations for Selecting Skating Equipment

The following provides guidance on choosing adaptable skating equipment, focusing on factors that influence performance, comfort, and longevity.

Tip 1: Evaluate Attachment Security: Prioritize models with robust locking mechanisms to ensure stable and safe skating. Inspect the attachment points for signs of wear or potential failure before each use.

Tip 2: Assess Wheel Quality and Bearing Performance: Higher-quality wheels provide better grip and durability. Similarly, smooth-rolling bearings contribute to efficient skating and reduced energy expenditure. Examine the durometer rating of the wheels for suitability to different surfaces.

Tip 3: Examine Boot Comfort and Support: The interface between the foot and the skate should offer adequate support without causing discomfort. Consider adjustable features to accommodate different foot shapes and sock thicknesses.

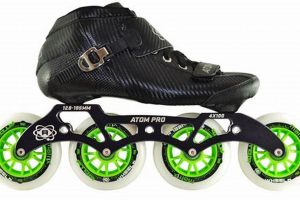

Tip 4: Prioritize Frame Material and Construction: The frame’s material affects weight, stiffness, and vibration dampening. Aluminum frames offer a balance of strength and weight, while composite frames may provide enhanced vibration absorption.

Tip 5: Consider Braking System Efficiency: Evaluate the effectiveness and ease of use of the braking mechanism. Ensure it is accessible and provides adequate stopping power in various conditions.

Tip 6: Research Replacement Part Availability: Before purchasing, verify the availability of replacement wheels, bearings, straps, and other components. This ensures long-term usability and reduces the risk of obsolescence.

Tip 7: Inspect Weight Capacity Ratings: Adhere to the manufacturer’s specified weight limits to avoid compromising the equipment’s integrity and safety.

Selecting the correct equipment involves considering the security of the attachment, the wheel’s ability to grip, the boot’s comfort, the type of construction material used, the efficiency of the brakes, and the weight capacity. These factors all contributes to a safe and long lasting piece of equipment.

The subsequent sections will address maintenance procedures to prolong the lifespan and performance of this specialized skating equipment.

1. Attachment Security

Attachment security is a paramount consideration in the design and use of modular skating systems. The reliability of the connection between the boot and the skate frame directly impacts user safety, performance, and overall confidence. A compromised attachment can lead to instability, loss of control, and potential injury.

- Locking Mechanism Integrity

The locking mechanism is the core component that secures the boot to the frame. Its design should incorporate multiple redundancies and fail-safes to prevent unintentional detachment. Examples include lever-actuated clamps, multi-point locking systems, and durable materials resistant to wear and fatigue. A poorly designed locking mechanism, conversely, may be prone to loosening under stress, leading to catastrophic failure.

- Material Strength and Durability

The materials used in the attachment interface must possess sufficient strength and resistance to withstand the dynamic forces encountered during skating. High-grade alloys, reinforced polymers, and robust composites are commonly employed. Inadequate material selection can result in deformation, cracking, or breakage, compromising the connection and increasing the risk of detachment. Regular inspection for signs of stress or damage is crucial.

- Interface Fit and Tolerance

The precision of the fit between the boot and the frame is essential for maintaining a secure connection. Excessive clearance or play in the interface can introduce instability and increase the likelihood of detachment. Tight tolerances and well-defined mating surfaces ensure a stable and reliable connection. Manufacturing defects or wear over time can degrade the interface fit, necessitating adjustments or component replacement.

- Regular Inspection and Maintenance

Regardless of the initial design and construction, the long-term reliability of the attachment system depends on regular inspection and maintenance. This includes visually inspecting the locking mechanism, checking for signs of wear or damage, and lubricating moving parts as necessary. Neglecting maintenance can lead to corrosion, reduced locking force, and an increased risk of failure. Following the manufacturer’s recommended maintenance schedule is essential for ensuring continued safety and performance.

These interconnected facets of attachment security highlight the critical role it plays in the practical application of modular skating systems. By prioritizing robust locking mechanisms, durable materials, precise fit, and diligent maintenance, users can maximize the safety and longevity of their equipment.

2. Wheel Durometer

Wheel durometer, measured on the Shore A scale, is a critical determinant of performance characteristics in adaptable skating equipment. This measurement quantifies the hardness of the wheel material, directly influencing factors such as grip, rolling resistance, and wear rate. In these skates, the selection of an appropriate durometer is especially important due to the varied surfaces on which the equipment may be used. For instance, a softer wheel (e.g., 78A-82A) provides enhanced grip on rough or uneven terrain, resulting in improved control and stability. Conversely, a harder wheel (e.g., 84A-90A) exhibits lower rolling resistance, facilitating higher speeds on smooth surfaces. The cause and effect relationship between durometer and performance is thus evident: softer wheels grip better but roll slower and wear faster, while harder wheels roll faster but offer less grip and wear more slowly.

The adaptability inherent in the design emphasizes the need for considering the intended usage environment when selecting wheel durometer. Commuters using adaptable skates on mixed surfaces, such as sidewalks and paved bike paths, may benefit from wheels in the mid-range (e.g., 82A-85A), offering a compromise between grip and speed. Aggressive skaters performing tricks in skate parks may prefer harder wheels for increased speed and durability on smooth concrete surfaces. Conversely, recreational skaters using the equipment on rough asphalt surfaces may opt for softer wheels to absorb vibrations and improve comfort. Furthermore, individual skater weight and skill level can influence the optimal durometer selection. Heavier skaters or those with less refined technique may benefit from harder wheels that provide greater support and stability.

In summary, wheel durometer is a pivotal factor influencing the performance and suitability of modular skating equipment. The selection of an appropriate durometer requires careful consideration of the intended usage environment, skater weight, and skill level. While softer wheels offer enhanced grip and comfort on rough surfaces, harder wheels prioritize speed and durability on smooth surfaces. The ideal durometer represents a balance between these competing factors, optimizing the skating experience for the specific application. The trade-offs between grip, speed, and wear rate underscore the importance of informed wheel selection for maximizing the benefits and minimizing the drawbacks of this equipment.

3. Boot Comfort

Boot comfort is a critical determinant of the overall user experience and performance associated with modular skating systems. Its influence extends beyond mere physical sensation, directly affecting stability, control, and endurance during use. Neglecting boot comfort can lead to discomfort, blisters, impaired circulation, and reduced skating efficiency, thereby undermining the intended benefits of the design.

- Anatomical Fit and Support

The boot’s anatomical design should conform closely to the contours of the foot, providing adequate support to the arch, ankle, and heel. A well-designed boot minimizes pressure points and prevents excessive movement within the skate, reducing the risk of blisters and chafing. Conversely, a poorly fitting boot can cause localized discomfort and instability, particularly during prolonged use or aggressive maneuvers. For example, a boot with insufficient arch support may lead to foot fatigue and pronation, impacting skating efficiency.

- Material Breathability and Moisture Management

The materials used in the boot’s construction should promote breathability and effective moisture management. Perspiration accumulation within the boot can create a damp and uncomfortable environment, increasing the likelihood of blisters and fungal infections. Breathable materials, such as mesh fabrics and perforated linings, allow for air circulation and promote moisture evaporation, maintaining a more hygienic and comfortable environment. Moisture-wicking linings further enhance comfort by drawing sweat away from the skin.

- Padding and Cushioning

Strategic placement of padding and cushioning within the boot can significantly enhance comfort and shock absorption. Padding around the ankle, tongue, and instep reduces pressure from straps and buckles, preventing discomfort and chafing. Cushioning in the sole absorbs impact forces during skating, reducing stress on the feet and joints. The type and density of the padding should be carefully selected to balance comfort and performance, avoiding excessive bulk that can compromise fit and control.

- Adjustability and Customization

Features that enable adjustability and customization contribute to improved boot comfort. Adjustable straps, buckles, and laces allow users to fine-tune the fit to accommodate individual foot shapes and sock thicknesses. Heat-moldable liners offer a further level of customization, conforming precisely to the contours of the foot for a personalized fit. The ability to adjust the boot’s fit not only enhances comfort but also improves control and stability, particularly for users with atypical foot shapes or specific fit requirements.

These intertwined aspects of boot comfort are central to the satisfactory application of modular skating systems. By emphasizing proper fit, breathable materials, effective padding, and adjustability, manufacturers can create boots that enhance the user experience and promote prolonged, comfortable skating. The ultimate success hinges on the capacity to integrate these comfort-enhancing characteristics without sacrificing the performance attributes fundamental to adaptable inline designs.

4. Frame Material

The selection of frame material is a critical design consideration for modular skating systems, significantly impacting their performance, durability, and overall user experience. The frame, serving as the structural backbone connecting the boot to the wheels, must withstand substantial forces and stresses during skating. The material properties directly influence factors such as weight, stiffness, vibration dampening, and resistance to wear and fatigue. For example, a frame constructed from a lightweight material, like aluminum alloy, reduces the overall weight of the skate, enhancing maneuverability and reducing fatigue during prolonged use. Conversely, a stiffer frame material, such as carbon fiber composite, improves energy transfer from the skater to the wheels, increasing efficiency and responsiveness. The practical significance of understanding frame material lies in its direct effect on the functionality and longevity of the skate. The material’s durability ensures continued safe functionality for the equipment.

Different materials offer varied trade-offs in these performance characteristics. Aluminum alloys, commonly used due to their favorable strength-to-weight ratio and relatively low cost, provide a good balance of stiffness and durability. However, they may exhibit less vibration dampening compared to composite materials. Carbon fiber composites, known for their exceptional stiffness and lightweight properties, are often employed in high-performance skates to maximize efficiency and responsiveness. However, they are typically more expensive and may be more susceptible to impact damage. Thermoplastic materials offer a cost-effective alternative, providing reasonable durability and vibration dampening, but generally lack the stiffness of aluminum or carbon fiber. These materials also allow for flexibility in design, which can improve comfort as well. Each material impacts the cost and usability of the skates.

In summary, the choice of frame material represents a fundamental design decision in modular skating systems, with significant implications for performance, durability, and cost. The optimal material depends on the intended application and user requirements, requiring a careful balance of weight, stiffness, vibration dampening, and cost. Understanding the properties and trade-offs associated with different frame materials enables informed decision-making, ultimately enhancing the overall skating experience and ensuring long-term reliability of the equipment.

5. Braking Efficiency

Braking efficiency is a critical safety parameter in the context of modular skating systems. A reliable and effective braking mechanism is essential for controlled deceleration and prevention of accidents. The integration of braking systems with detachable skates presents unique design challenges, as the mechanism must function effectively while accommodating the detachable nature of the equipment.

- Brake Pad Material and Contact Area

The friction coefficient of the brake pad material and the contact area between the pad and the wheel significantly influence braking effectiveness. High-friction materials, such as certain rubber compounds, provide greater stopping power but may exhibit increased wear. A larger contact area distributes the braking force, reducing localized heat buildup and extending pad life. Inadequate pad material or insufficient contact area can result in reduced braking efficiency and increased stopping distances. Consider a brake pad made from a high-friction compound, providing superior stopping power in wet conditions. The material composition directly impacts the safety and stopping distance of the skate.

- Braking Mechanism Actuation and Responsiveness

The ease and speed with which the braking mechanism engages directly affect the skater’s ability to react to potential hazards. A responsive actuation system, such as a well-designed heel brake or cuff-activated brake, allows for quick and controlled deceleration. Lag in the actuation system, caused by excessive friction or poorly designed linkages, can compromise braking efficiency and increase the risk of accidents. A system with low friction is key to a responsive breaking system.

- Brake Placement and Leverage

The position of the brake relative to the skater’s center of gravity and the leverage provided by the braking mechanism influence the stability and control during deceleration. A brake positioned too high or too far from the center of gravity can increase the risk of instability and loss of control. Adequate leverage is necessary to generate sufficient braking force without requiring excessive effort from the skater. The location of the breaking system is key to stability.

- Maintenance and Adjustment

Regular maintenance and adjustment of the braking system are essential for maintaining optimal braking efficiency. Brake pads wear down over time and require periodic replacement. Linkages and pivots may require lubrication to ensure smooth operation. Cables may stretch or fray, affecting actuation responsiveness. Neglecting maintenance can compromise braking efficiency and increase the risk of failure. Therefore, a maintenance schedule is essential.

The aforementioned factors are vital for reliable and effective braking with detachable inline skates. High-friction pads, a responsive mechanism, optimal brake placement, and diligent maintenance collectively contribute to enhanced braking efficiency. Addressing these considerations will promote user safety and control when utilizing this type of skating equipment.

6. Portability

Portability represents a primary advantage in the design of detachable inline skates, offering a significant benefit over traditional, non-detachable models. The capacity to separate the skate component from the footwear enhances convenience for users in various scenarios, particularly where transitions between skating and walking are frequent.

- Reduced Bulk and Weight During Non-Use

Detachment significantly diminishes the bulk and weight of the footwear when skating is not desired. The user can remove the skate portion, reducing the overall profile and mass carried. For example, a commuter arriving at a destination can detach the skates and store them in a backpack or carrying case, rather than being encumbered by the full skate assembly. This is particularly useful in crowded environments or where storage space is limited.

- Facilitation of Multi-Modal Commuting

These skates support multi-modal commuting strategies, allowing seamless transitions between skating and other forms of transportation, such as public transit or cycling. The ability to quickly detach the skates enables users to board a bus or train without the inconvenience of wearing bulky skates. Moreover, it simplifies the process of switching between skating and cycling, as the skates can be easily stored while riding a bicycle.

- Simplified Storage in Confined Spaces

The detachable design simplifies storage in confined spaces, such as lockers, offices, or apartments. Separating the skate component allows for more efficient packing and storage compared to integrated skates. This is advantageous for individuals living in urban environments with limited storage space or for travelers seeking to minimize luggage volume.

- Enhanced Versatility for Travel

Detachable skates enhance versatility for travel by offering the option to skate only when and where desired. Travelers can pack the skates in their luggage and use them for recreational skating at their destination without being burdened by the skates during other activities. This provides a flexible means of exploring new environments and engaging in physical activity while traveling.

The enhanced portability afforded by detachable inline skates expands their practical applications and user appeal. By reducing bulk, facilitating multi-modal commuting, simplifying storage, and enhancing travel versatility, detachable skates offer a distinct advantage over conventional designs, catering to the needs of individuals seeking convenience and adaptability in their recreational or transportation choices.

Frequently Asked Questions About Detachable Inline Skates

The following addresses common inquiries regarding this type of skating equipment, aiming to provide clarity and comprehensive understanding.

Question 1: What are the primary advantages of detachable inline skates compared to traditional inline skates?

The chief advantage lies in enhanced portability. Detachment allows users to transition between skating and walking without carrying a separate pair of shoes. This facilitates multi-modal commuting and simplifies storage.

Question 2: How secure are the attachment mechanisms on detachable inline skates?

Attachment security varies by model. Reputable brands employ robust locking mechanisms with multiple fail-safes. Regular inspection for wear and proper maintenance are essential to ensure a secure connection.

Question 3: Are detachable inline skates suitable for all skill levels?

Suitability depends on the specific model and the skater’s experience. Beginner models often prioritize stability and ease of use, while advanced models cater to experienced skaters seeking performance and maneuverability. Assess personal skill level and select a model accordingly.

Question 4: What types of maintenance are required for detachable inline skates?

Maintenance includes regular cleaning, lubrication of moving parts, inspection for wear and tear, and periodic replacement of brake pads and wheels. Adherence to the manufacturer’s recommendations is crucial for optimal performance and longevity.

Question 5: Do detachable inline skates offer the same level of performance as traditional inline skates?

Performance can be comparable, but may be determined by the specific design and materials used. High-quality detachable models can deliver performance similar to that of traditional skates, but lower-quality models may compromise performance for portability.

Question 6: Are replacement parts readily available for detachable inline skates?

Availability of replacement parts depends on the brand and model. Before purchasing, it’s advisable to verify the availability of replacement wheels, bearings, straps, and locking mechanisms to ensure long-term usability.

These FAQs highlight the practical considerations and potential benefits associated with this skating equipment. Understanding these aspects enables informed decision-making and responsible use.

The following sections will offer a comparative analysis of available models, pricing, and user reviews to facilitate the selection process.

Conclusion

The preceding exploration has detailed the characteristics, benefits, and critical considerations surrounding detachable inline skates. Key aspects encompass attachment security, wheel durometer, boot comfort, frame material, braking efficiency, and portability. Each element contributes to the overall performance, safety, and practicality of this equipment. Understanding these factors empowers consumers to make informed decisions and maximize their investment.

The future of detachable inline skates hinges on continued innovation in materials science and engineering. Further refinements in attachment mechanisms, enhanced comfort features, and improved braking systems will likely drive adoption and expand the application of this versatile technology. Continued research and rigorous testing are crucial to ensure the safety and reliability of this equipment, ultimately shaping its role in both recreational and transportation contexts.

![Best Roller Derby Brand Inline Skates: [Brand] & [Benefit] How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Roller Derby Brand Inline Skates: [Brand] & [Benefit] | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-196-300x200.jpg)