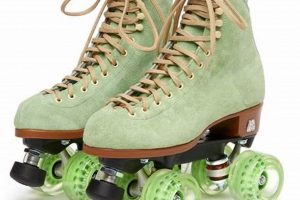

This equipment encompasses wheeled boots designed for locomotion on surfaces, coupled with items intended to mitigate potential injury during use. Examples include helmets, wrist guards, elbow pads, and knee pads, all crucial for user safety.

The combination offers a recreational and sporting activity that promotes physical fitness, balance, and coordination. Historically, advancements in materials and design have enhanced both performance and safety, broadening accessibility across age groups and skill levels. Furthermore, the use of safeguards reduces the risk of fractures, abrasions, and head trauma, allowing participants to engage with greater confidence.

The subsequent sections will delve into specific types of wheeled boots, a detailed analysis of relevant safety equipment standards, and best practices for their effective and responsible application.

Usage Guidance

The following guidelines address the proper utilization and maintenance of wheeled boots and associated safety apparatus, aiming to maximize both enjoyment and personal well-being.

Tip 1: Always select equipment appropriate for the intended activity. Aggressive skating requires more robust wheeled boots and heavier-duty safeguards compared to recreational rolling.

Tip 2: Ensure a snug, but comfortable, fit for all safeguarding components. Loose fitting components offer diminished impact protection.

Tip 3: Routinely inspect wheeled boots for wear and tear, paying particular attention to wheel integrity, brake condition, and fastener security. Replace worn parts promptly.

Tip 4: Practice in a controlled environment, such as a designated skating area or smooth, flat surface, before attempting more challenging maneuvers or navigating public spaces.

Tip 5: Develop fundamental skills, including proper stance, balance, and braking techniques. Consistent practice builds confidence and reduces the likelihood of accidents.

Tip 6: Be aware of the surroundings. Maintain a safe distance from pedestrians, cyclists, and vehicular traffic. Obey all posted signage and regulations.

Tip 7: Clean safeguards regularly with mild soap and water to remove dirt and perspiration, which can degrade material performance over time.

Adhering to these recommendations will contribute to a safer and more rewarding experience. Proper attention to equipment and technique significantly mitigates potential risks.

The subsequent section will address common pitfalls and frequently asked questions related to wheeled boot use and safety precautions.

1. Proper Fit

The correct sizing and securement of wheeled boots and safety apparatus are paramount to their effective function and the user’s safety. Ill-fitting equipment compromises protection and can directly contribute to accidents and injuries.

- Roller Skate Stability

Wheeled boots must fit snugly to the foot to provide adequate ankle support and prevent excessive movement within the boot. Overly loose boots can lead to instability, increasing the risk of falls and ankle sprains. Conversely, boots that are too tight can restrict circulation and cause discomfort, ultimately affecting performance and concentration.

- Helmet Security

A helmet’s effectiveness is contingent upon its ability to remain in place during impact. A helmet that is too large or improperly fastened may shift or detach upon impact, leaving the head vulnerable. The helmet should sit level on the head, covering the forehead, and the straps should be adjusted to create a secure and comfortable fit beneath the chin.

- Padding Placement and Coverage

Wrist guards, elbow pads, and knee pads are designed to shield specific joints from impact. If these safeguards are too large, they can slip out of position during a fall, exposing the joint to injury. Conversely, if they are too small, they may not provide adequate coverage. Correct fit ensures that the padding remains centered over the intended area of protection throughout the activity.

- Range of Motion

While a secure fit is essential, it should not unduly restrict movement. Overly tight safeguards can impede circulation, reduce flexibility, and hinder performance. A proper fit allows for a full range of motion without compromising protection. The user should be able to bend and extend their limbs comfortably while wearing the equipment.

In summary, attention to precise fitting across all elements of wheeled boot equipment directly influences user safety and performance. Neglecting this aspect significantly elevates the risk of injury, regardless of equipment quality or skating skill level.

2. Impact Absorption

Impact absorption is a critical performance characteristic of protective gear associated with wheeled boot activities. This function describes the capacity of materials to dissipate kinetic energy generated during a fall or collision, reducing the force transmitted to the wearer’s body. Insufficient impact absorption leads directly to increased risk of injury, ranging from minor abrasions to severe fractures and head trauma. For example, a helmet constructed with high-density foam is designed to compress upon impact, absorbing energy that would otherwise be transferred to the skull.

Materials commonly employed for enhanced impact absorption in safeguard equipment include expanded polystyrene (EPS) foam, polyurethane foams, and various composite materials. The effectiveness of these materials is typically measured through standardized testing procedures, such as those established by ASTM International or the European Committee for Standardization (CEN). These tests simulate real-world impact scenarios to assess the force reduction capabilities of the safeguarding. The results provide a quantifiable measure of the level of protection offered, assisting consumers in making informed choices. Furthermore, the design and construction of the safeguarding also play a crucial role. Strategically placed padding and multi-layered constructions can further enhance impact absorption capabilities.

In conclusion, impact absorption is a fundamental attribute of safeguards equipment and an indispensable factor in mitigating injury risk during wheeled boot activities. Continued advancements in material science and design are vital for improving impact absorption performance and ensuring the safety of participants. Awareness of these features and proper equipment selection are key to maximizing the benefits of safeguard applications.

3. Durability

Durability, the capacity of wheeled boots and their protective components to withstand wear, degradation, and potential damage over extended use, directly affects safety and cost-effectiveness. The lifespan and reliability of this equipment are inextricably linked to the materials and construction methods employed.

- Material Selection and Longevity

The choice of materials significantly influences the resilience of wheeled boots and safeguard. High-impact plastics, reinforced nylon, and durable metal alloys enhance the structural integrity of the boot frame and chassis. Similarly, abrasion-resistant fabrics and robust padding materials extend the life of protective components. For example, a wheeled boot with a metal frame will typically outlast one constructed primarily of plastic, and safeguard utilizing high-density foam will offer prolonged protection compared to those with less substantial padding.

- Construction and Assembly Quality

The manner in which the equipment is assembled directly impacts its ability to endure stress and impact. Reinforced stitching in safeguard, precision bearings in wheeled boots, and robust fastening systems all contribute to overall durability. Poor construction, such as weak seams or improperly aligned components, can lead to premature failure and compromise safety. For example, a helmet with a poorly bonded shell and liner may separate upon impact, rendering it ineffective.

- Environmental Factors and Degradation

Exposure to environmental elements, such as sunlight, moisture, and extreme temperatures, can accelerate the degradation of materials used in wheeled boots and safeguard. Ultraviolet radiation can cause plastics to become brittle, while moisture can promote corrosion in metal components. Proper storage and maintenance practices can mitigate these effects, extending the lifespan of the equipment. Regularly cleaning and storing wheeled boots and safeguard in a cool, dry place reduces the risk of premature deterioration.

- Usage Intensity and Wear Patterns

The frequency and intensity of use directly influence the rate at which wheeled boots and safeguard experience wear and tear. Aggressive skating styles and frequent use on rough surfaces will accelerate the degradation process. Regular inspection of components, such as wheels, bearings, and padding, allows for timely replacement of worn parts, preventing more extensive damage. Replacing worn wheels on wheeled boots can prevent damage to the frame, while replacing compressed padding in safeguards maintains impact absorption capabilities.

The durability of wheeled boots and safeguard is not merely a matter of convenience but a critical aspect of safety and economic viability. Investing in high-quality, durable equipment and adhering to proper maintenance practices minimizes the risk of failure and ensures reliable protection over time. This approach represents a responsible commitment to both personal well-being and long-term value.

4. Visibility

Visibility, in the context of wheeled boots and associated safety apparatus, refers to the degree to which a skater is discernible to other individuals, particularly in environments with limited lighting conditions or high traffic density. Adequate visibility is crucial for preventing collisions and ensuring the safety of skaters and those around them.

- Reflective Materials and Clothing

The incorporation of reflective materials into wheeled boot equipment and skater apparel significantly enhances visibility, particularly during nighttime or low-light conditions. Reflective strips or panels on wheeled boots, helmets, and clothing reflect light from external sources, such as vehicle headlights, making the skater more noticeable. These materials adhere to established standards for retroreflectivity, ensuring adequate light return to the source. Examples include the use of 3M Scotchlite material on safety vests and helmet decals. This application is vital for skaters navigating roadways or shared pathways after dark.

- High-Contrast Colors and Apparel

The use of brightly colored apparel, especially fluorescent shades, enhances visibility during daylight hours. High-contrast colors, such as neon yellow, orange, or pink, stand out against the background and make the skater more easily identifiable. This is particularly important in environments with visually complex backgrounds, such as urban areas or wooded trails. Fluorescent colors absorb ultraviolet and visible light, then re-emit the light at a longer wavelength, making them appear brighter than ordinary colors. This increased visibility is especially crucial in areas with pedestrian and vehicular traffic.

- Active Lighting Systems

The integration of active lighting systems, such as LED lights, into wheeled boots and safeguard offers an additional layer of visibility, particularly during nighttime or low-light conditions. LED lights can be incorporated into helmets, wrist guards, and wheeled boot frames, providing a constant source of illumination. These lights can be set to various modes, including flashing or steady-on, to further enhance visibility. Active lighting systems are particularly effective in urban environments, where they can help skaters stand out against the backdrop of city lights. For instance, LED lights embedded within the wheels of roller skates improve the skater’s presence.

- Environmental Awareness and Route Planning

Skaters must assess environmental conditions and plan their routes accordingly to maximize visibility and minimize risks. Avoiding skating in areas with poor lighting or high traffic density during peak hours can reduce the likelihood of collisions. Choosing routes with dedicated bike lanes or well-lit sidewalks can also enhance safety. Environmental awareness also includes considering weather conditions, such as fog or rain, which can significantly reduce visibility. Planning routes that prioritize safety and visibility is crucial for preventing accidents.

In summation, enhancing visibility through a combination of reflective materials, high-contrast colors, active lighting systems, and environmental awareness is paramount for ensuring the safety of skaters. Incorporating these elements into wheeled boot equipment and skating practices significantly reduces the risk of accidents and promotes a safer skating environment for all.

5. Mobility

Mobility, concerning wheeled boots and their associated safety components, denotes the degree of unrestricted movement afforded to the user while maintaining adequate protection. A balance between safeguarding and agility is essential for optimal performance and safety.

- Range of Motion and Padding Design

Protective equipment must allow a sufficient range of motion to enable necessary skating maneuvers. Overly restrictive padding hinders agility and increases the risk of falls. The design of knee pads, elbow pads, and wrist guards should incorporate flexible materials and articulated joints to permit natural movement while providing impact protection. Ill-fitting components compromise mobility and potentially create hazardous situations. For example, a wrist guard that excessively limits wrist flexion inhibits balance adjustments and increases the chance of upper extremity injuries.

- Weight and Equipment Burden

The overall weight of wheeled boots and safety apparatus directly impacts user fatigue and maneuverability. Heavier equipment requires more energy to operate and can reduce agility, particularly during prolonged use or complex maneuvers. Lightweight materials, such as carbon fiber composites and advanced polymers, can reduce the weight burden without compromising protection. Minimizing the weight of equipment translates to improved endurance and reduced risk of fatigue-related errors. For instance, a lighter helmet reduces strain on the neck muscles, minimizing fatigue during extended skating sessions.

- Aerodynamics and Drag Reduction

Aerodynamic considerations become increasingly relevant at higher speeds. Bulky or poorly designed safety apparatus can increase drag, reducing efficiency and stability. Streamlined designs and smooth surface finishes minimize air resistance, allowing skaters to maintain higher speeds with less effort. Optimizing aerodynamic properties is especially critical for competitive skating disciplines, where even small reductions in drag can significantly impact performance. An example includes form-fitting clothing, designed to reduce wind resistance, often used in speed skating.

- Adjustability and Individual Fit

Equipment that is adjustable to individual body types and preferences enhances both mobility and comfort. Adjustable straps, buckles, and liners allow skaters to customize the fit of their wheeled boots and safeguard, ensuring a secure and comfortable fit that does not restrict movement. This adaptability is particularly important for younger skaters, who may experience rapid growth spurts. Adjustable helmets and pads accommodate growth, extending the lifespan of the equipment and maintaining adequate protection. Customizable components lead to a more streamlined and comfortable skating experience.

These facets of mobility collectively influence the overall experience of using wheeled boots. Prioritizing both protection and ease of movement is essential for optimizing performance, reducing fatigue, and minimizing the risk of injury. Advanced designs and materials continually improve the balance between these crucial factors, leading to safer and more enjoyable skating experiences.

6. Maintenance

Scheduled and diligent upkeep of wheeled boots and accompanying safety equipment is paramount to ensuring both prolonged functionality and sustained user safety. Neglecting routine maintenance can compromise the integrity of components, leading to diminished performance and heightened risk of injury.

- Wheel and Bearing Maintenance

Wheels and bearings are crucial components that directly affect the performance and handling of wheeled boots. Periodic cleaning and lubrication of bearings minimize friction, optimize roll speed, and prevent premature wear. Regular rotation of wheels ensures even wear distribution, extending their lifespan. Neglecting these procedures results in reduced speed, increased effort, and potential bearing failure, leading to abrupt stops or instability. For instance, dirt and debris accumulating within bearings can cause them to seize, hindering wheel rotation and compromising control.

- Fastener and Closure System Inspection

Fasteners, buckles, and straps secure wheeled boots and safety components to the user. Routine inspection of these systems identifies potential weaknesses, such as worn straps, damaged buckles, or loose screws. Addressing these issues promptly prevents equipment failure during use, minimizing the risk of falls and injuries. A loose buckle on a helmet, for example, compromises its ability to protect the head during impact.

- Padding and Shell Integrity

The padding and outer shells of helmets, wrist guards, elbow pads, and knee pads provide critical impact protection. Regular inspection of these components identifies cracks, tears, or compression that may compromise their ability to absorb energy during a fall. Replacing damaged padding or shells maintains the integrity of the protection system. Compressed foam in a helmet, for example, loses its ability to effectively cushion impact forces, increasing the risk of head injury.

- Cleaning and Storage Practices

Proper cleaning and storage protect wheeled boots and safety apparatus from environmental damage. Removing dirt, sweat, and debris prevents material degradation and corrosion. Storing equipment in a cool, dry place away from direct sunlight and extreme temperatures extends its lifespan. Leaving wheeled boots and helmets exposed to direct sunlight can cause plastic components to become brittle, compromising their structural integrity. Consistent cleaning and storage practices preserve the functionality and appearance of the equipment.

The relationship between meticulous maintenance and the sustained efficacy of wheeled boot equipment is undeniable. Adherence to a regular maintenance schedule and diligent attention to detail ensures that these items continue to provide the intended level of performance and protection, enhancing the safety and enjoyment of wheeled boot activities.

7. Certification

Certification plays a pivotal role in ensuring the safety and reliability of wheeled boots and associated safeguards. It represents an independent verification process, attesting that these products meet specific performance standards and safety requirements. The presence of certification marks provides consumers with assurance regarding product quality and intended functionality.

- Standards Development and Compliance

Certification relies on the establishment of rigorous performance criteria and testing methodologies. Organizations such as ASTM International (American Society for Testing and Materials) and the European Committee for Standardization (CEN) develop standards for wheeled boots and safety equipment. Certification bodies then assess products against these standards to verify compliance. For instance, helmets intended for wheeled sports must meet impact resistance and retention system strength requirements defined by ASTM F1447 or EN 1078. Compliance ensures that products offer a defined level of protection.

- Independent Testing and Verification

Certification involves independent testing conducted by accredited laboratories or certification organizations. These entities rigorously evaluate products to ensure they meet the requirements outlined in the relevant standards. Testing may include impact testing, penetration resistance assessments, strap strength evaluations, and materials analysis. The results of these tests determine whether a product qualifies for certification. Independent verification provides an objective assessment of product performance, minimizing the potential for bias or misrepresentation.

- Traceability and Accountability

Certification often includes provisions for traceability and accountability. Certified products are typically marked with a certification symbol or identification number, allowing consumers to verify the product’s certification status and identify the certifying body. This traceability enables manufacturers to be held accountable for product quality and adherence to standards. In cases of product recalls or safety concerns, traceability facilitates the identification and removal of affected products from the market. Accountability reinforces the responsibility of manufacturers to uphold safety standards.

- Continuous Monitoring and Recertification

Certification is not a one-time event but rather an ongoing process. Certification bodies conduct periodic audits and retesting to ensure that manufacturers maintain compliance with standards. This continuous monitoring helps to identify and address any changes in product design, materials, or manufacturing processes that could affect safety or performance. Recertification ensures that products continue to meet current standards and that manufacturers remain committed to quality control. The ongoing nature of certification reinforces its effectiveness as a safeguard for consumers.

In conclusion, certification serves as a critical mechanism for promoting safety and quality in the realm of wheeled boots and safety equipment. Through standards development, independent testing, traceability, and continuous monitoring, certification provides consumers with a greater degree of confidence in the products they purchase and use. The presence of certification marks indicates that a product has undergone rigorous evaluation and meets established safety criteria, contributing to a safer and more enjoyable experience for wheeled boot enthusiasts.

Frequently Asked Questions About Roller Skates and Protective Gear

The following addresses common inquiries regarding the selection, use, and maintenance of wheeled boots and associated safety apparatus. This information aims to enhance understanding and promote safe practices.

Question 1: How does one determine the appropriate size for wheeled boots?

Accurate sizing requires measuring the foot’s length and width, comparing the dimensions against the manufacturer’s sizing chart. It is advisable to try on wheeled boots with socks of similar thickness to those typically worn during use. A snug, but comfortable, fit is essential.

Question 2: What certifications should one look for when purchasing a helmet?

Helmets intended for wheeled sports should comply with standards such as ASTM F1447 (U.S.) or EN 1078 (Europe). These certifications indicate that the helmet has undergone testing to meet minimum impact resistance and retention system requirements.

Question 3: How often should wheeled boot wheels be rotated?

Wheel rotation frequency depends on usage patterns and surface conditions. However, a general recommendation is to rotate wheels after every 10-15 hours of use to ensure even wear and prolong wheel life. Uneven wear affects stability and performance.

Question 4: What is the proper method for cleaning wheeled boot bearings?

Bearing cleaning involves removing the bearings from the wheels, disassembling them (if possible), and cleaning them with a solvent designed for bearings. After cleaning, the bearings should be lubricated with a bearing-specific lubricant before reassembly.

Question 5: What are the signs that protective padding needs replacement?

Protective padding should be replaced if it exhibits signs of compression, tearing, or loss of elasticity. Any damage that compromises the padding’s ability to absorb impact necessitates replacement. Compromised padding offers diminished protection.

Question 6: How should wheeled boots and safety apparatus be stored when not in use?

Wheeled boots and protective equipment should be stored in a cool, dry place away from direct sunlight and extreme temperatures. This minimizes material degradation and extends the lifespan of the equipment. Proper storage prevents premature deterioration.

Proper understanding of these key aspects can improve the safety and longevity of both wheeled boots and protective equipment, leading to a more secure and enjoyable experience.

The subsequent section will provide a glossary of relevant terms related to wheeled boots and safety safeguards.

Conclusion

The preceding discussion has elucidated various facets of roller skates and protective gear, ranging from material composition and design considerations to standards compliance and user maintenance. A comprehensive understanding of these elements is critical for maximizing both the performance and safety attributes associated with these products.

Prioritizing informed decision-making, adherence to best practices, and commitment to regular equipment upkeep are essential steps in mitigating risks and cultivating a responsible approach to wheeled activities. Continued advancements in materials science and engineering offer ongoing opportunities to enhance the protective capabilities and user experience associated with roller skates and protective gear. This diligence fosters a safer environment for all participants.