A specialized coating designed for application on ice skating boots, this product serves both aesthetic and protective purposes. It’s formulated to adhere to the unique materials and contours of skating footwear, providing a durable and visually appealing finish. An example would be a skater applying a fresh coat to their boots, restoring their appearance and shielding them from scuffs.

The use of such coatings is significant because it allows skaters to personalize their equipment and maintain a professional appearance. Beyond aesthetics, these coatings contribute to the longevity of the boots by providing a barrier against moisture, wear, and tear. Historically, simpler methods were employed, but modern formulations offer enhanced durability and a wider range of color options.

The following sections will delve into the specific types of coatings available, proper application techniques, and factors to consider when selecting the optimal product for individual needs, ensuring both performance and aesthetic satisfaction.

Application and Maintenance Guidance

The subsequent guidelines offer insights into maximizing the effectiveness and lifespan of specialized coatings for ice skating boots. Adherence to these principles ensures optimal performance and aesthetic preservation.

Tip 1: Surface Preparation is Paramount: Thoroughly clean and degrease the boot’s surface prior to application. Residue impedes adhesion, potentially leading to premature chipping or peeling. For example, isopropyl alcohol can be used to remove oils and dirt.

Tip 2: Apply Thin, Even Coats: Multiple thin coats are preferable to a single thick coat. This technique promotes uniform drying and minimizes the risk of runs or drips. Each layer should be allowed to dry completely before applying the next.

Tip 3: Employ a Suitable Application Method: The choice of brush, sponge, or spray applicator impacts the final finish. Brushes are typically used for detail work, while spray applicators provide a more even coating over larger areas. Select the method appropriate for the specific product and desired outcome.

Tip 4: Allow Adequate Drying Time: Insufficient drying time compromises the integrity of the coating. Follow the manufacturer’s recommendations regarding drying intervals. Environmental conditions, such as humidity, may influence drying duration.

Tip 5: Consider Environmental Factors: Application should occur in a well-ventilated area, free from excessive dust or extreme temperatures. Contaminants in the air can become trapped in the finish, affecting its appearance and durability.

Tip 6: Protective Sealant Application: Applying a clear sealant coat after the color coat has fully cured enhances durability and resistance to scratches and abrasions. This additional layer protects the underlying finish and extends its lifespan.

Tip 7: Regular Inspection and Touch-Ups: Periodically inspect the coated surface for signs of wear or damage. Minor scratches or chips should be addressed promptly with touch-up applications to prevent further deterioration. This proactive maintenance preserves the overall appearance and protects the underlying boot material.

Consistent application of these principles will contribute significantly to maintaining the aesthetic appeal and protective qualities of specialized coatings on ice skating boots.

The concluding section will summarize the key considerations and highlight the long-term benefits of investing in quality materials and proper maintenance practices.

1. Adhesion

Adhesion is a critical property of specialized coatings for ice skating boots. Its performance directly impacts the longevity and visual integrity of the applied finish, influencing both the aesthetic appeal and protective qualities.

- Surface Preparation Influence

Surface preparation profoundly affects adhesion. Contaminants such as oils, waxes, and debris impede the bonding process. Proper cleaning and degreasing, often involving the use of solvents and abrasion, are essential to create a receptive surface for the coating to adhere to effectively. Failure to adequately prepare the surface results in a compromised bond, leading to premature peeling and flaking.

- Material Compatibility Considerations

The chemical compatibility between the coating and the boot material is a significant factor. Different boot materials, such as leather, synthetic polymers, or composites, possess varying surface energies and react differently to different coating formulations. Selecting a coating specifically designed for the boot material ensures a strong and durable bond. Incompatibility can lead to poor adhesion, blistering, or delamination.

- Application Technique Impact

The application technique plays a crucial role in achieving optimal adhesion. Applying too much coating at once can create a thick layer that does not fully bond to the substrate, increasing the likelihood of cracking or peeling. Multiple thin coats, applied evenly and allowed to dry completely between applications, promote better adhesion by allowing each layer to properly bond with the surface.

- Curing Process Importance

The curing process is essential for developing the final adhesive strength of the coating. The coating must be allowed sufficient time to cure according to the manufacturer’s instructions. Temperature and humidity can influence the curing rate, and deviations from recommended conditions may result in a weaker bond. Proper curing ensures the coating achieves its maximum adhesive potential and provides long-lasting protection.

In summary, achieving robust adhesion between specialized coatings and ice skating boots necessitates meticulous surface preparation, careful material selection, precise application techniques, and controlled curing processes. When attention is given to each of these factors, the integrity and longevity of the applied finish are enhanced, ensuring both the visual appeal and protective functionality of the boots are maintained over time. The link to the overall success of ice skate paint is a direct correlation, the better the adhesion the better and more long-lasting the paint will be.

2. Flexibility

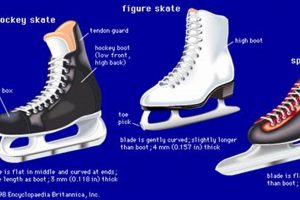

Flexibility, as a property of specialized coatings for ice skating boots, directly influences the longevity and performance of the applied finish. Skating boots undergo significant flexing and bending during use, particularly at the ankle and toe regions. A coating lacking sufficient flexibility will be prone to cracking and peeling, thereby compromising its aesthetic appeal and protective functionality. The causal relationship is clear: inadequate flexibility leads to premature coating failure.

The incorporation of flexible polymers into the coating formulation addresses this challenge. These polymers allow the coating to stretch and deform in concert with the boot material, minimizing stress concentrations and preventing the formation of cracks. For instance, coatings based on polyurethane or acrylic copolymers often exhibit superior flexibility compared to more rigid epoxy-based formulations. A practical example involves a skater performing complex maneuvers; the boot flexes significantly, and a flexible coating will maintain its integrity, whereas a brittle coating will likely develop surface cracks.

Understanding the practical significance of flexibility in these coatings extends beyond mere aesthetics. Cracks in the coating not only detract from the boot’s appearance but also create pathways for moisture to penetrate the underlying boot material. This moisture can weaken the boot’s structure and lead to degradation over time. In conclusion, flexibility is an essential attribute of specialized coatings, ensuring both the visual appeal and structural integrity of ice skating boots. Challenges remain in balancing flexibility with other desirable properties, such as durability and abrasion resistance, highlighting the need for continued innovation in coating formulations.

3. Durability

Durability, when considered in the context of specialized coatings for ice skating boots, reflects the coating’s capacity to resist degradation caused by physical stressors encountered during skating activities. These stressors include abrasion from skate blades, impacts against surfaces, and repeated flexing of the boot. The inherent connection lies in the coating’s ability to maintain its structural and aesthetic integrity under such demanding conditions. A coating lacking adequate durability will quickly exhibit scratches, chips, and fading, diminishing its protective and visual benefits. For instance, a coating on a figure skater’s boot must withstand repeated contact with the ice during intricate footwork, demanding a high level of abrasion resistance. Without it, frequent reapplication becomes necessary, negating the coating’s intended long-term benefits.

The selection of appropriate raw materials and the implementation of robust formulation techniques are pivotal in achieving the requisite durability. Coatings incorporating high-performance polymers, such as polyurethanes or acrylics modified with abrasion-resistant additives, demonstrate superior performance in this regard. Furthermore, the application process, including surface preparation and curing conditions, significantly influences the coating’s ultimate hardness and resistance to wear. A properly applied and cured coating forms a protective barrier that not only enhances the boot’s aesthetic appeal but also prolongs its service life by shielding the underlying material from damage. For instance, a hockey player’s boot, subjected to frequent impacts from pucks and skates, relies heavily on the coating’s impact resistance to prevent structural damage to the boot itself.

In summary, durability is a critical attribute of specialized coatings for ice skating boots, directly influencing their protective capabilities and aesthetic longevity. The strategic selection of materials, optimized formulation, and meticulous application are essential for maximizing durability and ensuring the coating effectively withstands the rigors of ice skating. Challenges remain in balancing durability with other desired properties, such as flexibility and color retention, necessitating ongoing research and development efforts to optimize coating performance. The long-term benefits are clear: enhanced boot protection, prolonged aesthetic appeal, and reduced maintenance requirements.

4. Color Retention

Color retention, in the context of specialized coatings for ice skating boots, refers to the ability of the coating to maintain its original hue and vibrancy over time, despite exposure to environmental factors and physical stresses. A direct correlation exists between the quality of the coating and its capacity to resist color degradation. The importance of color retention stems from its significant impact on the aesthetic appeal and perceived value of the boots. For instance, a vibrant blue coating that fades to a dull gray within a short period diminishes the overall appearance and necessitates premature recoating. This exemplifies the cause-and-effect relationship: inadequate formulation leads to compromised color retention, resulting in aesthetic dissatisfaction.

Environmental factors, such as ultraviolet (UV) radiation from sunlight and artificial lighting, are primary contributors to color fading. UV radiation can break down the chemical bonds in the pigments used in the coating, leading to a gradual loss of color intensity. Formulations incorporating UV absorbers and stabilizers mitigate this effect, providing enhanced protection against color degradation. Physical stresses, such as abrasion and cleaning with harsh chemicals, can also contribute to color loss. Durable coatings, formulated with abrasion-resistant polymers, are better equipped to withstand these stresses and maintain their color integrity. A practical example is observed in competitive skating environments, where boots are frequently exposed to bright lights and rigorous cleaning protocols; coatings with superior color retention maintain a professional and visually appealing appearance throughout the season.

In summary, color retention is a critical performance attribute of specialized coatings for ice skating boots, directly influencing their aesthetic longevity and perceived value. Formulations incorporating UV absorbers, stabilizers, and abrasion-resistant polymers offer enhanced protection against color degradation, ensuring the coating maintains its original hue and vibrancy over time. Challenges remain in balancing color retention with other desirable properties, such as flexibility and durability, necessitating ongoing research and development efforts. The practical significance of this understanding lies in enabling informed selection of coatings that provide both aesthetic appeal and long-term performance, ultimately enhancing the skater’s overall experience.

5. Water Resistance

Water resistance is a critical attribute of specialized coatings designed for ice skating boots. The sustained exposure to ice and meltwater necessitates that these coatings effectively prevent moisture penetration. Failure to provide adequate water resistance can lead to degradation of the boot materials, compromised performance, and reduced lifespan.

- Material Degradation Prevention

The primary role of water resistance is to protect the boot’s constituent materials, such as leather or synthetic fabrics, from absorbing moisture. Prolonged exposure to water weakens these materials, leading to structural damage, loss of shape, and reduced flexibility. For example, untreated leather becomes stiff and brittle after repeated wetting and drying cycles. Coatings that effectively repel water prevent this degradation, preserving the boot’s integrity and performance characteristics.

- Adhesive Bond Preservation

Water penetration can weaken the adhesive bonds that hold different components of the boot together, such as the sole, upper, and internal linings. Moisture intrusion promotes the growth of mold and mildew, further compromising these bonds. A water-resistant coating acts as a barrier, preventing water from reaching these critical areas and maintaining the structural integrity of the boot assembly. The outcome being that the boot lasts longer with proper care.

- Corrosion Inhibition

Metal components within the boot structure, such as rivets, eyelets, and blade mounts, are susceptible to corrosion when exposed to moisture. Corrosion weakens these components, potentially leading to structural failure and safety hazards. Water-resistant coatings provide a protective layer that shields these metal elements from water and corrosive elements, extending their service life and ensuring safe performance. A hockey skate that has been wet will eventually rust at the rivets, if not properly cared for.

- Thermal Insulation Maintenance

Water absorption reduces the thermal insulation properties of the boot. Wet materials conduct heat more readily, leading to colder feet and decreased comfort for the skater. A water-resistant coating helps maintain the boot’s thermal insulation by preventing moisture absorption, ensuring that the skater’s feet remain warm and comfortable even in cold conditions. This is vital, especially for prolonged skating sessions.

The implementation of effective water-resistant coatings is paramount in ensuring the longevity, performance, and safety of ice skating boots. These coatings provide a vital barrier against moisture penetration, preserving the boot’s structural integrity, protecting its components from degradation, and maintaining the skater’s comfort. Failure to address the issue of water resistance compromises the overall functionality and lifespan of the equipment.

6. Application Method

The method of application significantly influences the final quality and performance of specialized coatings on ice skating boots. The choice of application technique directly impacts adhesion, uniformity, and overall durability of the coating, thereby affecting both the aesthetic appeal and protective capabilities of the finish.

- Brush Application

Brush application is often employed for detail work and smaller areas on ice skating boots. It allows for precise control and can be advantageous for applying coatings to intricate designs or repairing minor imperfections. However, brush application may result in uneven coating thickness and visible brush strokes if not executed with sufficient skill. This method is typically favored for touch-up applications rather than complete recoating due to the time and effort required.

- Spray Application

Spray application, utilizing either aerosol cans or spray guns, provides a more uniform and efficient method for coating larger areas of ice skating boots. It allows for the application of thin, even layers, minimizing the risk of runs or drips. However, spray application requires careful masking to protect adjacent areas from overspray and necessitates proper ventilation to avoid inhalation of harmful vapors. This method is frequently preferred for professional refinishing and large-scale coating projects.

- Sponge Application

Sponge application offers a compromise between brush and spray methods, providing a relatively even coating while maintaining a degree of control. Sponges are particularly useful for applying coatings to textured surfaces or areas where brush strokes are undesirable. However, sponge application may result in uneven coating thickness if excessive pressure is applied, and the sponge material can absorb a significant amount of coating, leading to wastage. This method is often chosen for hobbyist applications and small-scale projects.

- Dip Application

Dip application is the process of submerging the material into the paint. This process is not recommended for the process of “ice skate paint” because the material can be damaged from being completely submerged.

In summary, the choice of application method for specialized coatings on ice skating boots depends on factors such as the size and complexity of the project, the desired level of finish, and the available equipment. Each method presents its own set of advantages and disadvantages, and selecting the appropriate technique is crucial for achieving optimal results. Irrespective of the chosen method, proper surface preparation and adherence to manufacturer’s instructions are essential for ensuring the coating’s long-term performance and aesthetic appeal.

Frequently Asked Questions

The following section addresses common inquiries regarding specialized coatings for ice skating boots, providing factual and objective responses.

Question 1: What distinguishes specialized coatings for ice skating boots from standard paints?

Formulations for ice skating boots are engineered to accommodate the specific materials and stresses inherent in skating footwear. Standard paints typically lack the necessary flexibility, adhesion, and durability to withstand the rigors of skating, potentially leading to cracking, peeling, and premature failure.

Question 2: How does proper surface preparation influence the outcome of coating application?

Meticulous surface preparation is paramount for achieving optimal adhesion and longevity of the coating. Contaminants such as dirt, grease, and wax impede the bonding process, potentially resulting in poor adhesion and premature coating failure. Thorough cleaning and degreasing are essential for creating a receptive surface.

Question 3: What factors should be considered when selecting a coating for specific ice skating disciplines (e.g., figure skating, hockey)?

The demands of each discipline necessitate consideration of specific performance characteristics. Figure skating boots require coatings with high flexibility and aesthetic appeal, while hockey boots demand coatings with superior abrasion and impact resistance. Selecting a coating tailored to the specific discipline ensures optimal performance and protection.

Question 4: How does the application environment impact the quality of the coating?

The application environment significantly influences the outcome of the coating process. Excessive humidity, extreme temperatures, and dust contamination can compromise the adhesion, curing, and overall finish quality. Application should occur in a well-ventilated, clean environment under controlled temperature and humidity conditions.

Question 5: What maintenance practices are recommended for preserving the integrity of coated ice skating boots?

Regular cleaning with mild detergents and prompt repair of minor scratches or chips are essential for preserving the integrity of the coating. Avoid harsh chemicals and abrasive cleaning agents, as these can damage the finish. Periodic inspection and touch-up applications are recommended to maintain both aesthetic appeal and protective functionality.

Question 6: How does the curing process contribute to the overall performance of the coating?

The curing process is essential for developing the final properties of the coating, including hardness, flexibility, and adhesion. Adhering to the manufacturer’s recommended curing time and temperature ensures that the coating achieves its maximum performance potential. Insufficient curing can result in a compromised finish with reduced durability and longevity.

These frequently asked questions aim to provide clarity regarding key aspects of specialized coatings for ice skating boots, promoting informed decision-making and optimal maintenance practices.

The subsequent section will explore advanced techniques and emerging technologies in the realm of ice skate boot coatings.

Conclusion

This exposition has detailed the critical aspects of specialized coatings for ice skating boots. The analyses of adhesion, flexibility, durability, color retention, water resistance, and application methods underscore the multifaceted requirements for effective performance. The information presented provides a comprehensive understanding of the factors influencing the selection, application, and maintenance of these coatings, contributing to enhanced boot longevity and performance.

Continued advancements in material science promise further improvements in coating technology, potentially leading to enhanced durability, flexibility, and environmental resistance. It is imperative for users to remain informed about these developments and to prioritize informed decision-making in order to maximize the benefits derived from specialized coatings for ice skating boots, ensuring both the aesthetic appeal and functional integrity of their equipment. The ongoing pursuit of improved coating solutions remains integral to the sustained performance and protection of ice skating footwear.