Equipment designed for the sport of aggressive inline skating, often referred to as blading, is a specialized subset of inline skates. These skates are characterized by durable construction, supportive features, and design elements specifically tailored for performing tricks, grinds, and jumps on urban terrain or skate parks. K2, a prominent manufacturer, offers a range of these specialized skates.

This type of skate provides several benefits to the user, notably increased durability and performance in demanding conditions. The robust design allows skaters to withstand the impact of jumps and the friction of grinding, extending the lifespan of the equipment. Furthermore, the specialized features often include enhanced ankle support, shock absorption, and replaceable components, all contributing to improved control and safety. Historically, the development of this skate category has been driven by the evolving needs of the aggressive skating community, leading to continual innovation in design and materials.

The subsequent discussion will delve into the specific features of these skates, including frame construction, wheel composition, liner technology, and closure systems, providing a detailed understanding of how these elements contribute to overall performance and suitability for aggressive skating disciplines.

Expert Guidance for Aggressive Skating Equipment

Optimal performance with aggressive inline skates hinges on careful selection, maintenance, and understanding of the equipment’s capabilities. The following insights are intended to enhance the skater’s experience and promote responsible use of this specialized gear.

Tip 1: Frame Selection: The frame is the foundational element of the skate. Opt for a robust frame, often constructed from reinforced nylon or metal, capable of withstanding high-impact landings and prolonged grinding. Consider frame designs that offer generous grinding surfaces and accommodate various wheel configurations.

Tip 2: Wheel Durometer and Size: Wheel durometer affects grip and speed. A higher durometer (e.g., 90A+) offers increased speed and durability on smooth surfaces, while lower durometers provide better grip on rougher terrains. Wheel size influences maneuverability. Smaller wheels (55-60mm) are typically preferred for aggressive skating due to their agility and responsiveness.

Tip 3: Bearing Quality: High-quality bearings minimize friction, resulting in smoother and faster rolling. ABEC ratings indicate bearing precision; however, consider durability alongside precision. Regular cleaning and lubrication of bearings are crucial for maintaining optimal performance.

Tip 4: Liner Fit and Support: A properly fitted liner provides comfort and enhances control. Ensure the liner offers adequate ankle support and heel lock to prevent slippage during aggressive maneuvers. Consider heat-moldable liners for a customized fit.

Tip 5: Protective Gear: Prioritize safety by consistently using protective gear, including a helmet, knee pads, elbow pads, and wrist guards. Ill-fitting or damaged protective equipment offers diminished protection and should be replaced promptly.

Tip 6: Regular Maintenance: Conduct routine inspections of the skates, checking for loose bolts, worn wheels, and damaged frames. Promptly replace worn or damaged components to maintain performance and safety. Clean the skates regularly to prevent debris accumulation.

Tip 7: Grind Plate Integrity: Grind plates are designed to withstand the friction of grinds. Regularly inspect them for excessive wear and tear. Replace grind plates when they become significantly worn to maintain consistent grinding performance.

Adhering to these guidelines will contribute to a safer and more rewarding aggressive skating experience. Proper equipment selection and meticulous maintenance are integral to maximizing performance and longevity.

The next section will explore specific techniques and training methodologies related to the effective utilization of aggressive inline skates.

1. Durable frame construction

Frame construction is a pivotal element in aggressive inline skates, directly influencing performance, safety, and longevity, especially within the K2 aggressive skate product line. The frame must endure substantial stresses from grinding, jumping, and landing, requiring specialized design and materials.

- Material Composition

Aggressive skate frames often utilize high-density polymers, reinforced nylon, or metal alloys. These materials provide impact resistance and minimize deformation during aggressive maneuvers. Material selection directly impacts the frame’s weight, stiffness, and ability to absorb shock. An example is the use of aircraft-grade aluminum in high-end K2 frames, offering a superior strength-to-weight ratio.

- Frame Design and Geometry

Frame design incorporates specific features to facilitate grinding, such as recessed areas or replaceable grind blocks. Geometry affects stability and maneuverability. Shorter frames offer increased agility, while longer frames provide greater stability at higher speeds. K2 aggressive skate frames are often designed with a specific “H-block” area for controlled grinds.

- Impact Resistance and Load Distribution

A durable frame distributes impact forces across its structure, minimizing stress concentration and preventing catastrophic failure. Ribbing, gussets, and internal bracing can enhance frame strength. K2 frame designs often include reinforced areas around axle mounting points, where stress is highest during landings.

- Compatibility and Customization

Frame design must be compatible with various wheel sizes and configurations, allowing skaters to customize their setup for specific skating styles. Some frames offer adjustable wheel positioning or accommodate anti-rocker setups. The ability to use different wheel setups gives flexibility in usage. The K2 frame systems are often designed to be modular allowing for after-market modifications.

The selection of a frame with appropriate material composition, design, impact resistance, and customization options is critical for optimizing performance and ensuring the durability of K2 aggressive inline skates. Failure to consider these aspects can lead to premature wear, compromised performance, and increased risk of injury, and ultimately, a less than satisfactory skate performance. These robust frames provide the structural backbone necessary to meet the demands of aggressive skating.

2. Wheel size, durometer

Wheel size and durometer represent fundamental characteristics of inline skate wheels directly influencing the performance and suitability of K2 aggressive inline skates for various skating styles and terrains. The selection of appropriate wheel specifications is critical for optimizing control, speed, and grip during aggressive maneuvers.

- Wheel Size and Maneuverability

Smaller wheel diameters (typically 55mm to 60mm) are generally favored in aggressive skating due to their increased maneuverability and responsiveness. These smaller wheels facilitate quicker turns and allow skaters to maintain better control during grinds and jumps. Conversely, larger wheels offer higher top speeds but sacrifice agility, making them less suitable for the technical aspects of aggressive skating. For K2 aggressive skates, a smaller wheel allows for more intricate footwork and immediate adjustments during complex trick combinations.

- Wheel Durometer and Grip/Speed Trade-off

Durometer, measured on the A scale, indicates the hardness of the wheel. A higher durometer (e.g., 90A or above) signifies a harder wheel, which provides lower rolling resistance and increased speed on smooth surfaces. However, harder wheels offer less grip, particularly on rough or uneven terrains. Conversely, a lower durometer (e.g., 86A or below) signifies a softer wheel, which offers enhanced grip and shock absorption but sacrifices speed. Aggressive skaters often choose wheels with a moderate durometer (around 88A-90A) to balance speed and grip for diverse skate park and street environments. K2’s wheel selection often reflects a consideration for balancing these factors.

- Wheel Profile and Contact Patch

The wheel profile, or shape of the wheel’s contact surface, influences grip and stability. A round profile provides smoother transitions and increased maneuverability, while a flat profile offers greater stability and a larger contact patch for enhanced grip. Aggressive skate wheels typically feature a round or slightly rounded profile to facilitate smooth transitions during grinds and spins. The contact patch is the area of the wheel in contact with the ground. A larger contact patch increases grip, while a smaller contact patch reduces friction and increases speed. Careful design of the wheel contact area is crucial for optimal aggressive skating performance in K2 inline skates.

- Core Design and Durability

The wheel core, or inner structure, influences the wheel’s durability and performance. A robust core provides support and prevents deformation under stress, while a lightweight core reduces overall weight and improves responsiveness. Many aggressive skate wheels feature a reinforced core designed to withstand the impact of jumps and landings. K2 aggressive skates often feature high-quality cores made from durable materials to resist damage and maintain wheel integrity, ensuring a longer lifespan under demanding conditions.

In summary, appropriate wheel size and durometer selection are crucial for optimizing the performance of K2 aggressive inline skates. By carefully considering the trade-offs between maneuverability, speed, grip, and durability, skaters can choose wheel specifications that align with their skating style and terrain preferences, ultimately enhancing their overall skating experience.

3. Bearing precision, maintenance

Bearing precision directly affects the performance of K2 aggressive inline skates. Precision refers to the manufacturing tolerances of the bearing components, primarily the balls, races, and retainer. Higher precision bearings, indicated by ABEC or similar ratings, exhibit lower rolling resistance, enabling smoother and faster wheel rotation. This translates to increased speed and reduced effort required for propulsion, essential attributes for executing intricate maneuvers in aggressive skating. Furthermore, precise bearings minimize vibration and friction, reducing heat buildup and extending bearing lifespan. Neglecting bearing precision can lead to diminished speed, increased fatigue, and a heightened risk of component failure during demanding aggressive skating sessions. As an example, bearings with lower precision (e.g., ABEC 1) may exhibit noticeable drag and reduced top speed compared to higher precision bearings (e.g., ABEC 5 or higher) on K2 aggressive skates, affecting jump height and grind initiation.

Maintenance is equally critical. Aggressive skating subjects bearings to significant stress from impacts, dirt, and moisture. Regular cleaning and lubrication are necessary to remove contaminants, prevent corrosion, and maintain optimal performance. Debris accumulation increases friction, leading to reduced speed and premature wear. Proper lubrication reduces friction, protects against corrosion, and prolongs bearing life. Skaters who neglect bearing maintenance often experience reduced speed, increased noise, and eventual bearing failure. For instance, aggressive skaters who routinely skate in wet conditions must clean and lubricate their bearings more frequently to prevent rust formation. Additionally, after landing heavily, bearings can sometimes become misaligned or damaged, requiring inspection and potential replacement.

The interplay between bearing precision and maintenance significantly impacts the overall performance and longevity of K2 aggressive inline skates. High-precision bearings, when properly maintained, offer enhanced speed, efficiency, and durability, contributing to a more responsive and enjoyable skating experience. However, even high-precision bearings will degrade rapidly without consistent maintenance. Challenges include the time and effort required for meticulous cleaning and lubrication, and the need for specialized tools. Ultimately, a commitment to both bearing precision and diligent maintenance is essential for maximizing the potential of K2 aggressive inline skates and ensuring safe and reliable performance in demanding conditions.

4. Liner fit, support

Within the context of K2 aggressive inline skates, liner fit and support are critical determinants of performance, comfort, and injury prevention. The skate liner serves as the interface between the skater’s foot and the rigid boot, directly influencing control, stability, and the ability to execute aggressive maneuvers effectively.

- Ankle Support and Stability

The liner’s design, particularly around the ankle, provides crucial lateral and medial support, preventing ankle roll during landings and transitions. Adequate ankle support allows the skater to maintain balance and control during high-impact maneuvers. Insufficient ankle support can lead to instability, increasing the risk of sprains or other injuries. K2 aggressive skate liners often incorporate reinforced materials or articulated designs to enhance ankle support without restricting mobility. For example, a liner with a high cuff and strategically placed padding can significantly improve ankle stability compared to a liner with a lower cuff and minimal padding.

- Heat Moldability and Custom Fit

Many K2 aggressive skate liners feature heat-moldable materials, allowing skaters to customize the fit to their individual foot contours. Heat molding ensures a snug, pressure-free fit, minimizing friction and hot spots that can cause blisters or discomfort. A custom fit also enhances responsiveness, as the liner conforms precisely to the foot, translating movements more efficiently to the skate. The benefits of a heat-moldable liner are exemplified by skaters who experience pressure points with standard liners; heat molding allows them to alleviate these issues, resulting in improved comfort and performance.

- Shock Absorption and Impact Dampening

The liner’s construction incorporates materials designed to absorb and dampen the impact forces generated during jumps and landings. Shock-absorbing foams or gel inserts reduce stress on the feet and joints, mitigating fatigue and preventing injuries. Adequate shock absorption is particularly important in aggressive skating, where skaters frequently encounter high-impact situations. K2 aggressive skate liners often feature specialized padding in the heel and forefoot areas to maximize shock absorption in these high-stress zones. For instance, a liner with a gel-padded heel can significantly reduce the impact felt during landings compared to a liner with minimal padding.

- Moisture Management and Ventilation

Aggressive skating is a physically demanding activity that generates significant heat and perspiration. Liners constructed with breathable materials and ventilation channels help to wick away moisture, keeping the feet dry and comfortable. Effective moisture management prevents the buildup of sweat, which can lead to blisters, fungal infections, and reduced thermal insulation. K2 aggressive skate liners often incorporate mesh panels or moisture-wicking fabrics to promote ventilation and keep the feet cool and dry. A liner with effective ventilation will contribute to a more comfortable skating experience, particularly during extended sessions or in warm weather.

The interconnected nature of these liner attributesankle support, heat moldability, shock absorption, and moisture managementcollectively determine the overall performance and comfort of K2 aggressive inline skates. A well-designed liner that addresses these key factors will enhance control, minimize injury risk, and optimize the skater’s ability to execute aggressive maneuvers with confidence.

5. Grind Plate Integrity

Grind plate integrity is a critical factor in the functionality and longevity of K2 aggressive inline skates. The grind plate, an integrated or replaceable component of the skate’s frame, directly interfaces with surfaces during grinding maneuvers. Its structural soundness dictates the skater’s ability to execute tricks safely and effectively, while also protecting the underlying frame from wear.

- Material Composition and Durability

The material composition of the grind plate directly influences its resistance to abrasion and impact. High-density polyethylene (HDPE), nylon, or composite materials are commonly employed for their balance of durability and sliding properties. The integrity of these materials is compromised by repeated grinding, leading to wear, cracking, or deformation. Premature degradation necessitates replacement, impacting both the skater’s performance and the skate’s operational lifespan. For K2 aggressive skates, grind plate materials are selected to withstand the specific demands of urban and skate park environments.

- Design and Surface Area

The design and surface area of the grind plate determine its effectiveness in distributing pressure and facilitating smooth grinds. A well-designed grind plate maximizes contact area, reducing friction and preventing snagging on surfaces. Insufficient surface area or poorly designed contours can lead to instability and increased wear on the surrounding frame components. K2 skate designs often incorporate strategically shaped grind plates to optimize grinding performance across various surfaces and trick types. A wider grind plate facilitates stability.

- Attachment Method and Structural Support

The method of attachment and the underlying structural support contribute significantly to the grind plate’s overall integrity. Secure attachment prevents the plate from detaching or shifting during grinding maneuvers, ensuring consistent performance and skater safety. Robust support structures distribute stress evenly across the frame, minimizing the risk of frame damage. K2 aggressive skates utilize various attachment methods, including bolts, rivets, or integrated mounting systems, each engineered to provide secure and reliable fixation. An integrated mounting method is preferable for high performance.

- Replaceability and Maintenance

The ability to replace worn or damaged grind plates is essential for extending the lifespan of K2 aggressive inline skates. Replaceable grind plates allow skaters to maintain optimal performance without replacing the entire frame. Regular inspection and replacement of worn grind plates are crucial for preventing damage to the underlying frame and ensuring consistent grinding performance. K2 often offers replacement grind plates specifically designed for their aggressive skate models, ensuring compatibility and ease of maintenance. Using non-OEM plates is not recommended.

The integrity of the grind plate, defined by material composition, design, attachment, and replaceability, is indispensable for the optimal use of K2 aggressive inline skates. Regular monitoring, proactive maintenance, and timely replacement are necessary to sustain performance levels, prolong equipment lifespan, and guarantee safety for skaters engaging in aggressive skating disciplines. The combination of these factors leads to safer skate park experiences.

6. Closure system security

The closure system on K2 aggressive inline skates is paramount for maintaining foot stability, optimizing energy transfer, and ensuring skater safety during high-impact maneuvers. A secure closure system minimizes foot movement within the boot, enhancing control and responsiveness. Compromised closure integrity elevates the risk of injury and diminishes skating performance.

- Buckle Design and Functionality

Buckles, a common component of closure systems, provide adjustable and secure fastening. Durable buckle construction and reliable locking mechanisms are essential. Malfunctioning buckles compromise foot stability, increasing the likelihood of ankle sprains or other injuries. K2 aggressive skates utilize buckles made from robust materials like reinforced nylon or metal alloys, designed to withstand repetitive use and impact forces. Poor functionality can lead to ill-fitting boots.

- Lace Materials and Configuration

Laces, in conjunction with buckles or straps, provide customizable fit and support. High-tensile strength laces resist stretching and breakage under stress. The lacing configuration influences the distribution of pressure across the foot. Improper lacing techniques or frayed laces diminish closure system effectiveness, resulting in reduced control and potential instability. K2 aggressive skates employ durable laces and strategic lacing patterns to optimize foot security. Inappropriate patterns can lead to discomfort.

- Power Straps and Velcro Closures

Power straps, often positioned around the ankle or instep, enhance support and responsiveness. Velcro closures offer quick and adjustable fastening. The integrity of the strap material and the Velcro’s adhesive strength directly impacts the closure system’s ability to maintain foot stability. Worn or damaged straps compromise ankle support, increasing the risk of injury during landings or grinds. K2 aggressive skates utilize power straps constructed from durable materials with reliable Velcro closures to provide enhanced support and control. Low quality straps compromise integrity.

- Integration with Liner and Boot Design

The closure system’s effectiveness is intrinsically linked to the design and construction of the skate’s liner and boot. A well-integrated closure system complements the liner’s padding and support features, creating a secure and comfortable fit. Incompatible closure systems or poorly designed boots can lead to pressure points, discomfort, and reduced control. K2 aggressive skates are engineered with integrated closure systems that work in harmony with the liner and boot to provide optimal foot security and responsiveness. Improper design leads to poor performance.

The security of the closure system, encompassing buckle functionality, lace integrity, strap effectiveness, and integration with the boot, is indispensable for maximizing the performance and safety of K2 aggressive inline skates. Neglecting closure system maintenance or utilizing substandard components can compromise foot stability, elevate injury risk, and diminish the skater’s ability to execute aggressive maneuvers confidently. Regular inspection, proper adjustment, and timely replacement of worn components are crucial for maintaining closure system integrity and ensuring a secure and responsive skating experience.

7. Ankle support rigidity

Ankle support rigidity in K2 aggressive inline skates is a critical design element directly impacting performance and safety. The inherent demands of aggressive skatingcharacterized by high-impact landings, rapid directional changes, and intricate grinding maneuversplace substantial stress on the skater’s ankles. Rigid ankle support mitigates excessive ankle flexion and eversion, preventing injuries such as sprains and fractures. The design of K2 aggressive skates prioritizes this support through reinforced shells, strategically placed padding, and secure closure systems. Failure to provide adequate rigidity compromises stability, reduces control, and elevates the risk of injury, making this a crucial component. Example: In a typical jump and landing scenario, rigid ankle support enables the skater to absorb impact forces more efficiently, minimizing strain on the ankle joint.

The practical significance of understanding ankle support rigidity lies in informed equipment selection and proper usage. Skaters should assess their skill level and skating style to determine the appropriate level of support. Beginners may benefit from more rigid support, providing added stability while learning fundamental techniques. Experienced skaters, who have developed stronger ankle musculature, may prefer slightly less rigid support to facilitate greater range of motion. Proper tightening of closures is crucial to maximize the benefits of the designed ankle support. Moreover, recognizing signs of wear or damage to the ankle support components, such as shell cracks or padding compression, allows for timely maintenance or replacement, preventing potential injuries. These decisions impact safety.

In summary, ankle support rigidity is an indispensable feature of K2 aggressive inline skates, directly correlating with injury prevention and enhanced performance. Recognizing the importance of rigidity, selecting appropriate equipment, and maintaining closure systems contribute to a safer and more rewarding skating experience. Ignoring this critical connection can significantly increase the risk of ankle injuries and hinder skill development. The evolution of skate design aims at continued improvements in protection.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection, usage, and maintenance of K2 aggressive inline skates, providing insights intended to enhance understanding and promote responsible skating practices.

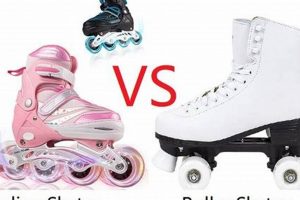

Question 1: What distinguishes aggressive inline skates from recreational inline skates?

Aggressive inline skates are characterized by durable construction, reinforced frames, smaller wheels, and specialized grind plates designed for performing tricks and grinds. Recreational inline skates typically feature larger wheels for speed and distance, and lack the specialized features required for aggressive skating disciplines.

Question 2: What wheel durometer is recommended for aggressive inline skating?

A wheel durometer between 88A and 90A is generally recommended for aggressive inline skating. This range provides a balance between grip and speed suitable for diverse skate park and street environments. Softer wheels offer greater grip but sacrifice speed, while harder wheels provide increased speed but reduced grip.

Question 3: How often should aggressive inline skate bearings be cleaned and lubricated?

Aggressive inline skate bearings should be cleaned and lubricated regularly, ideally after each skating session or at least once a month, depending on usage and environmental conditions. Debris accumulation increases friction and reduces bearing lifespan. Specialized bearing cleaning kits and lubricants are recommended for optimal maintenance.

Question 4: What safety gear is essential for aggressive inline skating?

Essential safety gear for aggressive inline skating includes a helmet, knee pads, elbow pads, and wrist guards. Ill-fitting or damaged protective equipment offers diminished protection and should be replaced promptly. Consistent use of appropriate safety gear is paramount for minimizing injury risk.

Question 5: How should the fit of aggressive inline skate liners be assessed?

Aggressive inline skate liners should fit snugly, providing adequate ankle support and heel lock. Ensure the liner offers sufficient padding to prevent pressure points and discomfort. Heat-moldable liners offer a customized fit, enhancing comfort and control. Excess movement within the boot compromises stability and increases the risk of blisters.

Question 6: How can the lifespan of aggressive inline skate grind plates be extended?

The lifespan of aggressive inline skate grind plates can be extended through regular inspection and maintenance. Promptly replace worn or damaged grind plates to prevent damage to the underlying frame. Avoid grinding on abrasive surfaces that accelerate wear. The material composition of the plate affects its resilience.

Adhering to these guidelines will contribute to a safer and more rewarding aggressive skating experience. Prioritizing proper equipment selection and meticulous maintenance is integral to maximizing performance and longevity.

The subsequent section will explore specific techniques and training methodologies related to the effective utilization of aggressive inline skates.

Conclusion

The preceding discussion has provided a comprehensive overview of the essential components and considerations pertinent to K2 aggressive inline skates. From frame construction and wheel characteristics to bearing precision, liner fit, grind plate integrity, closure system security, and ankle support rigidity, each element plays a crucial role in the overall performance, safety, and longevity of the equipment. Proper understanding and meticulous attention to these details are indispensable for skaters seeking to maximize their capabilities and minimize the risk of injury within the demanding discipline of aggressive inline skating.

As technology advances and materials evolve, continued innovation in skate design is anticipated. It remains the responsibility of the skater to maintain vigilance in selecting appropriate equipment, adhering to rigorous maintenance protocols, and prioritizing safety at all times. The mastery of aggressive inline skating demands not only skill and dedication but also a deep respect for the tools of the trade.

![Best Chicago Skates Inline Skates: [Year] Guide & More! How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Chicago Skates Inline Skates: [Year] Guide & More! | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-470-300x200.jpg)