A specific type of skateboard component, this refers to the wooden platform upon which a skateboarder stands. It is constructed from several layers of laminated maple wood, pressed together to create a durable and flexible surface. The dimensions, concave shape, and graphic design are key features. As an example, a deck might measure 8.0 inches wide and 32 inches long, featuring a moderate concave and a vibrant graphic depicting a skull.

The item described contributes significantly to skateboarding performance and aesthetics. Its quality influences the rider’s control, stability, and trick execution. Historically, innovations in wood lamination and pressing techniques have continuously improved the strength and responsiveness. The graphics often reflect current trends and the skater’s individual style, adding a personalized element to the riding experience. These aspects collectively contribute to both the functional and cultural dimensions of skateboarding.

The following sections will delve into the construction materials, design variations, and the selection criteria relevant to this important piece of skateboarding equipment. Further analysis will explore its impact on rider skill development and the evolving marketplace for skateboarding equipment.

Selection and Maintenance Recommendations

The following recommendations aim to guide the selection and upkeep of a skateboard platform to optimize performance and longevity.

Tip 1: Evaluate Dimensions Based on Riding Style: Consider the width and length relative to intended use. Wider platforms provide greater stability for vert skating, while narrower platforms offer enhanced maneuverability for street skating.

Tip 2: Assess Concave Depth: Deeper concaves facilitate foot locking for flip tricks. A shallower concave provides a flatter surface for improved stability during grinds and slides.

Tip 3: Inspect Ply Lamination Quality: Examine the edge of the platform to ensure consistent and tight lamination. Delamination reduces structural integrity and shortens lifespan.

Tip 4: Select Graphics with Protective Finish: A durable clear coat over the graphic protects against abrasion from shoe contact and environmental factors. This preserves aesthetic appeal and prevents splintering.

Tip 5: Rotate the Platform Regularly: Distribute wear evenly by rotating the front and back of the platform periodically. This extends the lifespan and maintains a consistent feel.

Tip 6: Avoid Exposure to Extreme Conditions: Excessive moisture or heat can warp the wood and compromise structural integrity. Store in a dry, temperate environment.

Tip 7: Consider Weight Rating: Adhere to the manufacturer’s recommended weight limit. Exceeding this limit can lead to premature failure and potential injury.

Adhering to these guidelines can optimize both the performance and longevity of skateboarding platforms, resulting in an enhanced riding experience.

The subsequent section will address common issues and troubleshooting methods related to this equipment.

1. Wood Ply Composition

The structural integrity and performance characteristics are intrinsically linked to the quality and arrangement of wood plies. The arrangement of these layers dictates its strength, flexibility, and pop, ultimately affecting the skater’s control and execution of tricks. Understanding wood ply composition is essential for selecting an appropriately performing platform.

- Maple Hardness and Density

The species of maple used, typically North American or Canadian hard rock maple, influences the deck’s durability and responsiveness. Denser maple provides greater resistance to impact and a more pronounced rebound, translating to increased pop. Lower-quality maple can result in premature cracking and reduced performance.

- Grain Direction and Orientation

The direction of the wood grain in each ply affects its resistance to bending and twisting. Alternating the grain direction in successive layers creates a cross-laminated structure, enhancing overall strength and preventing warping. Inconsistent grain orientation can lead to localized stress points and potential failure.

- Ply Thickness and Layer Count

The thickness of individual plies and the total number of layers impact the deck’s flexibility and stiffness. Generally, seven-ply construction is standard, providing a balance between strength and flex. Variations in ply thickness or layer count can be used to fine-tune performance characteristics, such as increasing stiffness for stability or enhancing flexibility for maneuverability.

- Adhesive Type and Application

The type of adhesive used to bond the plies significantly affects the deck’s long-term durability. High-quality epoxy resins create a strong and water-resistant bond, preventing delamination even under extreme stress. Improper adhesive application or the use of inferior adhesives can lead to ply separation and structural failure.

Variations in wood ply composition, from maple selection to adhesive quality, ultimately determine the deck’s performance and longevity. Skaters often prioritize decks with a proven wood ply composition to maximize control, pop, and resistance to wear and tear. An understanding of these factors allows for informed selection, contributing to an enhanced skateboarding experience.

2. Concave Design Variability

The curvature, or “concave,” present on the surface directly influences the rider’s feel, control, and trick execution. The variance in concave designs available allows for tailoring to specific skateboarding styles and preferences. A thorough examination of these variations is crucial for informed selection.

- Mellow Concave

Characterized by a subtle, gradual curve across the width, it provides a stable platform for flat-ground tricks and cruising. The flatter surface facilitates smoother foot placement adjustments and a more forgiving feel, which is suitable for beginners or skaters who prefer a less pronounced pocket for their feet. However, it may offer less grip and control during more technical maneuvers.

- Steep Concave

Exhibits a more aggressive, pronounced curve, creating deeper pockets for the feet. This steeper curvature enhances grip and responsiveness, enabling more precise foot control for flip tricks and technical skating. However, this can be less forgiving and requires greater skill and experience to master.

- Progressive Concave

A hybrid design that combines the features of mellow and steep options. It starts with a gentle curve near the edges and gradually increases toward the center, offering a balance between stability and responsiveness. This is a versatile choice suitable for various skateboarding styles, providing a good compromise between control and forgiveness.

- Asymmetrical Concave

Features a different concave depth on each side. This non-uniform design can cater to specific stances or foot orientations. For example, a deeper concave on the heel side might enhance heel-side flips, while a shallower concave on the toe side improves toe-side control. Asymmetrical designs cater to individual rider preferences and can fine-tune board feel for optimal performance.

The interplay between concave design and riding style is critical. Skaters often experiment with various concave profiles to find the optimal balance between stability, control, and trick execution. Understanding the nuances of concave variability enables selection of the optimal platform for individual needs and preferences.

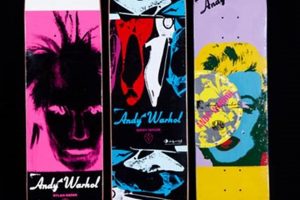

3. Graphic Application Durability

The longevity and resilience of graphic applications on skateboarding platforms are significant factors in both the aesthetic appeal and the overall value of the product. Premature degradation of graphic elements can diminish the visual impact and potentially compromise the resale value. Therefore, the methods and materials employed in graphic application are critical considerations.

- Screen Printing Techniques

Screen printing, a common method, involves forcing ink through a stenciled mesh onto the platform. The durability hinges on the ink’s chemical composition and the number of layers applied. Multi-layered applications with high-quality, UV-resistant inks offer increased protection against abrasion and fading. Conversely, single-layer prints with lower-grade inks are susceptible to wear and discoloration, especially in areas of frequent contact.

- Heat Transfer Processes

Heat transfer applies pre-printed designs to the platform using heat and pressure. This method often allows for more detailed and complex graphics. The durability depends on the adhesive properties of the transfer film and the temperature and pressure applied during the process. Inadequate adhesion results in peeling and cracking, while excessive heat can damage the wood or distort the graphic. High-quality heat transfers utilize durable films and precise application parameters to ensure longevity.

- Protective Clear Coats

The application of a clear coat over the graphic serves as a protective barrier against abrasion, UV exposure, and moisture. The type of clear coat and its thickness significantly impact its protective capabilities. Polyurethane clear coats, known for their durability and resistance to yellowing, are commonly used. The number of clear coat layers also contributes to graphic longevity, with multiple layers providing enhanced protection. A poorly applied or low-quality clear coat can result in chipping, cracking, and eventual graphic degradation.

- Adhesion Promoters and Surface Preparation

Proper surface preparation is essential for optimal graphic adhesion. This includes sanding, cleaning, and the application of adhesion promoters. Failure to properly prepare the surface can lead to poor ink or film adhesion, resulting in premature peeling or flaking. Adhesion promoters create a chemical bond between the wood and the graphic, enhancing durability. Inadequate surface preparation is a common cause of graphic failure, even when high-quality inks and clear coats are used.

The durability of graphic applications is a composite result of the methods, materials, and processes employed. High-quality screen printing, heat transfers with durable films, protective clear coats, and meticulous surface preparation are essential for maximizing graphic longevity and maintaining the aesthetic appeal of skateboarding platforms.

4. Size and Dimensions

The size and dimensions are critical specifications directly impacting performance and suitability. Width, length, wheelbase, and nose/tail lengths collectively determine stability, maneuverability, and responsiveness. Smaller dimensions generally increase agility for technical street skating. Conversely, larger dimensions enhance stability for vert riding and cruising. The interplay of these measurements dictates the skater’s control and trick execution. For example, a wider platform provides a larger landing surface, reducing the likelihood of missed landings. Selecting appropriate dimensions is therefore paramount.

Practical implications of dimensional choices are readily apparent. An 8.0-inch wide deck is a common starting point for many skaters, offering a balance between stability and maneuverability. Progressing to a wider deck, such as 8.5 inches, often provides enhanced stability for larger skaters or those transitioning to vert ramps. Shorter lengths often yield quicker turning responses, beneficial for navigating tight spaces. Conversely, longer lengths can increase stability at higher speeds. These dimensional effects directly correlate with the skater’s physical characteristics and riding style, making understanding these relationships essential for proper equipment selection. Furthermore, understanding these dimensions also directly relate to other components such as the Trucks and Wheels, making this knowledge base essential for maximizing the performance of a skateboard.

In summary, size and dimensions play a pivotal role in the overall performance and suitability. Accurate measurement specifications and a keen awareness of their impact are imperative. While personal preference remains a factor, an informed understanding of these specifications allows skaters to make optimal equipment choices, thereby enhancing their riding experience and progression.

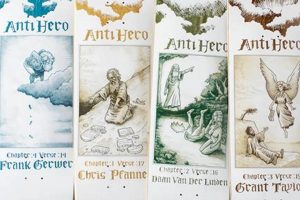

5. Brand Recognition

Brand recognition plays a pivotal role in consumer perception and purchasing decisions relating to skateboarding equipment, including the platform. Established brand recognition often indicates a history of product quality, performance consistency, and innovation. This recognition translates into a level of trust that is particularly significant in a sport where equipment failure can lead to injury. For example, a long-standing brand known for its durable construction and innovative concave designs will likely command a premium price and higher sales volume than a lesser-known competitor. This trust factor provides skaters with confidence in the product’s ability to withstand the rigors of skateboarding.

The influence extends beyond initial purchase decisions. Established brands cultivate a community and culture around their products, often sponsoring professional skateboarders and supporting skateboarding events. These efforts further solidify brand recognition and association with positive attributes such as skill, style, and innovation. Furthermore, it allows consumers to more easily identify the product from a sea of others. For example, if a skater is looking for a high-quality platform, the brand will likely be the first place they look. This association translates into enhanced brand loyalty. Over time, skaters may repeatedly purchase products from a particular brand, creating a cyclical relationship between recognition, trust, and sales.

The interconnectedness between brand recognition and skateboarding equipment encompasses tangible benefits. Consumers rely on established brands for assurance of quality, performance, and durability. Brands, in turn, leverage their recognition to maintain market share and foster brand loyalty. Challenges remain, particularly for new entrants seeking to establish themselves in a competitive market. These challenges require innovative marketing strategies and a consistent commitment to product excellence. Successful brands navigate these challenges through consistent product innovation, effective brand management, and genuine engagement with the skateboarding community.

Frequently Asked Questions

This section addresses common inquiries and clarifies prevalent misconceptions regarding skateboarding platforms. The information provided is intended to offer comprehensive insights into the selection, maintenance, and performance characteristics of these products.

Question 1: What factors determine the appropriate dimensions for a skateboarding platform?

The width, length, and wheelbase are key dimensional attributes. Width primarily influences stability and control. Narrower options facilitate quicker turns, while wider options provide a more stable landing surface. Length and wheelbase affect overall stability at higher speeds and turning responsiveness. Rider height, shoe size, and riding style should be considered when selecting dimensions.

Question 2: How does concave depth impact skateboarding performance?

Concave depth dictates the level of foot lock and board feel. Steeper concave provides greater grip and responsiveness, enabling more precise control for flip tricks. Mellow concave offers a flatter surface for improved stability, suitable for cruising and beginners. Selecting the appropriate concave depends on the rider’s skill level and preferred riding style.

Question 3: What wood ply composition ensures optimal durability and pop?

The type of maple used, grain direction, and adhesive quality are crucial for durability and pop. North American or Canadian hard rock maple, with alternating grain direction and high-quality epoxy resin, provides superior resistance to impact and a pronounced rebound. Consistent ply lamination is essential to prevent delamination and maintain structural integrity.

Question 4: How frequently should a skateboarding platform be replaced?

Replacement frequency depends on usage intensity and riding conditions. Visible signs of wear, such as cracks, delamination, or warping, indicate the need for replacement. Even without visible damage, performance may degrade over time. Professional skateboarders often replace their platforms weekly or bi-weekly, while recreational skaters may extend the lifespan to several months.

Question 5: What are the common causes of graphic degradation, and how can it be mitigated?

Abrasion, UV exposure, and moisture are primary causes of graphic degradation. Abrasion from shoe contact can be mitigated with a durable clear coat. UV-resistant inks and storage in shaded areas minimize fading. Proper surface preparation during graphic application ensures optimal adhesion. Applying protective rails along the edges helps preserve both the graphic and the structural integrity of the platform.

Question 6: Is there a significant performance difference between different brands of skateboarding platforms?

Performance differences can exist between brands due to variations in manufacturing processes, material quality, and design innovations. Established brands typically have rigorous quality control measures and a history of performance consistency. However, smaller, independent brands can offer unique features or construction techniques. Researching brand reputation and reading reviews can help in making an informed selection.

These responses provide a comprehensive overview of key considerations related to skateboarding platforms. Understanding these factors promotes informed purchasing decisions and optimizes performance and longevity.

The subsequent section will detail preventative measures to maintain your board over time.

Blind Skate Deck

The preceding analysis has elucidated the multifaceted nature of the skateboard platform, covering aspects from material composition and design variability to brand recognition and maintenance protocols. The importance of understanding each of these elementswood ply quality, concave design, graphic application, size and dimensions, and brand influencein the selection and upkeep of this crucial piece of equipment has been thoroughly examined.

The information provided serves as a foundation for making informed decisions, ultimately enhancing both performance and longevity. Continued advancements in materials science and manufacturing processes will undoubtedly lead to further refinements in platform design and construction. A proactive approach to equipment maintenance, coupled with a thorough understanding of performance characteristics, is essential for maximizing the skateboarding experience and mitigating potential risks.