Equipment designed for recreational or competitive activity involving wheeled boots, typically with wheels arranged in a single line, is the primary focus. These products, often manufactured by Roces, enable individuals to glide across surfaces with relatively low friction.

The benefits of using such equipment include enhanced cardiovascular health, improved muscular strength, and the development of balance and coordination. Furthermore, a history of innovation in design and material use has resulted in products that offer increased comfort, performance, and safety. The brand Roces, specifically, has a long-standing reputation in the industry.

The subsequent discussion will delve into various aspects related to their construction, usage, selection criteria, and maintenance procedures. A thorough understanding of these facets ensures informed decision-making and optimal enjoyment of the activity.

Tips for Optimizing Usage

The following guidelines are intended to enhance user experience and extend the lifespan of the equipment.

Tip 1: Prioritize Proper Fit. A snug, secure fit minimizes the risk of ankle instability and maximizes control. Ensure adequate room for toe movement while maintaining heel lock.

Tip 2: Implement Regular Wheel Rotation. Uneven wear is a common occurrence due to varying pressure on each wheel. Rotating the wheels periodically extends their lifespan and maintains consistent performance.

Tip 3: Employ Appropriate Protective Gear. Helmets, wrist guards, elbow pads, and knee pads are essential for injury prevention, particularly for novice users or when engaging in aggressive maneuvers.

Tip 4: Maintain Cleanliness. Regular cleaning of the bearings and wheels prevents the accumulation of dirt and debris, which can impede performance and shorten the equipment’s lifespan. Use a specialized bearing cleaner and lubricant.

Tip 5: Inspect Hardware Regularly. Examine all bolts, axles, and closures for looseness or damage before each use. Tighten or replace components as necessary to ensure structural integrity.

Tip 6: Practice in Controlled Environments. Begin with flat, smooth surfaces to develop fundamental skills and build confidence. Gradually progress to more challenging terrains as proficiency increases.

Tip 7: Utilize Proper Braking Techniques. Master heel braking and other stopping methods to ensure safe and controlled deceleration. Practice these techniques in a safe environment before encountering real-world scenarios.

Adherence to these guidelines promotes safety, optimizes performance, and extends the usable life of the equipment.

Subsequent sections will address maintenance procedures in greater detail.

1. Boot Structure

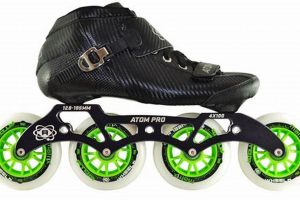

Boot structure in inline skates, particularly within the Roces product line, is fundamental to performance, safety, and comfort. The design and materials used directly impact ankle support, responsiveness, and overall skate control. A well-structured boot provides lateral stability, preventing ankle roll and reducing the risk of injury. Conversely, a poorly designed boot can lead to discomfort, fatigue, and compromised performance. For example, Roces utilizes a variety of boot constructions ranging from rigid shells for aggressive skating to softer, more flexible designs for recreational use. The choice of materials, such as carbon fiber or molded plastics, further contributes to the boot’s stiffness and weight. Improper fit or inadequate support can translate to decreased power transfer and increased strain on the skater’s joints.

Further analysis reveals that boot structure directly influences the skater’s ability to execute specific maneuvers. Aggressive skates often feature higher cuffs and reinforced shells to withstand the impacts associated with jumps and grinds. Speed skates, on the other hand, typically employ low-cut boots constructed from lightweight materials to maximize ankle mobility and reduce drag. Roces’s fitness skates strike a balance between support and comfort, offering a moderately stiff boot that caters to long-distance skating and recreational activities. The practical application of this understanding lies in selecting a boot that aligns with the intended skating style and skill level. A beginner, for instance, might benefit from a more supportive boot, while an experienced skater may prioritize a more responsive and lightweight design.

In summary, the boot structure represents a critical design element in Roces inline skates, affecting performance, safety, and user experience. Selecting the appropriate boot structure based on skating style and skill level is paramount. Challenges exist in balancing support and comfort, and manufacturers like Roces are continually innovating to improve boot designs and materials. Understanding the interplay between boot structure and overall skating performance is essential for informed equipment selection and optimal enjoyment of the sport.

2. Wheel Composition

Wheel composition is a crucial determinant of performance characteristics in Roces inline skates. The materials and construction of the wheels directly influence factors such as speed, grip, durability, and vibration absorption. Specifically, Roces utilizes varying durometers (hardness) of polyurethane (PU) in their wheels to cater to diverse skating styles and surfaces. Softer wheels (e.g., 78A-82A) provide enhanced grip and shock absorption, making them suitable for outdoor recreational skating on rough surfaces. Harder wheels (e.g., 84A-90A) offer greater speed and rolling efficiency on smooth surfaces such as indoor rinks or dedicated skate parks. Therefore, the choice of wheel composition has a direct and measurable impact on the skater’s experience. For instance, equipping a Roces fitness skate with high-durometer wheels intended for racing would result in a harsh, uncomfortable ride on a typical asphalt surface. Conversely, using soft recreational wheels on a speed skate would significantly hinder its performance potential.

Furthermore, the core material and design also play a significant role. Roces wheels frequently incorporate cores made of nylon or other composite materials. These cores provide structural support to the PU tire and influence the wheel’s responsiveness. A stiffer core allows for more efficient energy transfer, translating to increased speed. The wheel profile, or the shape of the tire, also affects performance. A rounded profile is more maneuverable, while a flatter profile provides greater stability and speed. Roces offers a range of wheel profiles to accommodate different skating styles. An example is the use of a narrow, elliptical profile in some of their aggressive skating wheels, designed to improve maneuverability for performing tricks. Different chemical formulations of the PU also contribute to the wheel’s resistance to wear and tear. Wheels designed for street skating, for example, will use formulations designed to withstand the abrasive nature of asphalt and concrete surfaces.

In summary, the performance characteristics of Roces inline skates are fundamentally tied to the wheel composition. Careful consideration of durometer, core material, profile, and PU formulation is vital for selecting wheels that are appropriate for the intended skating environment and style. Ignoring these factors can lead to compromised performance, discomfort, and even premature wheel wear. This understanding is a critical aspect of both equipment selection and maintenance within the Roces inline skate ecosystem.

3. Bearing Precision

Bearing precision is a critical determinant of the rolling efficiency and overall performance of Roces inline skates. The tolerances and quality of the bearings directly impact the smoothness of the wheel rotation, influencing speed, glide, and the amount of effort required for propulsion.

- ABEC Rating and Its Implications

The Annular Bearing Engineers’ Committee (ABEC) rating system (ABEC-1, 3, 5, 7, 9) is commonly used to classify bearing precision. Higher ABEC ratings indicate tighter tolerances and, theoretically, smoother rolling. However, ABEC rating alone does not guarantee superior performance in Roces inline skates, as other factors such as lubrication and material quality also play significant roles. For example, a Roces skate intended for recreational use may feature ABEC-5 bearings, providing a good balance of speed and durability, while a speed skate might utilize ABEC-7 or 9 bearings for optimal performance. The practical implication is that skaters should not solely rely on ABEC rating but also consider the intended use of the skates.

- Material Quality and Durability

The materials used in bearing construction, such as steel type and cage material, significantly impact bearing durability and resistance to corrosion. High-quality steel bearings maintain their shape and smoothness over time, resulting in consistent performance. Bearings exposed to moisture or dirt can corrode, leading to increased friction and reduced rolling efficiency. Roces inline skates typically utilize bearings constructed from hardened steel. The material choice should reflect the skating environment. Skaters who frequently skate in wet conditions should opt for bearings with corrosion-resistant materials. This is a critical aspect of Roces skate maintenance.

- Lubrication and Maintenance

Proper lubrication is essential for minimizing friction and extending bearing lifespan. Grease or oil-based lubricants reduce wear and prevent overheating. Over time, lubricant can become contaminated with dirt and debris, reducing its effectiveness. Regular cleaning and re-lubrication are necessary to maintain optimal bearing performance. Roces recommends specific cleaning and lubrication procedures for their inline skates. Failure to maintain proper lubrication can lead to premature bearing failure and increased rolling resistance, diminishing the skating experience.

- Bearing Types and Applications

Different bearing types cater to specific skating styles. Standard ball bearings are commonly used in Roces recreational and fitness skates. Ceramic bearings, which offer lower friction and greater durability, are often found in high-performance speed skates. The choice of bearing type should align with the intended use of the skates. Aggressive skating, for example, requires bearings capable of withstanding high impact forces. The impact of bearing selection on the performance and the longevity of skates should be emphasized in maintenance of Roces skates.

The selection and maintenance of bearings directly influence the performance and longevity of Roces inline skates. Understanding the interplay between ABEC rating, material quality, lubrication, and bearing type allows skaters to make informed decisions that optimize their skating experience. Neglecting bearing precision ultimately results in diminished performance and a less enjoyable skating experience, which are critical considerations of purchasing Roces brand skates.

4. Frame Material

Frame material significantly influences the performance characteristics of Roces inline skates. The frame serves as the structural foundation connecting the boot to the wheels, directly affecting stability, power transfer, and overall handling.

- Aluminum Alloys and Their Properties

Aluminum alloys are prevalent in Roces skate frames due to their high strength-to-weight ratio. Different alloys, such as 6061 or 7005 series aluminum, offer varying levels of stiffness and durability. Stiffer frames enhance power transfer, allowing for more efficient acceleration and responsiveness. For instance, a Roces aggressive skate frame might utilize a more rigid alloy to withstand the impacts associated with jumps and grinds, while a recreational skate may opt for a more flexible alloy for improved comfort. The specific alloy selection has noticeable implications for the skate’s handling and responsiveness.

- Composite Materials: Blends and Reinforcements

Some Roces frames incorporate composite materials, such as carbon fiber or fiberglass reinforced plastics, to achieve specific performance characteristics. Composite frames can be lighter than aluminum frames while maintaining adequate strength. Carbon fiber, in particular, offers excellent vibration damping, improving comfort on rough surfaces. Composite materials enable Roces to fine-tune frame properties, optimizing them for specific skating styles. For example, the composite frames on fitness skates prioritize comfort and weight reduction to improve the skating experience for long-distance skaters.

- Frame Length and Wheelbase Considerations

Frame length, or wheelbase, is a critical design parameter that affects stability and maneuverability. Shorter frames are more maneuverable, making them suitable for aggressive skating and tight turns. Longer frames provide greater stability at higher speeds, commonly found in speed or fitness skates. Roces offers frames of varying lengths to cater to different skating disciplines. A longer wheelbase in a Roces speed skate improves stability and minimizes wobble at high speeds, while a shorter wheelbase in an aggressive skate facilitates quick turns and trick execution.

- Frame Mounting Systems: Adjustability and Compatibility

The frame mounting system determines the adjustability and compatibility of the frame with different boots. Roces utilizes standardized mounting systems, such as the 165mm or 195mm mounting patterns, allowing for aftermarket frame upgrades or replacements. Adjustable frame mounting systems enable skaters to fine-tune the frame position for optimal balance and comfort. The ability to adjust frame position on some Roces skates allows skaters to shift the frame laterally or forward/backward to optimize balance and power transfer. Proper mounting ensures proper energy transfer, improving performance.

The selection of frame material, length, and mounting system significantly influences the performance and handling characteristics of Roces inline skates. Understanding these factors enables skaters to choose skates that are appropriate for their skating style and skill level. Roces’ diverse range of frames demonstrates a commitment to optimizing skate performance across different skating disciplines.

5. Closure System

The closure system in Roces inline skates directly impacts fit, support, and overall performance. This system, encompassing laces, buckles, power straps, or a combination thereof, secures the foot within the boot, influencing energy transfer and stability. A secure closure minimizes foot movement inside the skate, translating to improved control and reduced risk of injury. Conversely, a poorly designed or improperly fastened closure can lead to discomfort, blisters, and compromised performance. Roces inline skates, for instance, may feature a traditional lace system in conjunction with a micro-adjustable buckle. The laces provide a customizable fit across the instep, while the buckle offers secure closure around the ankle. The effectiveness of this system dictates the skater’s ability to efficiently transfer power to the wheels.

Variations in closure systems cater to different skating styles and user preferences. Roces aggressive skates often incorporate robust buckles and power straps to provide maximum support during high-impact maneuvers. Fitness skates may prioritize comfort and ease of use, employing a combination of laces and Velcro straps. Speed skates may feature a minimalist closure system to reduce weight and optimize aerodynamics. Practical application of this knowledge resides in selecting a closure system that aligns with the intended skating activity. For instance, a skater engaging in aggressive tricks would require a more secure and supportive closure than someone participating in leisurely recreational skating. Roces product development considers user-specific needs and preferences when designing closure systems.

In summary, the closure system represents a critical component in Roces inline skates, influencing fit, comfort, and performance. A properly functioning closure system enhances stability and control, while a poorly designed or improperly used system can compromise the skating experience. The range of closure system options available within the Roces product line reflects the diverse needs of different skating disciplines. This understanding highlights the significance of selecting skates with a closure system appropriate for the intended use, facilitating a secure and effective skating experience.

6. Braking Mechanism

The braking mechanism in Roces inline skates is a safety-critical element, fundamentally influencing control and preventing collisions. Its effectiveness hinges on design, maintenance, and user technique.

- Heel Brake Design and Functionality

The heel brake, a common feature on Roces recreational and fitness skates, utilizes a rubber pad affixed to the rear of one boot. Activation involves pivoting the foot forward to engage the pad with the ground, generating friction to decelerate. The design must ensure reliable contact with the surface, even under varying conditions. Roces designs often incorporate adjustable height settings to accommodate different wheel sizes and wear patterns. Failure to maintain adequate pad thickness or proper adjustment significantly reduces braking effectiveness, compromising safety.

- Alternative Braking Systems: Toe Stops and Specialized Designs

While heel brakes are prevalent, other braking systems exist, particularly in aggressive and artistic skating disciplines. Toe stops, similar to those found on roller skates, offer precise control but require a different skillset. Specialized braking systems, integrated into the frame or boot, are designed for specific applications, such as speed control on downhill runs. Roces aggressive skates, for example, may incorporate frame-mounted blocks for controlled slides and grinds. Transitioning between braking systems necessitates practice to ensure competency in diverse scenarios.

- Material Composition and Environmental Factors

The materials used in the braking mechanism influence its performance and durability. Rubber compounds, polyurethane, and composite materials are common choices. Environmental factors, such as temperature, moisture, and surface conditions, impact braking effectiveness. Wet surfaces reduce friction, increasing stopping distance. Brake pads wear down over time, requiring periodic replacement to maintain optimal performance. Roces recommends using genuine replacement parts to ensure compatibility and safety.

- Technique and Skill Level Influence

The effectiveness of any braking mechanism is contingent on the skater’s skill level and technique. Proper form involves controlled weight distribution and gradual application of pressure. Panic braking can lead to instability and loss of control. Novice skaters should practice braking techniques in a safe environment before venturing onto more challenging terrain. Roces provides instructional materials to guide users on proper braking techniques. Lack of proficiency in braking techniques can negate the benefits of even the most advanced braking system.

Ultimately, the braking mechanism in Roces inline skates constitutes an integrated system involving design, materials, user skill, and maintenance. A comprehensive understanding of these facets is essential for ensuring safe and controlled skating. The system is only as strong as its weakest link; thus, attention must be given to all contributing factors for optimal safety and performance.

Frequently Asked Questions About Roces Inline Skates

The following addresses common inquiries and concerns regarding Roces inline skates, providing factual and objective responses.

Question 1: What factors should be considered when selecting a Roces inline skate model?

The intended use, skill level, foot anatomy, and budget should be carefully evaluated. Recreational skaters may prioritize comfort and ease of use, while aggressive or speed skaters require specialized features and performance characteristics. Consulting size charts and seeking expert advice is recommended.

Question 2: How frequently should Roces inline skate wheels be rotated?

Wheel rotation frequency depends on skating style, surface conditions, and wear patterns. Uneven wear can significantly impact performance. Rotating wheels every 10-20 hours of use, or as needed based on visual inspection, is generally recommended to ensure even wear and optimal grip.

Question 3: What is the significance of the ABEC rating on Roces inline skate bearings?

The ABEC (Annular Bearing Engineers’ Committee) rating indicates the manufacturing tolerances of the bearings. Higher ABEC ratings (e.g., ABEC-7, ABEC-9) denote tighter tolerances and potentially smoother rolling. However, ABEC rating is not the sole determinant of bearing performance; material quality, lubrication, and proper maintenance also play crucial roles.

Question 4: What are the recommended cleaning and lubrication procedures for Roces inline skate bearings?

Remove bearings from the wheels. Clean with a specialized solvent or degreaser, ensuring all dirt and debris are removed. Allow bearings to dry completely. Apply a small amount of bearing lubricant (oil or grease) to each bearing. Reinstall bearings into the wheels. Refer to the Roces owner’s manual for specific product recommendations.

Question 5: How should Roces inline skates be stored to prolong their lifespan?

Clean skates after each use, removing dirt and moisture. Store skates in a dry, well-ventilated area, away from direct sunlight and extreme temperatures. Loosen laces or buckles to prevent deformation of the boot. Consider using skate bags or protective covers to prevent dust accumulation and scratches.

Question 6: What are the key indicators that Roces inline skates require professional maintenance or repair?

Excessive wheel wobble, grinding noises from bearings, loose or damaged frame components, and worn brake pads indicate a need for professional inspection and repair. Attempting to repair complex issues without proper knowledge or tools can compromise safety.

In summary, proper selection, maintenance, and storage practices significantly impact the performance and longevity of Roces inline skates. Adherence to recommended guidelines and addressing issues promptly is essential for a safe and enjoyable skating experience.

The next section will explore potential upgrade options for Roces inline skates.

Conclusion

This exposition has detailed critical facets of Roces inline skates, encompassing design elements, maintenance procedures, and usage considerations. From boot structure and wheel composition to bearing precision and braking mechanisms, each component contributes uniquely to performance and safety. Thorough understanding of these factors facilitates informed decision-making, optimal utilization, and prolonged equipment lifespan.

The continued evolution of materials and design underscores the brand’s commitment to innovation. As recreational and athletic pursuits adapt to changing trends, adherence to safety guidelines and proper maintenance protocols remains paramount. The responsible use of Roces inline skates ensures sustained enjoyment and minimizes potential risks, promoting both individual well-being and a thriving skating community.