A mechanism integrated into roller skates designed to decelerate or halt motion. Typically, this involves a rubber or composite material pad positioned at the front of one or both skates. Application is achieved by tilting the foot forward, causing the pad to make contact with the ground, generating friction and reducing speed. Variations include heel-mounted designs common on inline skates and specialized systems used in artistic or competitive skating.

Their incorporation is essential for skater safety, enabling controlled speed reduction and preventing collisions. Historically, rudimentary stopping methods, such as dragging a foot, were replaced by more effective and reliable mechanical solutions as roller skate technology advanced. Modern advancements focus on improving responsiveness, durability, and user-friendliness, reflecting the ongoing commitment to injury prevention and enhanced skating experiences. Furthermore, proper maintenance ensures optimal functionality and extends the lifespan of the equipment, directly impacting skater confidence and control.

The following sections will delve into the various types of these mechanisms, explore their functionalities, detail maintenance procedures, and provide guidance on selecting the most suitable option based on individual skating styles and needs.

Essential Usage and Maintenance Guidelines

Maximizing the effectiveness and longevity of stopping mechanisms on roller skates requires adherence to specific usage and maintenance protocols. Neglecting these protocols can compromise safety and reduce equipment lifespan.

Tip 1: Regular Inspection is Crucial: Examine the pads for wear and tear prior to each use. Worn or damaged pads significantly reduce stopping power and increase the risk of accidents. Replace components exhibiting excessive degradation.

Tip 2: Implement Proper Adjustment Techniques: Confirm the stopping component is correctly positioned and securely fastened. Misalignment can lead to uneven wear and inefficient braking. Consult the manufacturers guidelines for accurate adjustment procedures.

Tip 3: Utilize Appropriate Technique: Employ a controlled, gradual application of pressure when engaging. Abrupt or forceful engagement can cause skidding and loss of control, particularly on uneven surfaces.

Tip 4: Practice in a Controlled Environment: Before navigating public areas, practice applying and modulating pressure in a safe, obstacle-free zone. Develop muscle memory and refine technique to ensure confident and predictable stopping performance.

Tip 5: Surface Conditions Influence Performance: Be cognizant of the impact of varying surfaces on effectiveness. Wet, sandy, or oily surfaces will diminish friction and necessitate increased stopping distance. Adjust speed and technique accordingly.

Tip 6: Periodic Cleaning is Recommended: Remove accumulated dirt, debris, and contaminants from the pad surface with a mild cleaning solution. This ensures optimal contact and friction, maximizing stopping power.

Tip 7: Storage Considerations: Store roller skates in a cool, dry environment away from direct sunlight and extreme temperatures. These conditions can degrade the material and compromise structural integrity.

Adhering to these guidelines promotes consistent and reliable performance, ultimately enhancing skater safety and extending the lifespan of the stopping components. Prioritizing regular maintenance and proper technique is paramount.

The subsequent sections will further elaborate on specific maintenance procedures and offer guidance on selecting replacement parts.

1. Stopping Power

Stopping power, in the context of roller skates, directly pertains to the ability of its stopping mechanisms to effectively decelerate or halt motion. It’s a crucial performance characteristic directly impacting skater safety and control. The following facets detail the components that influence braking effectiveness.

- Friction Coefficient of Pad Material

The material composition of the pad directly influences the friction generated when it contacts the ground. Materials with a higher coefficient of friction, such as specialized rubber compounds, provide superior gripping ability, resulting in shorter stopping distances. Conversely, worn or low-quality materials exhibit reduced friction, compromising stopping effectiveness and increasing the risk of accidents. For instance, a pad composed of soft rubber will provide greater stopping force than a hard plastic pad, but it may wear more quickly.

- Surface Area of Contact

The area of the pad making contact with the ground during braking is proportional to the generated stopping force. Larger surface areas distribute the force more effectively, reducing the potential for skidding and enabling smoother deceleration. Conversely, smaller surface areas require greater pressure to achieve the same stopping force, potentially leading to abrupt stops and loss of control. Consider the difference between a small, pointed brake and a wide, flat brake; the latter will generally offer more controlled deceleration.

- Applied Pressure and Technique

The force applied by the skater to engage the stopping mechanism influences deceleration. Proper technique involves modulating pressure to achieve controlled deceleration, avoiding abrupt stops that can destabilize the skater. Inadequate pressure results in insufficient stopping power, while excessive pressure can cause skidding and loss of control. A skilled skater learns to adjust pressure based on speed, surface conditions, and desired stopping distance. For instance, learning to modulate pressure can prevent skidding on smooth surfaces.

- Surface Conditions

The condition of the skating surface significantly impacts stopping power. Smooth, dry surfaces provide optimal friction, enabling effective deceleration. Conversely, wet, oily, or uneven surfaces reduce friction, increasing stopping distances and demanding greater skater skill to maintain control. Skating on a wet surface requires more stopping distance than on a dry surface.

These interconnected facets highlight the complex relationship between stopping power and the overall performance of roller skates. While optimal pad material and surface area contribute significantly, skater technique and awareness of environmental conditions are equally essential for achieving safe and controlled deceleration. A comprehensive understanding of these factors enables skaters to select appropriate equipment and refine their technique to maximize stopping effectiveness.

2. Pad Material

The functionality of stopping mechanisms on roller skates is inextricably linked to the pad material employed. This component, responsible for generating friction against the skating surface, dictates the efficiency and reliability of deceleration. The selection of a specific material directly influences stopping distance, control, and the overall safety profile of the skates. A pad constructed from an unsuitable material can render the braking system ineffective, posing a significant hazard to the user. For example, a pad made from a hardened plastic compound will offer minimal friction compared to a specialized rubber blend, potentially leading to uncontrolled skidding and increased stopping distances. The material’s inherent properties, therefore, are paramount to its effectiveness.

Considerations beyond friction coefficient are also crucial. Durability, wear resistance, and responsiveness to varying surface conditions are essential attributes of a high-performing pad material. Pads that degrade rapidly necessitate frequent replacements, increasing maintenance costs and potentially compromising safety if wear is not promptly addressed. Furthermore, the material’s ability to maintain consistent performance across diverse environmental conditions, such as wet or abrasive surfaces, impacts its suitability for various skating applications. For instance, artistic skaters may prioritize a material that provides a consistent and predictable stopping force for precise maneuvers, while recreational skaters may favor a more durable material that withstands prolonged use on varied surfaces.

In conclusion, the pad material serves as a critical determinant of its overall effectiveness. A comprehensive understanding of material properties, including friction coefficient, durability, and environmental responsiveness, is essential for selecting appropriate components. Investing in high-quality materials tailored to specific skating needs enhances safety, control, and the overall user experience. The relationship between the material and its resulting performance is one of direct cause and effect, underlining its significance in roller skate design and maintenance.

3. Mounting Security

The operational efficacy of roller skate stopping mechanisms is directly contingent upon the integrity of their mounting system. Secure attachment to the skate chassis ensures consistent force transmission during engagement. A compromised mounting, evidenced by loose fasteners or structural damage, introduces instability, reducing stopping power and increasing the risk of uncontrolled deceleration. Consider the implications of a toe stop gradually detaching during a high-speed maneuver; the resulting instability could lead to a fall. The mounting system, therefore, serves as a critical link between the skater’s intended action and the actual braking response. Its integrity is not merely a convenience but a fundamental safety requirement.

The design of the mounting system significantly impacts its resistance to stress and wear. Robust materials and secure fastening methods, such as recessed bolts or reinforced attachment points, enhance durability and prolong the lifespan of the stopping system. Furthermore, proper installation and periodic inspection are essential for maintaining mounting security. Neglecting to tighten fasteners or replacing worn components can gradually weaken the system, increasing the likelihood of failure. Practical applications of this understanding include regular maintenance checks, ensuring correct torque specifications are adhered to when tightening fasteners, and promptly replacing any damaged mounting hardware. The consequences of overlooking these details can be severe.

In summation, mounting security is not an ancillary feature but an intrinsic element of effective stopping mechanisms. Its integrity directly influences stopping power, skater control, and overall safety. Prioritizing robust mounting designs, adhering to proper installation procedures, and implementing routine maintenance practices are essential steps in mitigating the risks associated with compromised roller skate stopping systems. The connection between secure mounting and reliable braking performance is undeniable, underscoring its importance for all skaters, regardless of skill level.

4. Adjustment Range

The adjustment range of roller skate stopping mechanisms directly influences the skater’s ability to personalize braking response and optimize control. This adjustability, defined as the degree to which a skater can modify the position or responsiveness of the stopping component, significantly impacts braking efficiency and user comfort. A limited adjustment range restricts customization, potentially leading to inefficient stopping techniques and increased fatigue. Conversely, an adequate adjustment range allows skaters to fine-tune their braking system to accommodate individual skating styles, skill levels, and preferences. The practical implication of this lies in the skater’s capacity to optimize brake engagement for swift deceleration and controlled maneuvers. For instance, a skater performing aggressive inline skating may prefer a low, close adjustment for rapid response, while a recreational skater may opt for a higher position for easier engagement.

Variations in skating disciplines and skate designs necessitate specific adjustment ranges. Artistic roller skates, for example, often feature adjustable toe stops that enable precise footwork and controlled stops. Inline skates frequently incorporate heel brakes with adjustable height settings, allowing skaters to customize the angle of engagement. The absence of appropriate adjustment can lead to compromised performance and increased risk of injury. Consider the case of a skater with smaller feet struggling to effectively engage a brake positioned too far forward due to a limited adjustment range. This misalignment can result in inefficient braking and potential falls. Understanding the relationship between adjustment range and brake performance is therefore crucial for selecting appropriate skates and optimizing braking technique.

In summary, the adjustment range of roller skate stopping mechanisms is a key factor influencing braking efficiency, skater comfort, and overall safety. An inadequate range restricts customization and can lead to inefficient braking and increased fatigue, while an appropriate range facilitates personalized control and optimized performance. This critical design aspect must be considered in relation to the intended skating discipline and the skater’s individual needs, ensuring optimal brake engagement and a safer skating experience. Failure to recognize this connection can compromise the effectiveness of stopping systems.

5. Wear Resistance

The service life and reliability of roller skate stopping mechanisms are significantly influenced by their wear resistance. This attribute, defined as the ability of a component to withstand degradation caused by friction, abrasion, and impact, directly dictates the frequency of replacements and the consistency of stopping performance. The selection of materials and construction methods impacts the mechanism’s longevity and operational effectiveness.

- Material Composition and Hardness

The inherent properties of the brake pad material, specifically its composition and hardness, are primary determinants of wear resistance. Materials with higher hardness ratings and robust molecular structures exhibit superior resistance to abrasion, minimizing material loss during braking. For instance, pads formulated with specialized polymers or reinforced composites demonstrate prolonged lifespan compared to pads composed of standard rubber compounds. The selection of appropriate materials directly translates to reduced replacement frequency and lower operational costs.

- Surface Finish and Texture

The surface finish and texture of the brake pad influence its interaction with the skating surface, impacting wear patterns. A smooth, consistent surface promotes uniform wear distribution, preventing localized stress concentrations that accelerate degradation. Conversely, a rough or uneven surface can lead to premature wear due to increased friction and abrasion. Manufacturing processes that produce a fine, even surface finish enhance wear resistance and contribute to the long-term reliability of the stopping mechanism.

- Braking Technique and Usage Patterns

The skater’s braking technique and usage patterns significantly influence wear rates. Aggressive braking, characterized by forceful application and abrupt stops, accelerates material loss compared to controlled, gradual deceleration. Similarly, frequent use on abrasive surfaces increases wear due to increased friction and abrasion. Adopting proper braking techniques and minimizing exposure to harsh environments can prolong the lifespan of the mechanism.

- Environmental Factors

Environmental factors, such as temperature, humidity, and exposure to contaminants, contribute to the degradation of the brake pad material. Extreme temperatures can alter the material’s mechanical properties, reducing its wear resistance. Humidity can promote corrosion and material breakdown, while exposure to dirt, debris, and chemicals can accelerate abrasion. Protecting the stopping mechanism from adverse environmental conditions preserves its integrity and extends its service life.

The interplay of material properties, surface characteristics, user behavior, and environmental influences dictates the wear resistance and longevity of roller skate stopping mechanisms. By selecting appropriate materials, implementing proper maintenance procedures, and adopting responsible skating habits, users can maximize the service life and reliability of their braking systems, ensuring safe and consistent performance.

6. Mechanism Type

The functionality and application of roller skates are significantly defined by the design of the stopping mechanism. Variations in the stopping system, each with distinct operational characteristics and suitability for different skating styles, impact the skater’s control and safety. A thorough understanding of the prevalent mechanism types is essential for informed equipment selection and competent utilization.

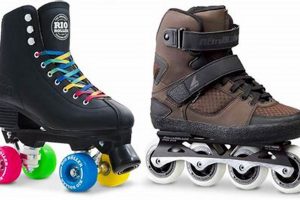

- Toe Stop

The toe stop, commonly found on traditional quad roller skates and artistic inline skates, employs a rubber or composite pad positioned at the front of the skate. Activation involves tilting the foot forward, bringing the pad into contact with the ground. This mechanism facilitates precise stops and allows for controlled maneuvers such as spins and jumps. For instance, artistic skaters utilize toe stops for controlled pivots and controlled landings, while roller derby players rely on them for rapid stops and positional adjustments. The toe stop design necessitates skill and practice for effective application.

- Heel Brake

The heel brake, prevalent on recreational inline skates, consists of a rubber pad mounted on the rear of one or both skates. Activation involves extending the leg forward, causing the heel-mounted pad to contact the ground. This mechanism offers a relatively stable and intuitive stopping method, particularly for novice skaters. For example, a beginner using inline skates on a paved trail would likely find the heel brake more accessible and predictable than alternative braking systems. The heel brake sacrifices maneuverability for ease of use.

- Inline Brake Systems (Advanced)

Advanced inline skate designs often incorporate specialized braking systems that offer enhanced control and performance. These systems may involve variations in pad material, actuation mechanisms, or mounting configurations. Examples include speed skates with minimal heel brakes designed for aerodynamics and responsiveness or aggressive skates with no brakes, relying solely on controlled slides and other techniques for stopping. Competitive speed skaters frequently employ controlled slides to manage speed during races.

- Brake-Free Systems

Certain roller skating disciplines, such as aggressive inline skating and some forms of roller derby, intentionally omit traditional stopping mechanisms. Skaters in these disciplines rely on advanced techniques, including controlled slides, transitions, and strategic use of obstacles, for deceleration and stopping. An aggressive inline skater executing a controlled slide on a ramp demonstrates mastery over movement and balance. This approach demands significant skill and experience, and is typically employed in controlled environments.

The diversity in mechanisms reflects the wide range of roller skating activities. Selection of a specific mechanism type is contingent on individual skating proficiency, intended application, and desired level of control. While heel brakes offer simplicity for beginners, toe stops enable advanced techniques for experienced skaters. An understanding of these variations enables skaters to make informed choices and enhance their overall experience. The absence of a ‘one-size-fits-all’ solution underscores the need for careful consideration of individual requirements.

7. Maintenance Frequency

The operational reliability of roller skate stopping mechanisms is inextricably linked to maintenance frequency. Regular inspection, cleaning, and component replacement are essential for ensuring consistent braking performance and mitigating the risk of accidents. Neglecting routine maintenance compromises the stopping mechanism’s effectiveness, regardless of its initial quality or design. The relationship between these two is one of direct cause and effect. Insufficient maintenance directly results in degraded braking performance, increased stopping distances, and a higher probability of equipment failure. As an illustrative example, a roller skate used frequently on outdoor surfaces accumulates dirt and debris that compromise the friction coefficient of the brake pad. If this accumulation is not regularly addressed, the stopping distance will increase, potentially leading to a collision or fall. Understanding and adhering to a proper maintenance schedule is therefore a crucial aspect of skater safety.

Continued use of worn or damaged components further exacerbates the problem. Brake pads, in particular, are subject to significant wear and tear, especially under heavy use or on abrasive surfaces. Regular inspection of these pads is necessary to assess their remaining thickness and structural integrity. Replacement should occur before the pad wears down to a point where it no longer provides adequate stopping power. Similarly, the mounting hardware that secures the stopping mechanism to the skate frame requires periodic attention. Loose or corroded fasteners can compromise the stability of the mechanism, reducing its effectiveness and increasing the risk of detachment. Practical application of this understanding involves creating and adhering to a checklist that encompasses all critical components. Such a checklist ensures consistent maintenance and prevents oversights that could compromise safety.

In summary, maintenance frequency is not an optional consideration but a fundamental requirement for safe and reliable roller skating. Its impact on the performance and longevity of braking systems cannot be overstated. By adhering to a routine schedule of inspection, cleaning, and component replacement, skaters can significantly reduce the risk of accidents and ensure their stopping mechanisms operate at peak efficiency. The challenges associated with neglecting maintenance are considerable, emphasizing the need for proactive care and attention to detail. The connection between proactive maintenance and safe skating is undeniably a fundamental safety requirement.

Frequently Asked Questions

This section addresses common inquiries regarding roller skate stopping mechanisms. It provides concise answers to ensure a clear understanding of their functionality, maintenance, and safe usage.

Question 1: How often should roller skate brake pads be replaced?

Replacement frequency depends on usage intensity and skating surface. Visual inspection prior to each use is recommended. Pads exhibiting significant wear, reduced thickness, or compromised structural integrity require immediate replacement.

Question 2: What types of cleaning agents are suitable for maintaining brake pads?

Mild soap and water solutions are generally appropriate. Abrasive cleaners or solvents can degrade the pad material, compromising its stopping power and longevity. Residue should be thoroughly rinsed following cleaning.

Question 3: Can the stopping power of the pads be increased?

Modifying the surface of the pad, such as roughening it, is not recommended. Altering the pads composition or texture may compromise its structural integrity and lead to unpredictable braking performance. Replacement with a higher-quality pad is the safest approach.

Question 4: Are after-market stopping mechanisms interchangeable between different skate brands?

Interchangeability varies. Compatibility is dependent on mounting mechanisms, skate design, and intended use. Consulting the skate manufacturer’s specifications is crucial before attempting to substitute components. Mismatched components can compromise safety.

Question 5: What are the signs of a poorly adjusted stopping mechanism?

Indications include uneven pad wear, reduced stopping power, difficulty engaging the mechanism, and instability during braking. Adjustment procedures should adhere to the manufacturers guidelines to ensure optimal performance and prevent potential hazards.

Question 6: How does skating in wet conditions affect brake performance?

Wet surfaces significantly reduce friction, increasing stopping distances. Caution is advised. Employing gradual pressure and allowing for increased stopping distance are essential safety precautions when skating in wet environments. Alternative skating activities might be more suitable.

Regular inspection, appropriate maintenance, and a clear understanding of the equipment’s limitations are essential for safe roller skating.

The subsequent section will discuss common problems.

Conclusion

This exploration of roller skate brakes has underscored their vital role in skater safety and control. Ranging from fundamental operational principles to meticulous maintenance protocols, each element influences overall braking efficacy. The selection of appropriate materials, secure mounting practices, adequate adjustment capabilities, and regular maintenance routines contribute directly to the consistent and reliable function of these systems.

Acknowledging the crucial role of roller skate brakes necessitates prioritizing their integrity. Consistent maintenance, vigilant inspection, and adherence to proper operating procedures should be fundamental to all skating activities. Further advancements in materials science and design could lead to enhanced braking performance and improved skater safety in the future.