A skateboard component constructed from multiple layers of pressed maple wood, providing the platform upon which a skateboarder stands. It commonly features a concave shape and upturned nose and tail, facilitating tricks. As an example, one might purchase a new platform featuring artwork from a favored skate brand.

The quality and construction influence the rider’s experience, affecting board feel, pop, and overall durability. The selection available, along with associated graphics, allow for personalization and expression of individual style within skateboarding culture. The evolution has tracked advancements in materials science, striving for lighter, stronger, and more responsive platforms.

Understanding the specifications and features of such equipment is essential for making informed decisions about skateboarding setups. Examining the construction, materials, and design elements provides a foundation for further exploration of related topics, such as truck selection, wheel choice, and overall board assembly.

Guidance on Selection and Maintenance

The following guidance offers practical advice for selecting and maintaining a quality skateboarding platform. Adherence to these points can enhance performance and extend the lifespan of equipment.

Tip 1: Evaluate Maple Composition. The arrangement and quality of the maple plies directly impact strength and pop. Examine specifications to ensure a robust, vertically laminated core.

Tip 2: Consider Concave Depth. The degree of curvature affects board feel and control. Select a depth that complements the rider’s stance and riding style, allowing comfortable foot placement and responsiveness during maneuvers.

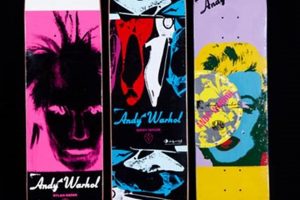

Tip 3: Inspect Graphic Application. While aesthetic, graphics can indicate manufacturing quality. Look for smooth, even application without bubbles or peeling, suggesting a higher standard of production.

Tip 4: Mindfully Grip Tape. Correct application of grip tape is crucial for secure footing. Ensure full coverage, free of air pockets, to optimize board control. Replace worn grip tape to maintain secure contact.

Tip 5: Store Appropriately. Prolonged exposure to moisture or extreme temperatures can warp or delaminate the wood. Store in a dry, temperate environment when not in use.

Tip 6: Rotate Regularly. Consistent use can cause uneven wear. Rotating the orientation periodically can distribute stresses and extend the overall lifespan.

Tip 7: Address Minor Damage Promptly. Small chips or cracks, if left unattended, can propagate. Apply epoxy resin to minor damage to prevent further deterioration.

By observing these precautions, individuals can maximize their investment and ensure reliable performance. Proper care contributes to a safer and more enjoyable skateboarding experience.

With a focus on selection and care, the user’s attention can shift to maximizing the platform’s potential. The following section addresses enhancing its use.

1. Maple Composition

The selection and treatment of maple significantly influence the performance characteristics. High-quality platforms rely on vertically laminated, hard rock maple plies, ensuring superior strength and pop. Inferior maple exhibits inconsistent density and can lead to premature breakage. For example, platforms constructed using a blend of maple species may display a diminished capacity for retaining shape and resisting impact forces, ultimately affecting the execution of tricks.

The manufacturing process also plays a role. Premium constructions utilize specialized adhesives and pressing techniques, creating a tightly bonded structure that maximizes the transfer of energy from the rider to the board. Consider the consequences when lower-grade adhesives are used, this leads to ply separation and weakening, directly compromising the platform’s integrity. Another example is, when heat pressing techniques are not correct, the Maple’s properties are not optimized.

Understanding the nuances of maple composition provides valuable insight for selecting durable and responsive equipment. Careful consideration of these factors contributes to an improved skateboarding experience and minimizes the risk of equipment failure. Therefore, the platform benefits and performance are optimized.

2. Concave Profile

The concave profile, an integral design element of the skateboard platform, profoundly influences a rider’s control and maneuverability. The curvature across the width significantly impacts foot placement and grip, dictating responsiveness to rider input.

- Concave Depth and Foot Lock

Deeper concave profiles generate a more pronounced “foot lock,” securing the rider’s feet and enhancing stability during advanced maneuvers. This heightened connection facilitates precise board control, especially during flip tricks. However, excessive depth may restrict foot movement, potentially hindering less technical riding styles.

- Concave Radius and Board Feel

The radius of the concave dictates the overall feel of the platform. A tighter radius creates a more responsive and sensitive connection, while a shallower radius provides a more stable and predictable platform. The selection should align with the rider’s skill level and preferred terrain.

- W Concave and Heel-Toe Steering

Certain platforms incorporate a “W concave” running lengthwise down the center. This feature creates distinct pockets for the heels and toes, augmenting leverage and enhancing heel-toe steering capabilities. The W concave becomes useful when performing slide tricks on the skateboard.

- Flat Concave and Freedom of Movement

A “flat” concave offers minimal curvature, prioritizing freedom of movement and a more traditional board feel. This profile suits riders who prefer a less restrictive platform or those engaging in old-school styles. The rider will have free movement and the skateboard has more flexibility.

The careful selection of the concave profile is paramount for optimizing the riding experience. It represents a crucial factor in tailoring equipment to specific skill levels, skating styles, and terrain preferences. Thus, understand that the overall performance and suitability of a specific skateboard platform depends on a variety of factors.

3. Deck Dimensions

Deck dimensionsspecifically length, width, wheelbase, and nose/tail measurementsdirectly influence the performance characteristics of a skateboard platform. These parameters dictate stability, responsiveness, and suitability for different skating styles. Careful consideration of dimensions is crucial when selecting equipment.

- Deck Width and Foot Placement

The width of the platform impacts foot placement and board feel. Narrower options, typically ranging from 7.5 to 8.0 inches, enhance flick and are favored for technical street skating. Wider platforms, exceeding 8.25 inches, provide greater stability and are preferred for transition or vert skating. An inadequate deck may compromise stability during landing.

- Deck Length and Overall Stability

The overall length contributes to stability and maneuverability. Shorter platforms offer increased responsiveness but may feel less stable at higher speeds. Longer platforms provide a more stable ride but can be less agile. The length impacts the board performance and handling.

- Wheelbase and Turning Radius

The wheelbase, the distance between the inner mounting holes for the trucks, directly affects the turning radius. A shorter wheelbase results in a tighter turning radius, facilitating quick maneuvers. A longer wheelbase provides greater stability at higher speeds. A good wheelbase facilitates performance and control.

- Nose and Tail Length and Pop

The length and angle of the nose and tail influence the “pop,” the upward force generated when initiating tricks. Steeper angles and longer lengths generally produce a more powerful pop. Variations in nose and tail shape also affect board feel and trick execution. Nose and tail length give force and quality to the board.

Properly matched dimensions optimize performance and safety. For instance, a street skater prioritizing flip tricks may opt for a narrower, shorter platform, while a vert skater seeking stability would choose a wider, longer configuration. The appropriate selection ensures greater comfort and confidence. The proper dimensions optimize the board.

4. Graphic Durability

Graphic durability, the ability of artwork applied to a skateboard platform to withstand wear and tear, is a key indicator of manufacturing quality and long-term aesthetic appeal. On a skateboard platform, the graphic is not merely decorative; it is a component subject to abrasion from shoes, rails, and other surfaces encountered during use.

- Printing Methods and Resistance to Abrasion

Screen printing and heat transfer represent the prevalent methods of graphic application. Screen-printed graphics, known for thicker ink layers, generally exhibit superior resistance to abrasion compared to heat-transferred images. The selection of ink type and curing process directly impacts the graphics ability to endure repetitive friction without fading or peeling.

- Clear Coat Application and Protection

The application of a clear coat over the graphic provides an additional layer of protection against scratches and scuffs. High-quality platforms incorporate a durable clear coat that resists chipping and cracking, preserving the underlying graphic. The absence of a clear coat or a subpar application can result in rapid degradation of the artwork.

- Graphic Placement and Wear Patterns

The positioning of the graphic on the platform influences its susceptibility to wear. Graphics located in high-contact areas, such as underfoot or near the nose and tail, experience more rapid degradation. Understanding common wear patterns informs the selection of platforms featuring graphics designed to withstand these specific stresses.

- Impact Resistance and Graphic Integrity

Beyond abrasion, the graphic must also resist damage from impacts. High-quality graphics maintain their integrity even after repeated impacts, resisting chipping or cracking that could compromise the aesthetic appeal. The adhesive properties of the ink and the flexibility of the clear coat contribute to impact resistance.

The longevity and visual appeal of a skateboard platform are directly correlated with the durability of its graphic. Consideration of printing methods, clear coat application, graphic placement, and impact resistance provides insights into the overall quality and value. Platforms with robust graphics offer enhanced satisfaction and maintain their aesthetic appeal longer.

5. Resin Quality

Resin quality is paramount to the structural integrity and performance of the skateboard platform. As the binding agent uniting the maple plies, the type and application of resin directly influence the board’s strength, flexibility, and resistance to delamination. Compromised resin diminishes durability and shortens the lifespan of the skateboard component.

- Resin Type and Bonding Strength

Epoxy-based resins offer superior bonding strength compared to water-based alternatives. The former penetrates the wood fibers more effectively, creating a robust and durable bond between plies. Platforms utilizing epoxy resins exhibit greater resistance to impact forces and delamination. The absence of this bond reduces the skateboard decks durability.

- Resin Saturation and Ply Adhesion

Adequate resin saturation is essential for complete ply adhesion. Insufficient saturation leads to weak points within the platform, increasing the likelihood of ply separation under stress. Properly saturated plies create a unified structure that distributes force evenly throughout the platform.

- Curing Process and Structural Integrity

The curing process dictates the final properties of the resin. Controlled temperature and humidity during curing optimize resin hardness and flexibility. Improper curing can result in a brittle resin matrix, compromising the platform’s ability to absorb impacts and withstand bending forces. The curing process impacts the performance of the platform.

- Resin Formulation and Environmental Resistance

High-quality resin formulations incorporate additives that enhance resistance to moisture and temperature fluctuations. These additives prevent resin degradation, minimizing the risk of warping or delamination due to environmental factors. Resin formulations are beneficial to environmental resistance.

In summary, the choice and application of resin critically influence the performance and longevity. Platforms constructed with high-quality resin and employing proper saturation and curing techniques exhibit superior strength, resilience, and resistance to environmental factors, ultimately delivering a more reliable and durable skateboarding experience.

6. Ply Arrangement

The configuration of wood plies within a skateboard platform significantly impacts its structural integrity, flex characteristics, and overall performance. The specific arrangement determines the board’s strength, responsiveness, and resistance to warping or breakage. Understanding ply arrangement is crucial for evaluating the performance characteristics and potential longevity.

- Vertical Lamination and Strength

Vertically laminated plies, oriented perpendicular to the platform’s length, enhance its resistance to bending and breaking forces. This arrangement effectively distributes stress across the width, preventing premature failure under heavy loads. Most high-quality platforms incorporate a core of vertically laminated plies for optimal strength.

- Cross-Grain Orientation and Torsional Rigidity

Alternating the grain direction of adjacent plies, known as cross-grain orientation, increases torsional rigidity. This prevents excessive twisting and improves board control during intricate maneuvers. Cross-grain arrangements provide a stable and predictable platform for technical skating styles.

- Fiberglass Reinforcement and Pop

The incorporation of fiberglass layers between the wood plies enhances the platform’s “pop,” the upward force generated when initiating tricks. Fiberglass increases stiffness and provides a more responsive feel. The strategic placement of fiberglass layers allows for fine-tuning the flex characteristics and maximizing energy transfer.

- Number of Plies and Overall Weight

The number of plies directly influences the platform’s weight and stiffness. Fewer plies result in a lighter, more flexible board, while more plies increase stiffness and durability. A balance between weight and strength is crucial for optimizing performance. The number of plies chosen must be correct for the individual.

The careful consideration of ply arrangement contributes to the overall quality. Variations in lamination techniques, grain orientation, and reinforcement materials allow for fine-tuning to match different skating styles and preferences. The appropriate configuration maximizes performance, board control, and equipment lifespan.

Frequently Asked Questions

The following addresses common inquiries regarding skateboard platform specifications, construction, and maintenance. The information provided is intended to assist in making informed decisions.

Question 1: What constitutes an acceptable maple composition for skateboarding?

Acceptable maple composition involves vertically laminated, hard rock maple sourced from sustainable forests. The arrangement should ensure uniform density and minimal defects. Deviations from this standard may compromise strength and performance.

Question 2: How does concave profile influence board control?

Concave profile affects foot lock and responsiveness. Deeper concaves enhance stability during technical maneuvers, while shallower concaves offer greater freedom of movement. The selection depends on riding style and personal preference.

Question 3: What are the key dimensions to consider when choosing a skateboard platform?

Key dimensions include width, length, and wheelbase. Width affects foot placement and stability; length influences overall board feel; wheelbase impacts turning radius. These parameters should align with the rider’s skill level and intended use.

Question 4: How does graphic durability reflect manufacturing quality?

Graphic durability indicates the quality of materials and printing processes employed. High-quality graphics resist abrasion and impact damage, preserving the aesthetic appeal over time. Inferior graphics are prone to fading, peeling, and chipping.

Question 5: Why is resin quality critical for skateboard platform construction?

Resin quality affects ply adhesion and overall structural integrity. Epoxy-based resins provide superior bonding strength compared to water-based alternatives, minimizing the risk of delamination. The resin must create stability.

Question 6: How does ply arrangement influence performance characteristics?

Ply arrangement dictates the platform’s strength, flex, and torsional rigidity. Vertical lamination enhances resistance to bending forces, while cross-grain orientation improves board control. The lamination affects the board.

Careful consideration of these factors ensures the selection of reliable equipment tailored to the specific demands of skateboarding. Informed choices maximize performance and extend the lifespan of components.

The following section transitions into strategies for optimizing skateboarding performance. This section will help people who choose to engage.

Conclusion

This exploration has delineated various facets of the skateboard platform, emphasizing the significance of material composition, dimensional considerations, graphic integrity, resin properties, and ply arrangement. These elements collectively determine the board’s performance characteristics, influencing durability, responsiveness, and suitability for different skating styles. A comprehensive understanding of these factors is essential for making informed purchasing decisions and optimizing the skateboarding experience.

The continued advancement in materials science and manufacturing techniques promises further refinements in skateboard platform design and performance. It is incumbent upon the discerning skateboarder to remain abreast of these developments, ensuring the selection of equipment that meets evolving demands and maximizes potential. A commitment to informed purchasing contributes to the longevity of equipment, fostering a safer and more rewarding engagement with the activity.