Skateboarding relies on a foundational element: the platform upon which riders perform. This platform, typically constructed from multiple layers of laminated wood, provides the necessary strength, flexibility, and surface area for executing maneuvers. The quality of materials and manufacturing processes involved directly impact the rider’s experience and the overall performance of the board.

The design and construction of these platforms have evolved considerably over time. Early versions often lacked durability and responsiveness, hindering advanced techniques. Modern iterations, however, are engineered to withstand significant stress and provide optimal pop, allowing for greater control and higher performance levels. This evolution reflects a continuous pursuit of improved materials and manufacturing techniques, resulting in enhanced rider capabilities and safety.

This article will delve into the specific materials, construction methods, and design considerations that contribute to the creation of high-quality platforms for skateboarding. It will further explore the impact of these factors on performance characteristics, such as responsiveness, durability, and overall feel, providing a comprehensive overview of the key elements involved in their production.

Considerations for Selecting Quality Skate Platforms

The following outlines essential factors to consider when evaluating skate platforms, ensuring optimal performance and longevity.

Tip 1: Wood Ply Composition: The number of wood plies and their orientation significantly impact strength and flexibility. Seven-ply maple is a standard, but variations exist. Evaluate the wood grain and any inconsistencies that may indicate weaknesses.

Tip 2: Glue Type: Industrial-strength glue is crucial for bonding the plies. Epoxies or specialized skateboard glues offer superior adhesion and resistance to delamination compared to cheaper alternatives.

Tip 3: Pressing Technique: Cold-pressing or heat-pressing methods influence the wood’s density and structural integrity. Consistent pressure application is vital to avoid warping or unevenness.

Tip 4: Shape and Concave: The shape and concave determine the board’s responsiveness and feel. Deeper concaves offer greater foot lock-in, while flatter shapes provide more stability. Select a shape that complements individual riding style.

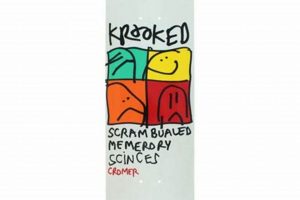

Tip 5: Graphic Application: While aesthetic, the graphic application process can impact durability. Screen-printed graphics tend to be more durable than heat-transferred graphics.

Tip 6: Weight: The platform’s weight influences its maneuverability. Lighter platforms are easier to flick and control, while heavier platforms offer greater stability. Consider the trade-offs based on riding style and preference.

Prioritizing these factors can significantly enhance the skateboarding experience, resulting in increased control, improved performance, and extended product lifespan.

The subsequent section will address common issues and maintenance practices to further optimize the performance and longevity of these essential components.

1. Wood Ply Selection

The selection of wood plies is a critical determinant in the overall performance and durability of skateboard platforms. The species of wood, its grain orientation, and the quality of the individual plies directly influence the deck’s strength, flexibility, and responsiveness, defining the capabilities and limitations of the final product.

- Wood Species and Density

Different wood species possess varying densities, impacting the platform’s weight and impact resistance. Canadian Maple, known for its tight grain and consistent density, is frequently utilized due to its optimal balance of strength and weight. Alternative woods, such as birch or bamboo, offer distinct characteristics in flexibility and vibration dampening, catering to specific riding styles. A less dense wood may result in a lighter deck, but at the sacrifice of durability.

- Grain Orientation and Strength

The direction of the wood grain within each ply influences its resistance to bending and breaking. Orienting the grain in alternating directions between plies creates a composite structure that distributes stress more effectively, enhancing overall strength and preventing warping. Deviations from consistent grain alignment can introduce weak points, leading to premature failure under stress. The angle and symmetry of the grain are therefore meticulously considered in the manufacturing process.

- Ply Quality and Defect Detection

The presence of knots, voids, or inconsistencies within the wood plies weakens the platform’s structure. Rigorous inspection processes are employed to identify and eliminate defective plies before lamination. Higher-grade plies are characterized by uniform thickness, consistent grain, and absence of imperfections, contributing to a more reliable and durable final product. The cost of materials and quality control directly influence the final skate platform price point.

- Layer Count and Thickness

The number of plies and their individual thickness dictates the overall flex and stiffness of the platform. A seven-ply construction is a common standard, providing a balanced compromise between strength and flexibility. Increasing the ply count or using thicker plies results in a stiffer platform, favored for stability at higher speeds. Reducing the ply count or utilizing thinner plies creates a more flexible platform, offering enhanced responsiveness for technical maneuvers. The proper balance for a particular riding style must be achieved to offer the desired performance characteristics.

The interrelation of wood species, grain orientation, ply quality, layer count, and thickness creates a complex matrix of factors that dictate the ultimate performance characteristics of skate platforms. Careful attention to each of these elements is crucial in achieving a high-quality platform capable of withstanding the rigors of skateboarding. The selection process is not trivial and the resulting performance directly informs the users experience.

2. Adhesive Bond Strength

Adhesive bond strength is a critical, yet often overlooked, factor in the construction of high-quality skate platforms. This characteristic determines the ability of the adhesive to resist shear stress between the wood plies, preventing delamination and ensuring structural integrity during the high-impact activities inherent in skateboarding. Insufficient bond strength leads to ply separation, resulting in decreased board performance, premature failure, and potential injury to the rider.

The selection of appropriate adhesives is therefore paramount. Traditional wood glues are generally unsuitable due to their limited resistance to moisture and impact. Instead, industrial-strength epoxy resins or specially formulated skateboard glues are employed. These adhesives possess superior bonding capabilities, flexibility, and resistance to environmental factors. Furthermore, proper application techniques, including consistent adhesive spread and controlled pressure during pressing, are vital to achieving optimal bond strength. Manufacturing defects in this area, such as insufficient adhesive or inconsistent pressure, directly correlate with reduced deck lifespan and performance degradation. The consequences of poor adhesive performance are readily apparent in the form of splintering, cracking, and eventual structural collapse of the deck.

In conclusion, adhesive bond strength is a non-negotiable element in the creation of durable and reliable skate platforms. The choice of adhesive, application technique, and manufacturing quality control measures collectively dictate the platform’s ability to withstand the stresses of skateboarding. Prioritizing this aspect contributes directly to enhanced rider safety, improved board performance, and extended product lifespan, demonstrating its indispensable role in the overall design and construction of skate platforms. Poor choice can result in immediate material damage.

3. Pressing Process Consistency

The pressing process in skateboard manufacturing is a crucial determinant of the final product’s structural integrity and performance characteristics. Consistent application of pressure, temperature, and duration during this phase is essential for achieving uniform density, shape retention, and adhesive bonding across the entirety of the deck. Inconsistencies in the pressing process directly impact the deck’s durability, pop, and overall ride quality.

- Uniform Pressure Distribution

Consistent pressure across the entire surface of the deck during pressing ensures even compaction of the wood plies and proper adhesive bonding. Uneven pressure distribution can lead to localized weak points, warping, and variations in deck thickness. These inconsistencies compromise the deck’s ability to withstand stress and impact, leading to premature failure. Precision in pressure application is therefore paramount for a durable and reliable skate platform.

- Controlled Temperature Regulation

Temperature plays a critical role in the curing of adhesives used to bond the wood plies. Maintaining a consistent and controlled temperature during the pressing process ensures optimal adhesive strength and prevents premature or incomplete curing. Fluctuations in temperature can weaken the adhesive bond, increasing the risk of delamination and reducing the deck’s overall lifespan. Precise temperature control is therefore vital for achieving a strong and durable bond between the wood plies.

- Precise Duration Management

The duration of the pressing cycle directly influences the degree of compaction and adhesive curing achieved. Insufficient pressing time may result in incomplete bonding and inadequate consolidation of the wood plies, while excessive pressing time can lead to over-compression and damage to the wood fibers. Precise management of the pressing duration is therefore essential for achieving the optimal balance between strength, flexibility, and durability. Variations from the ideal timeframe result in compromised structural integrity and performance.

- Mold Consistency and Tolerance

The molds used in the pressing process define the shape and concave of the skate platform. Inconsistent mold dimensions or tolerances can lead to variations in deck shape, affecting the board’s feel and performance. Warped or misshapen decks can negatively impact stability, maneuverability, and rider comfort. Maintaining strict quality control over mold manufacturing is therefore crucial for ensuring consistent deck shape and optimal ride characteristics.

The preceding aspects of the pressing process collectively determine the quality and performance characteristics of skate platforms. Achieving consistent pressure, temperature, and duration, alongside precise mold consistency, is essential for producing durable, reliable, and high-performing decks. Deviations from these standards can lead to compromised structural integrity, reduced lifespan, and diminished rider experience. Investment in precision equipment and rigorous quality control measures are therefore crucial for manufacturers seeking to deliver superior skate platforms.

4. Shape and Concave Design

The shape and concave design of a skateboard platform are integral to its performance characteristics. These elements dictate the rider’s foot placement, control, and the board’s responsiveness to various maneuvers. The selection of shape and concave directly influences the intended application and riding style for which the deck is best suited.

- Outline Shape and Foot Placement

The overall outline shape of the platform, including nose and tail dimensions, influences foot placement and leverage. Symmetrical shapes offer balanced control for riding switch stance, while directional shapes provide enhanced stability and responsiveness in a specific direction. The specific shape therefore defines the optimal positioning of the rider’s feet and impacts the execution of tricks.

- Concave Depth and Foot Lock-In

Concave refers to the curvature of the deck’s surface between the edges. Deeper concaves provide greater foot lock-in, enhancing control during flip tricks and technical maneuvers. Shallower concaves offer a more stable platform, favored for cruising and high-speed riding. The depth of the concave dictates the degree of foot security and influences the rider’s ability to execute complex tricks with precision.

- Kick Angle and Pop Generation

The angle of the nose and tail kicks affects the amount of leverage a rider can generate for popping the board. Steeper kick angles result in a more responsive and powerful pop, facilitating higher ollies and more aggressive maneuvers. Shallower kick angles provide a more mellow pop, suited for cruising and transition skating. The kick angle directly influences the potential energy a rider can transfer to the board for aerial maneuvers.

- Wheelbase and Turning Radius

The wheelbase, or the distance between the inner mounting holes, affects the turning radius and stability of the deck. Shorter wheelbases offer tighter turning radiuses, ideal for navigating tight spaces and executing quick maneuvers. Longer wheelbases provide greater stability at higher speeds, favored for downhill and vert skating. The wheelbase choice determines the balance between maneuverability and stability, catering to specific riding styles and terrain.

The interplay of outline shape, concave depth, kick angle, and wheelbase defines the performance envelope of a skateboard platform. These design elements are carefully considered to optimize the deck for specific riding styles and skill levels. Selecting a shape and concave that complements individual preferences and riding environments is crucial for maximizing performance and enjoyment.

5. Graphic Application Method

The graphic application method, while often perceived as purely aesthetic, significantly impacts the durability and structural integrity of skateboard platforms. The process employed to apply graphics influences the deck’s resistance to wear, delamination, and overall lifespan. Therefore, the selection and execution of the graphic application method are critical considerations in the manufacturing of durable and high-quality skateboard platforms.

- Screen Printing Durability

Screen printing involves forcing ink through a stenciled mesh onto the deck’s surface. This method creates a thick, durable layer of ink that is highly resistant to abrasion and wear. Screen-printed graphics tend to withstand the rigors of skateboarding, including board slides and impacts, more effectively than other application methods. Consequently, screen printing is often favored for high-end skate platforms where longevity is a priority.

- Heat Transfer Limitations

Heat transfer involves applying a printed image onto the deck using heat and pressure. While offering greater detail and color vibrancy, heat-transferred graphics are typically less durable than screen-printed graphics. The thin layer of ink is more susceptible to scratching, peeling, and fading, particularly under heavy use. Heat transfer is often employed on more economical decks where cost considerations outweigh durability concerns.

- Direct Digital Printing Impact

Direct digital printing allows for the application of intricate designs directly onto the deck’s surface using inkjet technology. The durability of direct digital printing varies depending on the ink type and application process. Some direct digital printing methods offer comparable durability to screen printing, while others are more prone to wear and tear. The long term effectiveness must be considered before application.

- Clear Coat Integration

Regardless of the graphic application method employed, the application of a clear coat sealant is essential for protecting the graphic and enhancing its longevity. The clear coat acts as a barrier against abrasion, moisture, and UV damage, extending the lifespan of the graphic and preventing it from fading or peeling. The quality and application technique of the clear coat significantly influence the overall durability of the graphic and the deck itself.

The choice of graphic application method is a critical decision in skateboard manufacturing, balancing aesthetic considerations with durability requirements. While screen printing offers superior resistance to wear, heat transfer and direct digital printing provide greater design flexibility. The integration of a high-quality clear coat is essential for maximizing the lifespan of the graphic, regardless of the application method employed. Therefore, the graphic application method is not merely a cosmetic consideration but a functional aspect that directly influences the performance and longevity of skateboard platforms.

Frequently Asked Questions About Real Skate Decks

This section addresses common inquiries regarding the selection, maintenance, and performance characteristics of skateboard platforms.

Question 1: What constitutes a “real” skateboard platform?

A legitimate skateboard platform is typically constructed from multiple plies of laminated wood, most commonly Canadian maple. Its construction and materials adhere to industry standards for dimensions, shape, and durability. Counterfeit or substandard platforms may utilize inferior materials or construction techniques, resulting in compromised performance and safety.

Question 2: How does wood ply composition impact deck performance?

The number of wood plies, wood species, and grain orientation significantly influence a platform’s strength, flexibility, and pop. Seven-ply maple is a common configuration, providing a balance of durability and responsiveness. Alterations to ply count or wood type can affect the deck’s stiffness and its suitability for specific riding styles.

Question 3: Why is adhesive bond strength so important in skateboard decks?

Adhesive bond strength prevents delamination between the wood plies, maintaining the structural integrity of the platform under stress. Substandard adhesives or improper application techniques can lead to ply separation, compromising the deck’s performance and increasing the risk of failure. Industrial-strength epoxy resins are commonly used for their superior bonding properties.

Question 4: What role does concave play in the functionality of a skateboard?

Concave refers to the curvature of the deck’s surface, influencing foot lock-in and control. Deeper concaves offer enhanced grip and responsiveness, facilitating technical maneuvers. Shallower concaves provide a more stable platform, suitable for cruising and high-speed riding. The selection of concave is largely dependent on individual preference and riding style.

Question 5: How does the graphic application method affect a deck’s longevity?

The method used to apply graphics can influence a deck’s resistance to wear and abrasion. Screen-printed graphics are generally more durable than heat-transferred graphics, withstanding the rigors of board slides and impacts more effectively. Clear coat sealants also play a crucial role in protecting the graphic and extending its lifespan.

Question 6: What are the key indicators of a high-quality skateboard platform?

Key indicators include consistent wood ply construction, strong adhesive bonds, uniform pressing, well-defined shape and concave, and durable graphic application. A platform exhibiting these characteristics is more likely to provide optimal performance, longevity, and rider safety.

Selecting a quality skateboard platform requires careful consideration of materials, construction techniques, and design elements. A well-constructed platform enhances performance, increases safety, and provides a more enjoyable riding experience.

The following section will address maintenance practices for extending the lifespan of skateboard platforms.

Conclusion

The preceding analysis has detailed the essential elements that define authentic skateboard platforms. From the selection of high-grade maple to the precision of the pressing process and the durability of the graphic application, each facet contributes to the performance and longevity of the equipment. Compromises in material quality or manufacturing rigor inevitably diminish the capabilities and lifespan of the product.

Understanding these critical factors empowers informed decision-making in the selection and maintenance of skateboard platforms. Investing in quality materials and construction is not merely a matter of preference, but a commitment to enhanced safety, optimal performance, and sustained enjoyment of the sport. The value placed on authentic construction reflects a deeper appreciation for the engineering and craftsmanship that underpin the skateboarding experience.