Equipment facilitating mobility on hard surfaces, characterized by reduced mass, enhances maneuverability. These items typically consist of a boot or shoe attached to a frame with wheels. Reduced weight contributes to ease of use and prolonged activity duration. For example, models constructed with lightweight composites and smaller wheel diameters prioritize agility.

Employing equipment with diminished heft offers several advantages. It allows for quicker acceleration, decreased fatigue during extended use, and improved control for intricate maneuvers. Historically, heavier models presented challenges for novice users and limited the performance capabilities of experienced skaters. The progression towards lighter designs has broadened accessibility and elevated the sport’s potential.

Subsequent sections will examine specific construction materials, optimal applications, and considerations for selecting equipment based on individual user requirements and skill level. Factors affecting performance and maintenance will also be discussed.

Guidance on Utilizing Reduced-Mass Foot-Mounted Wheeled Devices

The following guidance focuses on maximizing performance and ensuring safety when using foot-mounted wheeled devices designed for reduced weight. These recommendations address selection, maintenance, and technique for optimal results.

Tip 1: Prioritize Fit: Proper fit is paramount. Securely fastened, yet not constricting, the boot should provide ample support to prevent ankle strain. Ill-fitting equipment compromises control and increases the risk of injury. Consult sizing charts and consider professional fitting services.

Tip 2: Inspect Before Each Use: Thoroughly examine all components before each session. Check wheel integrity, axle tightness, and boot attachments. Any signs of wear or damage necessitate immediate repair or replacement. A pre-use inspection is a critical safety measure.

Tip 3: Master Fundamental Skills: Proficiency in basic skills such as stopping, turning, and maintaining balance is essential. Practice these maneuvers in a controlled environment before attempting advanced techniques. Competency reduces the likelihood of falls and accidents.

Tip 4: Adapt to Surface Conditions: Different surfaces affect performance. Smooth, even surfaces offer optimal speed and control. Uneven or abrasive surfaces can decrease speed and increase wear. Adjust technique and exercise caution accordingly.

Tip 5: Utilize Protective Gear: Helmets, wrist guards, elbow pads, and knee pads provide crucial protection against injuries. Consistent use of protective gear significantly reduces the severity of potential falls and impacts.

Tip 6: Regularly Maintain Equipment: Clean wheels and bearings regularly to remove debris and ensure smooth rotation. Periodically lubricate bearings to minimize friction and extend their lifespan. Consistent maintenance preserves performance and longevity.

Tip 7: Gradually Increase Intensity: Avoid overexertion and gradually increase the duration and intensity of skating sessions. This approach minimizes the risk of muscle strain and fatigue-related accidents. Proper warm-up and cool-down routines are also essential.

Adhering to these recommendations enhances safety, improves performance, and extends the lifespan of reduced-mass foot-mounted wheeled devices. Proper preparation and diligent maintenance are key to maximizing enjoyment and minimizing risk.

The subsequent section will delve into specific applications, highlighting the advantages of this equipment in various skating disciplines.

1. Agility Enhancement

Agility enhancement, a direct consequence of reduced mass, represents a significant performance advantage in foot-mounted wheeled locomotion. The diminished inertia associated with lighter equipment allows for quicker directional changes and more responsive control, thereby expanding the range of possible maneuvers and enhancing overall maneuverability.

- Reduced Rotational Inertia

The lighter the equipment, the less force required to initiate and cease rotation. This translates into quicker turns, spins, and transitions, particularly advantageous in disciplines demanding rapid directional changes, such as roller derby and slalom skating. The reduction in rotational inertia is a measurable and quantifiable improvement directly correlated to mass reduction.

- Improved Responsiveness

Decreased weight translates directly into improved responsiveness to user input. The equipment reacts more quickly to subtle shifts in weight and body positioning, enabling finer control and more precise execution of complex movements. This responsiveness is critical for maintaining balance and executing intricate routines.

- Enhanced Acceleration and Deceleration

Lighter equipment requires less energy to accelerate and decelerate. This allows for quicker bursts of speed and more efficient braking, essential for navigating crowded spaces or executing dynamic maneuvers. The ability to rapidly change speed contributes significantly to overall agility.

- Minimized Fatigue

The reduced effort required to maneuver lighter equipment results in decreased muscular fatigue over extended periods. This allows skaters to maintain peak performance for longer durations, enabling them to execute more complex maneuvers without sacrificing control or precision. Reduced fatigue indirectly enhances agility by preserving the skater’s physical capacity for rapid movements.

These facets, acting in concert, underscore the profound impact of reduced mass on agility. The enhanced responsiveness, quicker acceleration, and minimized fatigue collectively contribute to a more dynamic and controlled skating experience, making the equipment a preferred choice for disciplines demanding rapid and precise movements.

2. Fatigue Reduction

The correlation between equipment weight and user fatigue is a demonstrable principle in biomechanics. When applied to foot-mounted wheeled devices, a reduction in mass directly translates to a decrease in the energy expenditure required for locomotion. The equipment, therefore, demands less effort per stride, push, or maneuver. Over extended periods, this seemingly marginal reduction in energy expenditure accumulates, significantly mitigating muscular fatigue. Consider, for instance, long-distance skating events; heavier equipment necessitates greater muscular exertion, leading to premature exhaustion and diminished performance, a consequence effectively countered by lightweight alternatives.

The importance of fatigue reduction extends beyond endurance applications. In disciplines requiring precise and repetitive movements, such as artistic skating or roller hockey, sustained muscular control is paramount. Premature fatigue compromises accuracy, coordination, and ultimately, performance. Lightweight equipment enables skaters to maintain peak performance for longer durations, facilitating the execution of complex routines and prolonged gameplay. Moreover, for recreational skaters, minimized fatigue enhances enjoyment and encourages longer skating sessions, thereby promoting physical activity and overall well-being. The practical significance is evident in the growing adoption of lightweight materials and designs across various skating disciplines.

In summary, the integration of lightweight materials into the construction of foot-mounted wheeled devices directly addresses the challenge of user fatigue. The diminished energy expenditure associated with lighter equipment not only improves performance in endurance-based activities but also enhances precision and control in disciplines demanding repetitive movements. This principle underscores the enduring value of lightweight design in promoting both athletic performance and recreational enjoyment. The pursuit of further material advancements, aimed at achieving even greater weight reductions without compromising structural integrity, remains a critical area of ongoing research and development.

3. Material Composition

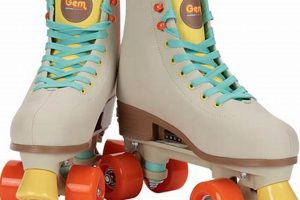

The material composition of foot-mounted wheeled devices significantly impacts their overall weight, directly influencing performance and user experience. The selection of materials constitutes a primary design consideration when developing equipment characterized by reduced mass. The cause-and-effect relationship is demonstrably clear: lighter materials yield lighter equipment. This reduction in weight facilitates enhanced agility, decreased fatigue, and improved control. Various materials, each possessing distinct properties, contribute to the construction. These include polymers, alloys, and composites. The judicious application of these materials, considering their strength-to-weight ratios and durability, is crucial in creating functional and effective lightweight equipment. For example, carbon fiber composites, known for their high strength and low density, are frequently employed in high-performance models to minimize mass without compromising structural integrity. The practical significance of understanding material properties is evident in the ability to engineer equipment tailored to specific performance requirements.

The specific materials used extend beyond the frame or chassis. Wheel composition also plays a vital role. Polyurethane, a versatile polymer, is widely used due to its abrasion resistance, rebound characteristics, and ability to be molded into various hardnesses. The durometer, or hardness, of the polyurethane affects grip, speed, and durability. Lighter-weight cores, constructed from polymers or alloys, can further reduce the overall mass of the wheel assembly. Furthermore, the materials used in bearings, such as ceramic or steel, influence rolling resistance and contribute to the overall efficiency of the equipment. Manufacturers continually explore novel materials and manufacturing techniques to optimize the balance between weight, strength, and performance.

In summary, material composition is an indispensable element in the design and construction of reduced-mass foot-mounted wheeled devices. The strategic selection and application of materials directly impact weight, performance, and durability. Ongoing research and development in materials science continue to drive innovation in this field, pushing the boundaries of what is achievable in terms of weight reduction and performance enhancement. Challenges remain in balancing weight reduction with structural integrity and cost-effectiveness, but the importance of material composition in achieving optimal performance remains paramount.

4. Wheel Diameter

Wheel diameter constitutes a critical parameter in the design and performance of foot-mounted wheeled devices with reduced mass. The size of the wheel directly influences speed, maneuverability, and stability, each of which interacts with the weight characteristics to determine the overall skating experience. Smaller diameter wheels, by virtue of their reduced circumference, require less energy to accelerate and decelerate. In configurations prioritizing lightness, smaller wheels complement the reduced mass to provide rapid responsiveness. Conversely, larger diameter wheels, while offering higher top speeds due to increased roll distance per revolution, necessitate greater effort to initiate movement and maintain momentum. The selection of wheel diameter is thus a carefully considered trade-off between speed, agility, and energy expenditure.

In the context of “light roller skates,” the emphasis on reduced mass often leads to the adoption of smaller diameter wheels. This choice amplifies the benefits of lightness, creating equipment characterized by exceptional maneuverability and responsiveness. For instance, recreational models designed for indoor use or figure skating often feature smaller wheels to facilitate tight turns and intricate movements. Conversely, speed skates, while also benefiting from lightweight construction, typically employ larger diameter wheels to maximize speed and efficiency over longer distances. The practical application of this principle is evident in the diverse range of wheel sizes available across different skating disciplines, each tailored to optimize performance for specific activities.

In summary, wheel diameter is inextricably linked to the performance characteristics of foot-mounted wheeled devices, particularly those designed for reduced mass. The choice of wheel size represents a carefully considered compromise between speed, maneuverability, and energy expenditure. While smaller diameter wheels enhance agility and responsiveness in lightweight configurations, larger diameter wheels prioritize speed and efficiency. Understanding this interplay is essential for selecting the optimal wheel diameter for a given application, ensuring both performance and user satisfaction.

5. Bearing Efficiency

Bearing efficiency plays a crucial role in the performance of foot-mounted wheeled devices characterized by reduced mass. Bearings, the components facilitating wheel rotation, directly influence rolling resistance and, consequently, the energy required for propulsion. The relationship between bearing efficiency and the overall lightness of the equipment is synergistic; high-efficiency bearings maximize the benefits of reduced mass, translating to improved speed, reduced fatigue, and enhanced control. An in-depth examination of specific facets reveals the nature of this relationship.

- Friction Reduction

The primary function of a bearing is to minimize friction between rotating surfaces. High-efficiency bearings achieve this through precision manufacturing, optimized lubricant selection, and advanced materials. Lower friction translates directly to reduced energy loss during rolling, enabling the equipment to maintain momentum with less effort. For instance, ceramic bearings, with their inherently lower coefficient of friction compared to steel bearings, are often incorporated into high-performance models to maximize efficiency. The implementation of advanced lubrication techniques further enhances friction reduction.

- Material Selection

Bearing material selection significantly impacts efficiency and durability. High-grade steel alloys, known for their hardness and resistance to deformation, are commonly used in bearing construction. However, ceramic materials, such as silicon nitride, offer superior hardness, lower density, and reduced friction, resulting in even greater efficiency. The selection of bearing material represents a trade-off between cost and performance, with ceramic bearings typically commanding a premium price due to their enhanced performance characteristics. The practical significance of material selection is evident in the differing performance levels between entry-level and high-end equipment.

- Precision Manufacturing

The precision with which bearings are manufactured directly affects their efficiency. Tighter tolerances and smoother surface finishes minimize friction and ensure consistent performance. High-precision bearings, manufactured to exacting standards, exhibit minimal runout and vibration, resulting in smoother and more efficient rolling. The manufacturing process significantly impacts the cost and performance of bearings, with higher-precision bearings demanding more sophisticated manufacturing techniques and quality control measures. The correlation between manufacturing precision and performance is a well-established principle in mechanical engineering.

- Lubrication Optimization

Proper lubrication is essential for minimizing friction and extending the lifespan of bearings. Lubricants reduce friction by creating a thin film between rolling surfaces, preventing direct contact and minimizing wear. The selection of lubricant, as well as the method of application, significantly impacts bearing efficiency. Synthetic lubricants, formulated with advanced additives, offer superior performance compared to conventional lubricants, particularly in high-speed and high-load applications. The use of appropriate seals and shields prevents lubricant contamination and ensures consistent performance over time. A well-lubricated bearing operates more efficiently, resulting in improved speed and reduced energy consumption.

In conclusion, bearing efficiency is a critical factor influencing the performance of foot-mounted wheeled devices designed for reduced mass. Friction reduction, material selection, precision manufacturing, and lubrication optimization all contribute to maximizing efficiency and translating the benefits of lightness into tangible performance gains. The integration of high-efficiency bearings enhances speed, reduces fatigue, and improves control, ultimately leading to a more enjoyable and rewarding skating experience. The ongoing development of advanced bearing technologies promises to further enhance performance and efficiency in the future.

6. Secure Fit

A secure fit is a paramount characteristic of foot-mounted wheeled devices, particularly those engineered for reduced mass. The interconnection between these two elements lightness and secure attachment constitutes a critical determinant of performance, control, and safety. A loosely fitted device, irrespective of its lightweight design, negates potential advantages by impeding efficient energy transfer from the skater to the wheels. This inefficiency manifests as reduced acceleration, diminished maneuverability, and increased fatigue. Conversely, an overly tight fit can restrict circulation, causing discomfort and hindering performance. Therefore, a properly secured, yet comfortable, fit is indispensable for realizing the full potential of lightweight equipment. Consider, for example, a competitive speed skater; a device that is not securely fastened will compromise their ability to maintain balance during high-speed turns, rendering the benefits of the lightweight construction irrelevant. A similar scenario arises in recreational skating; improperly fitted devices increase the risk of ankle instability and falls, regardless of their reduced mass.

The realization of a secure fit involves several key considerations. The selection of appropriate sizing is fundamental. Manufacturers provide sizing charts that account for foot length and width. However, individual foot morphology can vary significantly, necessitating professional fitting services in certain cases. Lacing systems, buckle mechanisms, and power straps play vital roles in securing the device to the foot. These mechanisms must provide adjustable tension to accommodate individual preferences and anatomical variations. Furthermore, the internal padding and support structure of the boot contribute to both comfort and security. High-quality padding materials mold to the contours of the foot, providing cushioning and preventing slippage. The integration of rigid support elements, such as ankle braces, enhances stability and minimizes the risk of injury. Material science contributes also as materials that can adapt to user feet during prolonged time usage, such as inner material that can change its form to fit the user’s feet.

In summary, a secure fit is not merely a desirable attribute but a fundamental requirement for foot-mounted wheeled devices, especially those designed for reduced mass. The proper fit optimizes energy transfer, enhances control, and minimizes the risk of injury. Achieving a secure fit necessitates careful attention to sizing, lacing mechanisms, internal padding, and support structures. Ongoing advancements in materials science and design continue to refine the methods by which a secure and comfortable fit can be achieved, contributing to improved performance and enhanced user safety across all skating disciplines. Challenges remain in accommodating the wide range of foot morphologies and individual preferences, but the pursuit of a secure and optimized fit remains a central focus in the development of high-performance skating equipment.

Frequently Asked Questions

The following questions address common inquiries regarding foot-mounted wheeled devices characterized by reduced mass. The answers provided aim to clarify technical aspects and address prevalent misconceptions.

Question 1: What constitutes “light roller skates” and how is their weight defined?

The term denotes equipment designed with a primary focus on minimizing mass. While a universally accepted weight threshold does not exist, these devices typically employ lightweight materials and designs to achieve a significantly lower weight compared to traditional models. The specific weight varies depending on size and intended application.

Question 2: Does reduced weight compromise durability?

Not necessarily. The durability is largely dependent on the materials used and the manufacturing process. High-performance lightweight models often utilize advanced composites and alloys engineered for both strength and weight reduction. However, entry-level models employing less robust materials may exhibit reduced durability compared to heavier, more traditionally constructed equipment.

Question 3: Are light roller skates suitable for all skill levels?

While generally accessible, the suitability depends on individual user characteristics. The enhanced maneuverability offered by lighter equipment can be beneficial for experienced skaters seeking greater agility. However, novice users may find the increased responsiveness challenging initially, requiring a period of adaptation to develop adequate control.

Question 4: How does wheel size affect the performance of light roller skates?

Smaller diameter wheels, often found on lighter models, generally prioritize maneuverability and acceleration. Larger diameter wheels, conversely, offer higher top speeds and improved roll distance. The optimal wheel size depends on the intended application and the user’s preference for speed versus agility.

Question 5: What maintenance is required for light roller skates?

Maintenance requirements are generally similar to those of traditional models, including regular cleaning of wheels and bearings, inspection of hardware for looseness or damage, and periodic replacement of worn components. Special attention should be paid to the integrity of lightweight components, as they may be more susceptible to certain types of damage.

Question 6: Do light roller skates offer any advantages beyond performance?

Beyond improved agility and reduced fatigue, lighter equipment can offer increased comfort during transport and storage. The reduced weight also minimizes strain on joints during use, potentially reducing the risk of certain types of injuries associated with repetitive impact.

In summary, “light roller skates” offer distinct advantages in terms of performance and user experience. However, careful consideration should be given to material quality, intended application, and individual skill level to ensure optimal selection and safe usage.

The subsequent section will explore specific purchasing considerations, offering guidance on selecting the most appropriate model based on individual needs and preferences.

Conclusion

This exploration has detailed the salient features, advantages, and considerations pertaining to foot-mounted wheeled devices characterized by reduced mass. Emphasis has been placed on the interrelationship between lightweight construction and performance attributes, including agility, fatigue reduction, and material composition. The impact of wheel diameter and bearing efficiency on overall performance has also been examined, along with the critical importance of a secure and properly fitted configuration. The analyses presented aim to provide a comprehensive understanding of the topic, enabling informed decision-making regarding equipment selection and usage.

The ongoing development and refinement of materials and designs continue to push the boundaries of what is achievable in the realm of foot-mounted wheeled locomotion. The pursuit of ever-lighter and more efficient equipment underscores a commitment to enhanced performance, improved user experience, and expanded accessibility. Further research and development will undoubtedly yield continued advancements, shaping the future of the sport and recreational activity.