Footwear designed specifically for skateboarding manufactured by a company known as World Industries. These specialized shoes often incorporate features such as reinforced stitching, durable materials like suede or canvas, and vulcanized rubber soles to provide enhanced grip and withstand the stresses of skateboarding. As an example, a particular model might feature triple-stitched ollie areas to prevent tearing during board tricks.

The development and marketing of durable, functional skate-specific footwear address the unique needs of skateboarders. These products provide improved board feel, impact absorption, and longevity compared to conventional athletic shoes. The historical context reveals a progression from adapted athletic shoes to purpose-built designs that cater to the evolving demands of skateboarding as both a recreational activity and competitive sport.

The subsequent sections will explore specific aspects of these shoes, including material science innovations, design elements influencing performance, market trends, and the overall impact on the skateboarding community.

Optimizing Performance and Longevity

The following guidelines aim to maximize the utility and lifespan of skate-specific footwear. Proper care and usage can significantly impact performance and prevent premature wear.

Tip 1: Select the Appropriate Size: Ensure a snug yet comfortable fit. Excess space can lead to instability and blisters, while overly tight shoes can restrict blood flow and cause discomfort. Refer to the manufacturer’s sizing chart for accurate measurements.

Tip 2: Utilize Shoe Goo for Reinforcement: Apply a thin layer of shoe repair adhesive to high-wear areas, such as the ollie patch and toe cap, before significant damage occurs. This preemptive measure prolongs the shoe’s lifespan.

Tip 3: Rotate Footwear: Alternate between multiple pairs of skate shoes. This allows the materials to recover between sessions, reducing stress and extending the overall lifespan of each pair.

Tip 4: Employ Shoe Shields: Consider using internal shoe shields to protect the toe box from excessive creasing and collapse. These inserts help maintain the shoe’s shape and structural integrity.

Tip 5: Practice Proper Lacing Techniques: Lacing patterns can affect both comfort and support. Experiment with different techniques to find a configuration that minimizes heel lift and maximizes board feel without over-tightening.

Tip 6: Clean Regularly: Remove dirt and debris from the shoe’s surface after each session. This prevents the build-up of abrasive materials that can accelerate wear. Use a soft brush and mild soap for effective cleaning.

Tip 7: Avoid Excessive Moisture: Prolonged exposure to moisture can degrade materials and promote mold growth. Allow wet shoes to air dry completely away from direct heat sources. Stuffing them with newspaper can expedite the drying process.

By adhering to these recommendations, users can optimize the performance, durability, and longevity of skate-specific footwear, ultimately enhancing their skateboarding experience and reducing replacement costs.

The subsequent section will delve into case studies and performance analysis related to specific skateboarding techniques and shoe design.

1. Durability

Durability constitutes a critical performance characteristic of skate footwear, particularly within the product lines of World Industries. The inherent abrasiveness of skateboarding, involving repeated contact with grip tape, concrete, and other rough surfaces, necessitates footwear capable of withstanding significant wear and tear. The construction methods and material selections directly impact the shoe’s lifespan and, consequently, its cost-effectiveness for the end user. For example, a shoe lacking reinforced stitching in high-stress areas, such as the ollie patch, will likely fail prematurely, requiring more frequent replacements. The connection between durability and World Industries skate shoes is causal; design choices related to materials and construction directly influence the shoe’s ability to endure the demands of skateboarding.

The importance of durability extends beyond mere longevity. Reliable construction minimizes the risk of shoe failure during critical maneuvers, potentially preventing injuries. Features such as double or triple stitching, reinforced toe caps, and robust sole construction contribute to enhanced durability. Real-world examples demonstrate this; a skateboarder consistently performing kickflips on a shoe with inadequate ollie protection will experience rapid wear in that specific area, compromising both the shoe’s structural integrity and the skateboarder’s performance. Recognizing this connection allows consumers to make informed purchasing decisions based on their individual skateboarding styles and the expected level of stress applied to the footwear.

In summary, the durability of skate shoes is inextricably linked to performance and safety. World Industries skate shoes, by employing durable materials and construction techniques, address the unique demands of skateboarding. Challenges remain in balancing durability with other desirable characteristics, such as weight, flexibility, and board feel. Understanding the importance of durability within the context of skate footwear enables consumers to select products that provide optimal performance and longevity, aligning with their specific skateboarding needs and minimizing the overall cost of ownership.

2. Board Feel

Board feel is a crucial characteristic of skate footwear, influencing a skateboarder’s connection to the board and impacting control and responsiveness. Within the context of World Industries skate shoes, board feel represents a deliberate design consideration, balancing thinness with protection to optimize the rider’s tactile feedback from the board surface.

- Sole Thickness and Material

Reduced sole thickness enhances board feel by minimizing the distance between the foot and the skateboard. Materials like vulcanized rubber, chosen for their flexibility and grip, contribute to this effect. World Industries skate shoes often employ specific rubber compounds designed to maximize board feel without sacrificing durability. A thicker, less flexible sole, conversely, would dampen board feel, hindering precise control.

- Insole Construction and Cushioning

While cushioning is essential for impact protection, excessive cushioning can negatively impact board feel. The insole design in World Industries skate shoes often seeks a balance, providing sufficient padding in key areas like the heel and forefoot while maintaining a relatively thin profile in the midfoot to allow for better board feel. The insole material itself, such as a low-profile foam, also plays a role in transmitting subtle board movements to the foot.

- Outsole Tread Pattern

The pattern and depth of the outsole tread impact the grip and tactile feedback received from the board. World Industries skate shoes frequently feature tread patterns designed to provide optimal grip in key areas while allowing for a degree of slide when needed for certain maneuvers. A shallower tread depth can enhance board feel by reducing the amount of rubber between the foot and the board, but this must be balanced against the need for sufficient grip and durability.

- Upper Construction and Flexibility

The flexibility of the upper materials influences the foot’s ability to conform to the board and transmit pressure changes. Softer, more pliable materials, such as canvas or certain types of suede, can enhance board feel compared to stiffer, more structured uppers. The overall construction of the upper, including the lacing system and padding, also contributes to the shoe’s ability to provide a secure and responsive fit, impacting the overall sense of board feel.

The design of World Industries skate shoes reflects a commitment to optimizing board feel within the constraints of durability and impact protection. Design choices regarding sole thickness, insole construction, outsole tread pattern, and upper flexibility each contribute to the overall tactile experience, enabling skateboarders to maintain a strong connection to their boards and execute maneuvers with greater precision.

3. Impact Protection

Impact protection constitutes a fundamental design consideration in skate footwear, particularly for products marketed under the World Industries brand. Skateboarding inherently involves repetitive high-impact landings, placing significant stress on the feet, ankles, and lower extremities. The capacity of skate shoes to mitigate these forces directly influences rider comfort, reduces the risk of injury, and contributes to prolonged performance. The incorporation of specific impact-absorbing materials and structural design elements represents a deliberate effort to address these biomechanical demands. A failure to adequately address impact forces can lead to conditions ranging from heel bruises and ankle sprains to more severe long-term joint damage. Therefore, impact protection isn’t merely a feature, but a crucial functional requirement.

Specific examples illustrate the importance of this connection. Models might incorporate polyurethane midsoles, known for their energy-absorbing properties, to attenuate the shock of landings. Airbag technology, strategically placed in the heel area, provides an additional layer of cushioning. Insole design, incorporating gel inserts or specialized foam compounds, further contributes to impact reduction. A skater repeatedly landing hard tricks on a shoe lacking these features will experience significantly greater discomfort and an elevated risk of injury compared to using a shoe with enhanced impact protection. This understanding informs both consumer purchasing decisions and the design strategies employed by manufacturers like World Industries.

In summary, impact protection is inextricably linked to the safety and performance of skate footwear. World Industries skate shoes, by incorporating impact-absorbing materials and structural design elements, aim to mitigate the forces generated during skateboarding. Challenges remain in balancing impact protection with other desirable characteristics, such as board feel and flexibility. A comprehensive understanding of the role of impact protection allows skaters to select footwear that minimizes injury risk and enhances their overall skateboarding experience.

4. Grip

The critical performance parameter of grip in skateboarding necessitates specialized footwear design, a need addressed directly by World Industries skate shoes. The interaction between the shoe’s outsole and the skateboard’s grip tape is fundamental for board control, trick execution, and overall rider safety. Insufficient grip can lead to slippage, loss of control, and potential injury. Conversely, excessive grip can hinder the necessary foot adjustments required for certain maneuvers. Therefore, the specific compounds and tread patterns employed in the outsole construction represent a calculated balance.

World Industries skate shoes utilize vulcanized rubber compounds selected for their high coefficient of friction against common grip tape surfaces. The specific durometer (hardness) of the rubber influences grip; softer compounds generally provide greater grip but may exhibit reduced durability. Tread patterns are engineered to maximize contact area while allowing for controlled sliding. For example, a herringbone pattern can provide excellent grip in multiple directions, while a flatter, less aggressive pattern might be preferred for skaters who prioritize foot repositioning. The consistent application of force during an ollie, a fundamental skateboarding maneuver, requires dependable grip to maintain contact with the board and execute the trick correctly. A lack of grip at this crucial moment would lead to a missed ollie and potential instability.

In summary, grip is not merely an attribute of skate shoes but a critical performance factor directly impacting control, safety, and trick execution. World Industries skate shoes address this need through the strategic selection of rubber compounds and tread patterns designed to optimize the interaction between the shoe and the skateboard. Challenges remain in balancing grip with durability and the preferences of individual skaters, but the fundamental importance of reliable grip remains paramount.

5. Style

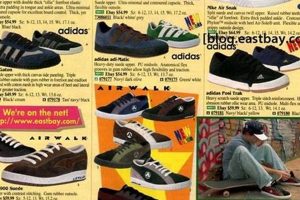

Style, in the context of World Industries skate shoes, operates as a multifaceted element encompassing aesthetics, cultural signaling, and individual expression. The visual design of skate footwear, including color palettes, logo placement, and silhouette, serves as a means of communicating affiliation with the skateboarding subculture and projecting a specific identity. The choice of footwear style directly impacts an individual’s perceived status and integration within the skateboarding community. For instance, a skater selecting a classic, low-profile design might signal an adherence to traditional skateboarding values, while a bolder, more contemporary style could indicate a preference for innovation and progression. Therefore, style transcends mere ornamentation; it represents a deliberate statement of identity and allegiance.

The influence of style extends beyond individual expression, impacting market trends and consumer preferences. World Industries, as a brand, has historically leveraged style to maintain relevance and appeal within the skateboarding market. The adoption of specific design cues, such as retro-inspired colorways or collaborations with influential skateboarders, reflects an understanding of the symbiotic relationship between style and consumer demand. Practical applications of this understanding include targeted marketing campaigns and product development strategies designed to capitalize on emerging stylistic trends. As an example, the resurgence of 1990s-era skate shoe aesthetics has prompted World Industries to reintroduce or reimagine classic designs from that period, catering to a consumer base seeking nostalgic appeal. This illustrates how style directly influences purchasing decisions and shapes the evolution of skate footwear design.

In summary, style is an integral component of World Industries skate shoes, serving as a vehicle for individual expression, cultural signaling, and market differentiation. The challenges lie in balancing stylistic innovation with functional performance and maintaining authenticity within the ever-evolving skateboarding subculture. Recognizing the significance of style within this context enables both consumers and manufacturers to make informed decisions, fostering a dynamic and responsive skateboarding footwear market.

6. Materials

The composition of World Industries skate shoes hinges on material selection, directly impacting durability, performance, and overall longevity. The abrasive nature of skateboarding necessitates robust materials capable of withstanding constant friction and impact. Inadequate material choices lead to premature wear, reduced functionality, and increased costs for the consumer. The strategic selection of materials, therefore, is not arbitrary but crucial to the shoe’s performance characteristics and value proposition.

Specifically, World Industries skate shoes frequently utilize suede and canvas for uppers, each offering distinct advantages. Suede provides enhanced abrasion resistance and a tactile feel, while canvas offers breathability and flexibility. The outsoles typically incorporate vulcanized rubber, chosen for its grip and ability to bond securely with the upper. Reinforced stitching with durable thread, such as nylon or polyester, reinforces high-stress areas like the ollie patch and toe cap. A real-world example demonstrates this connection: a skater performing frequent ollies on a shoe with a canvas upper and single stitching will experience significantly faster wear in the ollie area compared to a shoe with a suede upper and reinforced stitching. The inner linings often employ moisture-wicking fabrics to enhance comfort and prevent the build-up of sweat, which can degrade materials over time.

In summary, material selection forms the foundation of World Industries skate shoe design, dictating its ability to withstand the demands of skateboarding. Challenges remain in balancing durability, performance, and cost, requiring ongoing innovation in material science and manufacturing techniques. Understanding the properties of different materials allows both manufacturers and consumers to make informed decisions, optimizing the performance and value of skate footwear.

Frequently Asked Questions

The following addresses common inquiries regarding the attributes, maintenance, and performance expectations associated with World Industries skate shoes. It is intended to provide clarity and facilitate informed purchasing decisions.

Question 1: What constitutes the primary difference between World Industries skate shoes and conventional athletic footwear?

The fundamental distinction lies in the specific design and construction features tailored to withstand the stresses of skateboarding. This includes reinforced stitching, durable materials, and specialized outsole patterns designed to enhance grip and board feel. Conventional athletic shoes generally lack these skateboarding-specific adaptations.

Question 2: How can the lifespan of World Industries skate shoes be maximized?

Longevity is enhanced through preventative maintenance, including the application of shoe repair adhesives to high-wear areas, regular cleaning to remove abrasive debris, and the rotation of multiple pairs to allow materials to recover between sessions. Proper sizing and lacing techniques also contribute to extended shoe life.

Question 3: What factors influence board feel in World Industries skate shoes?

Sole thickness, insole construction, and outsole tread pattern collectively determine board feel. Thinner soles and lower-profile insoles enhance tactile feedback, while specialized tread patterns optimize grip without compromising the ability to make foot adjustments.

Question 4: What measures are incorporated into World Industries skate shoes to mitigate impact forces?

Impact protection is achieved through the integration of cushioning materials, such as polyurethane midsoles and gel inserts, in strategic areas. These components attenuate the shock of landings, reducing stress on the feet and ankles.

Question 5: How does the material composition of World Industries skate shoes affect their overall durability?

Material selection directly influences durability. Suede uppers offer superior abrasion resistance compared to canvas, while reinforced stitching and durable thread enhance structural integrity in high-stress zones. Vulcanized rubber outsoles provide grip and resist wear from contact with grip tape and pavement.

Question 6: Do World Industries skate shoes cater to specific skateboarding styles or preferences?

The brand offers a diverse range of styles to accommodate varying preferences. However, core design principles remain consistent: durability, board feel, impact protection, and grip. The selection process should consider individual skateboarding habits and the expected demands placed on the footwear.

Adherence to these principles will optimize the selection, use, and maintenance of World Industries skate shoes. This ensures the user experiences improved performance, longevity, and overall value.

The next section will consider customer testimonials and reviews to provide further insight into real-world performance.

Conclusion

This exploration of World Industries skate shoes has detailed the crucial design elements and material choices that define performance and longevity in skate footwear. The analysis has focused on critical aspects, including durability, board feel, impact protection, grip, style, and material composition. These features collectively determine a skateboarder’s experience and the suitability of the shoe for the demands of the sport.

Understanding the specific design principles underlying World Industries skate shoes enables informed purchasing decisions that prioritize both performance and safety. Further investigation into technological advancements in material science and manufacturing techniques will likely continue to shape the evolution of skate footwear, pushing the boundaries of what is possible in terms of durability, responsiveness, and overall performance.