This specialized equipment, designed for high-speed competitive skating, features four wheels arranged in a two-by-two configuration. The construction typically incorporates a low-cut boot for enhanced ankle mobility, a lightweight chassis for responsiveness, and high-performance wheels and bearings to maximize speed and grip. A skater utilizing these leverages balance and powerful strides to navigate banked tracks and tight corners at considerable velocity.

The pursuit of speed and agility drives the innovation behind this particular skating form. Its development reflects advancements in materials science and engineering, resulting in lighter, stronger, and more efficient designs. Historically, the evolution of this sport’s gear has been intertwined with the growth of roller derby and other competitive skating disciplines, each influencing the other to achieve peak performance.

Understanding the nuances of this equipment is paramount for anyone involved in the sport. The following sections will delve into specific aspects such as chassis materials, wheel types, bearing selection, and boot fitting, providing detailed information to inform equipment choices and enhance skating proficiency.

Optimizing Performance with Quad Racing Skates

The following guidelines are intended to assist individuals in maximizing their performance while utilizing specialized skating equipment. Proper application of these principles can contribute to enhanced speed, agility, and overall skating proficiency.

Tip 1: Chassis Selection: Consider the material and design of the chassis. Lightweight aluminum alloys or carbon fiber composites offer optimal stiffness-to-weight ratios, enhancing responsiveness and power transfer. A shorter wheelbase promotes agility, while a longer wheelbase provides increased stability at higher velocities.

Tip 2: Wheel Durometer: Select wheel durometer based on track surface and skating style. Softer wheels (lower durometer) provide increased grip on slick surfaces, while harder wheels (higher durometer) offer lower rolling resistance on smoother tracks. Experimentation is crucial to determine the optimal balance between grip and speed.

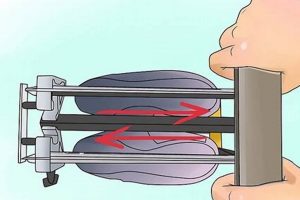

Tip 3: Bearing Maintenance: Regular maintenance of wheel bearings is essential for maintaining optimal speed. Clean and lubricate bearings frequently to reduce friction and ensure smooth rolling. High-precision bearings with tight tolerances can further enhance performance.

Tip 4: Boot Fitting: Ensure a snug and secure fit within the boot. A properly fitted boot minimizes energy loss and maximizes control. Consider heat-moldable boots for a customized fit that conforms to the individual’s foot shape. Lace tightness should be adjusted to provide adequate support without restricting circulation.

Tip 5: Ankle Support: Prioritize adequate ankle support to prevent injuries and enhance stability. Some boots incorporate reinforced ankle areas or adjustable straps to provide additional support. Strengthening exercises targeting the ankle muscles can further improve stability and control.

Tip 6: Stride Technique: Refine stride technique to optimize power and efficiency. Focus on maintaining a low center of gravity, maximizing push-off distance, and minimizing unnecessary movements. Video analysis can be a valuable tool for identifying and correcting stride flaws.

Tip 7: Protective Gear: Always prioritize safety by utilizing appropriate protective gear. This includes a helmet, knee pads, elbow pads, and wrist guards. Properly fitted protective gear can significantly reduce the risk of injuries in the event of a fall.

Effective application of these tips, emphasizing equipment selection, maintenance, and technique refinement, can contribute significantly to improved skating performance and overall enjoyment of the sport.

The following sections will delve into the biomechanics of skating and the physiological demands of competitive racing, providing a comprehensive understanding of how to optimize training and performance.

1. Boot Fit

The interface between skater and skate resides within the boot. In the context of equipment designed for high-velocity competitive skating, optimal boot fit is not merely a matter of comfort; it is a fundamental determinant of performance, control, and injury prevention.

- Energy Transfer Efficiency

A properly fitted boot minimizes slippage and movement within the boot structure. This ensures that the force generated by the skater’s leg muscles is directly and efficiently transferred to the chassis and wheels. Conversely, a loose-fitting boot results in wasted energy as the foot moves within the boot, reducing propulsion and responsiveness. Consider a scenario where a skater accelerates out of a corner; any lag in power delivery due to foot slippage inside the boot could mean the difference between gaining or losing position.

- Ankle Stability and Support

The boot provides crucial lateral support to the ankle, preventing excessive pronation or supination during skating maneuvers. Insufficient ankle support increases the risk of ankle sprains and instability, particularly during high-speed turns or sudden changes in direction. Many boots incorporate features such as reinforced ankle counters and adjustable straps to enhance support. The correct level of support is critical; excessive restriction can limit ankle mobility, while insufficient support compromises stability.

- Control and Responsiveness

A snug, secure fit allows the skater to execute precise movements and maintain optimal control. The boot acts as an extension of the skater’s body, transmitting subtle shifts in weight and balance directly to the skates. Conversely, a poorly fitted boot can create a disconnect between the skater’s intentions and the skate’s response, leading to imprecision and reduced control. This is especially important in tight pack skating where minute adjustments can have a significant impact.

- Blister and Hotspot Prevention

Improper boot fit is a primary cause of blisters and hotspots, particularly during prolonged skating sessions. Friction between the foot and the boot lining can quickly lead to skin irritation and discomfort, ultimately impacting performance. Heat-moldable boots and custom orthotics can help address fit issues and reduce the risk of blisters by conforming to the individual’s foot shape and providing targeted support.

Therefore, selecting a boot that conforms precisely to the skater’s foot shape and provides adequate support and stability is paramount in optimizing overall performance and mitigating the risk of injury when utilizing specialized skates for racing. Investing time and resources in achieving a proper fit is a critical component of maximizing potential in this demanding sport.

2. Chassis Rigidity

In the context of specialized skating equipment, chassis rigidity refers to the degree to which the frame resists deformation under applied forces. For skaters using this equipment, chassis rigidity directly impacts energy transfer, responsiveness, and overall control. A more rigid chassis minimizes energy loss due to flexing, allowing a greater proportion of the skater’s effort to translate into forward momentum. Conversely, a less rigid chassis absorbs more energy, resulting in reduced efficiency and responsiveness. The effect is analogous to that of a stiff versus flexible bicycle frame; a stiffer frame allows for quicker acceleration and more precise handling. For instance, a skater navigating a tight corner benefits from a chassis that resists twisting, enabling them to maintain a stable platform and execute the turn with greater precision.

The selection of chassis materials plays a crucial role in determining rigidity. Aluminum alloys, often heat-treated, offer a balance of strength, weight, and cost, making them a common choice. Carbon fiber composites, while more expensive, provide superior stiffness-to-weight ratios, further enhancing responsiveness. The design of the chassis, including the shape, thickness, and presence of reinforcing ribs, also contributes significantly to its overall rigidity. A chassis with inadequate rigidity can lead to a “mushy” feel, particularly at higher speeds, diminishing confidence and control. Skaters may experience difficulty maintaining a consistent line through corners, requiring more effort and potentially compromising stability.

Understanding the interplay between chassis rigidity, skating technique, and track conditions is essential for optimizing performance. While a highly rigid chassis may be advantageous on smooth, high-grip surfaces, a slightly more flexible chassis can provide better shock absorption and control on rougher tracks. Ultimately, the optimal level of rigidity is dependent on individual skating style, body weight, and personal preference. Careful consideration of these factors, combined with experimentation and expert guidance, allows skaters to select equipment that maximizes their potential and enhances their overall skating experience.

3. Wheel Durometer

Wheel durometer, a measure of a wheel’s hardness, profoundly influences performance in quad racing. Measured on the Shore A scale, durometer ratings typically range from 80A (softer) to 101A (harder), with specific values dictating the wheel’s behavior regarding grip, roll, and durability. In quad racing, the selection of an appropriate durometer is a critical decision directly impacting a skater’s speed, control, and overall performance. For instance, a softer wheel, with a lower durometer rating, deforms more readily under load, increasing the contact patch with the track surface. This enhanced grip is advantageous on slick or uneven surfaces, providing greater control during cornering and acceleration. Conversely, a harder wheel, with a higher durometer rating, maintains its shape more effectively, reducing rolling resistance on smoother tracks. Consider a concrete track versus a polished wood surface; the former would generally benefit from a softer wheel, whereas the latter would be more conducive to a harder wheel.

The relationship between durometer and performance extends beyond surface conditions. Skaters must consider their skating style and body weight. A heavier skater may prefer a harder wheel to prevent excessive compression and maintain speed. Similarly, a skater with a powerful stride may benefit from a harder wheel to maximize energy transfer. The choice of durometer is therefore a balancing act, considering track conditions, skater attributes, and the specific demands of the race. Different wheel brands and compounds can also influence the perceived durometer and performance. One manufacturer’s 88A wheel may feel significantly different than another’s, necessitating experimentation and personal preference. Factors like urethane formulation, core design, and wheel profile all contribute to the overall performance characteristics.

Ultimately, understanding wheel durometer and its impact on quad racing represents a vital element of competitive skating. The challenge lies in optimizing wheel selection for specific conditions and individual needs. Effective implementation requires consistent experimentation, detailed observation, and a comprehensive understanding of equipment capabilities. Furthermore, this expertise provides the ability to adapt to dynamic environments and refine performance strategies in a specialized, competitive sport.

4. Bearing Precision

Bearing precision, measured by the ABEC (Annular Bearing Engineers’ Committee) scale or similar ISO standards, dictates the tolerances to which bearings are manufactured. In equipment designed for competitive skating, bearing precision directly influences rolling resistance and, consequently, speed. Higher ABEC ratings (e.g., ABEC 7, ABEC 9) signify tighter tolerances, resulting in smoother rotation and reduced friction. The bearings facilitate the wheels’ ability to spin freely around their axles. High-precision bearings minimize energy loss due to friction, allowing for greater efficiency and higher speeds, especially in sustained skating efforts. Conversely, lower-precision bearings (e.g., ABEC 1, ABEC 3) introduce more friction, impeding speed and requiring more effort to maintain momentum. For example, a skater using high-precision bearings may experience a noticeable reduction in fatigue over long distances compared to a skater using lower-precision bearings, all other factors being equal.

The impact of bearing precision on performance is most pronounced during high-speed maneuvers and sustained skating. The reduced rolling resistance translates into increased acceleration and higher top speeds. Moreover, high-precision bearings maintain their performance characteristics for longer periods due to their tighter tolerances and reduced wear. This longevity is crucial in competitive racing, where equipment reliability is paramount. Proper bearing maintenance, including regular cleaning and lubrication, further enhances performance and extends bearing lifespan. Neglecting maintenance can negate the benefits of high-precision bearings, as accumulated dirt and debris increase friction and diminish performance. The choice of lubricant also affects bearing performance, with specialized lubricants designed to minimize friction and dissipate heat.

In summary, bearing precision is a critical factor influencing speed and efficiency in competitive skating. Higher precision bearings minimize rolling resistance, enabling skaters to achieve greater speeds with less effort. However, the benefits of high-precision bearings are contingent upon proper maintenance and the use of appropriate lubricants. While high-precision bearings represent a significant investment, their contribution to performance makes them a valuable component for serious competitors. The challenges lie in balancing the cost of high-precision bearings with the benefits they provide and ensuring they are properly maintained to maximize their lifespan and performance.

5. Track Surface

The surface upon which skating occurs exerts a fundamental influence on performance outcomes. Its characteristics dictate equipment configuration and skating strategy in the realm of quad racing.

- Friction Coefficient

The friction coefficient of a track surface defines the grip available to the skater. Higher friction surfaces allow for greater acceleration and tighter cornering due to increased traction. Conversely, low-friction surfaces necessitate adjustments in technique to avoid slippage and maintain control. Examples include polished concrete, characterized by lower friction, and textured asphalt, which offers higher friction. Surface friction directly determines wheel durometer selection, as skaters adapt to maximize grip while minimizing rolling resistance.

- Surface Uniformity

Variations in surface texture and consistency impact stability and control. Smooth, uniform surfaces provide predictable grip and allow for consistent performance. Irregularities, such as cracks or bumps, introduce unpredictable forces that can disrupt balance and reduce speed. Track maintenance is critical for maintaining uniformity and minimizing the risk of falls. Skaters must be prepared to adapt their technique to compensate for surface imperfections.

- Track Material Composition

The specific material comprising the track influences its friction coefficient, wear characteristics, and overall feel. Concrete, wood, and synthetic materials each offer distinct performance profiles. Concrete tracks, commonly found outdoors, tend to be durable but can exhibit variable surface textures. Wood tracks, typically found indoors, offer smoother, more consistent grip. Synthetic surfaces, such as those found in specialized skating arenas, can be engineered to provide specific performance characteristics. Material composition informs wheel selection and skating style, influencing the skater’s ability to generate power and maintain control.

- Environmental Conditions

Environmental conditions, such as temperature and humidity, can alter track surface properties and affect performance. High temperatures can soften certain track surfaces, reducing grip. Humidity can influence friction, particularly on wood tracks. Rain or moisture can render some surfaces dangerously slippery. Skaters must be cognizant of these environmental factors and adjust their equipment and technique accordingly to maintain optimal performance and safety. Pre-race inspection and ongoing monitoring of track conditions are essential.

The interplay between track surface characteristics and quad racing performance is multifaceted. Skaters must possess a thorough understanding of how surface conditions influence grip, stability, and speed. This knowledge, combined with appropriate equipment selection and adaptive skating technique, is crucial for achieving competitive success and mitigating risk.

Frequently Asked Questions

This section addresses common inquiries regarding equipment designed for competitive, high-speed skating. The information presented aims to clarify technical aspects and inform equipment choices.

Question 1: What differentiates equipment used for racing from recreational models?

Equipment intended for racing incorporates specific design features and materials optimized for performance. These include lighter, more rigid chassis materials, high-precision bearings to minimize rolling resistance, and boot designs that prioritize ankle support and energy transfer. Recreational models typically prioritize comfort and durability over peak performance.

Question 2: How does wheel durometer affect skating performance?

Wheel durometer, a measure of wheel hardness, directly impacts grip and rolling resistance. Softer wheels (lower durometer) provide greater grip on slick surfaces but exhibit higher rolling resistance. Harder wheels (higher durometer) offer lower rolling resistance on smooth surfaces but provide less grip. The optimal durometer depends on track conditions and skating style.

Question 3: What is the significance of bearing precision in racing?

Bearing precision, typically measured by the ABEC scale or equivalent ISO standards, dictates the manufacturing tolerances of the bearings. Higher-precision bearings minimize friction, resulting in greater rolling efficiency and higher speeds. Regular maintenance is essential to preserve bearing performance and lifespan.

Question 4: What are the key considerations for boot fit in racing?

A snug, secure boot fit is crucial for maximizing control and energy transfer. The boot should provide adequate ankle support without restricting mobility. Heat-moldable boots can offer a customized fit that conforms to the skater’s foot shape, enhancing comfort and performance.

Question 5: How does track surface influence equipment selection?

Track surface characteristics, such as friction coefficient and uniformity, significantly influence wheel durometer selection and skating technique. Smooth surfaces favor harder wheels, while slick or uneven surfaces necessitate softer wheels for increased grip. Surface imperfections can impact stability and require adjustments to skating style.

Question 6: Is protective gear essential for quad racing?

The utilization of protective gear is mandatory in competitive settings and strongly advised during training. Helmets, knee pads, elbow pads, and wrist guards are crucial for mitigating the risk of injuries associated with falls and collisions. Proper fit and maintenance of protective gear are essential to ensure its effectiveness.

Optimal utilization of equipment requires a thorough understanding of technical specifications, combined with practical experience and expert guidance. Continuous refinement of equipment choices and skating technique is essential for achieving peak performance.

The next section will explore advanced training methodologies and physiological considerations for competitive skaters.

Conclusion

The preceding discussion explored various aspects of equipment specialized for competitive skating, focusing on elements that contribute to optimized performance. This analysis encompassed considerations ranging from boot fit and chassis rigidity to wheel durometer, bearing precision, and the influence of track surface characteristics. A thorough understanding of these factors is crucial for informed equipment selection and effective utilization in high-speed competitive contexts.

Continued advancement in materials science, engineering design, and training methodologies promises further refinements in this equipment and the sport itself. The pursuit of enhanced performance and increased safety remains a driving force, ensuring continued innovation and adaptation within the skating community. Therefore, dedication to knowledge acquisition and diligent application of performance-enhancing strategies is paramount for skaters seeking competitive success.