The procurement of skateboard platforms in bulk quantities from a supplier, typically at a reduced cost per unit compared to individual purchases, is a common practice within the skateboarding industry. This approach allows retailers, skate shops, and manufacturers to maintain sufficient inventory levels and achieve cost efficiencies. An example would be a skate shop ordering fifty units of blank, seven-ply maple platforms directly from a distributor.

Acquiring these skateboard components in large volumes offers significant advantages. It lowers the cost per deck, improving profit margins for retailers and manufacturers. Historically, this type of purchasing has been essential for the growth and sustainability of the skateboarding market, enabling wider accessibility and promoting innovation in deck design and construction. This practice contributes to the overall health of the skate industry ecosystem.

The subsequent sections will delve into the diverse aspects of these mass-purchased skateboard platforms, including material selection, manufacturing processes, customization options, and the dynamics of the supply chain. Understanding these elements is crucial for anyone involved in the retail, distribution, or manufacturing of skateboarding equipment.

Considerations for Acquiring Skateboard Platforms in Bulk

Optimizing the acquisition of skateboard platforms in large quantities necessitates careful consideration of several factors to ensure product quality, cost-effectiveness, and alignment with business objectives.

Tip 1: Material Assessment: Prioritize platforms constructed from high-quality materials, such as Canadian maple. This wood type is renowned for its strength, flexibility, and durability, contributing to a superior riding experience and reduced risk of breakage. Verify the origin and grade of the wood to ensure consistency and performance.

Tip 2: Manufacturing Standards Verification: Thoroughly investigate the manufacturing processes employed. Ensure that the production facility adheres to strict quality control measures, including proper pressing techniques, glue application, and curing procedures. Request certifications or independent lab tests to validate adherence to industry standards.

Tip 3: Size and Shape Diversification: Offer a diverse range of sizes and shapes to cater to varied rider preferences and skateboarding styles. Stock both traditional popsicle shapes and directional boards in various widths and lengths. This variety appeals to a broader customer base and enhances market competitiveness.

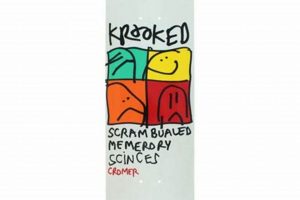

Tip 4: Graphic Customization Options: Providing customization options, such as graphic printing or laser etching, can significantly enhance the perceived value of the platforms. Offer blank platforms for custom graphics or collaborate with artists to create exclusive designs. This service attracts customers seeking personalized skateboard experiences.

Tip 5: Supplier Relationship Management: Establish strong relationships with reputable suppliers. Negotiate favorable pricing and payment terms based on order volume and long-term commitment. Conduct regular performance reviews to assess product quality, delivery reliability, and customer service responsiveness.

Tip 6: Inventory Management Optimization: Implement an effective inventory management system to minimize storage costs and prevent obsolescence. Track sales trends, forecast demand accurately, and adjust order quantities accordingly. Employ just-in-time inventory practices where feasible to reduce holding costs and improve cash flow.

Tip 7: Secure Transportation and Storage: Protect the platforms during transportation and storage to prevent damage from moisture, temperature fluctuations, or physical impact. Utilize appropriate packaging materials and maintain a controlled environment to preserve the integrity of the wood and graphics.

Strategic acquisition of skateboard platforms in bulk, coupled with diligent quality control and effective inventory management, is essential for sustained success in the competitive skateboarding market. By adhering to these considerations, businesses can optimize profitability, enhance brand reputation, and deliver superior products to customers.

The subsequent sections will delve into advanced strategies for maximizing the return on investment from acquiring skateboard platforms in quantity, including marketing tactics, distribution channel optimization, and trend analysis.

1. Material quality standards

Material quality standards represent a crucial determinant of the performance, durability, and ultimately, the market value of skateboard platforms acquired in bulk. Strict adherence to these standards is essential for businesses engaged in the procurement and distribution of these items.

- Wood Species and Grade

The selection of wood species, primarily maple, and its subsequent grading significantly impacts the structural integrity of the platform. Higher grades of maple exhibit fewer defects, such as knots or grain irregularities, resulting in increased strength and resistance to delamination. The use of inferior wood compromises the platform’s ability to withstand stress, leading to premature failure and potential safety hazards.

- Moisture Content Control

Maintaining optimal moisture content within the wood is critical throughout the manufacturing process. Excessive moisture can lead to warping, cracking, and reduced adhesive bond strength. Insufficient moisture content, conversely, can result in brittleness and increased susceptibility to splitting. Controlled drying and storage procedures are essential to preserve the wood’s integrity.

- Adhesive Selection and Application

The adhesive used to laminate the wood veneers must possess exceptional strength, flexibility, and water resistance. Inadequate adhesive selection or improper application techniques can lead to delamination, compromising the platform’s structural integrity. Stringent testing protocols should be implemented to ensure that the adhesive meets or exceeds industry standards for bond strength and durability.

- Dimensional Accuracy and Tolerances

Precise dimensional accuracy is essential for consistent performance and compatibility with hardware components. Deviations from specified dimensions, such as length, width, or thickness, can affect the platform’s handling characteristics and create difficulties during assembly. Tight tolerances must be maintained throughout the manufacturing process to ensure uniformity and minimize the risk of defective products.

The integration of rigorous material quality standards within the production of skateboard platforms secured in bulk is not merely a matter of compliance but a strategic imperative. It directly influences product reliability, customer satisfaction, and the long-term viability of businesses operating within this sector. Compromising on material quality undermines the integrity of the product and erodes brand reputation.

2. Manufacturing process efficacy

The effectiveness of manufacturing processes directly dictates the quality, consistency, and ultimately, the cost-effectiveness of skateboard platforms acquired in bulk. Inefficient processes can lead to defects, material waste, and increased production costs, thereby impacting the profitability and market competitiveness of businesses dealing in these products. For instance, improper pressing techniques during lamination can result in weak or delaminated platforms, leading to higher rates of returns and damaged reputation. Conversely, streamlined and controlled processes ensure uniformity, reduce waste, and optimize resource utilization.

An example illustrating the impact involves two hypothetical manufacturers. One employs outdated equipment and manual processes, resulting in a high percentage of platforms failing quality control checks. This manufacturer experiences increased material waste, higher labor costs, and delays in fulfilling bulk orders. The second manufacturer, on the other hand, invests in automated machinery and implements stringent quality control procedures. This results in consistent platform quality, reduced material waste, and faster production times, allowing them to offer competitive pricing and reliable delivery to their wholesale clients. The choice of adhesives, curing times, and sanding processes are also critical points that directly impact the structural integrity and finish of the final product.

In conclusion, a robust and efficient manufacturing process is not merely an operational detail but a critical factor determining the viability and success of wholesale skateboard platform operations. Attention to process optimization, investment in appropriate technology, and rigorous quality control are essential for maximizing product quality, minimizing costs, and ensuring customer satisfaction within this sector. Without effective control over the manufacturing process, suppliers are unable to deliver the promised value for these components.

3. Customization possibilities

The capacity for customization serves as a significant value-add when considering skateboard platforms purchased in bulk. Manufacturers and retailers leveraging wholesale options frequently seek opportunities to differentiate their products. Customization, in this context, encompasses graphic application, shape modification, and material selection alternatives, all impacting the final product’s appeal and market position. For instance, a skate shop might procure blank platforms in large quantities and then apply unique, locally-designed graphics, thereby establishing a distinct brand identity and catering to a specific customer base. The availability of diverse concave molds from the manufacturer is also part of customization that can be customized to fit customers.

The implementation of customization strategies presents certain operational and logistical considerations. Efficient management of the design approval process, accurate graphic reproduction, and timely delivery are essential for maintaining customer satisfaction and minimizing delays. Additionally, customization can extend beyond aesthetics to include functional adaptations, such as specialized grip tape application or reinforced construction for specific riding styles. A practical example involves a retailer specializing in longboards, who could offer customized deck lengths and wheelbases to accommodate individual rider preferences and enhance board performance. The capacity to modify the core components of the deck allows for more advanced customization.

In conclusion, customization represents a critical element in maximizing the potential of wholesale skateboard platform acquisitions. It enables businesses to cultivate unique brand identities, cater to niche markets, and enhance the perceived value of their products. While customization introduces complexities in the production and distribution processes, the strategic implementation of these capabilities can result in significant competitive advantages and increased market share. It also helps to improve customer satisfaction and provide a value-add that other manufacturers may not have considered.

4. Cost-effectiveness analysis

A rigorous evaluation of cost-effectiveness is paramount when procuring skateboard platforms in bulk quantities. This analysis extends beyond the immediate per-unit price, encompassing a range of factors that collectively determine the true economic value of the acquisition. Failing to conduct a thorough assessment can lead to suboptimal purchasing decisions, negatively impacting profitability and competitiveness within the skateboarding market.

- Unit Price vs. Total Cost of Ownership

The initial per-unit price of a platform is a superficial metric. A comprehensive analysis must consider associated costs, including shipping, storage, potential for damage during transit, and anticipated defect rates. A lower initial price may be offset by higher shipping expenses due to supplier location or inadequate packaging, ultimately increasing the total cost of ownership. Examples may include a manufacturer being farther away vs one local.

- Material Quality and Longevity Considerations

Platforms constructed from higher-quality materials, such as Canadian maple, typically command a premium price. However, their enhanced durability and resistance to breakage translate to lower replacement rates and improved customer satisfaction. A cost-effectiveness analysis must weigh the initial investment against the projected lifespan and performance of the platform. Inferior materials may lead to customer dissatisfaction and result in more defective products.

- Manufacturing Process and Defect Rates

The efficiency and precision of the manufacturing process directly impact the likelihood of defects. Platforms produced using outdated or poorly maintained equipment are prone to inconsistencies in shape, size, and structural integrity. A comprehensive cost-effectiveness analysis must factor in the potential costs associated with quality control, returns, and warranty claims. A brand offering a higher quality platform offers better profit margins through longevity.

- Customization and Value-Added Services

Suppliers offering customization options, such as graphic printing or shape variations, may charge a higher premium. However, these value-added services can enhance the platform’s appeal to specific market segments and enable businesses to differentiate their products. A cost-effectiveness analysis must assess the potential return on investment from customization, considering factors such as increased sales volume and brand recognition. Some suppliers are a one stop shop.

In summary, a robust cost-effectiveness analysis is essential for informed decision-making in the wholesale acquisition of skateboard platforms. By considering the interplay between unit price, material quality, manufacturing processes, and value-added services, businesses can optimize their purchasing strategies and maximize their return on investment. Failing to address these factors can result in higher total costs, reduced product quality, and diminished competitiveness in the marketplace.

5. Distribution network reach

The extent and efficacy of a distribution network exert a considerable influence on the success of any venture involving skateboard platforms obtained at wholesale prices. A limited distribution network constrains market access, restricting sales volume and hindering brand visibility. Conversely, a well-established and strategically managed network facilitates broader market penetration, enabling businesses to reach a larger and more diverse customer base.

The relationship between wholesale acquisition and distribution network reach is symbiotic. Securing platforms at competitive wholesale prices enables businesses to invest in expanding their distribution capabilities. This expansion can take several forms, including establishing relationships with retailers, developing online sales channels, or engaging with distributors in different geographical regions. For example, a company that acquires blank platforms in bulk may partner with local skate shops to offer customized decks, leveraging the retailer’s existing customer base and local market expertise. Alternatively, the company might establish an e-commerce platform to sell directly to consumers, bypassing traditional retail channels and expanding its reach nationally or internationally. In regions where skateboarding is growing, local distribution may not exist, hindering access to products.

The practical significance of understanding this relationship is substantial. Businesses involved in the wholesale acquisition and distribution of skateboard platforms must prioritize the development of a robust and adaptable distribution network. This requires careful consideration of factors such as target market, logistical infrastructure, and competitive landscape. Effective distribution is not simply about moving product from one point to another; it’s about strategically positioning platforms to maximize sales and build brand equity. Challenges such as varying transportation costs, international import regulations, and regional demand fluctuations must be addressed. A robust supply chain is essential to mitigate disruption. Failure to do so will result in a failure to launch the products.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the acquisition of skateboard platforms at wholesale.

Question 1: What constitutes a “wholesale” purchase of skateboard platforms?

A wholesale purchase refers to the acquisition of skateboard platforms in substantial quantities directly from a manufacturer or distributor, typically at a reduced per-unit cost compared to individual retail purchases. The precise quantity defining a “wholesale” order varies between suppliers.

Question 2: What are the principal benefits of acquiring skateboard platforms wholesale?

The primary benefits include reduced per-unit costs, enabling higher profit margins for retailers and manufacturers. Wholesale purchasing also facilitates the maintenance of sufficient inventory levels to meet market demand and streamlines the supply chain.

Question 3: What key factors should be considered when selecting a supplier of skateboard platforms at wholesale?

Critical considerations include the supplier’s reputation, the quality of materials used (e.g., Canadian maple), the manufacturing processes employed, the availability of customization options, and the overall cost-effectiveness of their offerings.

Question 4: What are the typical materials used in the construction of skateboard platforms available at wholesale?

The most common material is Canadian maple, prized for its strength, flexibility, and durability. Other materials may include birch, bamboo, or composite materials, although these are less prevalent in high-quality platforms.

Question 5: What is the significance of deck concave when purchasing skateboard platforms wholesale?

Concave refers to the curvature of the deck’s surface between the nose and tail. Different concave depths and shapes cater to various riding styles and preferences. Offering a range of concave options allows retailers to appeal to a broader customer base.

Question 6: What are the potential risks associated with acquiring skateboard platforms from unverified or unknown suppliers?

Risks include inconsistent product quality, substandard materials, unreliable delivery schedules, and potential exposure to counterfeit products. It is essential to conduct thorough due diligence before engaging with any new supplier.

In conclusion, the successful procurement of skateboard platforms at wholesale requires careful consideration of numerous factors, including supplier selection, material quality, manufacturing processes, and distribution strategies. Informed decision-making is crucial for maximizing profitability and maintaining a competitive edge in the skateboarding market.

The subsequent sections will explore advanced techniques for optimizing inventory management and mitigating supply chain risks associated with wholesale skateboard platform acquisitions.

Wholesale Skate Decks

This exploration has illuminated the critical aspects surrounding the acquisition of skateboard platforms at wholesale. Considerations ranging from material quality and manufacturing efficacy to customization potential, cost-effectiveness analysis, and distribution network reach directly influence the profitability and sustainability of businesses operating within the skateboarding sector. Neglecting these elements introduces significant risk.

The informed and strategic procurement of wholesale skate decks is not merely a transactional process, but a cornerstone of competitive advantage. Diligence in supplier selection, rigorous quality control, and a comprehensive understanding of market dynamics are essential for long-term success. Entities engaging in this practice are urged to prioritize these considerations to navigate the complexities of the market and ensure the delivery of high-quality products to consumers.