The process of crafting bladed footwear for gliding across ice within a digital twin environment, specifically a Digital Twin Implementation (DTI), involves simulating the design, manufacturing, and performance of such equipment. This includes modeling the blade geometry, boot construction, and material properties to ensure optimal functionality and safety in a virtual setting, allowing for iterative design improvements before physical prototyping.

Accurate representation and manipulation of product design parameters through a DTI offers substantial advantages. Potential benefits encompass reduced development costs via virtual testing, accelerated innovation through rapid prototyping, and enhanced product performance stemming from data-driven optimization. Historically, this approach represents a significant evolution from traditional trial-and-error methods, ushering in an era of precision engineering and preemptive problem-solving.

The subsequent discussion will delve into the specifics of leveraging digital twin technology to optimize the design and manufacture of such specialized footwear, touching upon aspects of material selection, structural analysis, and performance simulation. It also will cover the advantages of virtual prototyping and testing, as well as the cost and time savings it provides.

Digital Twin Implementation Tips for Bladed Footwear Design

Effective utilization of a Digital Twin Implementation (DTI) requires a structured approach. The following tips offer guidance on employing digital twin technology for optimizing the design and manufacturing of bladed footwear designed for ice surfaces.

Tip 1: Emphasize High-Fidelity Modeling: The accuracy of the digital twin hinges on the fidelity of its models. Detailed representations of blade geometry, boot construction, and material properties are essential for reliable simulation results. This includes incorporating precise measurements, material characteristics, and manufacturing tolerances into the virtual model.

Tip 2: Prioritize Material Property Validation: Accurate material properties are crucial for simulating performance under stress and environmental conditions. Conduct thorough virtual testing that considers material elasticity, strength, and thermal expansion coefficients. Validate these properties against real-world data to ensure the reliability of simulation outcomes.

Tip 3: Integrate Multi-Physics Simulation: Implement simulation capabilities that account for multiple physical phenomena. This includes structural analysis, thermal analysis, and fluid dynamics to accurately predict performance under varying conditions. Simulating the interaction between the blade and ice, as well as heat transfer from the skater’s foot, can provide valuable insights.

Tip 4: Implement Iterative Design Optimization: Use the digital twin to systematically explore design alternatives. Automate the process of generating and evaluating different design parameters to identify optimal configurations. This can involve employing optimization algorithms to find the best balance between weight, stiffness, and blade profile.

Tip 5: Validate with Physical Testing: Complement virtual simulations with targeted physical testing. Conduct laboratory experiments to validate the accuracy of the digital twin and refine its parameters. This helps to build confidence in the predictive capabilities of the DTI.

Tip 6: Ensure Seamless Data Integration: Establish a robust data management system to ensure seamless integration between the digital twin and real-world data sources. This includes sensor data from physical prototypes, manufacturing process data, and performance data from field tests. Efficient data management is essential for maintaining the accuracy and relevance of the digital twin.

Adhering to these principles enables a robust design and manufacturing process for bladed footwear within a digital twin framework, leading to optimized product performance and reduced development costs.

The ensuing section will focus on the practical application of these tips within a case study, demonstrating their real-world impact on the design of high-performance bladed footwear.

1. Digital Design

Digital design constitutes a foundational element in the execution of bladed footwear fabrication within a Digital Twin Implementation (DTI). It serves as the initial phase, translating conceptual ideas and specifications into precise, three-dimensional virtual models. The accuracy and detail of these digital representations directly influence the effectiveness of subsequent simulation, analysis, and manufacturing processes. Inaccurate or incomplete digital designs propagate errors throughout the DTI workflow, resulting in suboptimal final products.

The deployment of Computer-Aided Design (CAD) software and related digital design tools allows for the meticulous modeling of all components, from the blade’s curvature and edges to the boot’s ergonomic form and structural support. This includes defining precise material properties, dimensions, and assembly methods within the digital environment. For example, in designing the blade, digital design enables the simulation of different blade profiles to evaluate their impact on glide efficiency and turning radius. Similarly, for the boot, digital design can model varying stiffness levels in different zones to optimize ankle support and flexibility. The integration of digital design with other DTI components allows for iterative refinement of the product based on virtual testing and performance analysis.

Ultimately, digital design’s contribution to DTI is crucial. Faulty digital design results in suboptimal final product. The role of “Digital Design” is essential for the rest of the DTI process. Effective digital design, therefore, underpins the entire DTI process, ensuring that the final bladed footwear meets stringent performance, safety, and manufacturing requirements. Continuous advancements in digital design software and techniques further enhance the potential for innovation and optimization within bladed footwear fabrication.

2. Material Simulation

Material simulation plays a critical role within the broader framework of digital twin implementation for bladed footwear production. It provides a virtual environment to assess how different materials respond to the forces and conditions experienced during use. The accuracy of these simulations directly impacts the reliability of design choices and the ultimate performance of the final product. For example, simulating the behavior of a specific polymer used in the boot’s construction under cold temperatures and repetitive stress is crucial to predict its durability and prevent premature failure. Neglecting material simulation increases the risk of developing footwear with inadequate performance characteristics, leading to potential safety hazards and increased warranty claims.

The influence of material properties on the overall design and manufacturing process is undeniable. The simulation tools allow engineers to test various composites for the blade’s construction, predicting the optimal balance between stiffness, weight, and resistance to impact. Material simulation determines the most suitable choice for construction in the physical world. These choices impact ice-surface performance, comfort and longevity of the equipment. Without these assessments, selection becomes guesswork, potentially resulting in less durable or effective blades. This leads to unnecessary costs and reduces design efficiency.

In essence, material simulation acts as a predictive instrument, mitigating the risks associated with material selection and design choices for bladed footwear. Proper execution of material simulation leads to informed decision-making, minimizing costly physical prototyping and accelerating the design cycle. This results in a stronger, safer, and more durable final product, representing a significant benefit of a robust DTI process.

3. Blade Geometry

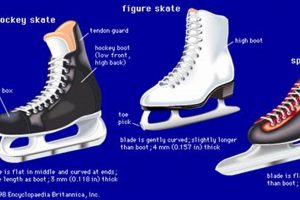

Blade geometry, encompassing the curvature, thickness, edges, and overall profile of the ice skate blade, constitutes a critical element within the Digital Twin Implementation (DTI) for ice skate design and manufacturing. Variations in blade geometry directly impact the skater’s ability to glide, turn, and maintain balance. Therefore, the DTI process must accurately simulate and optimize these geometric parameters to achieve desired performance characteristics. For instance, a deeper radius of hollow (the concave groove along the blade’s running surface) provides greater edge grip for enhanced turning ability but may also increase friction and reduce glide speed. Conversely, a shallower radius offers faster glide but less precise control. The DTI environment allows for the virtual testing of numerous blade geometry configurations to determine the optimal balance for a specific skating discipline.

The design and optimization of blade geometry within a DTI necessitate considering several factors, including the skater’s skill level, weight, and intended use (e.g., hockey, figure skating, speed skating). The simulation capabilities of the DTI enable engineers to analyze stress distribution, vibrational characteristics, and fluid dynamics associated with different blade geometries under simulated skating conditions. This level of analysis allows for the identification of potential weaknesses, areas of stress concentration, and opportunities for performance enhancement. For example, a DTI may reveal that a specific blade profile generates excessive vibration at high speeds, leading to instability. By altering the blade geometry within the digital twin, engineers can mitigate this issue before committing to physical prototyping.

In summary, precise control and simulation of blade geometry are indispensable for effective bladed footwear design using a DTI. It reduces the time and resources required for physical prototyping. Optimization leads to performance enhancement. This element allows for the creation of skates tailored to specific skater needs and performance objectives. The fidelity of the blade geometry representation and simulation directly influences the overall success of the DTI in producing high-quality, performance-oriented ice skates. The process directly affects “how to make ice skates in dti”.

4. Performance Analysis

Performance analysis forms a pivotal element within the process of crafting bladed footwear within a Digital Twin Implementation (DTI). It constitutes the systematic evaluation of a digital prototype’s operational characteristics under simulated conditions, providing actionable insights into its strengths and weaknesses before physical production. The influence of performance analysis on “how to make ice skates in dti” is direct and substantial; without it, design iterations would rely on costly and time-consuming physical prototypes, significantly hindering optimization and innovation. Performance analysis acts as a virtual testbed, revealing design flaws, identifying areas for improvement, and quantifying the impact of design changes on critical performance metrics, such as glide efficiency, turning radius, and stability. The application of Finite Element Analysis (FEA) to simulate stress distribution within the blade under load, or Computational Fluid Dynamics (CFD) to analyze the blade’s interaction with the ice surface, exemplifies this process. These analyses provide data-driven insights, enabling designers to refine their designs based on quantifiable results rather than subjective assessments.

The practical significance of this understanding extends to several key areas. Firstly, it facilitates the identification of design flaws early in the development cycle, preventing costly rework and delays in production. Secondly, it enables the exploration of novel design concepts and materials without incurring the expense of physical prototypes, fostering innovation and accelerating the development process. For instance, a designer might use performance analysis to evaluate the impact of different blade materials on energy return during skating, identifying materials that offer superior performance without the need for physical testing. This predictive capability allows for informed decision-making, optimizing the final product for specific skating disciplines and skill levels. Finally, performance analysis provides a means to ensure that the final product meets stringent safety and performance standards, reducing the risk of product recalls and enhancing customer satisfaction. The use of advanced simulation techniques enables engineers to assess the structural integrity of the boot and blade under extreme conditions, ensuring that the footwear can withstand the rigors of competitive skating.

In conclusion, performance analysis is integral to “how to make ice skates in dti”. Its capabilities in predictive analysis and virtual testing enable a more efficient and effective design process. The insights gained through performance analysis inform design decisions, optimize material selection, and ensure that the final product meets the needs of the skater. Despite the computational demands and expertise required to implement performance analysis effectively, the benefits in terms of cost savings, improved product performance, and enhanced safety make it an indispensable component of modern ice skate design and manufacturing.

5. Virtual Prototyping

Virtual prototyping constitutes a fundamental aspect of “how to make ice skates in dti.” It facilitates the creation of digital representations of ice skates, allowing for testing and refinement without the expense and time associated with physical prototypes. This process reduces development time and cost while simultaneously enabling exploration of design variations.

- Design Iteration Efficiency

Virtual prototyping enables rapid iteration of designs. Changes to blade geometry, boot structure, or material properties can be quickly implemented and evaluated in a simulated environment. This contrasts with physical prototyping, where each iteration requires manufacturing and testing physical samples, a process that can be significantly more time-consuming and costly. For example, a designer can virtually test the impact of varying blade curvature on turning performance, refining the design based on simulation results before creating a physical prototype.

- Cost Reduction

The use of virtual prototypes substantially lowers development costs. Physical prototypes involve material procurement, manufacturing processes, and testing, all of which contribute to significant expenses. Virtual prototyping reduces or eliminates these costs by allowing for testing and refinement in a digital environment. A virtual model enables extensive evaluation without the need for physical materials.

- Performance Prediction

Virtual prototyping allows for the prediction of ice skate performance under various conditions. Through simulation, designers can assess factors such as glide efficiency, stability, and energy transfer. This predictive capability enables the optimization of designs for specific skating styles and performance requirements. For example, the virtual prototype could be used to analyze the impact of boot stiffness on ankle support and energy transfer during skating.

- Early Defect Detection

Virtual prototyping facilitates the early detection of potential design flaws. By simulating stress, strain, and other physical phenomena, designers can identify areas of weakness or potential failure points in the ice skate design. This early detection allows for corrective action to be taken before physical prototypes are created, reducing the risk of costly rework and improving product reliability. Examples can include discovering areas of high stress concentration in the boot structure or identifying potential points of failure in the blade attachment mechanism.

The application of virtual prototyping significantly enhances the effectiveness of “how to make ice skates in dti.” This facilitates the design of improved products, reduces associated costs, and allows for early detection of design errors. Through this process, design choices and manufacturing approaches are improved.

6. Manufacturing Integration

Manufacturing integration, within the context of creating ice skates using a Digital Twin Implementation (DTI), directly translates the digital design into a physical product. It bridges the gap between the virtual design and the actual manufacturing processes, ensuring that the digital model accurately reflects the final product. Effective manufacturing integration necessitates seamless communication and data exchange between the digital twin environment and the manufacturing equipment. A primary cause of failure in DTI implementation is the inability to accurately translate design specifications from the digital model to the physical manufacturing processes. Without meticulous manufacturing integration, the potential benefits of digital design, material simulation, blade geometry optimization, performance analysis, and virtual prototyping are diminished, as the final product may not accurately reflect the intended design. For example, a highly optimized blade geometry generated in the digital twin may not be achievable if the manufacturing process lacks the precision to replicate the intricate curves and edges. The successful implementation of manufacturing integration ensures design becomes reality.

The practical application of manufacturing integration spans various stages of ice skate production. It impacts material selection, machining processes, assembly procedures, and quality control. For instance, the DTI can provide real-time feedback to the manufacturing equipment, adjusting parameters such as cutting speed and temperature to optimize material removal and minimize defects. Furthermore, integrated quality control systems can utilize data from the digital twin to identify potential deviations from the design specifications, enabling proactive intervention and preventing the production of substandard components. One can see that the ability to detect early in the production process affects the value of the product. In the instance that there is a design change it also enables a smoother transition between the digital and physical realms.

In summary, manufacturing integration constitutes a crucial element in achieving the full potential of a Digital Twin Implementation for ice skate production. It enables the accurate and efficient translation of digital designs into physical products, ensuring that the final product reflects the intended design specifications and meets performance requirements. Key challenges in achieving seamless manufacturing integration include ensuring compatibility between different software and hardware systems, managing data flow, and adapting to evolving manufacturing technologies. Addressing these challenges is essential for realizing the full benefits of DTI in the ice skate industry.

Frequently Asked Questions

The following addresses frequently encountered questions concerning the application of Digital Twin Implementation (DTI) in the design and manufacture of bladed footwear, providing clear and informative answers.

Question 1: What specific software is typically employed in a DTI for bladed footwear?

Common software suites include CAD (Computer-Aided Design) programs for 3D modeling, CAE (Computer-Aided Engineering) programs for simulation and analysis (FEA, CFD), and CAM (Computer-Aided Manufacturing) programs for production planning. Specific brands and versions vary based on budget, complexity, and organizational infrastructure.

Question 2: How does one validate the accuracy of a digital twin in the context of bladed footwear?

Validation involves comparing simulation results with experimental data obtained from physical prototypes. This includes comparing stress distribution patterns, vibrational frequencies, and performance metrics such as glide efficiency and turning radius. Discrepancies should be investigated and corrected to improve the digital twin’s fidelity.

Question 3: What level of expertise is required to implement a DTI for bladed footwear effectively?

Effective implementation necessitates a multidisciplinary team comprising design engineers, materials scientists, simulation specialists, manufacturing engineers, and data analysts. Proficiency in CAD/CAE software, a strong understanding of material properties and manufacturing processes, and analytical skills are crucial.

Question 4: How does DTI address the challenges associated with material selection for bladed footwear?

DTI facilitates virtual testing of various materials under simulated conditions, allowing engineers to predict their performance characteristics, such as durability, strength, and resistance to wear. This minimizes the reliance on costly and time-consuming physical testing, leading to more informed material selection decisions.

Question 5: What are the primary benefits of integrating manufacturing processes into the DTI for bladed footwear?

Manufacturing integration enables real-time monitoring and optimization of production processes, reducing defects, improving efficiency, and enhancing product quality. It also facilitates the implementation of closed-loop feedback systems, where data from the manufacturing floor is used to refine the digital twin and improve future designs.

Question 6: How does the initial investment in a DTI compare to the long-term cost savings for bladed footwear design and manufacturing?

While the initial investment in software, hardware, and training can be substantial, the long-term cost savings resulting from reduced prototyping costs, faster development cycles, improved product quality, and optimized manufacturing processes typically outweigh the initial expense. A thorough cost-benefit analysis should be conducted to assess the potential return on investment.

In essence, careful planning, skilled personnel, and a rigorous validation process are essential for reaping the benefits of a Digital Twin Implementation for bladed footwear.

The following section will present a case study that demonstrates the practical application of DTI.

Conclusion

The preceding discussion elucidates the complexities and potential benefits associated with how to make ice skates in dti, emphasizing the pivotal role of digital design, material simulation, blade geometry optimization, performance analysis, virtual prototyping, and manufacturing integration. These components collectively contribute to a more efficient, cost-effective, and performance-driven approach to ice skate development, minimizing reliance on traditional trial-and-error methodologies.

Continued exploration and refinement of digital twin technologies will undoubtedly shape the future of bladed footwear design, enabling engineers to push the boundaries of performance, safety, and sustainability. The transition necessitates a commitment to data-driven decision-making and cross-disciplinary collaboration to fully realize the potential of this paradigm shift in manufacturing.