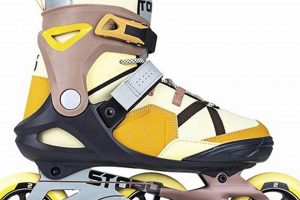

These sporting goods are a type of roller skate designed for recreational and potentially competitive use. They feature a specific chassis, boot, and wheel configuration intended to provide a balance of speed, agility, and durability for skaters of varying skill levels. Assembled, the complete product offers a platform for movement and performance on smooth, hard surfaces.

The appeal of these skates lies in their versatility and performance capabilities. They offer an opportunity for physical activity, skill development, and social engagement. Historically, such products have evolved from simple wheeled contraptions to sophisticated pieces of equipment, reflecting advancements in materials science and engineering. The design caters to individuals seeking enjoyable exercise, transportation alternatives, or participation in roller sports.

The subsequent sections will delve into a detailed analysis of the construction materials, performance characteristics, maintenance requirements, and user considerations associated with this type of recreational equipment. A thorough examination will provide potential buyers and enthusiasts with a comprehensive understanding of these skates and their potential applications.

Optimizing the Performance of Rock GT50 Skates

The following guidelines aim to enhance the skating experience through optimized equipment usage and maintenance. Adhering to these suggestions can potentially improve performance, extend product lifespan, and ensure user safety.

Tip 1: Wheel Rotation: Regularly rotate the wheels to promote even wear. This practice extends the life of the wheels and maintains consistent rolling characteristics across all eight positions. Wheel rotation should occur after every five to ten skating sessions, depending on surface conditions and skating intensity.

Tip 2: Bearing Maintenance: Clean and lubricate the bearings periodically. Dirt and debris accumulation within the bearings can significantly impede performance and potentially damage the bearing components. Use a solvent designed for bearing cleaning, followed by a suitable lubricant to ensure smooth rotation.

Tip 3: Boot Care: Wipe down the boot exterior after each use to remove dirt and moisture. This prevents the buildup of grime and helps maintain the integrity of the boot material. Periodically check for any signs of wear or damage, addressing issues promptly to prevent further deterioration.

Tip 4: Tighten Axle Nuts: Before each use, confirm that the axle nuts are securely tightened. Loose axle nuts can lead to wheel instability and potentially cause accidents. Use an appropriate wrench to tighten the nuts to the manufacturer’s specified torque.

Tip 5: Inspect the Chassis: Regularly inspect the chassis for any signs of cracks or damage. The chassis is the frame that supports the boot and wheels; any structural compromise can impact performance and safety. Replace damaged chassis components immediately.

Tip 6: Use Appropriate Protective Gear: Always wear appropriate protective gear, including a helmet, knee pads, elbow pads, and wrist guards. Protective gear significantly reduces the risk of injury in the event of a fall.

Consistent application of these maintenance and usage principles promotes optimal performance and longevity. By implementing these proactive measures, skaters can maximize their investment and enjoy a safer, more enjoyable skating experience.

The following sections will address specific performance characteristics and address common troubleshooting scenarios associated with this equipment.

1. Boot Construction

The boot construction of these skates directly influences skater comfort, support, and overall performance. The choice of materials and manufacturing techniques determines the boot’s ability to provide ankle stability, resist wear and tear, and efficiently transfer energy from the skater to the wheels. For example, a boot constructed with reinforced vinyl might offer a balance of affordability and durability for recreational use, while a boot made with leather or composite materials could provide superior support and responsiveness for more demanding skating styles. The fit of the boot is also critical; an ill-fitting boot can lead to discomfort, blisters, and impaired control. A properly fitted boot, on the other hand, enhances the skater’s ability to maneuver and maintain balance.

The practical significance of understanding boot construction becomes apparent when selecting skates for specific purposes. A skater engaging in aggressive skating or roller derby, for instance, requires a boot with robust ankle support and reinforced impact resistance. In contrast, a recreational skater may prioritize comfort and flexibility. Manufacturers often incorporate features such as padded linings, adjustable straps, and heat-moldable materials to further customize the fit and feel of the boot. The materials used in the boot’s construction also affect its weight, breathability, and water resistance, all of which can impact the skating experience.

In summary, the boot construction is a critical determinant of the these skate’s performance and suitability for a given application. Skaters must consider the materials, fit, and support characteristics of the boot to ensure comfort, safety, and optimal performance. Understanding the relationship between boot construction and skating style enables informed decision-making and enhances the overall skating experience.

2. Chassis Material

The chassis material of these skates profoundly impacts their performance characteristics, durability, and overall suitability for diverse skating styles. Typically constructed from aluminum or reinforced nylon, the chassis serves as the foundational structure connecting the boot to the wheels. Aluminum chassis offer superior strength and responsiveness, enabling efficient energy transfer and precise control, particularly beneficial in competitive contexts or aggressive skating. However, aluminum variants tend to be more expensive. Conversely, nylon chassis provide a lighter and more cost-effective alternative, suitable for recreational use and beginners. The material’s inherent properties dictate the skate’s weight, torsional rigidity, and vibration dampening capabilities. A stiffer chassis enhances responsiveness, while a more flexible chassis can improve comfort on rough surfaces.

Consider, for instance, the practical implications of chassis material selection. A skater engaging in roller derby requires a robust aluminum chassis capable of withstanding high-impact collisions and providing immediate response during rapid maneuvers. Conversely, a recreational skater might prioritize the comfort and affordability of a nylon chassis for casual skating sessions. Moreover, manufacturers employ various manufacturing techniques, such as extrusion or casting, to further optimize the chassis’s strength-to-weight ratio and structural integrity. The design of the chassis, including the wheelbase and mounting points, also influences the skate’s stability and maneuverability. Understanding the interplay between chassis material, design, and intended use is crucial for making an informed purchase decision.

In conclusion, the chassis material represents a critical determinant of these skate’s performance, durability, and suitability for specific skating styles. The choice between aluminum and nylon depends on the skater’s priorities, skill level, and intended application. By considering the material’s properties, manufacturing techniques, and design features, skaters can select skates that provide the optimal balance of performance, comfort, and value. Neglecting this aspect can lead to suboptimal performance or premature equipment failure, undermining the overall skating experience.

3. Wheel Hardness

Wheel hardness, measured on the durometer scale, represents a critical performance factor influencing the speed, grip, and durability of these skates. A higher durometer rating indicates a harder wheel, which typically results in faster rolling speeds and reduced rolling resistance on smooth surfaces. Conversely, a lower durometer rating signifies a softer wheel, providing enhanced grip and shock absorption, particularly advantageous on rough or uneven surfaces. The selection of appropriate wheel hardness depends largely on the skater’s skill level, skating environment, and preferred style. The interaction between wheel hardness and surface conditions directly affects the overall skating experience, influencing control, stability, and maneuverability.

For instance, a skater primarily utilizing these skates in an indoor roller rink with a polished concrete floor would likely benefit from harder wheels with a higher durometer rating. The reduced friction enables greater speed and effortless gliding. Conversely, a skater navigating outdoor environments with asphalt or rough pavement requires softer wheels to absorb vibrations, maintain grip, and prevent premature wear. Furthermore, wheel hardness affects the wheel’s ability to withstand abrasion and impact. Harder wheels generally exhibit greater wear resistance on smooth surfaces, while softer wheels may degrade more rapidly, especially under abrasive conditions. Skaters often experiment with different wheel hardness levels to optimize their performance based on specific skating contexts. Considerations such as skater weight and skating style may also influence the ideal wheel hardness selection.

In summary, wheel hardness is a crucial characteristic that directly affects the performance of these skates. Understanding the relationship between durometer rating, surface conditions, and skating style allows skaters to make informed decisions regarding wheel selection. Careful consideration of wheel hardness optimizes speed, grip, durability, and overall comfort, ultimately enhancing the skating experience and contributing to improved control and performance. Inadequate wheel hardness selection can lead to diminished performance, increased fatigue, and potential safety hazards.

4. Bearing Precision

Bearing precision, a critical determinant of rolling efficiency and speed, significantly impacts the overall performance of these skates. Defined by the Annular Bearing Engineering Committee (ABEC) rating system (or similar ISO standards), bearing precision dictates the manufacturing tolerances and dimensional accuracy of the bearing components. Higher ABEC ratings, such as ABEC 5 or ABEC 7, indicate tighter tolerances and improved rotational smoothness, resulting in reduced friction and increased rolling speed. The selection of appropriate bearing precision depends on the skater’s skill level, skating style, and performance objectives. Bearings form a core component of the entire skating experience of these skates, allowing for smoother movement.

- Reduced Friction

Higher precision bearings minimize internal friction, enabling the wheels to rotate more freely with less energy expenditure. This translates to increased skating speed and reduced fatigue over extended periods. For instance, a skater transitioning from ABEC 3 to ABEC 5 bearings may experience a noticeable improvement in rolling efficiency, requiring less effort to maintain a given speed. The application of synthetic lubricants further enhances this effect, optimizing bearing performance and longevity.

- Enhanced Speed

The lower frictional resistance of high-precision bearings directly contributes to enhanced skating speed. Skaters seeking to maximize their speed, such as those participating in speed skating or roller derby, often prioritize bearings with higher ABEC ratings. The cumulative effect of reduced friction across all eight bearings can result in a significant increase in overall speed potential. Real-world examples demonstrate that even marginal improvements in bearing precision can translate to measurable gains in lap times or sprint speeds.

- Improved Durability

While primarily focused on precision, higher ABEC ratings often correlate with improved material quality and manufacturing processes, leading to enhanced bearing durability. Precision-engineered bearings are less susceptible to wear and tear, extending their lifespan and reducing the frequency of replacements. This is particularly relevant for skaters who subject their equipment to rigorous use or demanding conditions. The initial investment in high-precision bearings may be offset by their increased longevity and reduced maintenance requirements.

- Consistent Performance

High-precision bearings exhibit greater consistency in performance across a wider range of operating conditions. They are less prone to performance degradation due to variations in temperature, load, or lubrication. This consistent performance is crucial for skaters who require predictable and reliable equipment, such as those performing complex maneuvers or participating in competitive events. The stability and predictability of high-precision bearings instill greater confidence in the skater’s equipment.

In conclusion, bearing precision represents a crucial determinant of the overall skating experience of these skates. The benefits of reduced friction, enhanced speed, improved durability, and consistent performance underscore the importance of selecting bearings that align with the skater’s skill level, skating style, and performance objectives. While higher ABEC ratings may command a premium price, the resulting improvements in rolling efficiency, speed, and longevity can justify the investment for skaters seeking optimal performance and a more enjoyable skating experience. Conversely, for casual or recreational skaters, lower-rated bearings may provide adequate performance at a more affordable price point. The selection of bearing precision should therefore be based on a careful assessment of individual needs and priorities.

5. Skate Size

Skate size is a fundamental determinant of user comfort, control, and safety when using “rock gt50 skates.” An incorrectly sized skate can lead to discomfort, blisters, impaired balance, and an increased risk of injury. The relationship between skate size and foot dimensions is not always linear; variations in skate manufacturer sizing conventions necessitate precise foot measurement and adherence to specific size charts. For example, a user with a foot length of 270 mm may require a size 9 in one brand but a size 9.5 or 10 in another. Ill-fitting skates compromise the skater’s ability to execute maneuvers effectively and efficiently, potentially hindering performance and enjoyment. The primary function of the skates is compromised if there is not a correct skate size selected.

The practical significance of accurate skate sizing extends beyond mere comfort. A skate that is too large allows excessive foot movement within the boot, reducing stability and increasing the likelihood of ankle sprains. Conversely, a skate that is too small restricts circulation, causing discomfort and potential long-term foot problems. Consider a scenario where a skater purchases skates online without properly measuring their feet; the resulting ill-fitting skates could lead to a fall during a skating session, resulting in injuries. Professional skaters often have their skates custom-fitted to ensure optimal performance and minimize the risk of injury. Furthermore, skate size considerations extend to width; individuals with wider feet may require specialized skates or modifications to accommodate their foot shape properly. Ignoring such considerations can lead to discomfort, blisters, and the potential for long-term foot problems.

In summary, selecting the correct skate size is paramount for ensuring user comfort, safety, and optimal performance with “rock gt50 skates.” Accurate foot measurement, adherence to manufacturer-specific size charts, and consideration of foot width are essential steps in the skate selection process. Challenges arise from inconsistencies in sizing conventions across different brands and the need for individual fit adjustments. Failure to prioritize skate size can undermine the intended benefits of the skates, leading to discomfort, impaired control, and an elevated risk of injury. Prioritize measuring the foot and looking at the size chart before purchasing.

6. Intended Use

The intended use of these skates directly dictates the suitability of specific models and configurations. Matching the skate’s design characteristics to the skater’s activities optimizes performance, safety, and longevity. Diverging from the intended use can result in equipment failure, injury, and a diminished skating experience. The construction quality of the skate also matters in these applications.

- Recreational Skating

For casual skating on smooth, paved surfaces, these skates with a focus on comfort and affordability are appropriate. Features such as padded liners, durable nylon chassis, and moderately soft wheels enhance the skating experience. Recreational use typically involves shorter durations and lower intensity levels compared to other skating disciplines, permitting the use of less specialized equipment. The primary objective is enjoyment and exercise, rather than competitive performance.

- Aggressive Skating

Aggressive skating, encompassing tricks, jumps, and grinds performed in skate parks or urban environments, requires these skates engineered for impact resistance and maneuverability. Key features include reinforced boots, durable aluminum chassis, small, hard wheels for grinding, and replaceable grind plates. Aggressive skating subjects the equipment to extreme stress, necessitating robust construction and specialized components. The skater’s safety is paramount, requiring the use of protective gear and skates designed to withstand high-impact forces.

- Roller Derby

Roller derby, a contact sport involving strategic skating and physical interaction, demands these skates that provide agility, stability, and responsiveness. Critical features include low-cut boots for ankle mobility, durable chassis for impact resistance, and high-rebound wheels for acceleration. Roller derby skaters require equipment that can withstand the demands of rapid turns, collisions, and sudden stops. The skates must facilitate precise control and efficient energy transfer for optimal performance in a competitive environment.

- Speed Skating

Speed skating, focused on maximizing velocity and efficiency over a designated course, necessitates these skates designed for minimal rolling resistance and optimal energy transfer. Key features include lightweight boots, stiff chassis, and large-diameter, hard wheels for maximum speed. Speed skating prioritizes aerodynamic efficiency and minimizing friction. The skates must provide a secure and stable platform for sustained high-speed skating, requiring precise fit and advanced materials.

Matching the intended use to the specific features and construction of these skates ensures a safe, enjoyable, and productive skating experience. Deviation from the intended use can compromise performance, accelerate equipment wear, and increase the risk of injury. Understanding the diverse skating disciplines and their corresponding equipment requirements is essential for making informed purchasing decisions and maximizing the benefits of this skating equipment.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding these skates, offering concise and informative answers to guide users in making informed decisions.

Question 1: What is the typical lifespan of Rock GT50 Skates?

The lifespan of these skates varies depending on usage frequency, skating style, and maintenance practices. With proper care and regular maintenance, they can last for several years. However, aggressive skating or frequent use in harsh environments may shorten their lifespan.

Question 2: How do I determine the correct size for Rock GT50 Skates?

Accurate foot measurement is crucial. Consult the manufacturer’s size chart and measure foot length in millimeters. Account for sock thickness and individual foot shape when selecting the appropriate size. Prioritize a snug, comfortable fit that does not restrict circulation.

Question 3: What type of maintenance is required for Rock GT50 Skates?

Regular maintenance includes cleaning and lubricating bearings, rotating wheels to ensure even wear, inspecting the chassis for damage, and cleaning the boot exterior. Tightening axle nuts before each use is also recommended.

Question 4: Can the wheels on Rock GT50 Skates be replaced?

Yes, the wheels are replaceable. Select replacement wheels that are compatible with the skate’s bearing size and axle diameter. Consider wheel hardness (durometer) based on skating surface and style.

Question 5: Are Rock GT50 Skates suitable for outdoor use?

These skates can be used outdoors, but wheel selection is important. Softer wheels are recommended for rough or uneven surfaces to provide better grip and shock absorption. Regular cleaning is crucial to prevent dirt and debris from damaging the bearings.

Question 6: What safety gear is recommended when using Rock GT50 Skates?

Always wear a helmet, knee pads, elbow pads, and wrist guards. Protective gear significantly reduces the risk of injury in the event of a fall. Ensure that all safety gear fits properly and is in good condition.

These answers provide a foundation for understanding critical aspects of these skates. Adherence to recommended maintenance practices and safety guidelines enhances both performance and longevity.

The following section will delve into potential performance enhancements and customization options for these skates.

Concluding Remarks on Rock GT50 Skates

This exploration has illuminated the multifaceted nature of these skates, underscoring the importance of understanding their construction, maintenance, and appropriate application. Key aspects, including boot construction, chassis material, wheel hardness, bearing precision, and skate size, have been examined to provide a comprehensive overview. Proper selection and maintenance contribute significantly to performance, longevity, and user safety. The preceding discussion serves as a resource for skaters seeking to optimize their equipment and enhance their skating experience.

The information presented is intended to foster informed decision-making and responsible equipment usage. Continued adherence to safety guidelines and proactive maintenance practices will ensure that these skates provide years of reliable service. The evolution of skating technology continues, and staying informed about advancements in materials and design will further enhance the user experience and promote the growth of skating as a recreational and competitive activity.