Protective elements affixed to the front of roller skates safeguard the boot’s vulnerable area from abrasion and impact. These components, generally constructed from durable materials like leather, rubber, or synthetic polymers, are designed to absorb shocks and resist wear caused by contact with skating surfaces. For example, a skater performing tricks or navigating uneven terrain benefits from this added layer of defense against scuffs and damage.

The incorporation of such safeguarding features enhances the longevity of the roller skate, mitigating potential repair costs and maintaining aesthetic appeal. Historically, rudimentary versions of these were employed to prolong the life of leather boots. The modern iterations not only provide protection but also offer opportunities for customization through various colors and designs, allowing skaters to personalize their equipment. They also provide skaters a degree of control when performing artistic skating moves.

Understanding the material composition, proper installation techniques, and maintenance practices related to these essential skate accessories is crucial for optimizing performance and ensuring the continued protection of the skate itself. This article will explore these facets in greater detail, providing a comprehensive overview of selection criteria, upkeep procedures, and the broader implications for skate durability.

Optimizing Roller Skate Protection

The following guidelines are intended to assist in maximizing the protective capabilities and lifespan of forward boot coverings on roller skates.

Tip 1: Material Selection: Opt for components crafted from durable materials such as high-grade leather or reinforced polymers. These materials offer superior abrasion resistance and impact absorption, crucial for safeguarding the boot during rigorous use.

Tip 2: Secure Attachment: Ensure that the protective covering is securely fastened to the roller skate boot. Loose or improperly fitted elements provide inadequate protection and may detach during use. Consider using reinforced stitching or robust adhesive solutions for a secure connection.

Tip 3: Regular Inspection: Conduct routine inspections of the coverings for signs of wear, tear, or damage. Promptly address any issues, such as frayed edges or cracks, to prevent further degradation and maintain optimal protective performance.

Tip 4: Cleaning and Maintenance: Implement a regular cleaning regimen to remove dirt, debris, and contaminants that can accelerate wear and tear. Use appropriate cleaning agents specific to the material of the covering. Regular maintenance will extend the lifespan of the protective element.

Tip 5: Strategic Replacement: Replace worn or damaged protective coverings promptly to ensure continuous protection. Ignoring signs of degradation can compromise the structural integrity of the skate boot and increase the risk of injury.

Tip 6: Consider Skate Style: The style of skating impacts the type of front protection needed. Aggressive skating may require heavier-duty materials and reinforced designs, while recreational skating may benefit from lighter, more flexible options.

Tip 7: Evaluate Coverage Area: Ensure that the chosen covering provides adequate coverage of the skate boot’s vulnerable areas. A larger coverage area offers greater protection against impacts and abrasions from various angles.

Implementing these strategies will contribute significantly to preserving the structural integrity of roller skates and enhancing skater safety. Prioritizing preventative maintenance and timely replacements maximizes the return on investment in skating equipment.

The subsequent sections will address advanced topics related to customization and performance enhancement.

1. Material Durability

Material durability directly influences the protective efficacy and longevity of a roller skate boots front covering. A component constructed from a weak or easily degraded material will provide insufficient protection against abrasion, impact, and the elements. This deficiency can lead to premature wear, compromising the structural integrity of the skate boot itself. For example, a covering made from low-grade synthetic leather will quickly succumb to scuffs and tears, particularly during aggressive skating disciplines involving frequent contact with rough surfaces. Conversely, a covering employing high-grade leather or reinforced polymer composites offers superior resistance to these damaging forces, extending the component’s lifespan and ensuring sustained boot protection.

The selection of durable materials is not merely a matter of extending the product’s lifespan; it is intrinsically linked to skater safety. Compromised protection can increase the risk of injury to the foot and ankle during falls or collisions. The initial investment in a component featuring high material durability can thus mitigate the need for frequent replacements and potentially prevent costly medical expenses. Furthermore, certain materials offer enhanced resistance to environmental factors such as moisture and UV radiation, further prolonging the protective components usability. Leather can provide superior protection against abrasion, as a high-grade leather covering can survive impacts that would tear open a synthetic alternative. Certain reinforced polymers are also extremely durable and resilient.

In summary, the material composition and inherent durability represent a critical factor in the overall performance of a roller skates front covering. Prioritizing durable materials is essential for maximizing protection, extending product life, and ultimately enhancing skater safety. The understanding of material properties and their impact on performance is thus a fundamental aspect of informed skate equipment selection.

2. Impact Absorption

Impact absorption is a primary function of a protective component located on the front of a roller skate, mitigating the force transmitted to the skate boot and, by extension, the skater’s foot and ankle. The effectiveness of this impact absorption is directly correlated with the material composition and structural design of the component. A poorly designed or constructed protective element will fail to adequately dissipate energy from collisions, potentially leading to injury. For example, a skater colliding with an obstacle during a fall relies on the component to cushion the blow, reducing the risk of bone contusions, sprains, or fractures. Therefore, the capacity for impact absorption is not merely a desirable attribute, but a fundamental requirement for skater safety.

Materials such as dense rubber or specialized foams are often incorporated into protective features to maximize their ability to absorb impacts. These materials deform upon contact, converting kinetic energy into other forms, such as heat, thereby reducing the peak force experienced by the skate boot. The thickness and density of the material, along with the overall shape of the feature, influence the degree of protection afforded. Advanced designs may incorporate layered materials with varying densities to optimize energy dissipation across a range of impact forces. The presence of air pockets or strategically placed grooves can also enhance impact absorption by allowing the material to compress more effectively.

In summary, impact absorption is an indispensable characteristic of a protective component. A properly designed and constructed element significantly reduces the risk of injury by attenuating impact forces during falls and collisions. Understanding the material properties and structural design principles that govern impact absorption is crucial for both skaters and manufacturers to ensure the selection and production of safe and effective skating equipment.

3. Attachment Security

Attachment security, concerning protective elements affixed to roller skates, directly dictates the efficacy of these safeguarding components. The method by which these elements are secured to the skate boot critically influences their ability to perform their intended function. Compromised attachment can render the protection negligible, regardless of material quality or design.

- Stitching Integrity

Stitching, where applicable, represents a primary means of securing protective elements. Robust, properly executed stitching resists detachment under stress. Inferior stitching, characterized by weak thread or inadequate stitch density, is prone to failure, particularly during high-impact events. A broken seam compromises the structural integrity, leaving the boot vulnerable.

- Adhesive Bond Strength

Adhesive bonding serves as an alternative or supplementary attachment method. The adhesive employed must exhibit sufficient shear strength and flexibility to withstand the dynamic forces encountered during skating. Premature adhesive failure results in detachment, negating the intended protective function. Environmental factors, such as temperature and moisture, can influence adhesive bond strength.

- Hardware Reliability

Certain protective elements incorporate hardware, such as rivets or screws, for securement. The quality and installation of this hardware directly impact attachment security. Loose or corroded hardware compromises the connection, increasing the risk of detachment. Regular inspection and maintenance of hardware are essential for sustained security.

- Interface Compatibility

The design of the protective element and the skate boot must ensure a compatible interface. Incompatibility, resulting from mismatched contours or inappropriate dimensions, can hinder secure attachment. Proper alignment and surface preparation are crucial for achieving optimal bonding or mechanical fastening. Incompatible interfaces compromise the overall protective system.

The interconnectedness of stitching integrity, adhesive bond strength, hardware reliability, and interface compatibility underscores the multifaceted nature of attachment security. Adequate consideration of each facet is crucial for ensuring the reliable performance of protective additions, thereby safeguarding the roller skate boot from damage and potentially reducing the risk of skater injury.

4. Wear Resistance

Wear resistance, concerning the protective covering on roller skate boots, denotes the material’s capacity to withstand surface degradation resulting from friction, abrasion, and impact. This attribute is directly proportional to the component’s lifespan and its ability to consistently shield the skate boot from damage.

- Material Composition and Hardness

The intrinsic hardness and composition of the material dictate its resistance to scratching and abrasion. Materials such as high-grade leather, reinforced polymers, and certain synthetic rubbers exhibit superior wear resistance compared to softer or more pliable alternatives. For example, a skate covering constructed from ballistic nylon will demonstrate greater resistance to scuffs and tears than one made from standard canvas. The choice of material significantly influences the protective efficacy over time.

- Surface Treatment and Coatings

Surface treatments and coatings can augment the wear resistance of a protective skate covering. Applied coatings create a sacrificial layer that absorbs abrasion, shielding the underlying material. Examples include polyurethane coatings or specialized treatments that enhance the material’s resistance to UV degradation and chemical exposure. These surface modifications extend the component’s lifespan and maintain its aesthetic appeal.

- Structural Design and Reinforcement

The structural design of the protective covering, including the presence of reinforcement elements, contributes to its overall wear resistance. Reinforced stitching, strategically placed padding, and the incorporation of high-density materials in critical wear areas enhance the component’s ability to withstand stress and impact. For instance, a covering featuring double-layered construction in the toe region will exhibit greater resistance to abrasion during toe stops and similar maneuvers.

- Environmental Factors and Maintenance

Environmental factors, such as exposure to moisture, sunlight, and abrasive surfaces, significantly impact the wear resistance of a protective skate covering. Proper maintenance, including regular cleaning and the application of protective treatments, mitigates the effects of these factors and extends the component’s lifespan. Neglecting maintenance can accelerate degradation and compromise the covering’s ability to effectively protect the skate boot.

The interplay of material composition, surface treatment, structural design, and environmental factors collectively determines the wear resistance of a protective covering. Selecting a component with inherently high wear resistance and implementing a proactive maintenance regimen are critical for maximizing the lifespan and protective capability of this essential skating accessory.

5. Boot Coverage

Boot coverage, in the context of protective elements for roller skates, refers to the extent to which the protective covering shields the boot from abrasion, impact, and environmental elements. The roller skate toe cap, a specialized protective component, directly contributes to this coverage by specifically addressing the vulnerable front portion of the boot. Inadequate coverage in this region can lead to premature wear and potential damage to the boot’s structural integrity. The toe cap, therefore, serves as a critical element in achieving comprehensive boot coverage. For example, without a properly sized and affixed toe cap, the boot’s toe area is susceptible to scuffs, scrapes, and more severe damage during maneuvers involving ground contact, such as toe stops or falls.

The effectiveness of the toe cap in providing adequate boot coverage is further determined by its design and material properties. A toe cap that only covers a minimal area may offer limited protection against impacts from certain angles or specific types of hazards. Similarly, a toe cap constructed from a material lacking sufficient abrasion resistance will quickly degrade, diminishing its protective capabilities. Skaters engaging in aggressive skating styles or those frequently skating on rough surfaces require toe caps that offer enhanced coverage and robust material construction to ensure sustained protection. The toe cap’s design can also contribute to even more coverage to the toe and even the top portion of the boot.

Understanding the relationship between boot coverage and the roller skate toe cap is crucial for skaters seeking to optimize the protection of their equipment. By carefully selecting toe caps that offer adequate coverage and durable construction, skaters can significantly extend the lifespan of their boots and mitigate the risk of damage resulting from typical skating activities. Challenges exist in balancing the need for comprehensive coverage with considerations such as weight and flexibility. The ultimate goal is to select a toe cap that provides effective protection without unduly compromising the skater’s performance or comfort, ultimately leading to an overall better and safer skating experience.

6. Skate Style

Skate style significantly influences the demands placed upon the roller skate and, consequently, the selection and implementation of appropriate protective elements. This includes the design and material composition of protective toe coverings.

- Aggressive Skating

Aggressive skating, characterized by high-impact maneuvers, frequent contact with ramps and rails, and a high risk of falls, necessitates robust protective elements. Toe coverings designed for this style typically feature reinforced materials, such as heavy-duty leather or high-density polymers, to withstand severe abrasion and impact. Enhanced durability and secure attachment mechanisms are paramount.

- Artistic Skating

Artistic skating, encompassing disciplines such as figure skating and rhythm skating, places a premium on precision and aesthetics. Toe coverings in this context often prioritize a streamlined design and flexible materials to facilitate intricate footwork. While impact resistance remains important, the emphasis shifts towards minimizing interference with the skater’s performance and maintaining visual appeal. Specialized toe plugs, rather than complete coverings, are often used.

- Recreational Skating

Recreational skating, generally conducted on smooth surfaces at moderate speeds, presents a lower risk of damage to the roller skate boot. Toe coverings for this style typically prioritize comfort and affordability. Lightweight materials, such as synthetic leather or basic rubber, are commonly employed. The focus is on providing basic protection against scuffs and scrapes while maintaining a comfortable skating experience.

- Roller Derby

Roller derby, a contact sport performed on roller skates, demands protective elements capable of withstanding frequent collisions and impacts. Toe coverings designed for roller derby often incorporate reinforced materials and extensive padding to safeguard against foot injuries. Durability and secure attachment are crucial considerations, as the coverings are subjected to significant stress during gameplay.

The selection of an appropriate toe covering should be predicated upon the specific demands imposed by the chosen skate style. Failure to align the protective element with the skating discipline can compromise both the skater’s safety and the longevity of the roller skates.

7. Aesthetic Customization

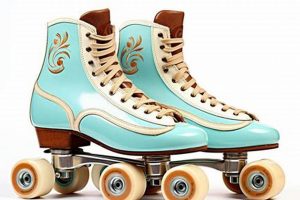

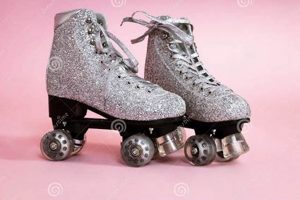

Aesthetic customization, pertaining to roller skate toe caps, represents a significant aspect of skater individuality and equipment personalization. While the primary function of a toe cap is protection, its visual design and material choices contribute directly to the overall aesthetic of the roller skate. This customization ranges from selecting colors and patterns to incorporating embellishments or unique material finishes. The cause-and-effect relationship is evident: a skater’s desire for personal expression drives the demand for diverse aesthetic options in toe cap design. Real-life examples include skaters opting for vibrant, patterned toe caps to complement their skating apparel or choosing minimalist designs for a more understated appearance. The availability of customizable toe caps allows skaters to transform functional equipment into a personalized statement, enhancing their overall skating experience. Understanding the significance of aesthetic customization allows manufacturers to cater to a wider range of preferences and market segments, offering toe caps that not only protect but also reflect individual style.

Further, the material choice in toe cap construction is not solely a matter of durability but also one of visual appeal. Leather toe caps, for instance, can be dyed in various colors and textures, offering a classic and customizable aesthetic. Synthetic materials, such as vinyl or reinforced polymers, provide opportunities for more vibrant colors and unconventional designs. The practical application of this understanding is evident in the availability of toe caps with holographic finishes, glitter overlays, or embossed patterns. Additionally, some manufacturers offer custom-printed toe caps, allowing skaters to incorporate unique graphics or logos. This level of personalization underscores the practical importance of aesthetic customization in meeting the diverse needs and desires of the skating community.

In summary, the aesthetic customization of roller skate toe caps extends beyond mere visual appeal; it represents a tangible expression of skater individuality. By offering a range of design options, material choices, and customization possibilities, manufacturers empower skaters to personalize their equipment and enhance their overall skating experience. The challenge lies in balancing aesthetic considerations with functional requirements, ensuring that customized toe caps continue to provide adequate protection while reflecting the skater’s unique style. The appreciation of how and why it exists is critical to an understanding of roller skate toe caps, in their entirety.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions surrounding roller skate toe caps, providing factual information to aid in informed decision-making.

Question 1: What is the primary function of a roller skate toe cap?

The primary function is to protect the front portion of the roller skate boot from abrasion, impact, and general wear and tear. It serves as a sacrificial layer, extending the boot’s lifespan and preventing damage from ground contact.

Question 2: Are roller skate toe caps essential for all types of skating?

While not strictly essential, toe caps are highly recommended for most types of skating, particularly those involving frequent ground contact or risk of falls. Skaters engaged in aggressive or recreational skating will benefit significantly from their use. Artistic skaters are less likely to require them.

Question 3: What materials are commonly used in the construction of roller skate toe caps?

Common materials include leather, reinforced polymers, synthetic rubbers, and occasionally, ballistic nylon. The choice of material depends on the desired balance of durability, flexibility, and aesthetic appeal.

Question 4: How should roller skate toe caps be properly installed and secured?

Installation methods vary depending on the toe cap design. Some toe caps feature elastic straps or laces for attachment, while others require adhesive bonding or the use of hardware such as rivets. Secure attachment is critical to ensure the toe cap remains in place during skating activities.

Question 5: How often should roller skate toe caps be inspected and replaced?

Regular inspection is recommended to identify signs of wear, tear, or detachment. The replacement frequency depends on the intensity of use and the quality of the materials. Replace as wear occurs and becomes significant enough that it risks damage to the boot. Severely worn toe caps should be replaced immediately to maintain adequate protection.

Question 6: Do roller skate toe caps affect skating performance or maneuverability?

Generally, properly fitted toe caps have minimal impact on skating performance. However, excessively bulky or poorly designed toe caps may impede foot movement. Select toe caps that provide adequate protection without compromising flexibility or agility.

In summary, roller skate toe caps serve a crucial role in protecting skate boots. Proper selection, installation, and maintenance are paramount for maximizing their effectiveness and ensuring skater safety.

The next section will delve into advanced customization techniques for roller skates.

Conclusion

This exploration of the roller skate toe cap has elucidated its critical role in protecting the vulnerable front portion of skate boots. Durable materials, secure attachment, and appropriate design, tailored to specific skating styles, contribute to its efficacy. The investigation highlights wear resistance, impact absorption, boot coverage, and a basic understanding of material selection.

Considering this protective component transcends mere accessory status; it directly impacts skate longevity and skater safety. Further research into advanced material technologies and ergonomic designs holds the potential to enhance the protective capabilities. It is a crucial decision in buying or assembling a roller skate, given it provides additional safety to the equipment and the person.