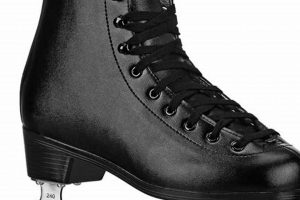

Equipment utilized for gliding across frozen surfaces, specifically those manufactured under the Brentwood brand, offers a recreational and athletic outlet during colder months. These items consist of a rigid boot, often constructed from leather or synthetic materials, securely fastened to a blade designed for efficient movement on ice. A common application is found in recreational skating rinks and frozen ponds where individuals seek exercise and leisure.

The availability of reliable and affordable skating equipment enables participation in a popular winter activity. This contributes to physical fitness, providing cardiovascular exercise and strengthening lower body muscles. Historically, the ability to traverse frozen bodies of water efficiently has been advantageous for transportation and trade during winter. The Brentwood brand, among others, provides an accessible entry point into this activity for many consumers.

Understanding the features and maintenance of such equipment, as well as the techniques for safe and enjoyable usage, are crucial for both beginners and experienced skaters. Detailed reviews, safety guidelines, and maintenance instructions will be covered in the following sections. This resource aims to provide a comprehensive overview for anyone interested in utilizing this type of recreational equipment.

Essential Guidance for Using Ice Skates

The following recommendations serve to enhance the skating experience and ensure the longevity of equipment used on frozen surfaces.

Tip 1: Proper Boot Fit: Ensure the boot fits snugly, providing ankle support without restricting circulation. Ill-fitting boots can lead to discomfort and reduced control.

Tip 2: Blade Sharpening: Maintain blade sharpness for optimal glide and control. Regular sharpening, performed by a qualified technician, is crucial for performance and safety.

Tip 3: Secure Lacing: Tighten laces firmly, particularly around the ankle area, to provide necessary support. Loosen laces slightly at the top of the boot for comfort.

Tip 4: Ankle Support Awareness: Pay attention to ankle stability. Weak ankles can lead to injury. Consider using ankle supports or braces for added stability.

Tip 5: Ice Condition Assessment: Before skating, assess the ice surface for cracks, debris, or unevenness. Avoid skating on unsafe surfaces.

Tip 6: Regular Cleaning: After each use, wipe down the blades with a dry cloth to prevent rust. Moisture can corrode the blades and degrade performance.

Tip 7: Blade Protection: Always use blade guards when walking on surfaces other than ice. This protects the blades from damage and prolongs their sharpness.

Tip 8: Storage Considerations: Store skates in a dry, well-ventilated area. Avoid storing them in a bag or container where moisture can accumulate.

Adhering to these guidelines promotes safety, improves skating performance, and extends the lifespan of skating equipment.

The subsequent section will delve into specific maintenance procedures and troubleshooting common issues that may arise with this equipment.

1. Blade Material

The blade material used in the construction of skating equipment significantly impacts performance characteristics. Various materials, each possessing distinct properties, are employed. Carbon steel, stainless steel, and alloy variations represent common choices. Each material impacts edge retention, corrosion resistance, and overall durability. For example, carbon steel provides excellent edge sharpness but is susceptible to rust if not properly maintained. Stainless steel offers enhanced corrosion resistance but may not hold an edge as sharply as carbon steel. The selection of blade material directly influences the glide efficiency and responsiveness of the skating experience, with the chosen material having the greatest role of the quality of the skating experience.

The manufacturing process and heat treatment applied to the blade material are critical factors. Hardness impacts edge retention, while flexibility affects blade responsiveness. Improper heat treatment can compromise the structural integrity of the blade, leading to premature wear or breakage. Some models feature coatings designed to enhance glide or reduce friction. These coatings often consist of specialized polymers or metal alloys applied to the blade surface. Such innovations can improve performance, particularly in recreational settings. Blades crafted from high-quality steel alloys are more costly, but in turn, will be of higher value and of better use.

Understanding the properties of different blade materials allows skaters to make informed decisions based on their individual needs and skating style. The trade-offs between edge retention, corrosion resistance, and cost necessitate careful consideration. Proper maintenance, including regular cleaning and sharpening, is crucial for maximizing the lifespan and performance of skating equipment. The material that the blade consists of affects the lifetime of the item. Ultimately, the blade material is the backbone of the skating product. The best blade material makes for the best skating product.

2. Boot Stiffness

Boot stiffness, measured by the resistance of the boot to bending or flexing, profoundly affects the stability and control afforded to the skater. In the context of the Brentwood brand, variations in boot stiffness cater to different skill levels and skating styles. Softer boots provide greater flexibility, which can be advantageous for beginners learning basic movements. However, these boots offer less support and energy transfer, potentially hindering advanced techniques. Stiffer boots, conversely, provide superior ankle support and more efficient energy transfer, enabling more powerful strides and precise maneuvers. This difference manifests practically in the stability experienced when executing turns or jumps, where a stiffer boot will provide more control.

The selection of appropriate boot stiffness hinges on the skater’s experience and intended use. Recreational skaters often benefit from moderately stiff boots that balance comfort and support. Figure skaters, particularly those performing advanced jumps and spins, generally require significantly stiffer boots to withstand the forces involved. Hockey players also rely on stiff boots for responsiveness and protection against impacts. The practical application of this understanding is evident in the design of various Brentwood skate models, where boot stiffness is tailored to specific target audiences. A beginner model will prioritize comfort and ease of movement, whereas a higher-end model will emphasize stiffness for enhanced performance.

In summary, boot stiffness is a critical determinant of skating performance and safety. The Brentwood brand’s product line likely reflects this consideration, offering a range of boot stiffness levels to accommodate diverse needs. Failure to select a boot with appropriate stiffness can lead to discomfort, reduced control, and potentially, increased risk of injury. Therefore, understanding the implications of boot stiffness is essential for all skaters, from novice to expert, and boot stiffness allows greater performance and protection against ankle or leg injuries.

3. Ankle Support

Ankle support is a critical element in the design and functionality of skating equipment. It directly influences the stability, control, and safety of the skater. The structural integrity of the boot, particularly around the ankle region, dictates the level of support provided. This support mitigates the risk of injury and enhances performance by facilitating proper biomechanics. The interplay between boot design and ankle stability is a paramount consideration for manufacturers.

- Boot Height and Cuff Design

The height of the boot and the design of the cuff that encircles the ankle directly impact the degree of support offered. Higher boots with rigid cuffs provide greater stability and restrict lateral movement, minimizing the risk of sprains or twists. Conversely, lower boots with flexible cuffs offer increased mobility but less support, which may be preferable for certain specialized skating styles. For Brentwood skates, the cuff design and boot height reflect the intended use, with recreational models often featuring a balance of support and flexibility, and hockey or figure skating models prioritizing maximum ankle stability.

- Material Composition and Construction

The materials used in the construction of the boot contribute significantly to its overall stiffness and support characteristics. Leather, synthetic materials, and composite structures each offer varying degrees of rigidity and resistance to deformation. Stiffer materials provide greater ankle support, while more flexible materials allow for a greater range of motion. The layering and reinforcement of these materials in specific areas of the boot, particularly around the ankle, further enhances support. The composition of these boots greatly affects the skater and the impact on the joints of the ankle, the core of support.

- Lacing Systems and Closure Mechanisms

The lacing system plays a crucial role in securing the boot and providing customized ankle support. Traditional lacing patterns, power straps, and buckle systems each offer different levels of adjustability and tightness. Properly tightened laces, especially around the ankle region, ensure a snug fit and prevent excessive movement. Advanced closure mechanisms, such as ratcheting buckles or BOA systems, offer precise adjustments and consistent support throughout the skating session. Secure and stable closure mechanisms are paramount for the prevention of injuries.

- Internal Padding and Anatomical Design

The internal padding and anatomical design of the boot contribute to both comfort and support. Strategically placed padding can cushion the ankle and provide additional support in key areas. An anatomically contoured boot shape conforms to the natural curves of the foot and ankle, enhancing stability and reducing pressure points. Heat-moldable liners allow for further customization, creating a personalized fit that optimizes both comfort and support.

These facets underscore the importance of ankle support in the design of skating equipment. The Brentwood brand, in aligning with general manufacturing concerns, likely addresses these considerations to provide products suited to the diverse needs of skaters. The degree of ankle support required is dependent upon the experience of the skater and what the desired activity entails. The higher the activity level, the stiffer the material needs to be, providing the necessary stability for proper functionality. This is important for the skater to note during the equipment purchase.

4. Blade Sharpening

The efficacy of skating equipment, including products manufactured by Brentwood, hinges significantly on the condition of the blade edge. Blade sharpening, a routine maintenance procedure, directly influences the skater’s ability to control movement, execute turns, and maintain speed. Dull blades impede glide efficiency, requiring greater exertion and reducing maneuverability. Conversely, a properly sharpened blade grips the ice surface more effectively, allowing for precise movements and controlled stops. The absence of regular sharpening leads to a gradual degradation of the blade edge, resulting in a noticeable decline in skating performance. A skater is therefore more likely to fall, injuring himself, if the blades are not sharpened regularly.

Consider a scenario in which a recreational skater using Brentwood equipment attempts a simple crossover turn with dull blades. The lack of a sharp edge prevents the blade from properly biting into the ice, causing the skater to slip and lose balance. The skater, as a result, loses his balance. Conversely, the same maneuver executed with a freshly sharpened blade would allow for a clean, controlled turn, requiring less effort and minimizing the risk of a fall. The frequency of sharpening depends on several factors, including the ice conditions, the skater’s skill level, and the amount of usage. Generally, recreational skaters should sharpen their blades after every 20-30 hours of skating. A highly skilled skater needs to sharpen their skates far more often.

In conclusion, blade sharpening constitutes an indispensable aspect of maintaining skating equipment, directly affecting performance and safety. The Brentwood brand, while providing quality products, cannot negate the necessity of regular maintenance. Neglecting blade sharpening undermines the potential of the equipment and compromises the skater’s experience. Adherence to a consistent sharpening schedule is therefore essential for realizing the full benefits and ensuring a safe and enjoyable skating experience. It must be noted that if the equipment is not sharpened, that can lead to injury. Therefore, it is highly advised to get the skates sharpened on a regular basis.

5. Lace Security

Lace security, with respect to skating equipment from manufacturers like Brentwood, is a paramount factor influencing skater stability, control, and overall safety. A compromised lacing system can lead to ankle instability, reduced maneuverability, and an increased risk of injury.

- Knot Integrity and Friction

The type of knot used and its resistance to slippage are crucial elements of lace security. A poorly tied knot, or one susceptible to loosening, can compromise the boot’s fit and ankle support. High-friction laces, often made of textured materials, enhance knot retention, reducing the likelihood of slippage during skating. Regular inspection of the knot and laces for wear is essential. If the skater is constantly adjusting his/her laces, it is of the utmost importance to seek new skates to make sure that the skater is not in danger of losing balance or injuring himself.

- Lace Material and Durability

The material composition of the laces directly affects their tensile strength, resistance to abrasion, and overall lifespan. High-quality laces, constructed from durable synthetic fibers, withstand the rigors of repeated tightening and flexing. Inferior laces may fray, weaken, or break, compromising the security of the lacing system. Lace integrity must be verified before each session to help avoid any type of injury that may occur if laces were to break. This can be done by a simple inspection prior to putting the equipment on.

- Eyelet Integrity and Configuration

The eyelets, through which the laces are threaded, play a vital role in distributing tension and maintaining lace security. Securely fastened eyelets, constructed from durable materials, prevent lace slippage and minimize wear. The configuration of the eyelets, including their spacing and alignment, influences the distribution of pressure across the foot and ankle. Missing or damaged eyelets should be professionally replaced immediately.

- Lace Locking Mechanisms

Some Brentwood models may incorporate lace locking mechanisms, such as hooks or clamps, to enhance security and prevent loosening. These mechanisms provide an additional layer of retention, ensuring that the laces remain securely fastened throughout the skating session. The functionality of these mechanisms should be regularly inspected and maintained to ensure optimal performance.

These interconnected factors highlight the importance of lace security in the context of skating, irrespective of the brand. A well-maintained and properly secured lacing system contributes directly to skater confidence, control, and safety. Conversely, a compromised lacing system undermines the performance potential of even high-quality skating equipment. This is all taken into account for the skater’s safety.

6. Rust Prevention

The metallic components of skating equipment, particularly the blades, are susceptible to oxidation, commonly known as rust. This corrosion weakens the structural integrity of the blades, diminishes their sharpness, and ultimately impairs skating performance. The Brentwood brand, like all manufacturers of ice skates, acknowledges this inherent vulnerability. The environment in which skating equipment is used, characterized by exposure to moisture and fluctuating temperatures, accelerates the rusting process. The chemical reaction between iron, oxygen, and water results in the formation of iron oxide, a brittle and abrasive substance that degrades the blade’s surface. Regular rust prevention measures are, therefore, essential for maintaining the functionality and longevity of these products. Without regular rust prevention, the equipment would not last as long, creating a need to replace the equipment, which is a waste of money.

Practical rust prevention strategies encompass several key steps. After each use, meticulously drying the blades with a clean cloth removes residual moisture that promotes corrosion. Application of a rust-inhibiting compound, such as silicone spray or specialized blade protectant, creates a barrier against moisture and atmospheric oxygen. Storage in a dry, well-ventilated environment further minimizes the risk of rust formation. Blade guards, while primarily intended to protect the blades from physical damage, also contribute to rust prevention by shielding the blades from direct exposure to moisture and debris. Implementing these steps prolongs the life of the equipment.

Rust prevention, while seemingly a minor consideration, represents a critical aspect of responsible equipment ownership. Neglecting this preventative measure can lead to premature degradation, requiring costly repairs or replacements. By diligently implementing rust prevention strategies, skaters can ensure the continued performance and safety of their equipment, maximizing their investment and extending the lifespan of Brentwood skates. Therefore, this small step ensures that the skates will continue to provide excellent utility for a great period of time. In short, it helps saves money and provides a quality tool for skating.

7. Proper Fit

Proper fit is paramount when selecting “brentwood ice skate” or any skating equipment. An ill-fitting skate compromises performance, comfort, and safety. The selection of the appropriate size and shape is essential for optimal functionality.

- Length and Width Considerations

The length and width of the boot must correspond to the skater’s foot dimensions. Excess space in the toe box can lead to instability and reduced control, while a boot that is too narrow can cause discomfort and potential injury. Brentwood ice skates are typically available in a range of sizes and widths to accommodate various foot shapes. The size of the skates is key to the comfort and usability of them. An improperly sized skate could be a complete waste of money.

- Ankle Support and Heel Lock

A properly fitted skate provides adequate ankle support and heel lock. The skater’s heel should be firmly seated in the heel cup, preventing excessive movement and minimizing the risk of blisters or chafing. The ankle should be snugly supported by the boot, allowing for proper flexion and extension without compromising stability. Ankle support is the most important function of ice skates and skates, in general. Without that support, the skater is in danger of injuring their ankle.

- Lacing and Closure Systems

The lacing or closure system must allow for a secure and adjustable fit. Laces should be tightened evenly to distribute pressure across the foot and ankle, providing customized support. Buckles, straps, or other closure mechanisms should be adjusted to ensure a snug and comfortable fit without restricting circulation. The closure systems is integral to a comfortable skate. The closure system secures all the different pieces of the skate together, so it must be tight, durable, and of the correct size.

- Break-in Period and Customization

New skates often require a break-in period to conform to the skater’s foot. During this time, the boot’s materials will gradually mold to the shape of the foot, improving comfort and fit. Heat molding or other customization techniques can accelerate this process and provide a more personalized fit. The importance of breaking in the skates cannot be understated. If the skates are not broken in properly, then the skater will not be comfortable while skating, and the skater is also at risk of injury, as well.

These components highlight the intricate relationship between proper fit and the overall performance of “brentwood ice skate.” A well-fitted skate enhances comfort, control, and safety, allowing the skater to fully enjoy the skating experience. Conversely, an ill-fitting skate can lead to discomfort, reduced performance, and an increased risk of injury. Therefore, careful attention to fit is paramount when selecting skating equipment. If the skater is not comfortable while skating, it removes the enjoyment of the exercise.

Frequently Asked Questions

This section addresses common inquiries and misconceptions surrounding the proper use, maintenance, and selection of Brentwood ice skates. Information presented aims to clarify prevalent concerns and ensure safe and optimal utilization of the equipment.

Question 1: How frequently should Brentwood ice skate blades be sharpened?

Blade sharpening frequency is contingent upon usage intensity and ice surface conditions. Recreational skaters should consider sharpening after every 20-30 hours of use. More frequent sharpening may be necessary for individuals engaging in rigorous skating activities or encountering abrasive ice surfaces.

Question 2: What constitutes a proper fit for Brentwood ice skates?

Proper fit is characterized by a snug yet comfortable feel, with the heel firmly seated in the heel cup and adequate ankle support. Toes should not be cramped, and circulation should not be restricted. A professional fitting is recommended to ensure optimal comfort and performance.

Question 3: How should Brentwood ice skates be stored to prevent rust?

Following each use, thoroughly dry the blades with a clean cloth. Apply a rust-inhibiting compound and store the skates in a dry, well-ventilated environment. Blade guards should be utilized to protect the blades from physical damage and moisture exposure.

Question 4: What is the significance of ankle support in Brentwood ice skates?

Ankle support is crucial for stability, control, and injury prevention. A well-designed skate provides adequate ankle support, minimizing the risk of sprains or twists. Skaters with weak ankles may require additional support or bracing.

Question 5: How does boot stiffness affect skating performance with Brentwood ice skates?

Boot stiffness dictates the level of support and energy transfer. Stiffer boots provide greater stability and responsiveness, while softer boots offer increased flexibility. The selection of appropriate boot stiffness depends on the skater’s skill level and intended use.

Question 6: What measures should be taken to ensure lace security in Brentwood ice skates?

Utilize high-quality laces and ensure a secure knot that resists slippage. Regularly inspect the laces and eyelets for wear or damage. Consider using lace locking mechanisms for enhanced security and to prevent loosening during skating sessions.

Adherence to these guidelines promotes safe and efficient usage of Brentwood ice skates. Regular maintenance and careful attention to fit contribute to optimal performance and longevity.

The subsequent section will provide detailed instructions on troubleshooting common issues encountered with Brentwood ice skates.

Conclusion

This exploration of “brentwood ice skate” functionality has underscored the critical interplay between design, maintenance, and user responsibility. Key areas of focus have included proper fit, blade maintenance, ankle support, and the impact of material composition on performance and longevity. Adherence to established best practices directly influences the safety and enjoyment derived from using this equipment.

Ultimately, informed consumers equipped with a thorough understanding of these factors are best positioned to maximize the value of their skating equipment. The continued emphasis on safety protocols and diligent maintenance ensures a positive experience, minimizing the potential for injury and extending the useful lifespan of “brentwood ice skate” products.