A crucial component of recreational and competitive skating, these circular objects attach to the frame of the skate boot, facilitating movement across surfaces. Typically constructed from polyurethane, their durometer, or hardness, significantly impacts speed and grip. For instance, a harder composition allows for faster speeds, while a softer one offers increased traction.

The performance characteristics of these items are fundamental to the skating experience. Durability, rolling resistance, and rebound are key factors that influence efficiency and control. Historically, advancements in materials and manufacturing processes have led to significant improvements in their overall quality and longevity, enabling skaters to achieve greater speeds and execute more complex maneuvers.

The following sections will delve into the specific considerations for selecting the appropriate type, exploring the impact of size and profile, and providing guidance on maintenance and care to maximize lifespan and ensure optimal performance.

Inline Skate Wheels

Optimizing the use of these skate components requires attention to several critical factors. The following guidelines are designed to enhance skating performance and extend the lifespan of the product.

Tip 1: Select the appropriate durometer. Hardness ratings impact both speed and grip. A higher durometer, such as 85A, provides faster roll but reduced grip, suitable for smooth surfaces. Softer materials, like 78A, offer enhanced grip on rougher terrain, but may sacrifice speed.

Tip 2: Rotate regularly. Uneven wear is common due to skating technique and surface conditions. Rotating the position of these items on the frame periodically distributes wear, maximizing overall lifespan and maintaining consistent performance.

Tip 3: Choose the correct size. Larger diameters generally offer greater speed and smoother roll, while smaller ones provide enhanced maneuverability. The frame of the skates dictates the maximum allowable size; exceeding this limit can compromise safety.

Tip 4: Clean after use. Debris, such as dirt and small stones, can accumulate and damage the bearings. Regular cleaning with a suitable solvent and lubricant helps maintain optimal rolling efficiency.

Tip 5: Inspect for damage. Prior to each use, thoroughly inspect these components for cracks, chips, or flat spots. Damaged ones should be replaced immediately to prevent accidents and ensure consistent performance.

Tip 6: Consider the skating surface. The type of surface significantly affects wear and performance. Rough asphalt will degrade these skating components more rapidly than a smooth, polished surface. Adjusting the hardness and size based on the typical skating environment can optimize performance and longevity.

Adhering to these guidelines ensures that these skating components perform optimally and maintain their integrity over an extended period. By focusing on selection, maintenance, and surface awareness, skaters can enhance both their skating experience and the lifespan of their equipment.

The final section will summarize the key considerations discussed throughout this guide, providing a consolidated overview for making informed decisions regarding product maintenance and purchasing choices.

1. Durometer (Hardness)

The durometer rating of constitutes a critical specification that dictates performance characteristics. Measured on the A scale, this rating quantifies the material’s resistance to indentation, with higher numbers indicating greater hardness. The durometer directly influences the speed, grip, and wear rate of these skating components. A harder compound, typically in the range of 84A to 88A, offers reduced rolling resistance, resulting in higher speeds on smooth surfaces. However, harder materials provide less grip, making them less suitable for rough or uneven terrain where traction is essential. Conversely, softer skating components, ranging from 78A to 82A, exhibit superior grip and shock absorption but tend to roll slower and wear down more quickly.

The selection of an appropriate durometer is contingent upon the intended skating environment and the skater’s skill level. For example, speed skaters competing on polished tracks generally prefer harder components to maximize velocity, accepting the trade-off in grip. Recreational skaters who primarily skate on sidewalks or asphalt may opt for a softer durometer to enhance stability and control. Incorrect durometer selection can negatively impact both performance and safety. Using excessively hard ones on a slick surface can lead to loss of control, while excessively soft ones on a smooth surface can result in sluggish performance and accelerated wear.

In summary, the durometer rating serves as a pivotal indicator of these skating component’s suitability for a specific application. Understanding the relationship between hardness, surface conditions, and skating style is essential for making informed choices that optimize performance and ensure a safe and enjoyable skating experience. Ignoring this aspect could lead to suboptimal performance and premature wear.

2. Size (Diameter)

The diameter of an inline skate wheel, measured in millimeters, is a primary determinant of performance characteristics. The dimension directly affects rolling speed, maneuverability, and energy expenditure. Larger diameters, typically ranging from 90mm to 125mm, offer increased rolling speed due to a greater circumference and reduced rolling resistance. This advantage is particularly noticeable over longer distances and smoother surfaces, as fewer rotations are required to cover the same ground. Conversely, smaller diameters, such as those between 72mm and 80mm, provide enhanced maneuverability and acceleration. Their lower profile facilitates quicker turns and rapid changes in direction, which is advantageous in tighter spaces or during activities requiring agility, such as slalom skating or hockey. Frame design dictates the maximum allowable diameter; exceeding this limit can compromise stability and safety.

Real-world applications underscore the practical significance of understanding the diameter. Speed skaters commonly utilize larger diameter, such as 110mm or 125mm to maximize speed and efficiency during races. Aggressive skaters, on the other hand, often prefer smaller diameters (55-72mm) on their anti-rocker or freestyle setups to improve control during grinds and tricks. Fitness skaters generally opt for wheels in the 80-90mm range, striking a balance between speed and maneuverability for diverse terrain. Incorrect size selection can result in suboptimal performance and increased fatigue. For instance, attempting to skate long distances on very small wheels would necessitate significantly more effort, whereas navigating a crowded urban environment with excessively large wheels would impede agility.

In summary, the size of an inline skate wheel is a crucial parameter influencing speed, maneuverability, and energy expenditure. Selecting the appropriate diameter based on intended use, skating environment, and individual skill level is essential for optimizing performance and maximizing skating enjoyment. While larger diameters offer enhanced speed on smooth surfaces, smaller diameters provide superior agility in tighter spaces. The wheel’s diameter, therefore, should be carefully considered in conjunction with other wheel properties, such as durometer and profile, to achieve the desired skating experience. Ignoring the influence of diameter can significantly compromise efficiency, control, and overall comfort.

3. Profile (Shape)

The cross-sectional contour of an inline skate wheel, termed its profile or shape, significantly influences the performance characteristics of the skating system. This aspect determines the contact area between the wheel and the skating surface, directly impacting speed, grip, and maneuverability. Varying profile designs cater to different skating styles and surface conditions.

- Round Profile

A round profile exhibits a curved cross-section, maximizing maneuverability and facilitating smooth transitions between edges. This design reduces the contact patch with the skating surface, allowing for quicker turns and increased agility. This profile is often favored by freestyle and recreational skaters who prioritize responsiveness over maximum speed. In ice hockey training, skaters using inline skates often choose round profiles to mimic the agility required on ice.

- Flat Profile

A flat profile presents a broad, flattened cross-section, increasing the contact area between the wheel and the skating surface. This design maximizes grip and rolling efficiency on smooth surfaces, enabling higher speeds and enhanced stability. Speed skaters and distance skaters often opt for flat profiles due to their superior rolling characteristics. In practice, this profile’s stability is essential for maintaining a consistent speed on flat terrains.

- Elliptical Profile

An elliptical profile represents a compromise between round and flat designs, offering a balance of maneuverability and speed. This shape provides a moderately sized contact patch, allowing for responsive turning while maintaining reasonable rolling efficiency. Fitness skaters and recreational skaters often find elliptical profiles suitable for varied skating environments. A skater on a fitness trail, encountering both straightaways and turns, benefits from the balance offered by this design.

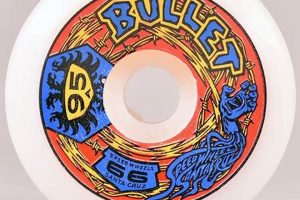

- Bullet Profile

A more pointed and aggressive design, the bullet profile minimizes contact surface for minimal rolling resistance and exceptional speed on perfectly smooth surfaces. Not ideal for general use due to reduced stability and grip, it is mostly suited for banked tracks (velodromes). Professional inline speed skaters often favour this design.

The selection of an appropriate wheel profile should be guided by the intended skating discipline and the predominant skating surface. While a round profile enhances agility in tight spaces, a flat profile maximizes speed on smooth, straightaways. An elliptical profile serves as a versatile compromise for varied terrain. Correct profile selection, in conjunction with durometer and size considerations, optimizes the performance and enhances the overall skating experience. A mismatched combination of profile and skating style can lead to reduced efficiency, compromised stability, or premature wheel wear.

4. Material (Polyurethane)

Polyurethane (PU) constitutes the primary material employed in the manufacture of inline skate wheels, owing to its unique combination of mechanical properties essential for skating performance. Its selection as the dominant material is a direct consequence of its capacity to withstand repeated stress, resist abrasion, and maintain a consistent coefficient of friction across varying surface conditions. The performance of inline skates is fundamentally dependent on the durability and rolling characteristics of the wheels; PU directly addresses these needs.

The specific formulation of the PU compound dictates the wheel’s durometer, rebound, and wear resistance. A higher durometer indicates a harder, more durable wheel, which provides increased speed but reduced grip. Conversely, a lower durometer results in a softer wheel with enhanced grip but decreased speed. The selection of an appropriate PU compound, therefore, involves a careful balancing act to optimize performance for the intended application. For example, speed skaters typically use wheels made from high-durometer PU for maximum speed on smooth surfaces, while aggressive skaters favor softer PU for enhanced grip and shock absorption during grinds and jumps. Furthermore, advancements in PU technology have led to the development of specialized compounds with improved heat resistance and reduced rolling resistance, enhancing the overall efficiency and longevity of inline skate wheels. Failure to employ high-quality PU results in rapid wheel degradation, compromised performance, and potential safety hazards.

In conclusion, the utilization of polyurethane in inline skate wheel construction is not arbitrary; it represents a deliberate engineering choice driven by the material’s superior performance characteristics. The specific PU formulation directly impacts the wheel’s durometer, rebound, and wear resistance, which in turn determines the skating experience. Understanding the interplay between PU composition and wheel performance is crucial for selecting appropriate wheels for various skating disciplines and surface conditions. Furthermore, ongoing research into advanced PU compounds continues to drive innovation in inline skate wheel technology, improving performance, durability, and safety.

5. Bearings (Rolling efficiency)

The rolling efficiency of inline skate wheels is intrinsically linked to the quality and type of bearings employed. Bearings, typically housed within the wheel’s core, facilitate rotation around the axle. A bearing’s primary function is to minimize friction, thereby enabling smoother, faster, and more energy-efficient skating. Inefficiencies in bearing design or maintenance directly translate into reduced speed and increased physical exertion for the skater. For example, corroded or inadequately lubricated bearings will impede wheel rotation, demanding more effort to maintain a desired speed. High-quality bearings, conversely, maximize the transfer of energy from the skater’s motion to the wheel’s rotation, optimizing performance.

Bearing performance is commonly quantified using the Annular Bearing Engineering Committee (ABEC) scale, which designates precision tolerances. Higher ABEC ratings, such as ABEC 7 or ABEC 9, indicate tighter tolerances and smoother operation, theoretically resulting in greater rolling efficiency. However, ABEC ratings primarily address manufacturing precision, not overall performance. Other factors, including bearing material, lubrication type, and seal design, also significantly influence rolling efficiency. A well-maintained ABEC 5 bearing can often outperform a poorly maintained ABEC 7 bearing. Competitive skaters frequently invest in ceramic bearings, which offer superior hardness, reduced friction, and improved heat resistance compared to traditional steel bearings, thereby enhancing rolling efficiency during prolonged use. The practical implication is that selecting appropriate bearings and adhering to a regular maintenance schedule are critical for maximizing the potential of the inline skate wheels.

In summary, the relationship between bearings and rolling efficiency is fundamental to inline skate performance. While ABEC ratings provide a general indication of bearing quality, other factors, such as material composition and lubrication, are equally important. Consistent maintenance, including cleaning and lubrication, is essential for preserving bearing performance and optimizing the rolling efficiency of the skate wheels. Ultimately, the selection and upkeep of bearings significantly impact the skater’s speed, endurance, and overall skating experience. Ignoring this vital component leads to decreased performance and increased physical strain.

6. Hub (Core Strength)

The structural integrity of an inline skate wheel hinges significantly on the hub, also known as the core. This central component provides the foundation upon which the polyurethane tire is molded and ensures the wheel maintains its shape under stress. The hub’s design and material composition directly impact the wheel’s load-bearing capacity, resistance to deformation, and overall performance characteristics. A robust hub is essential for efficient power transfer and consistent rolling, especially during high-intensity skating.

- Material Composition

Hubs are typically constructed from either plastic (often reinforced nylon) or aluminum. Aluminum hubs offer superior strength and rigidity, allowing for more efficient energy transfer and reduced flex during acceleration and cornering. Plastic hubs are lighter and more cost-effective, but they are more prone to deformation under heavy loads. The choice of material depends on the intended application; recreational skaters may find plastic hubs adequate, while competitive skaters often prefer the performance benefits of aluminum.

- Spoke Design

The spoke pattern and number of spokes in a hub significantly influence its strength and weight. Solid hubs offer maximum rigidity but are heavier. Spoked hubs, on the other hand, reduce weight while maintaining adequate strength. The specific spoke designstraight, curved, or radialaffects the distribution of stress and the hub’s resistance to lateral forces. More complex spoke patterns generally offer a better balance of weight and strength.

- Impact Resistance

The hub’s ability to withstand impacts and vibrations is critical for durability, particularly in aggressive skating or on rough surfaces. A poorly designed or constructed hub may crack or deform under stress, leading to wheel failure. Reinforcements, such as ribs or thicker cross-sections, can enhance the hub’s impact resistance. The hub’s material composition and spoke design are primary factors in determining its ability to absorb impact energy.

- Bearing Seat Precision

The hub’s precision in accommodating bearings directly affects the wheel’s rolling efficiency. A precisely machined bearing seat ensures proper alignment and reduces friction, allowing for smoother and faster rolling. Loose or misaligned bearings can cause vibration, premature wear, and reduced speed. High-quality hubs feature tight tolerances and smooth surfaces to ensure optimal bearing performance and longevity.

In essence, the hub acts as the backbone of the inline skate wheel, translating the skater’s power into efficient movement. A strong and well-designed hub ensures that the wheel maintains its shape, provides a stable platform for the bearings, and resists deformation under stress. Whether constructed from plastic or aluminum, the hub’s material composition and spoke design are critical factors in determining its performance and durability. Investing in wheels with high-quality hubs is essential for skaters seeking optimal performance, longevity, and safety.

Frequently Asked Questions

The following addresses common inquiries regarding design, selection, maintenance and performance, and provides detailed, technical, serious responses, based on scientific and technical expertise.

Question 1: What factors primarily dictate the optimal durometer selection for inline skate wheels?

Durometer selection hinges upon the intended skating surface and skating style. Softer wheels (78A-82A) offer superior grip and shock absorption on rough surfaces but sacrifice speed. Harder wheels (84A-88A) provide greater speed and rolling efficiency on smooth surfaces but offer less grip. Skaters must balance these trade-offs based on their specific needs.

Question 2: How frequently should inline skate wheels be rotated to ensure uniform wear?

Rotation frequency depends on skating style and surface conditions. However, a general guideline suggests rotating wheels every 5-10 hours of skating. Uneven wear patterns indicate the need for more frequent rotation. Regular rotation prolongs wheel life and maintains consistent performance.

Question 3: What are the key differences between plastic and aluminum hubs in inline skate wheels?

Aluminum hubs offer superior strength, rigidity, and energy transfer compared to plastic hubs. Plastic hubs are lighter and more cost-effective but are more prone to deformation under stress. Aluminum hubs are generally preferred for competitive skating, while plastic hubs are adequate for recreational use.

Question 4: How does wheel size (diameter) influence skating performance?

Larger diameter wheels (90mm-125mm) provide increased rolling speed and efficiency on smooth surfaces. Smaller diameter wheels (72mm-80mm) offer enhanced maneuverability and acceleration. The frame of the skates dictates the maximum allowable wheel size; exceeding this limit compromises safety.

Question 5: What constitutes proper maintenance for inline skate wheel bearings?

Proper maintenance involves regular cleaning, lubrication, and inspection. Bearings should be cleaned with a solvent to remove dirt and debris, lubricated with a suitable lubricant to reduce friction, and inspected for damage or corrosion. Regular maintenance prolongs bearing life and ensures optimal rolling efficiency.

Question 6: How does wheel profile (shape) affect skating characteristics?

Round profiles enhance maneuverability and edge control, while flat profiles maximize speed and grip on smooth surfaces. Elliptical profiles offer a balance between maneuverability and speed. The selection of an appropriate profile depends on the intended skating style and surface conditions.

Understanding these factors, including durometer, rotation, hub material, wheel size, maintenance, and profile, is essential for optimizing inline skate wheel performance and longevity. Consider all elements to increase efficiency and safety.

The next section provides a summary of current market trends and emerging technologies of this product.

Inline Skate Wheels

This article has presented a thorough examination of inline skate wheels, encompassing critical elements such as durometer, size, profile, material composition, bearing systems, and hub design. Each of these parameters significantly impacts performance characteristics, durability, and the overall skating experience. A comprehensive understanding of these factors is essential for skaters seeking to optimize their equipment for specific skating disciplines and surface conditions.

The continuous advancements in materials science and engineering promise further innovations in these essential skating components. As technology evolves, skaters are encouraged to remain informed about new developments and select the equipment best suited to their needs. The informed selection and consistent maintenance of these items are paramount for both maximizing performance and ensuring a safe and enjoyable skating experience. This concludes our analysis.