These items, frequently used for recreational and athletic activities, are often priced and sold in United States Dollars. They offer a versatile form of exercise and transportation, suitable for a variety of skill levels. For example, a beginner might purchase a pair for leisurely skating on paved trails, while an experienced skater might invest in higher-end models for aggressive skating or speed competitions.

The availability of these items in USD reflects their global market presence and accessibility. The price point can influence consumer purchasing decisions and reflects factors such as brand reputation, material quality, and included features. Their development and widespread adoption have roots in the late 20th century, revolutionizing roller skating and creating a new niche in sporting goods.

Understanding the characteristics and associated costs is essential for prospective buyers. Therefore, a thorough examination of relevant aspects such as model types, construction, and market value will provide a comprehensive overview.

Considerations for Purchasing Inline Skates

Acquiring inline skates involves careful consideration of several factors to ensure a suitable choice. Prior planning aids in a satisfactory purchasing experience.

Tip 1: Determine Usage Intent: Identify the intended use, whether recreational, fitness, or aggressive skating. Different disciplines require specific skate features and construction.

Tip 2: Assess Skill Level: Select skates appropriate for one’s skill level. Beginner skates often prioritize stability and ease of use, while advanced models emphasize performance and maneuverability.

Tip 3: Prioritize Fit and Comfort: Ensure a snug and comfortable fit. Ill-fitting skates can lead to discomfort, blisters, and decreased performance. Consult sizing charts and consider trying on skates before purchase.

Tip 4: Evaluate Wheel and Bearing Quality: Wheel durometer and bearing ABEC rating influence speed and smoothness. Softer wheels offer better grip, while harder wheels provide greater speed. Higher ABEC ratings indicate greater precision and efficiency.

Tip 5: Inspect Boot Construction and Support: Evaluate the boot’s material and construction. Stiffer boots provide greater ankle support, beneficial for aggressive skating and high speeds. Softer boots offer more flexibility, suitable for recreational skating.

Tip 6: Establish a Budget: Define a budget range and research models within that price point. Prices for inline skates in USD can vary significantly depending on features and brand reputation.

Tip 7: Research Brands and Reviews: Explore reputable brands and read customer reviews. Brand reputation often reflects product quality and durability. Customer reviews provide insights into real-world performance and potential issues.

Tip 8: Consider Safety Gear: Factor in the cost of essential safety gear, including a helmet, knee pads, elbow pads, and wrist guards. Prioritizing safety is crucial for preventing injuries.

Adhering to these guidelines increases the likelihood of selecting inline skates that meet individual needs and preferences, maximizing enjoyment and minimizing potential issues.

The following sections will delve deeper into specific aspects of inline skate selection and maintenance.

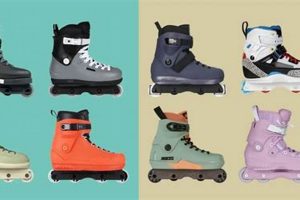

1. Model and brand

The model and brand of inline skates exert a substantial influence on their price in United States Dollars. Established brands with a reputation for quality and innovation often command higher prices, reflecting investments in research, development, and manufacturing processes. Specific models within a brand’s product line also exhibit varying price points based on their features, target audience, and performance capabilities. For instance, a high-end aggressive skating model from a leading brand will typically be priced significantly higher than a basic recreational model from a lesser-known brand. This differential is attributable to factors such as material composition, bearing quality, and overall design sophistication. Consequently, the model and brand serve as significant determinants of the final cost.

The perception of brand value significantly impacts consumer willingness to pay. A recognized brand often provides a sense of assurance regarding durability, performance, and customer support. This perceived value translates directly into higher prices within the market. Moreover, limited-edition models or collaborations between brands further amplify the price due to scarcity and exclusivity. For example, a collaboration between a skate manufacturer and a renowned streetwear brand will typically result in a higher price point than a standard inline skate model. This is because the collaboration model becomes a status symbol, driving up demand and, consequently, the price.

In conclusion, the interplay between model and brand is a critical factor in determining the price of inline skates in USD. Brand reputation and model-specific features directly affect the cost, influencing consumer decisions and shaping market dynamics. Understanding this relationship is essential for making informed purchasing decisions and appreciating the value proposition associated with different inline skate offerings.

2. Material quality

Material quality is a direct determinant of the price of inline skates in United States Dollars. The selection of materials used in the construction of inline skates directly impacts their durability, performance, and overall lifespan, resulting in a corresponding effect on their market value. For example, high-grade aluminum or carbon fiber frames, offering superior strength-to-weight ratios and increased responsiveness, will significantly increase the cost compared to skates constructed with lower-grade plastics or composite materials. Similarly, the type of padding, liner materials, and fastening systems employed directly influence user comfort and skate longevity, reflecting in the final retail price. Thus, the choice of materials serves as a foundational element in establishing the USD value of these products.

The importance of material selection extends beyond initial purchase price. Skates constructed with durable, high-quality materials require less frequent replacement and maintenance, representing a long-term cost-saving. Conversely, cheaper materials are prone to wear and tear, leading to premature failure and increased expenses for repairs or replacements. For instance, bearings made from precision-machined steel and sealed against contaminants will outperform and outlast bearings constructed from cheaper alloys. The quality of wheels, typically made from polyurethane, directly affects grip, roll, and wear resistance; higher-quality formulations offer improved performance and longevity. Therefore, the long-term financial implications of material quality represent a crucial factor influencing purchasing decisions.

In conclusion, material quality stands as a fundamental driver of the price of inline skates in USD. The selection of premium materials directly translates to enhanced durability, performance, and user experience, thereby justifying higher initial costs. Conversely, sacrificing material quality often leads to compromised performance, reduced lifespan, and increased long-term expenses. Therefore, understanding the material composition and its implications is crucial for making informed purchasing decisions and maximizing the value derived from inline skate acquisitions.

3. Bearing precision

Bearing precision, a critical factor influencing the performance of inline skates, directly affects the price point in United States Dollars. The manufacturing tolerances and materials used in bearing construction determine their efficiency and durability, impacting the overall cost of the final product. High-precision bearings reduce friction, enhancing speed and roll, while also exhibiting extended lifespans. This translates to a premium price point.

- ABEC Rating and its Impact

The Annular Bearing Engineering Committee (ABEC) rating system quantifies bearing precision, with higher numbers indicating tighter tolerances. Higher ABEC ratings, such as ABEC-7 or ABEC-9, signify superior precision and smoother operation. Inline skates equipped with such bearings command a higher price due to the increased manufacturing costs and enhanced performance characteristics. For example, skates designed for speed skating typically feature high ABEC-rated bearings to maximize velocity and minimize energy expenditure.

- Material Composition and Durability

Bearing materials, such as chromium steel or ceramic, influence both precision and durability. Ceramic bearings, characterized by their hardness and resistance to heat and corrosion, offer exceptional performance and longevity. However, these advantages come at a higher cost. Inline skates equipped with ceramic bearings are typically priced significantly higher than those with steel bearings. This is evident in high-performance skates used in competitive skating events.

- Sealing and Maintenance Requirements

Bearing seals protect internal components from contaminants, such as dirt and moisture, extending their lifespan and maintaining their precision. High-quality seals, such as rubber or labyrinth seals, offer superior protection but also add to the overall cost. Inline skates designed for outdoor use or aggressive skating often feature enhanced sealing mechanisms to withstand harsh conditions, contributing to a higher price point. Properly sealed bearings require less frequent cleaning and lubrication, reducing maintenance costs over the long term.

- Manufacturing Processes and Quality Control

Advanced manufacturing processes and rigorous quality control measures ensure consistent bearing precision and performance. These processes involve specialized machinery, skilled technicians, and meticulous inspection procedures, all of which contribute to increased production costs. Inline skate manufacturers that prioritize bearing quality invest heavily in these processes, resulting in a higher price for their products. Skates designed for professional use or high-performance applications often undergo extensive testing to ensure optimal bearing performance and reliability.

The cumulative effect of ABEC rating, material composition, sealing mechanisms, and manufacturing processes directly influences the price of inline skates in USD. Bearings represent a critical component affecting performance, durability, and maintenance requirements, thus justifying the premium associated with higher precision and quality. Understanding the connection between bearing precision and the overall value proposition is essential for informed purchasing decisions.

4. Wheel durometer

Wheel durometer significantly impacts the price of inline skates, measured in United States Dollars. The term refers to the hardness of the wheel material, typically polyurethane, and is measured on the Shore A scale. This characteristic directly influences performance, durability, and intended application, subsequently affecting the market value of the skates.

- Impact on Performance Characteristics

Lower durometer wheels (e.g., 78A-82A) offer greater grip and shock absorption, ideal for recreational skating and uneven surfaces. Higher durometer wheels (e.g., 84A-90A) provide faster speeds and increased durability, suitable for speed skating and smooth surfaces. The specialized composition and performance benefits of each type directly correlate to their manufacturing cost and, therefore, the price of the inline skates. For example, skates designed for aggressive skating often feature harder wheels to withstand the wear and tear of grinds and slides, contributing to a higher price point compared to recreational models.

- Influence on Wheel Longevity

Wheel durometer affects the lifespan of the wheels themselves. Softer wheels wear down more quickly, especially on abrasive surfaces, necessitating more frequent replacements. Harder wheels, while offering increased durability, may compromise grip and comfort, potentially leading to decreased user satisfaction. Manufacturers must strike a balance between performance and longevity, impacting material selection and manufacturing processes. Skates designed for high-mileage use or demanding conditions typically feature higher-durometer wheels, which can increase the initial cost but reduce long-term replacement expenses.

- Material Composition and Manufacturing Processes

The specific polyurethane formulation and manufacturing processes employed to achieve a desired durometer influence the cost of production. Higher-quality polyurethane blends with additives to enhance performance characteristics, such as rebound and abrasion resistance, are more expensive than standard formulations. Precision molding techniques and quality control measures further contribute to the overall manufacturing cost. Inline skates featuring wheels made with advanced materials and processes command a premium price, reflecting the improved performance and durability they offer.

In conclusion, wheel durometer is a crucial factor affecting the performance, longevity, and ultimately, the price of inline skates in USD. The selection of appropriate durometer wheels depends on the intended use and skating environment, with higher-performance and more durable options typically resulting in a higher initial investment. Consumers should carefully consider their individual needs and preferences when evaluating the relationship between wheel durometer and the overall value proposition of inline skates.

5. Boot support

Boot support within inline skates significantly influences their price in United States Dollars. The level of support offered dictates the skate’s intended use and target skill level, consequently affecting material selection, design complexity, and manufacturing costs. Increased boot support, typically achieved through rigid materials and sophisticated construction techniques, enhances stability and control, especially at higher speeds or during aggressive maneuvers. This increased performance capability warrants a higher price point compared to skates with less robust support systems. For instance, skates designed for aggressive skating feature stiff, high-cut boots that provide maximum ankle support, allowing skaters to execute complex tricks and jumps. The advanced materials and construction needed for this level of support contribute to a higher overall cost.

The type of boot support directly impacts the skater’s ability to maintain proper form and prevent injuries. Skates with insufficient support can lead to ankle instability, increasing the risk of sprains and other related ailments. Consequently, manufacturers targeting serious athletes or individuals seeking enhanced performance prioritize boot support, investing in advanced materials and ergonomic designs. For example, speed skates often incorporate carbon fiber boots molded to the skater’s foot, providing exceptional support and energy transfer. The bespoke nature and high-performance characteristics of these boots significantly increase the overall cost of the skates. The design of the lacing system or closure mechanism also plays a crucial role in providing support, with higher-end skates often featuring ratchet buckles, power straps, and advanced lacing patterns to ensure a secure and supportive fit.

In summary, boot support is a key determinant of inline skate price, reflecting its importance in performance, safety, and overall user experience. The level of support directly correlates with the skate’s intended use, skill level, and material construction, influencing manufacturing costs and retail prices. Understanding the relationship between boot support and price is crucial for consumers seeking to make informed purchasing decisions that align with their individual needs and skating goals. Neglecting boot support considerations can lead to compromised performance, increased risk of injury, and ultimately, dissatisfaction with the purchased product.

6. Market demand

The price of inline skates, expressed in United States Dollars, is directly and significantly influenced by market demand. An increase in demand, driven by factors such as seasonal trends, heightened interest in fitness activities, or promotional campaigns, typically leads to a corresponding increase in prices. This reflects a fundamental economic principle: when demand exceeds supply, sellers can command higher prices. Conversely, a decline in market demand, perhaps due to economic downturns or shifting consumer preferences towards alternative recreational activities, often results in price reductions aimed at stimulating sales and clearing inventory. For instance, during the initial months of the COVID-19 pandemic, interest in outdoor activities surged, leading to increased demand for inline skates and subsequently, higher prices across various models. This illustrates a direct cause-and-effect relationship between heightened demand and increased USD prices.

Furthermore, market demand dictates the types of inline skates that manufacturers prioritize for production, influencing both the availability and pricing of specific models. If a particular style, such as aggressive inline skates or fitness-oriented models, experiences a surge in popularity, manufacturers are likely to increase production of these items. This, in turn, affects the supply chain, potentially leading to increased competition among retailers and a stabilization or even reduction in prices for those specific categories. Conversely, less popular or niche models may become more expensive due to limited production runs and decreased availability. A real-world example of this is the fluctuation in prices for high-performance speed skates, which tend to be more expensive and less readily available than recreational models due to a smaller, more specialized market.

Understanding the interplay between market demand and inline skate prices is crucial for both consumers and retailers. Consumers can leverage this understanding to make informed purchasing decisions, identifying periods of lower demand (e.g., off-season) to secure better deals. Retailers, in turn, utilize market demand data to optimize inventory management, pricing strategies, and promotional efforts, ensuring they are adequately stocked to meet consumer needs while maximizing profitability. The challenge lies in accurately forecasting demand fluctuations, which requires careful analysis of market trends, consumer behavior, and economic indicators. This knowledge forms an essential component of success within the competitive inline skate market.

Frequently Asked Questions About Inline Skates (USD)

This section addresses common inquiries regarding the purchase and pricing of inline skates in United States Dollars. The information provided aims to clarify key aspects related to cost, quality, and selection.

Question 1: What factors contribute to the wide price range observed in inline skates priced in USD?

The price range is influenced by several factors, including brand reputation, material quality (frame, boot, wheels, bearings), manufacturing precision, and intended use (recreational, fitness, aggressive). Premium materials and advanced features contribute to higher prices.

Question 2: Is it necessary to purchase the most expensive inline skates to ensure quality and performance?

Not necessarily. The ideal choice depends on individual needs and skill level. A moderately priced skate from a reputable brand can offer excellent performance for recreational or fitness purposes. High-end models are typically reserved for competitive or specialized use.

Question 3: How can the authenticity of branded inline skates, offered in USD, be verified to avoid counterfeit products?

Purchase from authorized retailers or the brand’s official website. Examine the packaging, product markings, and construction quality for irregularities. Compare the listed price with the manufacturer’s suggested retail price (MSRP). Research retailer reputation.

Question 4: What are the essential safety gear requirements and their associated costs when purchasing inline skates in USD?

Essential safety gear includes a helmet, wrist guards, elbow pads, and knee pads. Costs vary depending on brand and quality, typically ranging from $50 to $150 USD for a complete set. Prioritizing safety is crucial.

Question 5: How frequently should inline skates components (wheels, bearings) be replaced, and what are the estimated replacement costs in USD?

Replacement frequency depends on usage intensity and skating conditions. Wheels may require replacement every few months to a year, costing between $30 and $80 USD per set. Bearings may last longer, but replacement costs range from $20 to $60 USD per set.

Question 6: What maintenance practices are recommended to prolong the life of inline skates and minimize repair costs in USD?

Regular cleaning to remove dirt and debris, proper lubrication of bearings, and periodic inspection for loose or damaged components are essential. Avoid skating in wet or abrasive conditions. Professional servicing is recommended annually.

Understanding these aspects empowers informed purchasing decisions and ensures a satisfactory experience with inline skates acquired in USD.

The subsequent section explores potential issues and troubleshooting tips related to inline skate ownership.

Conclusion

This exploration of inline skates, specifically considering their valuation in United States Dollars, reveals the multifaceted nature of their market dynamics. Factors such as brand prestige, material composition, bearing precision, wheel durometer, and boot support collectively determine the price point. Market demand further influences pricing strategies, creating a complex interplay between product attributes and consumer behavior.

The information presented herein underscores the importance of informed decision-making for both purchasers and vendors. A thorough understanding of these elements allows for optimized product selection, cost-effective acquisition, and ultimately, enhanced user satisfaction. Continued analysis of these trends remains essential for navigating the evolving landscape of inline skate commerce.

![True Inline Skates: Performance & Speed [Expert Guide] How to Skateboard: A Beginner's Guide to Your First Board & Tricks True Inline Skates: Performance & Speed [Expert Guide] | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-493-300x200.jpg)

![Best Chicago Skates Inline Skates: [Year] Guide & More! How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Chicago Skates Inline Skates: [Year] Guide & More! | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-470-300x200.jpg)