Protective casings designed to fit over the wheels of roller skates allow for ambulation without damaging floors or the skating surface. These accessories, typically fabricated from rubber, silicone, or similar non-marring materials, prevent direct contact between the skate wheels and the underlying surface. For example, a skater might employ these to walk through a building without scratching the floor or tracking debris onto the rink.

The implementation of these safeguards preserves the integrity of both the skating area and the surrounding environment. They offer practical advantages, reducing the need for frequent floor maintenance and minimizing the risk of accidents caused by tracking dirt or debris. Historically, such accessories were often homemade, but modern manufacturing techniques have led to standardized designs offering enhanced durability and ease of use.

This article will delve into the various types available, examine their specific applications, and provide guidance on selecting the appropriate style for different roller skate models and skating environments. Furthermore, considerations for maintenance and proper usage will be discussed, ensuring optimal performance and longevity of both the skates and the flooring.

Using Roller Skate Covers Effectively

The following guidelines offer advice for optimizing the use and maintenance of protective wheel coverings, ensuring both the longevity of the skates and the preservation of skating surfaces.

Tip 1: Select the Appropriate Material. Consider the floor surface to be traversed. Rubber provides adequate grip on smooth surfaces, while silicone may be more suitable for delicate or easily scratched floors.

Tip 2: Ensure Proper Fit. Ill-fitting accessories can slip or detach, posing a safety hazard and failing to protect the floor adequately. Measure wheel dimensions and consult product specifications to guarantee a secure fit.

Tip 3: Inspect Regularly for Wear. Examine for cracks, tears, or thinning material before each use. Damaged coverings should be replaced promptly to maintain functionality.

Tip 4: Clean After Each Use. Remove dirt, debris, or moisture to prevent deterioration and maintain optimal grip. Use a mild detergent and allow to air dry completely.

Tip 5: Store Properly. When not in use, store in a cool, dry place away from direct sunlight or extreme temperatures to prevent deformation or degradation of the material.

Tip 6: Consider the Skating Environment. For outdoor use, opt for durable materials designed to withstand abrasion from concrete or asphalt. Indoor use may warrant softer materials to minimize noise and prevent damage to sensitive flooring.

Tip 7: Practice Mounting and Dismounting. Become proficient in attaching and removing the covers without compromising balance or causing damage to the skates. A stable and controlled technique is essential.

Adhering to these guidelines will maximize the protective capabilities of wheel coverings, prolonging their lifespan and safeguarding valuable skating surfaces from unnecessary wear and tear.

The subsequent sections will provide detailed information on specific types of coverings and their applications, facilitating informed purchasing decisions.

1. Surface Protection

Surface protection constitutes a primary function of roller skate covers. Preventing damage to various floor types necessitates an understanding of materials, design, and application.

- Material Composition

The composition of the cover directly affects its ability to protect surfaces. Softer materials, such as silicone or certain rubbers, minimize scratching on delicate floors like hardwood or polished concrete. Conversely, more rigid materials may offer greater durability but pose a higher risk of surface abrasion.

- Impact Absorption

Beyond preventing scratches, the cover’s ability to absorb impact is crucial. This is particularly relevant in environments with uneven surfaces or where accidental drops are likely. Materials with higher elasticity and thickness provide greater impact absorption, reducing the risk of dents or cracks in the floor.

- Contaminant Containment

Covers also serve to contain contaminants that may be present on the skate wheels, preventing the transfer of dirt, debris, or liquids onto the floor. This is especially important in environments with strict hygiene standards or where cleanliness is paramount. Textured surfaces or integrated cleaning mechanisms can further enhance contaminant containment.

- Acoustic Dampening

The use of covers can significantly reduce the noise generated by roller skates, particularly on hard surfaces. Materials with sound-dampening properties minimize the impact sound, creating a quieter and more comfortable environment for both skaters and those in the vicinity.

These facets of surface protection highlight the multifaceted role of roller skate covers in maintaining the integrity of flooring. Selection criteria should consider the specific environment, the type of flooring, and the desired level of protection.

2. Wheel Compatibility

Wheel compatibility is a fundamental consideration in the selection and application of roller skate covers. The degree to which a cover corresponds to the dimensions and profile of a skate wheel directly influences its protective efficacy and operational safety.

- Diameter Matching

The diameter of the cover must closely align with the wheel’s outer diameter. A cover that is too small will be difficult or impossible to install, while one that is too large may slip or detach during use, negating its protective function. Variations in wheel diameter across different skate models necessitate a range of cover sizes.

- Width Accommodation

Wheel width, also known as tire profile, dictates the cover’s lateral fit. Covers designed for narrow wheels may not adequately encapsulate wider wheels, leaving portions of the wheel exposed and vulnerable to damage. Conversely, oversized covers can bunch or wrinkle, creating instability and increasing the risk of tripping.

- Hub Design Integration

The hub, or central portion of the wheel, can influence cover compatibility. Certain skate models feature protruding or uniquely shaped hubs that require covers with corresponding cutouts or flexible materials to ensure a secure fit. Failure to account for hub design may result in improper cover seating and compromised performance.

- Material Elasticity and Grip

The material properties of the cover play a crucial role in wheel compatibility. Elastic materials provide a degree of adaptability, accommodating slight variations in wheel size and shape. Adequate grip is essential to prevent slippage between the cover and the wheel surface, particularly during maneuvers such as turns or stops.

These considerations highlight the importance of careful measurement and assessment when selecting roller skate covers. Proper wheel compatibility ensures optimal protection, enhanced safety, and extended lifespan for both the skates and the surfaces on which they are used.

3. Material Durability

Material durability, in the context of roller skate covers, represents a critical determinant of product longevity, protective efficacy, and overall value. The selection of materials directly impacts the ability of these covers to withstand the rigors of repeated use, environmental exposure, and mechanical stress.

- Abrasion Resistance

Abrasion resistance defines a material’s capacity to resist wear and tear from frictional contact with surfaces. Roller skate covers fabricated from materials with low abrasion resistance will degrade rapidly, losing their protective qualities and necessitating frequent replacement. Conversely, materials such as high-density rubber or reinforced polymers exhibit superior abrasion resistance, extending the lifespan of the covers and minimizing the risk of surface damage. For example, covers used on abrasive concrete surfaces require significantly higher abrasion resistance than those intended for smooth, indoor flooring.

- Tear Strength

Tear strength measures a material’s ability to resist tearing or ripping when subjected to tensile stress. Roller skate covers are often subjected to stretching and pulling during installation and removal. Materials with inadequate tear strength are prone to tearing at stress points, rendering the cover unusable and potentially creating a safety hazard. Durable materials, such as reinforced silicone or synthetic elastomers, offer enhanced tear strength, maintaining the integrity of the cover under demanding conditions. A cover repeatedly stretched over skate wheels will exhibit premature failure if the material lacks sufficient tear strength.

- Environmental Degradation Resistance

Environmental degradation encompasses the effects of factors such as ultraviolet (UV) radiation, ozone exposure, temperature fluctuations, and chemical contact on a material’s structural integrity. Roller skate covers used outdoors are particularly susceptible to UV degradation, which can cause discoloration, embrittlement, and loss of elasticity. Materials with inherent UV resistance, or those treated with UV stabilizers, provide increased protection against these effects, ensuring long-term performance. Similarly, resistance to ozone and chemical exposure is crucial in industrial or chemically contaminated environments. Example: a roller skate cover exposed to sunlight will quickly degrade.

- Fatigue Resistance

Fatigue resistance refers to a material’s ability to withstand repeated cycles of stress without fracturing or failing. Roller skate covers undergo repeated flexing and deformation during each use cycle. Materials with low fatigue resistance will develop cracks or fissures over time, compromising their protective function. Polymers engineered for high fatigue resistance, such as thermoplastic polyurethanes (TPUs), offer superior durability under cyclic loading, prolonging the service life of the covers. A roller skate cover, used daily, will eventually begin to crack and lose elasticity due to this.

The interrelation of abrasion resistance, tear strength, environmental degradation resistance, and fatigue resistance collectively determines the overall material durability of roller skate covers. Selecting covers manufactured from materials that exhibit superior performance across these metrics ensures a prolonged lifespan, consistent protection, and reduced replacement costs, ultimately providing a more sustainable and cost-effective solution. This assessment is paramount for both individual consumers and commercial skating venues.

4. Ease of Application

Ease of application significantly influences the practical utility and adoption rate of roller skate covers. The complexity involved in fitting these protective accessories onto roller skates directly impacts user experience and the likelihood of consistent usage. If the process is cumbersome or requires specialized tools, individuals may be discouraged from using them regularly, thereby negating their intended benefits of floor protection and skate maintenance. For example, a cover design necessitating intricate adjustments or forceful stretching is less likely to be favored compared to a simpler, slip-on style. This preference stems from a desire for efficiency and convenience, particularly in situations where frequent transitions between skating and walking are required.

A primary determinant of application ease is the cover’s material composition and design. Highly elastic materials, coupled with intuitive fastening mechanisms, streamline the fitting process. Covers employing hook-and-loop closures, snap-fit systems, or simple stretch-over designs offer a more user-friendly experience than those relying on complex lacing or tightening procedures. Furthermore, clear and readily accessible instructions play a crucial role in minimizing user frustration and ensuring correct installation. The design should also consider variations in skate wheel sizes and configurations, accommodating a broad range of skate models with minimal adjustments. Instances where covers are easily applied without requiring the removal of the skate from the foot showcase the pinnacle of user-centered design.

In summation, ease of application is not merely a superficial attribute of roller skate covers but a fundamental factor driving their real-world effectiveness. Cumbersome application processes can undermine the protective and maintenance benefits they offer, leading to reduced usage and ultimately, a failure to achieve the intended goals. Therefore, designers and manufacturers must prioritize user-centric design principles to ensure that these accessories are not only effective but also convenient and accessible for a wide range of users. The challenge lies in balancing protective functionality with a streamlined application process, thereby maximizing the value proposition for consumers and promoting consistent utilization.

5. Hygiene Maintenance

Roller skate covers, while primarily designed for surface protection, play a significant role in hygiene maintenance within skating environments. The covers act as a barrier, preventing the transfer of dirt, debris, and potentially harmful microorganisms from skate wheels to clean surfaces. For example, without covers, wheels that have traversed outdoor areas can track contaminants onto indoor skating rinks or personal residences, increasing the risk of germ transmission and requiring more frequent cleaning of the skating surface. The simple act of covering the wheels effectively mitigates this transfer.

Regular cleaning of roller skate covers is crucial to their function as hygiene maintenance tools. Covers that accumulate dirt and grime become breeding grounds for bacteria and fungi, essentially negating their initial purpose. Practical examples include washing the covers with disinfectant solutions after outdoor use and allowing them to air dry completely before storage. Failure to maintain cleanliness can lead to unpleasant odors and, more importantly, contribute to the spread of pathogens. The material from which the covers are constructed also impacts hygiene; non-porous materials are easier to clean and disinfect compared to porous ones.

In summary, the connection between roller skate covers and hygiene maintenance is multifaceted. The covers serve as a preventative measure, inhibiting the spread of contaminants, while proper cleaning protocols ensure their continued effectiveness. Challenges include educating users on appropriate cleaning practices and selecting cover materials that facilitate hygiene. The implementation of these measures contributes to healthier skating environments and underscores the importance of considering hygiene as an integral aspect of roller skate cover utilization.

Frequently Asked Questions

This section addresses common inquiries regarding roller skate covers, providing detailed information to assist in informed decision-making.

Question 1: What are the primary benefits of using roller skate covers?

Roller skate covers primarily protect flooring from damage caused by skate wheels. They also prevent the transfer of dirt and debris from the wheels onto clean surfaces and may reduce noise generated during ambulation on skates.

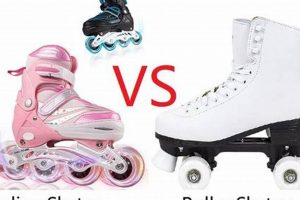

Question 2: Are roller skate covers universally compatible with all skate types?

No, roller skate covers are not universally compatible. Compatibility depends on wheel diameter, width, and hub design. It is essential to select covers specifically designed for the user’s skate model.

Question 3: How frequently should roller skate covers be cleaned?

Roller skate covers should be cleaned after each use, particularly after skating outdoors or in potentially dirty environments. Regular cleaning prevents the accumulation of dirt and bacteria and maintains their protective function.

Question 4: What materials are commonly used in the manufacture of roller skate covers, and what are their respective advantages?

Common materials include rubber, silicone, and various polymers. Rubber offers good grip and durability. Silicone provides superior surface protection and flexibility. Polymers offer a balance of durability and cost-effectiveness. The selection depends on intended use and flooring type.

Question 5: How does the material impact the longevity of the product?

The chosen material significantly affects product lifespan. Materials with high abrasion resistance and tear strength, such as reinforced polymers, exhibit greater longevity compared to less durable options like thin, inexpensive rubber. Environmental factors, such as UV exposure, also play a role.

Question 6: What are the key indicators that roller skate covers need to be replaced?

Key indicators include visible wear and tear, such as cracks, tears, or thinning material. Slippage during use or difficulty maintaining a secure fit also indicates the need for replacement. Compromised material integrity diminishes their protective capabilities.

Roller skate covers provide a valuable safeguard for flooring and enhance hygiene within skating environments. Understanding their proper application, maintenance, and material properties is crucial for maximizing their effectiveness.

The following section will delve into selecting the right roller skate covers for various skating environments and purposes.

Conclusion

This exploration has underscored the significance of roller skate covers as protective and hygienic accessories. Key aspects examined include surface protection capabilities, wheel compatibility considerations, the importance of material durability, ease of application factors, and hygiene maintenance requirements. Each of these facets contributes to the overall effectiveness and value proposition of these products.

The selection and utilization of appropriate roller skate covers represent a proactive measure in safeguarding valuable surfaces and promoting a cleaner, safer skating experience. Continued innovation in materials and design will further enhance their functionality and broaden their applicability, solidifying their role as an essential component for both recreational and professional roller skating. The responsible implementation of these measures remains paramount for preserving infrastructure and optimizing skating environments.