These recreational footwear items, designed for gliding movement, typically feature a boot or shoe attached to a frame that holds wheels. They provide a mobile platform for various activities, ranging from casual skating to organized sports. The construction and design influence performance characteristics.

Such equipment offers a means of physical exercise and transportation. Historically, their evolution reflects advancements in materials and engineering, influencing recreational trends and athletic pursuits. Their use promotes balance, coordination, and cardiovascular health.

The following discussion will address specific aspects such as design variations, maintenance considerations, and the selection criteria relevant to choosing appropriate equipment for individual needs.

Guidelines for Optimal Usage

The following recommendations are intended to enhance the experience and longevity of the equipment, ensuring safety and maximizing performance.

Tip 1: Pre-Use Inspection: Prior to each session, a thorough examination of the equipment is imperative. Check wheel integrity for wear or damage, ensuring all bearings are properly seated and spin freely. Axle nuts should be tightened securely, but not over-tightened to prevent damage.

Tip 2: Surface Selection: The skating surface significantly impacts both performance and the lifespan of the wheels. Smooth, paved surfaces are ideal. Avoid areas with excessive debris, cracks, or unevenness, as these can pose safety hazards and accelerate wear.

Tip 3: Proper Footwear Fit: The fit should be snug and supportive, preventing excessive movement within the boot. Ill-fitting footwear can lead to discomfort, blisters, and reduced control. Ensure laces or buckles are secured appropriately to provide adequate ankle support.

Tip 4: Wheel Rotation: Regular rotation of the wheels is crucial for even wear. Wheels tend to wear more on the inside edge due to the mechanics of skating. Rotating the wheels periodically will extend their lifespan and maintain consistent performance.

Tip 5: Bearing Maintenance: Bearings are susceptible to dirt and grime, which can impede performance. Periodically cleaning and lubricating the bearings will maintain their efficiency and extend their lifespan. Use a bearing cleaner specifically designed for this purpose and apply a light lubricant afterward.

Tip 6: Secure Fastenings: Routinely check the screws and bolts that hold the frame to the boot. Loose fastenings can compromise stability and increase the risk of accidents. Tighten as needed, being careful not to strip the threads.

Adherence to these guidelines promotes a safer and more enjoyable skating experience, while also preserving the equipment’s condition. Consistent maintenance translates to optimized performance and extended usability.

The subsequent sections will delve into advanced techniques and considerations for competitive applications.

1. Boot Construction

Boot construction in skating equipment directly influences performance, comfort, and longevity. Its design and materials contribute significantly to the overall skating experience and safety.

- Material Selection and its Influence

The choice of materials, ranging from leather to advanced synthetics, impacts factors such as weight, durability, and thermal regulation. Leather offers traditional durability and conforms to the foot over time, while synthetics may provide lighter weight and enhanced moisture-wicking properties. The selected material dictates the boot’s ability to withstand stress and maintain structural integrity.

- Structural Design and Support

The structural design of the boot provides varying degrees of ankle and foot support. High-cut boots offer maximum ankle stabilization, crucial for aggressive skating styles or individuals requiring additional support. Lower-cut boots prioritize flexibility and range of motion, often preferred in speed skating or recreational use. The internal structure, including padding and reinforcement, contributes to comfort and prevents injury.

- Closure Systems and Fit Optimization

Closure systems, such as laces, buckles, and power straps, enable precise adjustment and secure fit. Laces provide customizable tightening across the entire foot, while buckles offer quick and efficient closure. Power straps enhance ankle support and prevent heel lift. An effective closure system minimizes movement within the boot, translating to improved control and responsiveness.

- Heat Moldability and Customization

Certain boots offer heat moldability, allowing for customized fitting to the individual’s foot contours. This process involves heating the boot and then wearing it as it cools, conforming to the unique shape of the foot. Heat moldability enhances comfort and reduces pressure points, optimizing fit for prolonged use and reducing the risk of discomfort.

These attributes collectively determine the boot’s suitability for specific skating disciplines and user preferences. Understanding boot construction aids informed decision-making, ensuring equipment aligns with intended use and individual requirements.

2. Wheel Material

The performance characteristics of skating equipment are intrinsically linked to the material composition of its wheels. For skating equipment, polyurethane (PU) is the dominant material, offering a versatile combination of durability, grip, and rebound. The durometer, or hardness, of the PU dictates its suitability for different surfaces and skating styles. A lower durometer (e.g., 78A) indicates a softer wheel, providing enhanced grip on slick surfaces and a smoother ride, suitable for outdoor recreational skating. Conversely, a higher durometer (e.g., 101A) signifies a harder wheel, offering less rolling resistance and greater speed on smooth, indoor surfaces. The selection of appropriate wheel material directly impacts the skater’s ability to control the equipment and achieve desired performance outcomes.

The core construction of the wheel also influences its behavior. Wheels with a solid core provide maximum energy transfer and responsiveness, favored by skaters seeking high-speed performance. Wheels with a hollow core offer greater shock absorption, enhancing comfort on uneven surfaces. The wheel’s profile, whether rounded or elliptical, affects maneuverability and stability. For example, a rounded profile facilitates tighter turns, while an elliptical profile provides greater stability at high speeds. Furthermore, the bonding process between the PU material and the wheel core dictates the wheel’s resistance to delamination, a common failure mode under heavy use. The selection of appropriate wheel material must account for intended use, surface conditions, and skater preferences to optimize performance and safety.

In summary, wheel material plays a pivotal role in determining the performance capabilities and suitability of skating equipment for various applications. Understanding the relationship between durometer, core construction, and profile enables informed selection, maximizing the skating experience and ensuring equipment longevity. Future advancements in material science may introduce novel compounds with enhanced properties, further refining the performance envelope of these devices.

3. Bearing Precision

Bearing precision is a critical determinant of performance in skating equipment. The efficiency with which wheels rotate directly influences speed, glide, and overall skating experience. Precision bearings minimize friction, translating to greater energy transfer and reduced effort for the user.

- ABEC Rating and its Significance

The Annular Bearing Engineers’ Committee (ABEC) rating system quantifies the manufacturing tolerances of bearings. Higher ABEC ratings (e.g., ABEC 7, ABEC 9) indicate tighter tolerances and greater precision. While a higher rating generally correlates with smoother and faster rotation, factors such as bearing material, lubrication, and maintenance also play significant roles. For instance, a skater seeking high-speed performance on a smooth surface may benefit from higher ABEC-rated bearings. Conversely, for recreational skating on varied surfaces, lower-rated bearings may suffice, provided they are properly maintained.

- Bearing Materials and Friction Reduction

Bearing materials, typically steel or ceramic, influence friction and durability. Steel bearings offer cost-effectiveness and sufficient performance for most applications. Ceramic bearings exhibit superior hardness, reduced friction, and greater resistance to heat, making them suitable for high-performance skating where speed and efficiency are paramount. Hybrid ceramic bearings, combining steel races with ceramic balls, offer a compromise between cost and performance. The material selection significantly impacts the bearing’s ability to maintain its shape and minimize friction under load.

- Lubrication and Maintenance Strategies

Proper lubrication is essential for minimizing friction and extending bearing lifespan. Lubricants, such as oil or grease, create a thin film between the bearing components, reducing metal-to-metal contact. Oil-based lubricants offer lower viscosity, promoting faster rotation, while grease-based lubricants provide greater durability and resistance to water and contaminants. Regular cleaning and re-lubrication of bearings are crucial for removing dirt and debris that can impede performance. Neglecting bearing maintenance can lead to increased friction, reduced speed, and premature bearing failure.

- Impact on Glide and Energy Efficiency

Precision bearings directly influence the glide efficiency of skating equipment. Low-friction bearings allow the skater to maintain momentum with less effort, conserving energy and extending skating duration. Conversely, bearings with high friction require greater effort to overcome resistance, leading to fatigue and reduced performance. The choice of bearings directly affects the skater’s ability to maintain speed and glide smoothly, influencing overall enjoyment and performance outcomes. For example, a competitive skater would prioritize bearings that minimize friction to maximize speed and efficiency during races.

In conclusion, bearing precision is a crucial aspect of skating equipment performance. Understanding the ABEC rating system, material properties, lubrication requirements, and impact on glide enables informed decision-making, ensuring that the selected bearings align with intended use and performance goals. Consistent maintenance of bearings is crucial, ensuring that high-precision components continue to operate effectively.

4. Frame Rigidity

Frame rigidity is a critical design parameter influencing the performance characteristics of skating equipment. It dictates the extent to which the frame resists bending or deformation under load. In skating equipment, the frame serves as the structural foundation, connecting the boots to the wheels and transmitting forces generated by the skater’s movements. Insufficient frame rigidity leads to energy loss, diminished responsiveness, and compromised control. For instance, during a sharp turn, a flexible frame may flex excessively, delaying the response and reducing the precision of the maneuver. The choice of material and frame design directly impacts the equipment’s overall performance and stability. Higher rigidity translates to more efficient power transfer, allowing skaters to accelerate and maintain speed more effectively. This is especially important in competitive skating, where marginal gains can significantly impact race outcomes.

The materials used in frame construction, such as aluminum alloys or composite materials, greatly influence rigidity. Aluminum frames are common due to their favorable strength-to-weight ratio, offering a balance of stiffness and durability. Composite frames, utilizing carbon fiber or fiberglass, provide enhanced stiffness and vibration damping. Frame design also plays a significant role; reinforced structures and optimized geometries increase resistance to bending forces. Frame length is also a determining factor: Shorter frames are more rigid and responsive, while longer frames provide greater stability. Skaters must consider their skill level, skating style, and the intended application when selecting frame rigidity. For recreational use, a moderately rigid frame offers a comfortable and stable ride. Aggressive skaters, performing jumps and tricks, require high frame rigidity to withstand impact forces and maintain control. Speed skaters prioritize lightweight frames with maximum rigidity to optimize power transfer and minimize energy loss.

In summary, frame rigidity profoundly affects the performance and handling of skating equipment. Selecting a frame with appropriate rigidity based on skating discipline and individual preferences is crucial for optimizing performance, ensuring stability, and enhancing the overall skating experience. Future innovations in materials science and frame design will likely yield even stiffer and lighter frames, further pushing the boundaries of what is achievable in skating. A rigid frame is particularly important for high performance. This is a practical consideration for achieving the skater’s goals.

5. Closure System

The closure system constitutes a crucial element in the design and functionality of recreational equipment, specifically affecting fit, support, and overall performance. A secure and well-designed closure mechanism directly influences the skater’s control and stability. Inadequate closure can lead to slippage, diminished energy transfer, and an increased risk of injury. Conversely, an optimized closure system provides a snug, supportive fit, enabling precise movements and enhanced responsiveness. The practical significance of this system is exemplified in various skating disciplines. For instance, in aggressive skating, a robust closure system is paramount for withstanding the high-impact forces associated with jumps and tricks. A failure in the closure mechanism during such maneuvers can result in significant injury.

Various closure system designs cater to diverse needs and preferences. Traditional lace systems offer customizable tightening across the entire foot, allowing for a tailored fit. Buckle systems provide quick and easy adjustments, while hook-and-loop straps offer a balance of convenience and security. Hybrid systems, combining multiple closure types, are increasingly common, aiming to optimize both fit and ease of use. Material selection is another critical factor; durable materials such as reinforced nylon or metal buckles ensure longevity and reliability. The placement and design of closure components also influence comfort and performance. Properly positioned straps and buckles minimize pressure points and prevent chafing, enhancing the overall skating experience. A prime example of an advanced closure system can be seen in speed skating, where micro-adjustable buckles and heat-moldable boots work in concert to create a virtually seamless connection between the skater’s foot and the equipment, maximizing power transfer and minimizing energy loss.

In conclusion, the closure system is an integral component influencing the safety and performance. The design, materials, and functionality of the closure mechanism directly impact the skater’s control, stability, and overall experience. Selecting appropriate equipment with a well-designed closure system is essential for maximizing performance and minimizing the risk of injury. Future advancements in closure technology will likely focus on improving adjustability, comfort, and durability, further enhancing the skating experience.

6. Ankle Support

Ankle support, a pivotal factor in the functionality and safety of skating equipment, significantly influences stability, control, and the risk of injury during use. The design and construction of the boot, particularly around the ankle region, play a crucial role in determining the level of support provided. Inadequate ankle support can lead to instability, making users vulnerable to sprains and other injuries. Conversely, well-designed ankle support enhances balance, control, and overall skating performance.

- High-Cut vs. Low-Cut Boot Designs

The height of the boot cuff directly impacts the degree of ankle support offered. High-cut boots extend higher up the ankle, providing increased stability and restricting lateral movement. These designs are often favored for activities requiring greater support, such as aggressive skating or for individuals with weaker ankles. Low-cut boots offer greater flexibility and range of motion, sacrificing some ankle support for increased maneuverability. Such designs are common in speed skating, where maximizing agility is paramount. The choice between high-cut and low-cut designs depends on the intended use and the user’s individual needs.

- Material Rigidity and Reinforcement

The materials used in the ankle region’s construction, and their reinforcement, influence the level of support. Stiffer materials, such as reinforced polymers or leather, provide greater stability and resistance to ankle roll. Padding and internal supports further enhance ankle support by conforming to the ankle’s contours and preventing excessive movement. The integration of supportive materials directly correlates with the boot’s ability to stabilize the ankle joint and minimize the risk of injury. The composition of the ankle support material is a determining factor in safety.

- Closure System Integration

The closure system, encompassing laces, straps, and buckles, plays a significant role in securing the ankle and providing adjustable support. Properly tightened closures ensure a snug fit around the ankle, preventing slippage and enhancing stability. Power straps, positioned across the ankle, provide additional support and prevent heel lift. The closure system works in conjunction with the boot’s design to provide a customized level of ankle support. Effective use of the closures can optimize the equipment’s comfort and protective capabilities.

- Customization and Aftermarket Options

Recognizing the diverse needs of skaters, aftermarket ankle supports are available to supplement or enhance the support provided by the equipment. These supports range from simple ankle sleeves to more complex bracing systems. Heat-moldable boots allow for customized fitting around the ankle, further optimizing support and comfort. Customization options enable users to tailor the level of ankle support to their specific requirements. A tailored fit is essential for maximizing performance and safety.

The interplay between ankle support design elements, materials, and closure systems significantly influences the usability and enjoyment of skating equipment. Selecting equipment that aligns with individual needs and skating style, paying close attention to ankle support features, is crucial for ensuring safety and maximizing performance. A functional support structure is essential for the practical use of skating equipment.

7. Braking Mechanism

The braking mechanism on skating equipment is an essential safety component. The functionality and reliability of the braking system directly influence the user’s ability to control speed and avoid collisions. These safety features are often located at the rear of one or both boots, allowing the skater to apply controlled deceleration by tilting the foot and applying pressure to the braking surface. Without a functional braking mechanism, the risk of uncontrolled acceleration and subsequent injury significantly increases. For instance, in urban environments, skaters frequently encounter unpredictable obstacles, pedestrians, and traffic, necessitating the immediate ability to reduce speed or stop. This is an undeniable fact.

The effectiveness of skating equipment braking systems depends on several factors, including the materials used, the design of the braking pad, and the user’s technique. Braking pads constructed from durable materials, such as high-friction rubber compounds, offer superior stopping power and extended lifespan. The size and shape of the braking pad influence the contact area with the ground, affecting the deceleration rate. Skaters must develop proper braking techniques, involving controlled weight distribution and gradual pressure application, to maximize the braking system’s performance. Some advanced skating equipment incorporates braking systems that utilize hand-operated levers or electronic controls, offering enhanced precision and modulation. These systems are most beneficial in applications such as downhill skating, where precise speed control is paramount.

In summary, the braking mechanism is a fundamental safety feature on skating equipment, directly impacting the user’s ability to control speed and mitigate potential hazards. Understanding the components, design considerations, and proper usage techniques associated with skating brakes is crucial for safe skating practices. Continued innovation in braking system technology aims to enhance performance and safety, reflecting the ongoing commitment to user protection. This is all for the skaters’ security.

Frequently Asked Questions

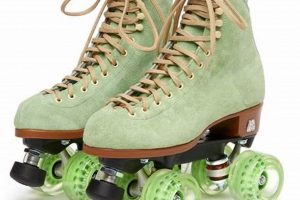

The following questions and answers address common inquiries regarding the selection, use, and maintenance of Hyde roller skates.

Question 1: What factors determine the appropriate wheel durometer for Hyde roller skates?

Wheel durometer, measured on the “A” scale, reflects the wheel’s hardness. Lower durometer wheels (e.g., 78A-85A) provide enhanced grip and shock absorption, suitable for outdoor surfaces. Higher durometer wheels (e.g., 85A and above) offer lower rolling resistance and increased speed, optimized for smooth, indoor surfaces.

Question 2: How frequently should Hyde roller skate bearings be cleaned and lubricated?

Bearing cleaning and lubrication frequency depends on usage conditions. Under normal use, bearings should be cleaned and re-lubricated every 1-3 months. If skates are exposed to water, dirt, or sand, more frequent maintenance is necessary to prevent corrosion and performance degradation.

Question 3: What are the key considerations when selecting a Hyde roller skate boot size?

Proper boot fit is crucial for comfort and performance. Foot length and width should be accurately measured. When possible, the boots should be tried on with skating socks to ensure a snug yet comfortable fit. Ill-fitting boots can lead to blisters, reduced control, and potential injury.

Question 4: How does frame material impact the performance of Hyde roller skates?

Frame material affects rigidity and weight. Aluminum frames offer a balance of strength and affordability. Carbon fiber frames provide superior stiffness and reduced weight, enhancing responsiveness. The choice of frame material depends on the skater’s skill level and intended use. A stiffer frame increases responsiveness but may be less forgiving on uneven surfaces.

Question 5: What braking system options are available for Hyde roller skates, and which is most appropriate?

Toe stops and heel brakes are common braking system options. Toe stops offer quick stops and maneuverability but may require more skill. Heel brakes provide stability and ease of use, particularly for beginners. The choice of braking system depends on individual preference and skating style. Regular inspection and replacement of worn brake pads are essential for safety.

Question 6: How can ankle support be optimized for Hyde roller skates?

Ankle support can be optimized through several methods. Ensure proper boot fit and lace tightening. Consider using aftermarket ankle supports or heat-moldable boots for a customized fit. High-cut boots provide greater ankle support than low-cut designs. Strengthening ankle muscles through targeted exercises can also enhance stability.

These FAQs provide guidance on various aspects of Hyde roller skates. Proper selection, maintenance, and technique are essential for a safe and enjoyable skating experience.

The subsequent section will address advanced techniques and considerations for competitive applications.

Hyde Roller Skates

This exploration has addressed fundamental aspects of hyde roller skates, from construction materials and design variations to maintenance protocols and performance optimization. A thorough understanding of boot fit, wheel durometer, bearing precision, frame rigidity, closure systems, ankle support, and braking mechanisms is essential for informed equipment selection and safe operation.

Continued advancements in materials science and engineering will undoubtedly influence the future of these recreational devices. Skaters are encouraged to prioritize safety and informed decision-making to maximize the benefits and enjoyment derived from this activity. Rigorous adherence to recommended maintenance practices will further ensure prolonged equipment lifespan and optimal performance.