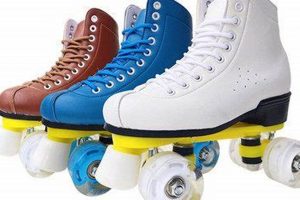

This recreational equipment, characterized by its classic aesthetic and function, provides a traditional skating experience. A common example includes a four-wheeled boot setup, often favored for its stability and control during recreational activities.

The enduring appeal of this style lies in its simplicity and accessibility. It offers a comfortable introduction to skating, fostering balance and coordination. Historically, it represents an early form of wheeled footwear, contributing to the evolution of various skating disciplines and recreational pursuits.

The following sections will delve into the specific components, maintenance practices, and selection considerations relevant to this equipment, offering detailed insights for both beginners and experienced enthusiasts.

Tips for Classic Roller Skate Usage

The following guidance assists in maximizing the safety, longevity, and enjoyment derived from classic roller skates.

Tip 1: Protective Gear is Essential: Always wear appropriate protective equipment, including a helmet, wrist guards, elbow pads, and knee pads. These items mitigate the risk of injury during falls or collisions.

Tip 2: Pre-Skate Inspection is Necessary: Before each use, examine the skates for any signs of wear, looseness, or damage. Pay particular attention to the wheels, axles, and boot attachments. Address any issues before skating.

Tip 3: Gradual Skill Development is Recommended: Beginners should start in a controlled environment, such as a smooth, flat surface away from traffic. Practice basic movements, such as balancing, gliding, and stopping, before attempting more advanced maneuvers.

Tip 4: Surface Awareness is Paramount: Skate only on surfaces that are suitable for roller skating. Avoid uneven, cracked, or wet surfaces, as these can cause loss of control and increase the risk of falls.

Tip 5: Regular Maintenance Extends Lifespan: Clean the wheels and bearings regularly to remove dirt and debris. Lubricate the bearings periodically to ensure smooth rolling. Tighten any loose hardware as needed.

Tip 6: Proper Storage Prevents Degradation: Store the skates in a cool, dry place away from direct sunlight and extreme temperatures. This helps prevent damage to the materials and extends the lifespan of the skates.

Tip 7: Brake Proficiency is Crucial: Master the use of the brake(s) before venturing onto more challenging terrain. Practice stopping smoothly and efficiently to avoid sudden stops that can lead to falls.

Adhering to these guidelines promotes a safer and more fulfilling skating experience. Regular attention to maintenance and safety practices ensures the continued usability and enjoyment of the equipment.

The subsequent sections will explore further aspects of roller skate selection, maintenance, and advanced techniques, offering a comprehensive resource for skaters of all levels.

1. Durability

Durability is a critical attribute in the context of classic roller skates due to the inherent demands of the activity. The physical stresses of repeated impacts, abrasions from various surfaces, and the constant pressure exerted by the skater necessitate robust construction and high-quality materials. A lack of durability directly translates to a reduced lifespan for the skates, requiring frequent replacements and incurring higher long-term costs. For instance, skates used regularly on outdoor surfaces are subject to greater wear and tear compared to those used primarily indoors, underscoring the importance of material selection and construction techniques that enhance resistance to abrasion and impact.

The longevity of the boot, frame, wheels, and bearings are all indicators of overall durability. A boot constructed from inferior materials may crack or tear under stress, compromising support and safety. Similarly, a frame lacking structural integrity can bend or break, leading to potential injuries. Wheel durability is often gauged by its resistance to wear and tear, which directly influences grip and performance. Finally, the quality and sealing of bearings determine their resistance to contamination and corrosion, significantly impacting their lifespan and rolling efficiency.

Ultimately, the investment in durable classic roller skates results in enhanced safety, prolonged usability, and improved performance. By prioritizing quality materials and robust construction, manufacturers cater to consumers who value longevity and reliability. This focus on durability not only provides a more cost-effective solution in the long run but also promotes a more sustainable approach to recreational equipment consumption.

2. Wheel Composition

Wheel composition is a defining characteristic that directly influences the performance and suitability of classic roller skates. Material selection dictates grip, durability, and the overall skating experience. Variations in composition cater to diverse skating environments and user preferences, impacting speed, control, and comfort.

- Durometer Rating

Durometer is a measure of a wheel’s hardness, typically ranging from 78A (soft) to 101A (very hard). Softer wheels provide enhanced grip and shock absorption, ideal for outdoor surfaces or uneven terrains. Harder wheels offer increased speed and rolling efficiency, suitable for smooth indoor surfaces like rinks. The durometer rating directly affects the skate’s maneuverability and comfort levels depending on the skating environment.

- Polyurethane Formulation

Polyurethane is the primary material used in the creation of roller skate wheels due to its versatile properties. Different polyurethane formulations can alter the wheel’s resilience, rebound, and resistance to abrasion. Higher-quality polyurethane formulations often exhibit superior durability and grip compared to less expensive alternatives. This impacts the longevity of the wheels and the consistency of performance over time.

- Wheel Diameter and Profile

The diameter and profile of the wheel also play a role in performance. Larger diameter wheels generally offer increased speed and momentum, while smaller diameter wheels provide improved maneuverability and acceleration. Wheel profile, which refers to the shape of the wheel’s edge, can influence grip and stability during turns. A rounded profile is typically more forgiving, while a sharper edge offers more precise control.

- Core Material

Many roller skate wheels feature a core, which is the central component around which the polyurethane is molded. The core material, often made of nylon or other rigid polymers, provides structural support and helps maintain the wheel’s shape under load. A stiffer core can enhance rolling efficiency and power transfer, while a more flexible core may offer improved shock absorption. The selection of core material contributes to the overall performance characteristics of the wheel.

In essence, wheel composition is a critical design element that directly impacts the functionality and suitability of classic roller skates. Understanding the properties of various materials and their influence on performance allows users to select equipment best suited to their skating style and intended environment. Careful consideration of durometer, polyurethane formulation, wheel diameter, and core material ensures an optimal skating experience characterized by control, comfort, and durability.

3. Boot Comfort

Boot comfort is a paramount factor in the overall experience associated with classic roller skates. It directly influences user endurance, performance, and enjoyment, making it a critical design consideration for manufacturers and a primary concern for skaters.

- Anatomical Fit

The anatomical fit of the boot is essential for distributing pressure evenly across the foot. A boot that conforms closely to the natural contours of the foot minimizes friction and reduces the likelihood of blisters or pressure points. Examples include boots designed with specific widths to accommodate varying foot sizes or features like heat-moldable liners that allow for a customized fit. An ill-fitting boot can lead to discomfort, reduced performance, and potential foot injuries.

- Padding and Cushioning

The type and placement of padding and cushioning materials within the boot significantly impact comfort levels. High-density foams and gel inserts are often strategically incorporated to provide shock absorption and reduce impact forces. Padding around the ankle, tongue, and heel cup can prevent rubbing and chafing. Inadequate cushioning can result in foot fatigue and discomfort, particularly during prolonged skating sessions.

- Ventilation and Breathability

Proper ventilation and breathability are crucial for maintaining a comfortable internal environment within the boot. Materials that allow for air circulation and moisture wicking help prevent overheating and excessive sweating. Perforations, breathable mesh panels, and moisture-wicking liners contribute to effective ventilation. Poor ventilation can lead to discomfort, odor buildup, and an increased risk of fungal infections.

- Closure System and Support

The closure system, including laces, buckles, and straps, plays a vital role in securing the foot within the boot and providing adequate support. A well-designed closure system ensures a snug and supportive fit that prevents excessive movement and reduces the risk of ankle sprains. Laces allow for precise adjustments, while buckles and straps offer convenience and ease of use. Insufficient support can compromise stability and increase the likelihood of injury.

The convergence of these facets anatomical fit, padding and cushioning, ventilation and breathability, and closure system support is essential for attaining optimal boot comfort in classic roller skates. When these elements are effectively integrated, skaters experience enhanced comfort, reduced fatigue, and improved performance, contributing to a more satisfying and enjoyable skating experience. Conversely, deficiencies in any of these areas can significantly detract from the overall skating experience and increase the risk of discomfort or injury.

4. Bearing Quality

Bearing quality is a determinant factor in the performance of classic roller skates. Bearings facilitate wheel rotation, and their quality directly impacts the smoothness, speed, and efficiency of the skating experience. Low-quality bearings introduce friction, hindering glide and requiring greater effort from the skater. Conversely, high-quality bearings minimize friction, allowing for effortless movement and increased speed. For instance, a skater using classic skates with ABEC 1 rated bearings will experience significantly more resistance compared to a skater using ABEC 7 or higher rated bearings, assuming all other factors are equal.

The internal construction, materials, and precision machining of bearings influence their quality. High-quality bearings utilize hardened steel or ceramic components and are manufactured to precise tolerances. This construction reduces friction and increases durability. Sealed bearings, which protect the internal components from dirt and moisture, contribute to extended lifespan and consistent performance. Regular maintenance, including cleaning and lubrication, is essential for preserving bearing quality and maximizing performance. Failure to maintain bearings leads to increased friction, decreased speed, and potential bearing failure. The impact of bearing quality is readily apparent in recreational skating scenarios where skaters may struggle to maintain momentum due to inefficient bearing performance.

In summary, bearing quality is integral to the efficient operation of classic roller skates. Prioritizing high-quality bearings results in a smoother, faster, and more enjoyable skating experience. Regular maintenance is crucial for sustaining bearing performance and extending their lifespan. The choice of bearing quality represents a tangible investment in both performance and durability, ultimately affecting the overall satisfaction derived from using classic roller skates.

5. Frame Rigidity

Frame rigidity, in the context of classic roller skates, directly influences stability, control, and power transfer. A frame exhibiting high rigidity minimizes unwanted flex during skating, translating the skater’s energy more efficiently into forward motion. Conversely, a flexible frame absorbs energy, reducing speed and responsiveness. The degree of rigidity required is dependent on the intended skating style and skill level. For example, a beginner learning basic maneuvers may benefit from a slightly more flexible frame, providing increased forgiveness and stability on uneven surfaces. A more experienced skater, engaging in aggressive skating or roller derby, necessitates a highly rigid frame for optimal power transfer and precise control during demanding maneuvers.

The material composition and design of the frame significantly impact its rigidity. Frames constructed from aluminum alloys or reinforced polymers generally offer higher rigidity compared to those made from less durable materials. Design elements, such as bracing and strategically placed reinforcement ribs, further enhance frame stiffness. Frame rigidity affects wheel alignment. A rigid frame maintains consistent wheel positioning, contributing to predictable handling and reduced wear. A frame lacking rigidity allows for wheel misalignment under load, leading to instability and uneven wear patterns on the wheels. This emphasizes the importance of selecting frames that meet the demands of the skater’s skill level and intended use.

Therefore, frame rigidity represents a critical component of classic roller skates, impacting performance, stability, and durability. Proper frame selection involves careful consideration of material properties, design features, and the skater’s individual needs. A frame that provides adequate rigidity ensures efficient power transfer, precise control, and a predictable skating experience. While a flexible frame may initially offer increased comfort, the compromise in performance and control can become a limiting factor as the skater progresses. Balancing comfort and performance is crucial when choosing classic roller skates, where frame rigidity emerges as a defining element.

6. Brake Effectiveness

Brake effectiveness is a critical safety parameter in classic roller skates. These recreational devices typically employ a toe stop or heel brake system to decelerate or halt motion. Inadequate brake effectiveness results in increased stopping distances, potentially leading to collisions or injuries. The design and condition of the braking mechanism directly influence its ability to generate sufficient friction to overcome the skater’s momentum. For instance, worn toe stops or improperly adjusted brake pads compromise the system’s functionality. Consequently, understanding the factors influencing brake effectiveness is paramount for safe operation.

Varied conditions affect brake performance. Wet or uneven surfaces reduce friction, extending stopping distances, which demonstrates the relevance of adaptable braking proficiency for each environment. Moreover, the skater’s weight, speed, and skill level necessitate varied levels of brake force to stop safely. Consistent maintenance, including regular inspection and replacement of worn components, guarantees reliable braking performance, and improves overall safety. Practical application of this understanding includes pre-skate checks to confirm brake functionality and adherence to safe skating practices, such as maintaining adequate distances from obstacles.

Effective braking is indispensable to the safe and controlled use of classic roller skates. The condition and proper maintenance of the braking mechanism, coupled with skater awareness and skill, are paramount in minimizing risks. While advancements in skating technology have introduced alternative braking methods, the fundamental principles of friction and momentum remain relevant to all braking systems. Therefore, comprehending and prioritizing brake effectiveness is crucial for responsible participation in the recreational activity.

7. Maintenance Schedule

A structured maintenance schedule is crucial for preserving the performance, safety, and lifespan of classic roller skates. Regular attention to specific components mitigates wear, prevents malfunctions, and ensures consistent functionality. Implementing a well-defined schedule is an investment in both user safety and the longevity of the equipment.

- Bearing Cleaning and Lubrication

Bearing maintenance involves removing dirt, debris, and old lubricant, followed by the application of fresh lubricant. This process reduces friction, enabling smoother wheel rotation and increasing glide efficiency. For example, bearings exposed to outdoor elements require more frequent cleaning due to the accumulation of contaminants. Neglecting bearing maintenance leads to reduced speed, increased effort, and potential bearing failure.

- Wheel Inspection and Rotation

Regular wheel inspection identifies signs of wear, such as flat spots or uneven wear patterns. Rotating the wheels distributes wear more evenly, extending their lifespan and maintaining consistent performance. For instance, if one wheel consistently experiences greater friction during braking, rotating it to a less stressed position prolongs its usability. Failure to rotate or replace worn wheels compromises grip, stability, and overall control.

- Brake Pad/Toe Stop Assessment and Replacement

Brake pads or toe stops gradually wear down with use, diminishing their braking effectiveness. Periodic assessment of their thickness and condition is essential for maintaining adequate stopping power. Replacing worn components restores braking performance, ensuring rider safety. A skater who postpones brake pad replacement risks extended stopping distances, increasing the potential for collisions.

- Hardware Tightening and Frame Inspection

Over time, bolts and fasteners can loosen due to vibration and impact forces. Regularly tightening these components ensures structural integrity and prevents instability. Inspecting the frame for cracks or deformities identifies potential structural weaknesses. A loose bolt on the frame can compromise the alignment of the wheels, resulting in instability. Neglecting hardware maintenance can lead to equipment failure and potential injury.

These facets of the maintenance schedule are integral to the sustained performance of classic roller skates. Consistent adherence to these practices ensures safety, maximizes lifespan, and preserves the intended functionality of the equipment. Neglecting even one aspect of the maintenance schedule can compromise the overall skating experience and increase the risk of equipment failure or injury. The implementation of a proactive maintenance plan is indispensable for responsible use and long-term enjoyment.

Frequently Asked Questions About Classic Roller Skates

This section addresses common inquiries regarding the selection, maintenance, and optimal usage of traditional four-wheeled roller skates. The information provided aims to offer clarity and assist in informed decision-making.

Question 1: What distinguishes classic roller skates from inline skates?

Classic roller skates feature two wheels in the front and two in the back, offering inherent stability. Inline skates, in contrast, arrange wheels in a single line, demanding more balance and control.

Question 2: What is the appropriate durometer rating for wheels used on outdoor surfaces?

Softer wheels, typically with a durometer rating between 78A and 85A, are recommended for outdoor surfaces. This rating provides enhanced grip and shock absorption on uneven terrain.

Question 3: How frequently should the bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage and environmental conditions. Skates used regularly in dusty or wet environments require more frequent cleaning, potentially as often as monthly.

Question 4: What are the essential safety gear items for classic roller skating?

Mandatory protective gear includes a helmet, wrist guards, elbow pads, and knee pads. These items mitigate the risk of injury during falls or collisions.

Question 5: How does frame material impact the performance of classic roller skates?

Frames constructed from aluminum alloys or reinforced polymers offer greater rigidity, facilitating more efficient power transfer and improved control compared to frames made from less durable materials.

Question 6: When should brake pads or toe stops be replaced?

Brake pads or toe stops should be replaced when their thickness is visibly reduced or when braking performance diminishes noticeably. Neglecting replacement compromises safety.

These FAQs highlight the importance of informed selection, consistent maintenance, and safety-conscious practices. Understanding these principles contributes to a more enjoyable and secure skating experience.

The subsequent section will explore resources for locating reputable retailers and qualified instructors, aiding in the pursuit of this recreational activity.

Conclusion

This exposition has illuminated key aspects relevant to classic roller skates. It highlighted the importance of wheel composition, boot comfort, bearing quality, frame rigidity, brake effectiveness, and a consistent maintenance schedule. Each element contributes significantly to the performance, safety, and longevity of the equipment.

The informed selection, diligent maintenance, and responsible use of these recreational devices ensure a safe and fulfilling experience. Further exploration of advanced techniques and innovative designs within the field will undoubtedly continue to enhance the capabilities and appeal of this enduring form of wheeled locomotion.