A high-quality platform for skateboarding is essential for optimal performance and rider safety. These platforms are constructed from durable materials, typically multiple layers of laminated wood, and engineered to withstand the stresses of various skateboarding maneuvers. Features such as appropriate concave, dimensions, and weight contribute to its overall functionality.

Utilizing a well-crafted board can significantly enhance a skater’s ability to execute tricks, maintain balance, and control their movements. The historical evolution of these platforms reflects a continuous pursuit of improved resilience, responsiveness, and rider comfort. Consequently, advancements in materials and construction techniques have resulted in enhanced riding experiences.

The following sections will delve into specific factors that contribute to the overall quality of skateboarding platforms, encompassing material composition, construction methods, design features, and performance metrics. A detailed examination of these aspects will provide a comprehensive understanding of what constitutes a reliable and effective tool for skateboarding.

Guidance for Selecting Quality Skateboarding Platforms

This section provides informational tips regarding the selection of a skateboarding platform that meets specific performance and durability standards. Adherence to these guidelines may improve rider safety and enhance the overall skateboarding experience.

Tip 1: Material Evaluation: Prioritize platforms constructed from high-quality maple wood. Multiple plies of this material offer a balance of strength and flexibility, contributing to the platform’s responsiveness.

Tip 2: Construction Assessment: Examine the lamination process. Uniform adhesive application and consistent pressing during manufacturing ensure structural integrity and prevent premature delamination.

Tip 3: Concave Consideration: Evaluate the degree of concave. The appropriate concave shape aids in foot lock-in and facilitates trick execution. Different concave profiles may suit varying riding styles.

Tip 4: Dimensional Verification: Confirm that the platform width and length align with the rider’s physical attributes and intended use. A mismatch in dimensions can negatively impact control and stability.

Tip 5: Weight Management: Consider the platform’s weight. A lighter platform may improve maneuverability, while a heavier platform might offer increased stability at higher speeds.

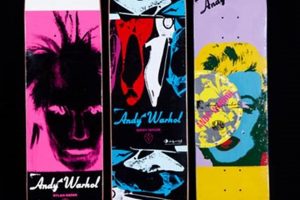

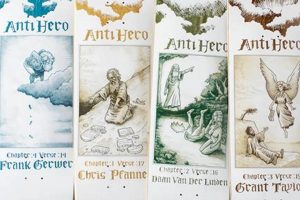

Tip 6: Graphic Inspection: While primarily aesthetic, ensure that the graphic application does not compromise the structural integrity of the platform. Thick layers of paint can impact the wood’s natural flex.

Tip 7: Hardware Compatibility: Verify compatibility with trucks, wheels, and bearings. Proper hardware integration is crucial for optimal performance and rider safety. Misalignment or incompatibility can lead to component failure.

Selection of a skateboarding platform should involve careful consideration of materials, construction, dimensions, and compatibility. Prioritizing these factors contributes to an informed decision and ultimately enhances the skateboarding experience.

The subsequent sections will explore the various types and features of skateboarding platforms in further detail.

1. Wood Quality

The material composition of a skateboarding platform, specifically wood quality, is a primary determinant of its performance characteristics and overall longevity. Wood selection directly influences the platform’s strength, flex, and ability to withstand the rigors of skateboarding.

- Maple Density and Hardness

The density and hardness of maple wood varieties used in platform construction directly correlate to impact resistance and durability. Denser, harder maple resists chipping, cracking, and deformation under stress. Variations in maple quality affect the platform’s ability to withstand repeated impacts during tricks and landings, directly impacting its lifespan.

- Grain Orientation and Alignment

The orientation and alignment of the wood grain within each ply are crucial for maximizing structural integrity. Consistent grain alignment across all plies distributes stress evenly throughout the platform, minimizing the risk of fractures. Deviations in grain alignment can create weak points, leading to premature failure.

- Moisture Content and Treatment

Controlling the moisture content of the wood during manufacturing is essential for preventing warping and maintaining dimensional stability. Wood that is either too dry or too moist is prone to cracking or becoming excessively flexible, negatively impacting performance. Proper drying and treatment processes are critical for achieving optimal moisture balance and long-term structural integrity.

- Ply Grade and Selection

Variations exist in the grade and quality of individual maple plies used in platform construction. Higher-grade plies exhibit fewer imperfections and knots, resulting in greater strength and consistency. Selective use of higher-grade plies in critical areas of the platform, such as the nose and tail, can enhance durability and pop.

The relationship between wood quality and the overall performance of skateboarding platforms is undeniable. Precise selection, processing, and integration of appropriate wood materials are essential for creating a platform that exhibits the strength, resilience, and responsiveness required for demanding skateboarding applications. Ultimately, prioritizing wood quality contributes directly to a product capable of withstanding repeated use and delivering a consistent riding experience.

2. Ply Construction

Ply construction is a fundamental element in the creation of a high-quality skateboarding platform. The manner in which multiple layers of wood, typically maple, are arranged and bonded directly affects the platform’s strength, durability, and responsiveness. The number of plies, the grain orientation of each ply, and the adhesive used to bind them together are all critical factors that determine the deck’s overall performance. A poorly constructed deck is susceptible to delamination, warping, or premature breakage, rendering it unsafe and ineffective for skateboarding. Conversely, a well-executed ply construction results in a resilient, responsive platform that provides a superior riding experience. An example includes decks made from 7-ply maple constructions, which are known for their balance between weight and strength.

The orientation of the wood grain in alternating plies is crucial for distributing stress evenly across the deck’s surface. This cross-grain lamination technique enhances torsional stiffness and prevents the deck from easily splitting along the grain. The adhesive used in ply construction must provide a strong, permanent bond that is resistant to moisture and temperature changes. High-quality adhesives prevent ply separation, even under extreme conditions. Variations in ply thickness and material composition can also be implemented to fine-tune the deck’s flex characteristics. Some manufacturers incorporate fiberglass or carbon fiber layers to enhance stiffness and pop. Understanding these nuances allows manufacturers to customize decks for specific riding styles.

In summary, ply construction is an indispensable aspect of a skateboarding platform’s quality. From material selection and lamination techniques to adhesive application, each factor contributes to the final product’s performance and longevity. The informed selection of these elements results in a durable and highly functional skateboard deck. Manufacturers focusing on ply construction demonstrate a commitment to the skater’s safety, enhancing their performance and overall experience, ultimately linking directly to a superior skateboarding platform.

3. Concave Profile

The curvature of a skateboard platform, known as its concave profile, is a critical design element that significantly influences rider control, trick execution, and overall board feel. This curvature, spanning the width and length of the platform, dictates how a rider’s feet engage with the board and directly impacts maneuverability. The selection of an appropriate concave profile is, therefore, an essential consideration in achieving a well-performing skateboarding platform.

- Foot Lock-In and Board Feel

The concave profile establishes a physical pocket for a rider’s feet, enhancing foot lock-in and providing a more secure connection to the board. This secure connection enables greater control during complex maneuvers and provides riders with enhanced tactile feedback, translating into more precise movements. Variations in concave depth and shape alter the degree of foot lock-in, influencing the rider’s responsiveness and confidence.

- Flipping and Trick Execution

A pronounced concave profile facilitates the execution of flip tricks by providing a distinct edge for initiating board rotation. This enhanced edge control allows riders to apply the necessary force for flipping the board with greater precision. The angle and sharpness of the concave edges directly impact the speed and consistency of flip tricks, leading to greater efficiency and control.

- Stability and Control

While a deeper concave generally enhances flip tricks, it can also reduce stability at higher speeds. A shallower concave profile provides a flatter, more stable platform for cruising and maintaining balance. Selecting the appropriate concave depth is a balance between maneuverability and stability, requiring consideration of the rider’s style and intended use.

- Concave Variations and Rider Preferences

Manufacturers offer a wide range of concave profiles, from mellow and radial shapes to steep and progressive designs. These variations cater to different riding styles and preferences. Riders may experiment with various concave profiles to identify the shape that best complements their individual technique and enhances their overall skateboarding experience. Understanding these variations is crucial in obtaining a platform that aligns with one’s specific needs.

The concave profile is a fundamental aspect that influences the functionality of skateboarding platforms. Careful consideration of the concave shape, depth, and transition is crucial for enhancing control, trick execution, and overall rider satisfaction. An informed approach to concave selection facilitates the identification of a platform that maximizes performance and contributes to a refined skateboarding experience.

4. Weight Distribution

Weight distribution within a skateboarding platform significantly influences its overall performance and usability. An uneven distribution of mass affects board responsiveness, stability, and the ease with which a skater can execute various maneuvers. A superior platform demonstrates a well-considered weight distribution, optimizing rider control and facilitating a more predictable riding experience. Consider a platform with excessive weight concentrated in the tail; this could enable quick pop but also lead to instability when landing tricks, negating some performance benefits. Conversely, a platform with even weight distribution might sacrifice some pop quickness but provide enhanced stability, suitable for specific riding styles.

The importance of balanced weight is evident in design choices such as platform shape, core construction, and material selection. Decks featuring asymmetrical designs or variations in ply thickness strategically manage the weight along the platform’s length. Core materials, ranging from lightweight composites to denser hardwoods, impact the overall mass and its distribution. Professional skateboarders often provide feedback on prototypes, influencing design alterations to enhance weight distribution and ultimately improve performance based on specific needs. For example, some skaters prefer a slightly nose-heavy board for better control during grinds on rails.

Optimal weight distribution is not a universally defined value but is rather contingent on rider preference and skating style. Downhill skaters may favor a heavier board for increased stability at high speeds, whereas street skaters often prefer lighter, more responsive platforms for technical tricks. Understanding the role of weight distribution allows manufacturers to tailor skateboarding platforms to specific performance requirements. Superior skate decks effectively balance weight distribution in conjunction with other features, resulting in an optimized piece of skateboarding equipment. A balanced deck leads to an overall improved riding experience which in turn enhance skater safety and the ability to progress their skills.

5. Resilience

A skateboarding platform’s resilience is its capacity to withstand repeated stress and impacts without sustaining permanent damage or degradation of performance characteristics. The constant forces exerted during skateboarding including landings, grinds, and slides place significant stress on the platform’s structure. Platforms lacking adequate resilience are prone to fracturing, delamination, or warping, resulting in a compromised riding experience and potential safety hazards. For example, a platform repeatedly subjected to high-impact landings that lacks inherent resilience might develop stress fractures in the wood plies, leading to an eventual catastrophic failure during a trick attempt. Resilience in skateboard platforms is not merely a measure of initial strength, but also of their ability to maintain structural integrity and performance attributes over prolonged periods of use.

The resilience of a skateboarding platform is directly influenced by the materials used in its construction, the manufacturing processes employed, and the overall design of the platform. High-quality maple wood, known for its strength and flexibility, is often the primary material in superior platforms. Advanced manufacturing techniques, such as precise lamination and consistent adhesive application, contribute to a platform’s ability to withstand repetitive stress. Design elements like concave profiles and reinforcement layers also play a role in enhancing resilience. For example, a deck reinforced with fiberglass or carbon fiber layers exhibits increased resistance to breakage and deformation, thereby extending its lifespan. The practical application of this understanding is evident in the performance of professionally designed and manufactured skateboarding platforms that consistently demonstrate superior resilience compared to cheaply made alternatives. Professional skaters often rely on resilient platforms to perform challenging maneuvers, where deck failure would likely result in injury.

In conclusion, resilience is an indispensable attribute of a skateboarding platform. It ensures safety, prolongs the deck’s lifespan, and maintains consistent performance. The selection of high-quality materials, the implementation of advanced manufacturing processes, and careful design considerations are all critical in achieving a resilient platform. Understanding the factors contributing to resilience empowers skaters and manufacturers to make informed choices, resulting in superior skateboard decks that stand up to the demands of skateboarding and promote a safe and rewarding riding experience.

6. Shape Precision

Shape precision, referring to the accuracy and consistency of a skateboarding platform’s contours and dimensions, is a critical determinant of overall performance and handling. Deviations from intended specifications, even subtle ones, can significantly impact a skater’s ability to control the board, execute tricks, and maintain balance. The relationship between shape precision and a superior skate deck is causal: accurate shapes contribute to consistent performance, whereas imprecisely shaped boards can lead to unpredictable handling and reduced confidence. For example, an inconsistent tail angle can alter the pop characteristics, making flip tricks more difficult to perform reliably. This inherent characteristic needs to be perfect.

The manufacturing process directly influences shape precision. Modern production techniques, including CNC machining and automated pressing, are employed to ensure uniformity across multiple platforms. However, variations in material density, adhesive application, and curing times can introduce inconsistencies. Furthermore, minor asymmetries in the nose and tail shapes can affect board tracking and stability, particularly at higher speeds. This is true for decks to ride safely. Real-world examples showcase the consequences of poor shape precision; skaters often report issues with “ghost pops” (unintentional board movements) or difficulty maintaining a straight line, directly attributable to shape irregularities. Understanding these potential manufacturing imperfections is essential for both producers and consumers seeking a reliable platform.

In summary, shape precision is an indispensable component of a superior skate deck. Its importance lies in its direct impact on board handling, trick execution, and overall skater control. Recognizing the potential causes and consequences of shape inaccuracies, and employing manufacturing techniques that minimize deviations, are key to producing high-quality skateboarding platforms. Efforts to improve and maintain shape precision contribute directly to enhanced rider experience and safety, reinforcing its role as a cornerstone of superior skateboarding equipment. Moreover, understanding leads to the ultimate knowledge for superior skateboards.

7. Graphic Integrity

Graphic integrity, in the context of a skateboarding platform, refers to the durability and resilience of the applied artwork and its adhesion to the platform’s surface. The connection between graphic integrity and a superior skate deck lies in the fact that it contributes to the overall longevity and aesthetic appeal of the product. While primarily cosmetic, the application method and materials used for graphics can indirectly impact the platform’s structural integrity. Poorly applied graphics can chip, peel, or fade prematurely, detracting from the deck’s appearance and potentially exposing the underlying wood to moisture, accelerating degradation. For example, graphics applied with thick layers of paint might stiffen the deck, negatively influencing its flex and responsiveness. Therefore, graphic integrity is a facet, albeit a less prominent one, of what constitutes a superior skateboard deck.

The practical application of graphic integrity considerations is evident in the manufacturing processes employed by reputable skateboarding companies. These companies utilize screen printing, heat transfers, or direct digital printing techniques that ensure the graphics are firmly bonded to the wood surface. UV-resistant inks and protective coatings are often applied to prevent fading and abrasion. Moreover, the graphic design itself can be strategically implemented to minimize stress points on the deck. For instance, designs that avoid large, solid blocks of ink in areas prone to flex can reduce the likelihood of cracking or peeling. This careful attention to graphic integrity helps to maintain the aesthetic value of the platform throughout its lifespan, which in turn, is a factor for consumer satisfaction and brand loyalty.

In conclusion, graphic integrity is an important, though often overlooked, aspect of a superior skate deck. Although it is not directly responsible for the deck’s primary function of supporting a skater, it contributes to the platform’s overall value and longevity. By employing robust application methods and durable materials, manufacturers can ensure that the graphics remain vibrant and intact, enhancing the skateboarder’s experience and increasing the perceived quality of the product. Maintaining graphic integrity requires balancing aesthetic goals with practical considerations of material science and manufacturing processes, a challenge that manufacturers must address to deliver genuinely superior skateboarding platforms.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, maintenance, and performance characteristics of high-quality skateboarding platforms. The responses aim to provide clear and concise information to facilitate informed decision-making.

Question 1: What constitutes a “superior” skateboarding platform?

A platform designated as “superior” typically exhibits a combination of factors, including high-quality material composition (e.g., maple), precise construction techniques (e.g., consistent lamination), optimized shape (e.g., appropriate concave), and demonstrable durability. The specific weighting of these factors may vary based on individual riding style and preferences.

Question 2: How does wood quality impact a platform’s performance?

Wood quality directly influences a platform’s strength, flex, and pop. Higher-grade maple exhibits greater density and fewer imperfections, resulting in a more resilient and responsive platform. The selection of inferior wood grades can lead to premature breakage or diminished performance.

Question 3: What is the significance of concave in platform design?

Concave refers to the curvature of the platform’s surface and affects foot lock-in, control, and flip trick execution. Different concave profiles cater to varying riding styles, with steeper concave generally favoring technical tricks and mellow concave providing increased stability.

Question 4: How should one maintain a skateboarding platform to maximize its lifespan?

Proper maintenance includes avoiding exposure to excessive moisture, storing the platform in a dry environment, and inspecting it regularly for signs of wear or damage. Replacing worn hardware (e.g., grip tape) can also extend the platform’s useful life.

Question 5: Does graphic application affect platform performance?

While primarily aesthetic, graphic application can indirectly impact performance if thick layers of paint or ink are used. Excessive graphic material can stiffen the platform and alter its flex characteristics. Reputable manufacturers employ application methods that minimize any adverse effects on performance.

Question 6: How does weight distribution impact a skateboarder’s riding?

Weight distribution impacts responsiveness and stability. A balanced weight distribution is crucial for predictable handling, while disproportionate weight can hinder a skateboarder’s ability to efficiently perform specific maneuvers.

Key takeaways from this section emphasize the multifaceted nature of skateboarding platform quality. A truly “superior” platform represents a synthesis of material science, engineering design, and manufacturing precision.

The subsequent section will address advanced topics related to skateboarding platform technology and performance optimization.

Superior Skate Deck

This exploration has detailed the multifaceted nature of a skateboarding platform, moving past simple product categorization to an understanding of critical performance elements. Material composition, manufacturing precision, design features, and graphic integrity converge to define the overall quality and functionality. Each element contributes in varying degrees to the deck’s responsiveness, durability, and suitability for a range of skateboarding styles.

The continuous refinement of skateboarding platform technology is essential for advancing the sport and ensuring rider safety. Manufacturers and skaters alike must maintain a discerning approach, recognizing that a superior skate deck is not merely a commodity but a complex piece of equipment directly impacting performance and potential. Further research and development into materials, construction methods, and performance metrics will continue to shape the future of skateboarding.