Footwear featuring a rigid blade attached to a wooden platform designed for gliding across ice surfaces during winter months exemplifies a bygone era of recreational and practical transportation. These artifacts, characterized by their handcrafted construction and often rudimentary fastening systems, represent an early form of personal mobility in frozen environments. They typically consist of a steel blade riveted or otherwise affixed to a shaped piece of wood, which is then secured to the foot with leather straps or other binding materials.

The significance of these early skating implements lies in their role as both recreational tools and necessities for navigating icy conditions. Historically, they provided a means of travel and trade during periods when waterways were frozen. Beyond their functional purpose, they hold cultural value, reflecting the ingenuity and resourcefulness of past generations in adapting to challenging climates. Their existence offers insight into social activities and winter lifestyles of communities dependent on frozen landscapes. The craftsmanship evident in these objects illustrates a blending of function and artistry.

Further examination will delve into the construction techniques, regional variations, and evolving designs that define these antique objects. Analysis will explore their impact on winter sports and leisure activities, highlighting their transition from practical tools to cherished relics of skating history. Specific attention will be given to the methods of preservation and conservation necessary to safeguard these fragile pieces for future generations.

Preservation Strategies for Antique Ice Skates

The safeguarding of early ice skating equipment requires diligent care and appropriate handling to prevent deterioration. The following guidelines outline crucial steps for maintaining the structural integrity and aesthetic value of these historical artifacts.

Tip 1: Environmental Control: Maintaining a stable environment is paramount. Excessive humidity and temperature fluctuations accelerate degradation of wood and metal components. Ideal storage conditions include a cool, dry location with controlled humidity levels.

Tip 2: Gentle Cleaning Protocols: Accumulated dust and debris should be removed using soft brushes and lint-free cloths. Abrasive cleaning agents are strictly prohibited, as they can damage the delicate surfaces. For persistent dirt, a mild soap solution may be used sparingly, followed by thorough drying.

Tip 3: Metal Component Maintenance: Metal elements, such as blades and rivets, are susceptible to corrosion. Regular inspection for rust is essential. Application of a thin layer of protective wax or specialized metal protectant can mitigate corrosion risks. Avoid prolonged exposure to moisture.

Tip 4: Wooden Element Stabilization: Wood components may exhibit cracking, warping, or decay. Wood consolidants or stabilizers can be applied by experienced conservators to reinforce weakened areas and prevent further structural damage. Self-treating with household glues is not recommended.

Tip 5: Proper Storage Methods: Storage should prevent direct contact with abrasive surfaces. Individual wrapping in acid-free tissue paper and placement in archival-quality boxes provides a protective barrier against physical damage and environmental contaminants.

Tip 6: Minimize Handling: Excessive handling contributes to wear and tear. When handling is necessary, use clean, dry hands or wear cotton gloves to prevent the transfer of oils and dirt. Support the object carefully to avoid undue stress on fragile areas.

The consistent application of these preservation strategies extends the lifespan of these cultural assets, ensuring their availability for future study and appreciation. Neglecting these preventative measures accelerates deterioration, potentially resulting in irreparable damage.

Further research into conservation techniques and consulting with professional conservators provides specialized guidance for addressing specific conditions and ensuring long-term preservation. Consider seeking professional assessments for valuable or exceptionally fragile examples.

1. Blade Material

The selection and properties of the blade material were critical determinants of the performance, longevity, and overall utility of early ice skating equipment. The composition of the blade directly influenced its ability to maintain an edge, resist corrosion, and withstand the stresses associated with gliding across ice surfaces.

- Wrought Iron Characteristics

Early examples often featured wrought iron blades, characterized by a fibrous structure and relative ease of shaping. This material, however, was prone to rapid corrosion and required frequent sharpening. Its malleability allowed for simpler manufacturing techniques, yet its limited hardness compromised performance on harder ice surfaces. The presence of slag inclusions within the iron also contributed to inconsistent edge quality and increased susceptibility to breakage under stress.

- Transition to Steel Alloys

The introduction of steel alloys represented a significant advancement in ice skate blade technology. Steel offered superior hardness, edge retention, and resistance to corrosion compared to wrought iron. This transition allowed for the creation of thinner, sharper blades capable of providing enhanced glide and maneuverability. The development of different steel alloys further refined blade characteristics, optimizing performance for various skating styles and ice conditions.

- Fastening Methods and Material Compatibility

The method of attaching the blade to the wooden platform influenced the choice of blade material. Riveting, bolting, or welding techniques were employed, each requiring consideration of the thermal expansion coefficients of both the metal and wood to prevent loosening or structural failure. Incompatibility between materials could lead to accelerated corrosion due to galvanic reactions, further emphasizing the importance of material selection.

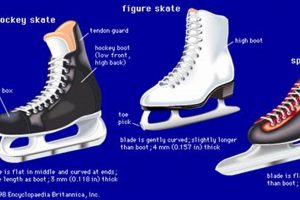

- Blade Profile and Material Requirements

The curvature and cross-sectional shape of the blade were intimately linked to the material’s properties. Blades designed for speed skating demanded a different material composition and hardening process than those intended for figure skating or recreational use. The material’s ability to be precisely shaped and retain its form under load was a crucial factor in achieving the desired performance characteristics for specific skating disciplines.

In summary, the evolution of blade material from wrought iron to steel alloys reflects a continuous pursuit of improved performance, durability, and safety in early ice skating equipment. The selection of appropriate materials, coupled with advancements in manufacturing techniques, directly impacted the functionality and longevity of these historical objects, contributing to the development of ice skating as both a practical means of transportation and a popular recreational activity.

2. Wood Type

The selection of wood in the construction of early ice skating equipment profoundly influenced its durability, flexibility, and overall performance. The type of wood dictated the skate’s ability to withstand stress, resist moisture, and maintain structural integrity under the demanding conditions of winter use. The characteristics of specific woods played a vital role in the functionality and longevity of these historical objects.

- Hardness and Density

Wood hardness, often measured by the Janka hardness scale, directly correlated with the skate’s resistance to wear and tear from repeated use on ice. Denser woods, such as maple or birch, offered greater durability and reduced the risk of splintering or cracking under pressure. Softer woods, while easier to shape, were more susceptible to damage and shorter lifespans. The choice of wood reflected a compromise between ease of manufacturing and long-term resilience.

- Flexibility and Shock Absorption

The capacity of the wood to flex without breaking was crucial for absorbing shocks and vibrations during skating. Woods with inherent elasticity, like ash or hickory, provided a degree of cushioning that reduced stress on the skater’s foot and improved overall comfort. This flexibility also helped to prevent the skate from shattering upon impact with uneven ice surfaces. The selection of wood with appropriate flexural properties contributed to a smoother and more controlled skating experience.

- Moisture Resistance

Exposure to moisture was a constant challenge for wooden ice skates. Woods with inherent resistance to water absorption, such as cedar or oak, were preferred for their ability to minimize swelling, warping, and rot. Proper sealing and finishing techniques further enhanced the wood’s resistance to moisture damage. The effectiveness of these protective measures directly influenced the lifespan and structural integrity of the skate in wet or icy conditions.

- Grain Pattern and Strength

The direction and arrangement of wood grain significantly affected its strength and resistance to splitting. Straight-grained woods were generally preferred for skate construction, as they provided uniform strength and reduced the likelihood of stress fractures. The orientation of the grain in relation to the direction of force was carefully considered to optimize the skate’s structural performance. A well-chosen grain pattern enhanced the skate’s ability to withstand the stresses of skating without failure.

The selection of a specific wood type for early ice skating equipment represented a careful consideration of material properties, manufacturing processes, and the demands of winter use. The characteristics of the chosen wood directly impacted the skate’s durability, performance, and overall utility, highlighting the importance of material selection in the design and construction of these historical artifacts.

3. Binding Mechanism

The binding mechanism of early ice skating equipment constituted a critical interface between the skater and the ice. Its design and functionality directly impacted stability, control, and overall safety. The efficacy of the binding system determined the skater’s ability to translate force into movement, navigate icy surfaces, and execute desired maneuvers. Early iterations demonstrated a range of solutions reflecting available materials and evolving understanding of biomechanics.

- Leather Strap Systems

Early designs frequently utilized simple leather straps to secure the skate to the boot or foot. These straps, typically made from tanned animal hide, were threaded through slots or loops on the wooden platform and tightened around the foot. Examples include basic laced configurations and more elaborate arrangements with buckles for increased adjustability. The effectiveness of these systems depended on the quality of the leather, the tightness of the straps, and the skater’s ability to maintain consistent tension. Slippage and loosening were common issues, particularly in wet conditions.

- Buckle and Clasp Arrangements

Advancements in binding technology incorporated buckles and clasps to enhance security and adjustability. These metal fasteners allowed for more precise control over strap tension and provided a more reliable hold than simple leather straps. Examples include hinged buckles with multiple adjustment points and spring-loaded clasps that could be quickly engaged and disengaged. The introduction of these mechanisms improved stability and reduced the likelihood of the skate detaching during use. Corrosion and mechanical failure were potential drawbacks associated with metal components.

- Integrated Boot Designs

Some early skates featured integrated boot designs, where the skate platform was directly attached to a purpose-built boot. These designs offered a more secure and comfortable fit compared to strap-on models. The boot, typically made from leather or other durable materials, provided enhanced ankle support and improved control over the skate. Examples include skates with riveted or stitched boot-to-platform connections. The complexity of manufacturing and the limited adjustability of integrated designs presented certain challenges.

- Adjustable Heel and Toe Pieces

To accommodate different boot sizes and shapes, some skates incorporated adjustable heel and toe pieces. These features allowed for customization of the skate’s fit and improved overall stability. Examples include sliding heel cups and adjustable toe clamps that could be repositioned to match the skater’s foot dimensions. The addition of these adjustable elements enhanced comfort and reduced the risk of slippage. The complexity of these mechanisms required precise manufacturing and careful maintenance.

These facets of the binding mechanism highlight the ingenuity and resourcefulness of early skate designers. The evolution from simple leather straps to more sophisticated buckle systems and integrated boot designs reflects a continuous effort to improve stability, control, and comfort. Understanding these binding mechanisms provides valuable insight into the technological and social context of early ice skating and the challenges associated with navigating icy surfaces with rudimentary equipment.

4. Manufacturing Era

The era in which early ice skating equipment was manufactured profoundly shaped its design, materials, and construction techniques. The prevailing industrial capabilities, technological advancements, and economic conditions of a given period directly influenced the characteristics of these objects, leaving discernible markers that reflect their historical context.

- Pre-Industrial Handcrafting (pre-1850)

Prior to the widespread adoption of industrial manufacturing processes, ice skates were predominantly handcrafted by local blacksmiths, carpenters, or specialized artisans. Production volumes were low, and each skate bore unique characteristics reflecting the individual craftsman’s skills and available resources. Materials were sourced locally, and designs were often based on traditional patterns passed down through generations. Standardization was minimal, resulting in considerable variation in size, shape, and performance. The rarity and individualized nature of these skates imbue them with significant historical value.

- Early Industrialization and Mass Production (1850-1900)

The advent of industrialization brought about significant changes in skate manufacturing. Factories began to mass-produce skates using machinery powered by steam or water. Standardized designs and interchangeable parts became increasingly common, leading to greater uniformity and affordability. Materials like machine-rolled steel and mass-produced leather straps replaced hand-forged iron and handcrafted bindings. While quality varied, mass production made skating more accessible to a wider segment of the population. Trade catalogs from this era document the burgeoning skate industry and the proliferation of new designs.

- Early 20th Century Advancements (1900-1950)

The early 20th century witnessed further refinements in skate manufacturing, driven by advances in metallurgy and engineering. Higher-quality steel alloys, improved blade tempering processes, and more sophisticated binding mechanisms became prevalent. Mass production techniques were further optimized, resulting in increased efficiency and lower costs. The development of specialized skates for different disciplines, such as figure skating and hockey, reflected a growing specialization within the sport. Patents from this period provide detailed insights into the innovative designs and technologies that shaped skate development.

The evolution of manufacturing techniques directly impacted the design, affordability, and accessibility of ice skates. Analyzing the manufacturing era provides a framework for understanding the technological, economic, and social forces that shaped the evolution of early ice skating equipment. Each period left its unique imprint on these artifacts, transforming them from rare, handcrafted objects into mass-produced recreational items.

5. Geographic Origin

The provenance of early ice skating equipment significantly influenced its design, construction, and utilization. Regional variations in climate, available materials, and cultural practices resulted in distinct styles of skates adapted to specific environmental conditions and societal needs. Tracing the geographic origin of these artifacts offers insight into the diverse adaptations and innovations that characterized early ice skating traditions.

- Scandinavian Skates: Efficiency and Utility

Northern European regions, particularly Scandinavia, boast a long history of utilizing ice skates for both practical transportation and recreation. Skates from these areas often prioritize efficiency and utility, featuring long, straight blades designed for traversing frozen lakes and rivers. Construction frequently involved locally sourced hardwoods and simple, robust binding systems tailored for extended use in harsh winter conditions. Archaeological finds and historical accounts attest to their significance in facilitating trade and communication during winter months.

- Dutch Skates: Blade Curvature and Canal Culture

The Netherlands, with its extensive network of canals, developed a unique skating culture reflected in the design of its skates. Dutch skates typically feature a distinctive upward curve at the front of the blade, facilitating maneuverability and speed on relatively smooth ice surfaces. The construction often incorporated hardwoods like elm or ash, and the binding systems emphasized secure attachment to the skater’s boot, reflecting the importance of stability in navigating narrow waterways. Historical paintings and literature provide ample evidence of their widespread use for transportation and leisure.

- North American Skates: Adaptation to Varied Ice Conditions

In North America, skate design varied depending on the specific region and its prevailing ice conditions. Skates from the northern regions, such as Canada and New England, often featured robust construction and durable materials to withstand the rigors of prolonged winter use on natural ice surfaces. Indigenous populations also developed their own forms of ice skates, adapted to the specific needs of hunting and transportation in their respective environments. Museum collections and historical records document the diversity of skate designs across the continent.

- Alpine Skates: Durability and Mountainous Terrain

The mountainous regions of Europe, such as the Alps, presented unique challenges for ice skating. Skates from these areas often emphasized durability and stability, featuring robust construction and secure binding systems designed to withstand the uneven and unpredictable ice conditions found in alpine environments. The use of sturdy hardwoods and reinforced metal components reflected the need for reliability in challenging terrain. Local traditions and historical accounts provide evidence of their use for both practical transportation and recreational activities in mountainous communities.

The geographic origin of these early skates is therefore a critical factor in understanding their purpose, construction, and place within the broader history of winter culture. Consideration of regional climate, available resources, and cultural practices provides valuable context for interpreting these artifacts and appreciating the diverse adaptations that shaped their evolution.

6. Intended Use

The design and construction of early ice skating equipment were fundamentally shaped by its intended application. The dichotomy between skates designed for practical transportation and those intended for recreational pursuits dictated variations in blade length, binding mechanisms, and overall structural integrity. Implements crafted for navigating frozen waterways as a means of conveyance or trade demanded durability and efficiency over extended distances. Conversely, examples made for leisure activities or sporting competitions prioritized maneuverability and responsiveness, often sacrificing some degree of ruggedness in favor of enhanced performance. This functional divergence represents a key determinant in categorizing and understanding historical skating equipment.

Examples illustrate this relationship vividly. In regions where frozen canals served as vital transportation arteries, such as the Netherlands, skates featured longer, straighter blades optimized for sustained gliding. The bindings were robust, designed to secure the skate firmly to the boot for hours of continuous use. By contrast, skates intended for early forms of ice hockey or figure skating possessed shorter, more curved blades, enabling quick turns and agile movements. These were often paired with more flexible binding systems that allowed for greater freedom of motion. The survival of examples of each type provides tangible evidence of the distinct functional demands that drove innovation in skate design.

Understanding the intended use is thus essential for properly interpreting and preserving early ice skating equipment. Recognizing the specific purpose for which a given skate was designed informs conservation efforts, ensuring that restoration techniques are aligned with the object’s original functionality. Furthermore, this knowledge contributes to a more nuanced understanding of the social and economic roles of ice skating throughout history, linking these artifacts to the daily lives and recreational activities of past generations. A failure to consider intended use would result in a limited and potentially inaccurate assessment of these historical objects.

Frequently Asked Questions

The following questions and answers address common inquiries and misconceptions surrounding antique ice skates, providing clarification and detailed information.

Question 1: What materials were commonly used in the manufacture of this equipment?

The primary materials consisted of wood, typically hardwoods such as ash, maple, or birch, for the platform and supporting structure. Blades were initially wrought iron, transitioning to steel alloys as metallurgy advanced. Binding mechanisms employed leather, supplemented by metal buckles or clasps in later models.

Question 2: How can one determine the age of antique ice skates?

Determining age involves examining manufacturing techniques, blade material, binding mechanism design, and the presence of maker’s marks or patents. Early hand-forged blades and rudimentary leather straps suggest older examples, while machine-made blades and more complex metal hardware indicate later production periods.

Question 3: What are the primary factors affecting the value of antique ice skates?

Value is influenced by factors such as rarity, condition, historical significance, maker’s reputation, and aesthetic appeal. Skates in excellent condition, with original components and provenance, command higher prices. Skates associated with notable individuals or events also possess enhanced value.

Question 4: What are the best practices for preserving antique ice skates?

Preservation necessitates environmental control, gentle cleaning, and appropriate storage. Maintain stable temperature and humidity levels. Remove dust with soft brushes and avoid abrasive cleaners. Store skates in acid-free materials and protect them from direct sunlight and moisture.

Question 5: Were these implements solely used for recreational purposes?

No, early ice skates served both practical and recreational roles. In regions with frozen waterways, they functioned as essential transportation tools for trade, communication, and daily travel. Recreational use emerged alongside, evolving into organized sports and leisure activities.

Question 6: What are some common pitfalls to avoid when acquiring early ice skating equipment?

Potential buyers should beware of reproductions or heavily restored examples presented as originals. Scrutinize blade material, binding mechanisms, and construction details for inconsistencies. Seek guidance from knowledgeable collectors or appraisers to ensure authenticity and avoid overpaying.

Understanding these key aspects fosters informed appreciation for the historical significance and cultural value of these artifacts.

Further exploration will delve into the social impact of this equipment.

Concluding Remarks

The preceding analysis has comprehensively explored the multifaceted aspects of old wooden ice skates, elucidating their construction, historical context, preservation, and significance. Their evolution from rudimentary transportation tools to recreational equipment reflects technological advancements and evolving societal practices. Understanding the materials used, manufacturing era, geographic origin, and intended use is crucial for a complete appreciation of these artifacts.

The continued study and preservation of old wooden ice skates are vital to maintaining a connection with the past and understanding the ingenuity of previous generations. Further research is encouraged to uncover additional insights into their social impact and technological development, ensuring that their historical value is recognized and preserved for future study and appreciation.